ASTM E1683-02(2014)e1

(Practice)Standard Practice for Testing the Performance of Scanning Raman Spectrometers

Standard Practice for Testing the Performance of Scanning Raman Spectrometers

SIGNIFICANCE AND USE

4.1 A scanning Raman spectrometer should be checked regularly to determine if its condition is adequate for routine measurements or if it has changed. This practice is designed to facilitate that determination and, if performance is unsatisfactory, to identify the part of the system that needs attention. These tests apply for single-, double-, or triplemonochromator scanning Raman instruments commercially available. They do not apply for multichannel or Fourier transform instruments, or for gated integrator systems requiring a pulsed laser source. Use of this practice is intended only for trained optical spectroscopists and should be used in conjunction with standard texts.

SCOPE

1.1 This practice covers routine testing of scanning Raman spectrometer performance and to assist in locating problems when performance has degraded. It is also intended as a guide for obtaining and reporting Raman spectra.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautions, see 7.2.1.

1.4 Because of the significant dangers associated with the use of lasers, ANSI Z136.1 should be followed in conjunction with this practice.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: E1683 − 02 (Reapproved 2014)

Standard Practice for

Testing the Performance of Scanning Raman

Spectrometers

This standard is issued under the fixed designation E1683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in Section 1.2 editorially in June 2014.

1. Scope 4. Significance and Use

1.1 This practice covers routine testing of scanning Raman

4.1 A scanning Raman spectrometer should be checked

spectrometer performance and to assist in locating problems

regularly to determine if its condition is adequate for routine

when performance has degraded. It is also intended as a guide

measurements or if it has changed. This practice is designed to

for obtaining and reporting Raman spectra.

facilitate that determination and, if performance is

unsatisfactory, to identify the part of the system that needs

1.2 The values stated in SI units are to be regarded as

attention. These tests apply for single-, double-, or triplemono-

standard. No other units of measurement are included in this

standard. chromator scanning Raman instruments commercially avail-

able. They do not apply for multichannel or Fourier transform

1.3 This standard does not purport to address all of the

instruments, or for gated integrator systems requiring a pulsed

safety concerns, if any, associated with its use. It is the

laser source. Use of this practice is intended only for trained

responsibility of the user of this standard to establish appro-

optical spectroscopists and should be used in conjunction with

priate safety and health practices and determine the applica-

standard texts.

bility of regulatory limitations prior to use. For specific

precautions, see 7.2.1.

5. Apparatus

1.4 Because of the significant dangers associated with the

use of lasers, ANSI Z136.1 should be followed in conjunction

5.1 Laser—Amonochromatic,continuouslasersource,such

with this practice.

asanargon,krypton,orhelium-neonlaser,isnormallyusedfor

Raman measurements. The laser intensity should be measured

2. Referenced Documents

at the sample with a power meter because optical components

2.1 ASTM Standards:

between the laser and sample reduce laser intensity.Afiltering

E131 Terminology Relating to Molecular Spectroscopy

device should also be used to remove non-lasting plasma

E1840 Guide for Raman Shift Standards for Spectrometer

emission lines from the laser beam before they reach the

Calibration

sample. Plasma lines can seriously interfere with Raman

2.2 ANSI Standard:

measurements. Filtering devices include dispersive monochro-

Z136.1 Safe Use of Lasers

mators and interference filters.

3. Terminology

5.2 Sampling Optics—Commercial instruments can be pur-

chased with sampling optics to focus the laser beam onto a

3.1 Terminology used in this practice conforms to the

sample and to image the Raman scattering onto the monochro-

definitions in Terminology E131.

mator entrance slit. Sample chamber adjustments are used to

centerthesampleproperlyandaligntheRamanscatteredlight.

This practice is under the jurisdiction of ASTM Committee E13 on Molecular

A schematic view of a conventional 90° Raman scattering

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

mittee E13.08 on Raman Spectroscopy. geometry is shown in Fig. 1. The laser beam propagates at a

Current edition approved May 1, 2014. Published June 2014. Originally

right angle to the direction in which scattered light is collected.

approved in 1995. Last previous edition approved in 2007 as E1683 – 02(2007).

It is focused on the sample at the same position as the

DOI: 10.1520/E1683-02R14E01.

monochromator entrance slit image. Other geometries such as

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

180° backscattering are also used. With single

Standards volume information, refer to the standard’s Document Summary page on

monochromators, a filter is normally placed in the optical

the ASTM website.

collection path to block light at the laser frequency from

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. entering the monochromator.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1683 − 02 (2014)

FIG. 1 Typical Raman Scattering Measurement Geometry

5.3 Polarization—For routine measurements the polariza- alignment is essential. A focused image on the entrance slit

tion of the laser at the sample is oriented normal to the plane should be optically transferred to and matched with the other

of the page in Fig. 1. However, measurements using different slits. If the monochromator is not functioning properly contact

polarizations are sometimes used to determine vibrational the manufacturer for assistance.

symmetries as part of molecular structure determinations. A

5.5 Photomultiplier Tube—A photomultiplier can be used

variety of optical configurations can be used to make polariza-

for detecting Raman scattered radiation. A tube with good

tionmeasurements;adetaileddiscussionoftheseisbeyondthe

response characteristics at and above the laser wavelength

scope of this practice. Briefly, for polarization simple measure-

should be selected. Dark signal can be reduced with thermo-

ments of randomly-oriented samples (most of the clear

electric cooling for improved detection of weak signals.

liquids), an analyzing element such as a polaroid filter or

Current and voltage amplification or photon counting are

analyzing prism is added to the optical system and Raman

commercially available options with photomultiplier tubes.

spectraarecollectedforlightscatteredin(1)thesamedirection

6. Guidelines for Obtaining and Reporting Raman

as the source (parallel), (2) perpendicular to the source.

Spectra

Depolarization ratios are calculated using Raman band inten-

sities from the two spectra as follows:

6.1 Alignment of Optical Elements—Refer to the manufac-

turerfordetailedsamplechamberalignmentinstructions.Upon

Intensityparallel

Depolarizationratio 5 (1)

installation, each optical component should be aligned indi-

Intensityperpendicular

vidually. For optimal alignment the sample image should be

5.3.1 A polarization scrambler is shown in Fig. 1. This

centered on the entrance slit of the monochromator (often

element is used to avoid making corrections for polarization-

viewed through a periscope accessory or with the aid of a

dependent grating effects. The scrambler is also frequently

highly scattering sample or a white card at the slit).To perform

used during routine measurements and should be placed

the alignment a test sample is mounted in the sample

between the sample and entrance slit, close to the collection

compartment, centered in the laser beam, and translated to the

lens. A polaroid filter placed between the scrambler and

approximate center of the monochromator optic axis. The

collection lens provides a simple polarization measurement

monochromator is set to monitor a strong Raman band and its

system.

signal is maximized by adjusting the sample stage, lenses, or a

5.4 Monochromator—A scanning monochromator used for combination of the two. Normally three orthogonal lens

Raman spectroscopy will exhibit high performance require- adjustments are used: (1) the laser focusing lens is translated

ments. Double and triple monochromators have particularly along the direction of the beam; (2) the Raman scattering

stringent performance standards. During the original instru- collectionlens,positionedbetweenthesampleandtheentrance

ment design, features are usually introduced to minimize slit, is translated along the direction of the propagating scat-

optical aberrations. However, proper maintenance of optical tered light in order to provide focus; and (3) the collection lens

´1

E1683 − 02 (2014)

istranslatedperpendiculartothescatteredlightinordertoscan 6.3.1 Recording With a Rate-Meter and Strip Chart

the image of the laser-excited scattering volume across the Recorder—Therangeontherate-meterissetbymonitoringthe

width of the monochromator entrance slit. (Refer to Fig. 1.) strongest peak in the spectrum. The relationship between the

This collection lens adjustment should be made during major scan rate, spectral slit width, and time constant of the rate-

instrument alignment (for example, during initial set-up), but meter, as recommended by IUPAC (10), is:

should not be necessary during routine sample-to-sample 21 21

Scan rate, cm /s # spectral slit width, cm

~ ! ~ !

(2)

alignment. Sample and lens adjustments should be repeated as

4 3time constant s

~ ~ !!

necessary while the slits are narrowed from a relatively large

initial width down to the size determined by the resolution In addition, the time constant of the recorder should be

considerably faster than the rate-meter’s time constant, and the

requirements of the measurement.

speed of the paper should be adequate to measure the spectral

6.2 Calibration:

features.

6.2.1 Spectral Response—The spectral response of an opti-

6.3.2 Recording With a Computer or Signal Averager—In

cal spectrometric system will depend on the efficiency of the

this case one needs to define the increments in wavenumbers

gratings (which is both wavelength and polarization depen-

betweendatapoints.Aminimumcriterionistocollectfivedata

dent) and the spectral response of the photomultiplier tube.

pointsinthefullwidthathalfthemaximumintensity(FWHM)

This can be measured routinely by collecting light from a

of the narrowest spectral band. For example, if the slits were

tungsten halogen lamp or other NIST-traceable standard light

set to provide a measured band width at half maximum of 4

source.Acomplete procedure for performing spectral response

wavenumbers, then 1-wavenumber increments would produce

corrections has been published by Scherer and Kint (1). It is

five data points within the FWHM in a scan of a line from a

stronglyrecommendedthatcorrectionsforspectralresponsebe

plasma emission source. To better define peak shape decrease

incorporateddirectlyintothesoftwarewhenacomputerisused

the size of the increments. This is especially important for

to collect spectra.

bands that deviate from Lorentzian shape.

6.2.2 Wavenumber—The accuracy of the wavenumber cali-

bration over a large region should be determined using a

6.4 Reporting Experimental Conditions—The spectral slit

standard low-pressure emission source with enough lines to

width(wavenumbers),scanrate,laserwavelengthandpowerat

make many measurements over the range of the instrument.

the sample, polarization conditions, integration time, correc-

Low-pressure mercury, argon, and neon lamps are frequently

tions for instrumental response, type of spectrometer and

used. The non-lasing emission lines of the laser can also be

detector, sample information (physical state, concentration,

used if the laser filtering device is removed. Accurate wave-

geometry, and so forth), and other important experimental

number values are available (2-9). For measurement at resolu-

conditions should always be recorded with the spectra and

tions <0.5 wavenumbers a more rigorous calibration method

reproduced for performance testing. A complete record of the

should be employed.

parameters to be specified is available in Table 1 of the IUPAC

Recommendations for the Presentation of Raman Spectra in

6.3 Recording Raman Spectra—The following guidelines

Data Collections (10).

are provided for recording spectra with a rare meter and strip

chart recorder or with a computer or digital signal averager. In

7. Evaluation of Raman Instrument Parameters

both cases it is important to record a spectrum so that spectral

features are not distorted by the mode of data acquisition.

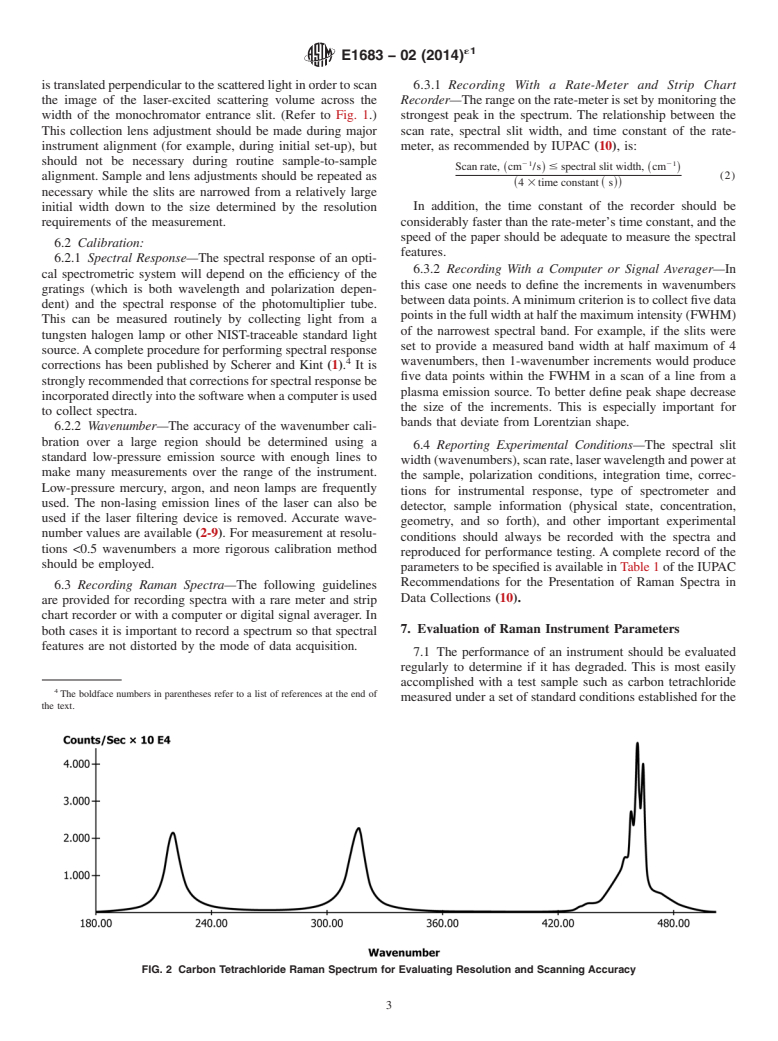

7.1 The performance of an instrument should be evaluated

regularly to determine if it has degraded. This is most easily

accomplished with a test sample such as carbon tetrachloride

The boldface numbers in parentheses refer to a list of references at the end of

measured under a set of standard conditions established for the

the text.

FIG. 2 Carbon Tetrachloride Raman Spectrum for Evaluating Resolution and Scanning Accuracy

´1

E1683 − 02 (2014)

TABLE 1 Recommended Frequencies from the Spectrum of

measuring the FWHM intensity of a sharp plasma line emitted

Indene for Evaluating Scanning Accuracy

from a low-pressure atomic source.The mercury line at 546.07

A 1

Band Frequency, cm

nm(1122.5cm-1shiftfromthe514.53-nmargonionlaserline)

1 730.4 ± 0.5

is often used. If a lamp is not available the laser emission lines

2 1018.3 ± 0.5

can be used. The spectral bandwidth of a double (additive)

3 1205.6 ± 0.5

dispersing monochromator should ideally be one half that of a

4 1552.7 ± 0.5

5 1610.2 ± 0.5

single monochromator with the same slits and grating. Most

6 2892.2 ± 1

manufacturers specify bandwidths for their monochromators

7 3054.7 ± 1

and measured values should be reasonably close to those

A

Bands from Fig. 3.

specified (using the same slit widths and grating). For a double

(additive) monochromator demonstrating an overly large

bandwidth, each of the monochromator stages can be checked

particular instrument. Signal intensity and wavelength accu-

separately by closing its slits to a relatively narrow width (for

racyarethetwospectralfeaturestocheck.Ifpeaksignallevels

example 50 µm), opening the slits of the other monochromator

have diminished or are shifted from accepted wavenumber

stagewider(forexample,300µm),andmeasuringtheemission

values, the components of the system should be evaluated

lineFWHM.Thebandwidthsoftheindividualstagesshouldbe

independentlytolocatethesourceofperformancedegradation.

the same and equal to twice the bandwidth of the combined

Guidelines for such an evaluation are as follows:

stages. If one stage has a significantly larger bandpass than the

7.2 TestSamples—Thefollowingreadilyavailablematerials

other, and that bandpass is much larger than twice that

are commonly used for evaluating the performance of Raman expected for the entire monochromator, then it has a problem.

spectrometers:

Also, if combining the stages does not reduce the bandwidth as

7.2.1 Carbon Tetrachloride—The major Raman bands are expected, then there is a problem and the manufacturer should

218, 314, and 459 cm-1 (see Fig. 2). (Warning—Carbon

be consulted.

tetrachloride is toxic a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1683 − 02 (Reapproved 2007) E1683 − 02 (Reapproved 2014)

Standard Practice for

Testing the Performance of Scanning Raman

Spectrometers

This standard is issued under the fixed designation E1683; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Units statement was inserted in Section 1.2 editorially in June 2014.

1. Scope

1.1 This practice covers routine testing of scanning Raman spectrometer performance and to assist in locating problems when

performance has degraded. It is also intended as a guide for obtaining and reporting Raman spectra.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautions, see 7.2.1.

1.4 Because of the significant dangers associated with the use of lasers, ANSI Z136.1 should be followed in conjunction with

this practice.

2. Referenced Documents

2.1 ASTM Standards:

E131 Terminology Relating to Molecular Spectroscopy

E1840 Guide for Raman Shift Standards for Spectrometer Calibration

2.2 ANSI Standard:

Z136.1 Safe Use of Lasers

3. Terminology

3.1 Terminology used in this practice conforms to the definitions in Terminology E131.

4. Significance and Use

4.1 A scanning Raman spectrometer should be checked regularly to determine if its condition is adequate for routine

measurements or if it has changed. This practice is designed to facilitate that determination and, if performance is unsatisfactory,

to identify the part of the system that needs attention. These tests apply for single-, double-, or triplemonochromator scanning

Raman instruments commercially available. They do not apply for multichannel or Fourier transform instruments, or for gated

integrator systems requiring a pulsed laser source. Use of this practice is intended only for trained optical spectroscopists and

should be used in conjunction with standard texts.

5. Apparatus

5.1 Laser—A monochromatic, continuous laser source, such as an argon, krypton, or helium-neon laser, is normally used for

Raman measurements. The laser intensity should be measured at the sample with a power meter because optical components

between the laser and sample reduce laser intensity. A filtering device should also be used to remove non-lasting plasma emission

lines from the laser beam before they reach the sample. Plasma lines can seriously interfere with Raman measurements. Filtering

devices include dispersive monochromators and interference filters.

This practice is under the jurisdiction of ASTM Committee E13 on Molecular Spectroscopy and Separation Science and is the direct responsibility of Subcommittee

E13.08 on Raman Spectroscopy.

Current edition approved March 1, 2007May 1, 2014. Published March 2007June 2014. Originally approved in 1995. Last previous edition approved in 20022007 as

E1683 – 02.E1683 – 02(2007). DOI: 10.1520/E1683-02R07.10.1520/E1683-02R14E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

E1683 − 02 (2014)

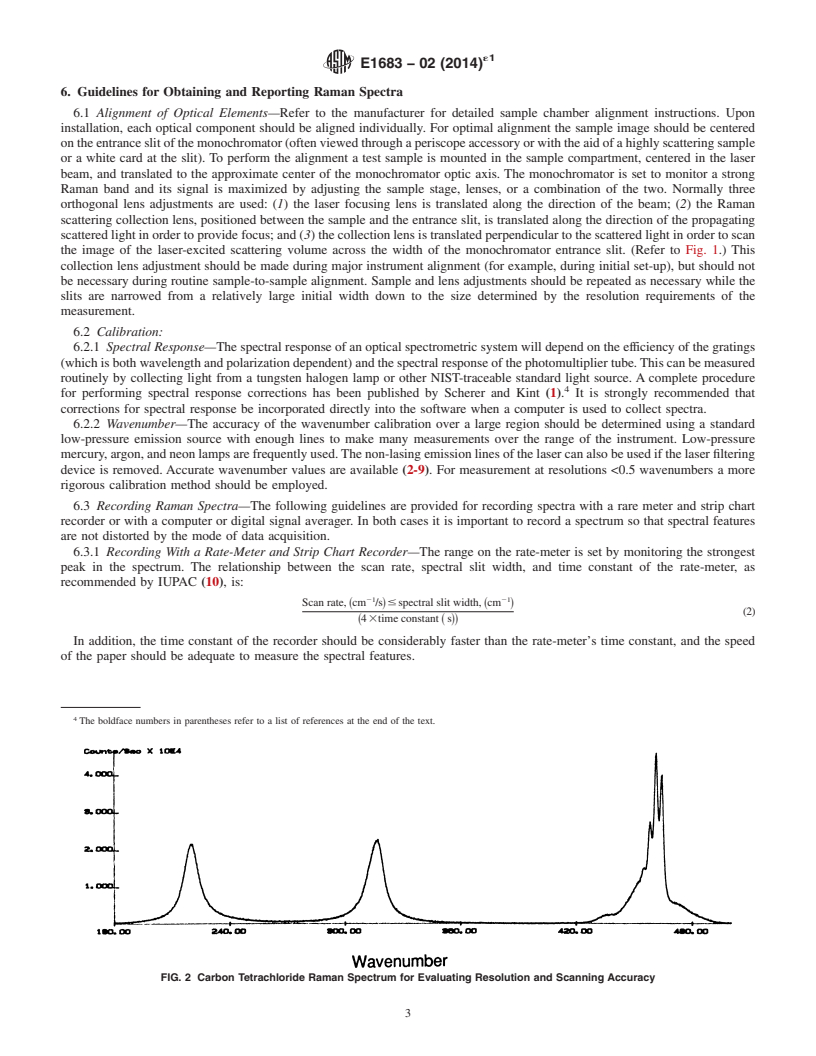

5.2 Sampling Optics—Commercial instruments can be purchased with sampling optics to focus the laser beam onto a sample

and to image the Raman scattering onto the monochromator entrance slit. Sample chamber adjustments are used to center the

sample properly and align the Raman scattered light. A schematic view of a conventional 90° Raman scattering geometry is shown

in Fig. 1. The laser beam propagates at a right angle to the direction in which scattered light is collected. It is focused on the sample

at the same position as the monochromator entrance slit image. Other geometries such as 180° backscattering are also used. With

single monochromators, a filter is normally placed in the optical collection path to block light at the laser frequency from entering

the monochromator.

5.3 Polarization—For routine measurements the polarization of the laser at the sample is oriented normal to the plane of the

page in Fig. 1. However, measurements using different polarizations are sometimes used to determine vibrational symmetries as

part of molecular structure determinations. A variety of optical configurations can be used to make polarization measurements; a

detailed discussion of these is beyond the scope of this practice. Briefly, for polarization simple measurements of randomly-

oriented samples (most of the clear liquids), an analyzing element such as a polaroid filter or analyzing prism is added to the optical

system and Raman spectra are collected for light scattered in (1) the same direction as the source (parallel), (2) perpendicular to

the source. Depolarization ratios are calculated using Raman band intensities from the two spectra as follows:

Intensity parallel

Depolarization ratio 5 (1)

Intensity perpendicular

5.3.1 A polarization scrambler is shown in Fig. 1. This element is used to avoid making corrections for polarization-dependent

grating effects. The scrambler is also frequently used during routine measurements and should be placed between the sample and

entrance slit, close to the collection lens. A polaroid filter placed between the scrambler and collection lens provides a simple

polarization measurement system.

5.4 Monochromator—A scanning monochromator used for Raman spectroscopy will exhibit high performance requirements.

Double and triple monochromators have particularly stringent performance standards. During the original instrument design,

features are usually introduced to minimize optical aberrations. However, proper maintenance of optical alignment is essential. A

focused image on the entrance slit should be optically transferred to and matched with the other slits. If the monochromator is not

functioning properly contact the manufacturer for assistance.

5.5 Photomultiplier Tube—A photomultiplier can be used for detecting Raman scattered radiation. A tube with good response

characteristics at and above the laser wavelength should be selected. Dark signal can be reduced with thermoelectric cooling for

improved detection of weak signals. Current and voltage amplification or photon counting are commercially available options with

photomultiplier tubes.

FIG. 1 Typical Raman Scattering Measurement Geometry

´1

E1683 − 02 (2014)

6. Guidelines for Obtaining and Reporting Raman Spectra

6.1 Alignment of Optical Elements—Refer to the manufacturer for detailed sample chamber alignment instructions. Upon

installation, each optical component should be aligned individually. For optimal alignment the sample image should be centered

on the entrance slit of the monochromator (often viewed through a periscope accessory or with the aid of a highly scattering sample

or a white card at the slit). To perform the alignment a test sample is mounted in the sample compartment, centered in the laser

beam, and translated to the approximate center of the monochromator optic axis. The monochromator is set to monitor a strong

Raman band and its signal is maximized by adjusting the sample stage, lenses, or a combination of the two. Normally three

orthogonal lens adjustments are used: (1) the laser focusing lens is translated along the direction of the beam; (2) the Raman

scattering collection lens, positioned between the sample and the entrance slit, is translated along the direction of the propagating

scattered light in order to provide focus; and (3) the collection lens is translated perpendicular to the scattered light in order to scan

the image of the laser-excited scattering volume across the width of the monochromator entrance slit. (Refer to Fig. 1.) This

collection lens adjustment should be made during major instrument alignment (for example, during initial set-up), but should not

be necessary during routine sample-to-sample alignment. Sample and lens adjustments should be repeated as necessary while the

slits are narrowed from a relatively large initial width down to the size determined by the resolution requirements of the

measurement.

6.2 Calibration:

6.2.1 Spectral Response—The spectral response of an optical spectrometric system will depend on the efficiency of the gratings

(which is both wavelength and polarization dependent) and the spectral response of the photomultiplier tube. This can be measured

routinely by collecting light from a tungsten halogen lamp or other NIST-traceable standard light source. A complete procedure

for performing spectral response corrections has been published by Scherer and Kint (1). It is strongly recommended that

corrections for spectral response be incorporated directly into the software when a computer is used to collect spectra.

6.2.2 Wavenumber—The accuracy of the wavenumber calibration over a large region should be determined using a standard

low-pressure emission source with enough lines to make many measurements over the range of the instrument. Low-pressure

mercury, argon, and neon lamps are frequently used. The non-lasing emission lines of the laser can also be used if the laser filtering

device is removed. Accurate wavenumber values are available (2-9). For measurement at resolutions <0.5 wavenumbers a more

rigorous calibration method should be employed.

6.3 Recording Raman Spectra—The following guidelines are provided for recording spectra with a rare meter and strip chart

recorder or with a computer or digital signal averager. In both cases it is important to record a spectrum so that spectral features

are not distorted by the mode of data acquisition.

6.3.1 Recording With a Rate-Meter and Strip Chart Recorder—The range on the rate-meter is set by monitoring the strongest

peak in the spectrum. The relationship between the scan rate, spectral slit width, and time constant of the rate-meter, as

recommended by IUPAC (10), is:

21 21

Scan rate, cm /s # spectral slit width, cm

~ ! ~ !

(2)

43time constant s

~ ~ !!

In addition, the time constant of the recorder should be considerably faster than the rate-meter’s time constant, and the speed

of the paper should be adequate to measure the spectral features.

The boldface numbers in parentheses refer to a list of references at the end of the text.

FIG. 2 Carbon Tetrachloride Raman Spectrum for Evaluating Resolution and Scanning Accuracy

´1

E1683 − 02 (2014)

6.3.2 Recording With a Computer or Signal Averager—In this case one needs to define the increments in wavenumbers between

data points. A minimum criterion is to collect five data points in the full width at half the maximum intensity (FWHM) of the

narrowest spectral band. For example, if the slits were set to provide a measured band width at half maximum of 4 wavenumbers,

then 1-wavenumber increments would produce five data points within the FWHM in a scan of a line from a plasma emission

source. To better define peak shape decrease the size of the increments. This is especially important for bands that deviate from

Lorentzian shape.

6.4 Reporting Experimental Conditions—The spectral slit width (wavenumbers), scan rate, laser wavelength and power at the

sample, polarization conditions, integration time, corrections for instrumental response, type of spectrometer and detector, sample

information (physical state, concentration, geometry, and so forth), and other important experimental conditions should always be

recorded with the spectra and reproduced for performance testing. A complete record of the parameters to be specified is available

in Table 1 of the IUPAC Recommendations for the Presentation of Raman Spectra in Data Collections (10).

7. Evaluation of Raman Instrument Parameters

7.1 The performance of an instrument should be evaluated regularly to determine if it has degraded. This is most easily

accomplished with a test sample such as carbon tetrachloride measured under a set of standard conditions established for the

particular instrument. Signal intensity and wavelength accuracy are the two spectral features to check. If peak signal levels have

diminished or are shifted from accepted wavenumber values, the components of the system should be evaluated independently to

locate the source of performance degradation. Guidelines for such an evaluation are as follows:

7.2 Test Samples—The following readily available materials are commonly used for evaluating the performance of Raman

spectrometers:

7.2.1 Carbon Tetrachloride—The major Raman bands are 218, 314, and 459 cm-1 (see Fig. 2). (Warning—Carbon

tetrachloride is toxic and a suspected carcinogen. It is recommended that carbon tetrachloride be used in closed containers to avoid

inhalation of harmful vapors.Warning)—Carbon tetrachloride is toxic and a suspected carcinogen. It is recommended that carbon

tetrachloride be used in closed containers to avoid inhalation of harmful vapors.)

7.2.2 Cyclohexane—The major Raman bands are at 384.1, 801.3, 1444.4, and 2852.9 cm-1.

7.2.3 Indene—There are many bands at well-known Raman Shift (2, 11, 12). Samples should be vacuum-distilled, sealed, and

stored in the dark. A reference spectrum is shown in Fig. 3 (2).

7.3 Monochromator—There is a trade-off between spectral resolution of a monochromator and the intensity throughput. The

following five characteristics of a monochromator can be evaluated independently:

7.3.1 Spectral Bandwidth—The minimum spectral bandwidth that can be measured with a Raman spectrometer is determined

by the focal length of the mirrors, the groove density of the gratings, and its optical alignment. Mirror focal length is determined

during instrument design. Usually gratings with severa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.