ASTM D2855-96(2010)

(Practice)Standard Practice for Making Solvent-Cemented Joints with Poly(Vinyl Chloride) (PVC) Pipe and Fittings

Standard Practice for Making Solvent-Cemented Joints with Poly(Vinyl Chloride) (PVC) Pipe and Fittings

SIGNIFICANCE AND USE

The techniques described herein can be used to produce strong pressure-tight joints between PVC pipe and fittings, either in shop operations or in the field. However, skill and knowledge on the part of the operator are required to obtain a good quality joint. This skill and knowledge can be obtained by making joints under the guidance of skilled operators and testing them until good quality joints are obtained.

SCOPE

1.1 This practice describes a procedure for making joints with poly(vinyl chloride) plastic (PVC) pipes, both plain ends and fittings, and bell ends, by means of solvent cements. These procedures are general ones for PVC piping. In non-pressure applications, simplified procedures may be used. Manufacturers should supply specific instructions for their particular products, if and when it seems necessary.

1.2 The techniques covered are applicable only to PVC pipe, both plain and bell-end, and fittings of the same classes as described in Specification D1784.

1.3 Pipe and fittings are manufactured within certain tolerances to provide for the small variations in the extrusion, belling, and molding processes and are not to exact size. A partial list of standards for PVC pipe, fittings, and cements suitable for use in making solvent-cemented joints is given in Appendix X1.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this practice references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2855 − 96(Reapproved 2010)

Standard Practice for

Making Solvent-Cemented Joints with Poly(Vinyl Chloride)

(PVC) Pipe and Fittings

This standard is issued under the fixed designation D2855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 This practice describes a procedure for making joints 2.1 ASTM Standards:

with poly(vinyl chloride) plastic (PVC) pipes, both plain ends D740Specification for Methyl Ethyl Ketone

andfittings,andbellends,bymeansofsolventcements.These D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

procedures are general ones for PVC piping. In non-pressure tics

applications, simplified procedures may be used. Manufactur- D1784Specification for Rigid Poly(Vinyl Chloride) (PVC)

ers should supply specific instructions for their particular Compounds and Chlorinated Poly(Vinyl Chloride)

products, if and when it seems necessary. (CPVC) Compounds

D2564Specification for Solvent Cements for Poly(Vinyl

1.2 The techniques covered are applicable only to PVC

Chloride) (PVC) Plastic Piping Systems

pipe,bothplainandbell-end,andfittingsofthesameclassesas

F402 Practice for Safe Handling of Solvent Cements,

described in Specification D1784.

Primers, and Cleaners Used for Joining Thermoplastic

1.3 Pipe and fittings are manufactured within certain toler-

Pipe and Fittings

ances to provide for the small variations in the extrusion,

F412Terminology Relating to Plastic Piping Systems

belling, and molding processes and are not to exact size. A

F656Specification for Primers for Use in Solvent Cement

partial list of standards for PVC pipe, fittings, and cements

Joints of Poly(Vinyl Chloride) (PVC) Plastic Pipe and

suitable for use in making solvent-cemented joints is given in

Fittings

Appendix X1.

3. Terminology

1.4 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3.1 Definitions—Definitions are in accordance with Termi-

conversions to SI units that are provided for information only nology F412, and abbreviations are in accordance with Termi-

and are not considered standard.

nology D1600, unless otherwise specified.

1.5 The text of this practice references notes and footnotes

4. Summary of Practice

that provide explanatory material. These notes and footnotes

4.1 To consistently make good joints, the following should

(excluding those in tables and figures) shall not be considered

be clearly understood and adhered to:

as requirements of the practice.

4.1.1 The joining surfaces must be softened (dissolved) and

1.6 This standard does not purport to address all of the

made semi-fluid.

safety concerns, if any, associated with its use. It is the

4.1.2 Sufficient cement must be applied to fill the gap

responsibility of the user of this standard to establish appro-

between pipe and fitting.

priate safety and health practices and determine the applica-

4.1.3 Assembly of pipe and fittings must be made while the

bility of regulatory limitations prior to use.

surfaces are still wet and fluid.

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.20 on Joining. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2010. Published March 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1970. Last previous edition approved in 2002 as D2855–96(2002). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D2855-96R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2855 − 96 (2010)

4.1.4 Jointstrengthdevelopsasthecementdries.Inthetight

part of the joint the surfaces will tend to fuse together; in the

loose part the cement will bond to both surfaces.

4.2 Penetration and dissolving can be achieved by the

cementitself,byasuitableprimer,orbytheuseofbothprimer

and cement. A suitable primer will penetrate and dissolve the

plastic more quickly than cement alone. In cold weather, more

time and additional applications are required (see Fig. 1).

4.3 More than sufficient cement to fill the loose part of the

joint must be applied (see Fig. 2). Besides filling the gap,

FIG. 2 Cement Coatings of Sufficient Thickness

adequate cement layers will penetrate the surfaces and also

remain wet until the joint is assembled.

4.4 If the cement coatings on the pipe and fittings are wet

and fluid when assembly takes place, they will tend to flow

together and become one cement layer. Also, if the cement is

wet the surfaces beneath them will still be soft, and these

dissolved surfaces in the tight part of the joint will tend to fuse

together (see Fig. 3).

4.5 As the solvent dissipates, the cement layer and the

dissolvedsurfaceswillhardenwithacorrespondingincreasein

FIG. 3 Assembly of Surfaces While They Are Wet and Soft

joint strength. A good joint will take the required working

pressure long before the joint is fully dry and final strength is

obtained. In the tight (fused) part of the joint, strength will

develop more quickly than in the looser (bonded) part of the

joint. Completed joints should not be disturbed until they have

cured sufficiently to withstand handling. Joint strength devel-

ops as the cement dries. Information about the development of

bond strength of solvent cemented joints is available (see Fig.

4).

5. Significance and Use

5.1 The techniques described herein can be used to produce

strong pressure-tight joints between PVC pipe and fittings,

FIG. 4 Bonded and Fused Surfaces of Joined Pipe

either in shop operations or in the field. However, skill and

knowledge on the part of the operator are required to obtain a

goodqualityjoint.Thisskillandknowledgecanbeobtainedby

making joints under the guidance of skilled operators and

6.2.1 Specification—Thesolventcementshouldmeetallthe

testing them until good quality joints are obtained.

requirements of Specification D2564.

6. Materials

6.2.2 Selection—PVC solvent cements are available in a

6.1 Pipe and Fittings—Thepipeandfittingsshouldmeetthe variety of viscosities and wet film thicknesses to cover the

requirementsofcurrentapplicablePVCpipingstandards.Alist range of pipe sizes from ⁄8 to 12 in. and for interference-fit

of these standards is given in Appendix X1. joints as well as noninterference joints, as found in some

Schedule 80 pipe and fittings. One of the general principles of

6.2 Solvent Cement:

solvent cementing that should be strictly adhered to is: suffi-

cient cement must be applied to fill the gap between pipe and

fitting.

6.2.2.1 Theabilityofasolventcementtofillagapinapipe

joint can be determined by considering its viscosity and

wet-film thickness (see Note X3.1). A guide to the proper

selectionofasolventcementforthevariouspipesizesisgiven

in Table X3.1and Table X3.2, where PVC solvent cements are

classified (for purposes of identification) as regular-bodied,

medium-bodied, and heavy-bodied cement based on minimum

viscosity and minimum wet-film thickness.

6.2.3 Storage—PVC solvent cements should be stored in a

FIG. 1 Areas of Pipe and Fittings to Be Softened (Dissolved) and

Penetrated cool place except when actually in use at the job site. These

D2855 − 96 (2010)

cements have a limited shelf life when not stored in hermeti- the fitting socket being scraped from the socket surface,

cally sealed containers. Screw top containers are not consid- producing a dry joint with a high probability of joint failure.

ered to be hermetically sealed. Consult the cement manufac- Remove all burrs with a knife, file, or abrasive paper.

turer for specific storage recommendations on storage

7.2 Joint Preparation—Chamfer or deburr pipe, or both,

conditions and shelf life. The cement is unsuitable for use on

approximately as illustrated in Fig. 6. Failing to chamfer the

the job if it exhibits an appreciable change from the original

edge of the pipe may remove the cement and softened material

viscosity,orifasignofgelationisapparent.Restorationofthe

from the fitting socket, and result in a leaking joint.

original viscosity or removal of gelation by adding solvents or

7.3 Test Dry Fit of the Joint (see Fig. 7)—The solvent

thinners is not recommended.

cement joint is designed so that there will generally be

6.3 Cleaners—Cleaners are of two types, chemical and

interference of pipe wall with the fitting socket before the pipe

mechanical (abrasives). Cleaners are used to remove surface

is fully inserted. Insert the pipe into the fitting and check that

impurities (oil, dirt, etc.) and surface gloss.

1 2

the interference occurs about ⁄3to ⁄3 of the socket depth.

6.3.1 Chemical Cleaners—The chemical cleaners are as

Sometimes, when the pipe and fittings are at their tolerance

follows:

extremes or when Schedule 80 pipe is used, it may be possible

6.3.1.1 Cleaner recommended by the pipe, fittings, or ce-

to fully insert the dry pipe into the fitting socket until it

ment manufacturer, and

bottoms. If this occurs, the fit between the pipe and fitting

6.3.1.2 Methyl ethyl ketone (MEK) in accordance with

should be snug. If the fit is loose or wobbly, other fittings or

Specification D740.

pipe should be selected which give a proper fit.

6.3.2 Mechanical Cleaners—The mechanical cleaners are

7.4 Cleaning—Surfacestobejoinedmustbecleanedandbe

as follows:

free of dirt, moisture, oil, and other foreign material (see Fig.

6.3.2.1 Fine abrasive paper or cloth (180 grit or finer), and

8). If this cannot be accomplished by wiping with a clean dry

6.3.2.2 Clean, oil-free steel wool.

cloth, a chemical or mechanical cleaner must be used. If a

6.4 Primers—Primersareusedtoclean,soften,anddissolve

chemicalcleanerisused,applywithanapplicator.Skincontact

the joining surfaces in order to better prepare them for solvent

with chemical cleaners should be avoided.

cementing.Primersmustbecapableofdissolving10weight%

7.5 Application Procedure:

of PVC resin as required in Specification F656. Primers may

7.5.1 Handling Cement—Keepthecementcanclosedandin

also be used as cleaners; refer to specific recommendations of

a shady place when not actually in use. Discard the cement

the manufacturer.

when an appreciable change in viscosity takes place, or at the

NOTE 1—In the event of conflicting instructions from the pipe, fittings,

first sign of gelation. The cement should not be thinned. Keep

or cement manufacturer, use a primer as well as solvent cement in the

the brush immersed in cement between applications.

joining procedure.

NOTE 2—A gel condition is indicated when the cement does not flow

6.4.1 Primer Specification—The primer shall meet the re-

freely from the brush or when the cement appears lumpy and stringy.

quirements of Specification F656.

7.5.2 Applicator Size—Apply the cement with a natural

7. Procedure

bristle, nylon brush or suitable applicator, using a ⁄2-in.

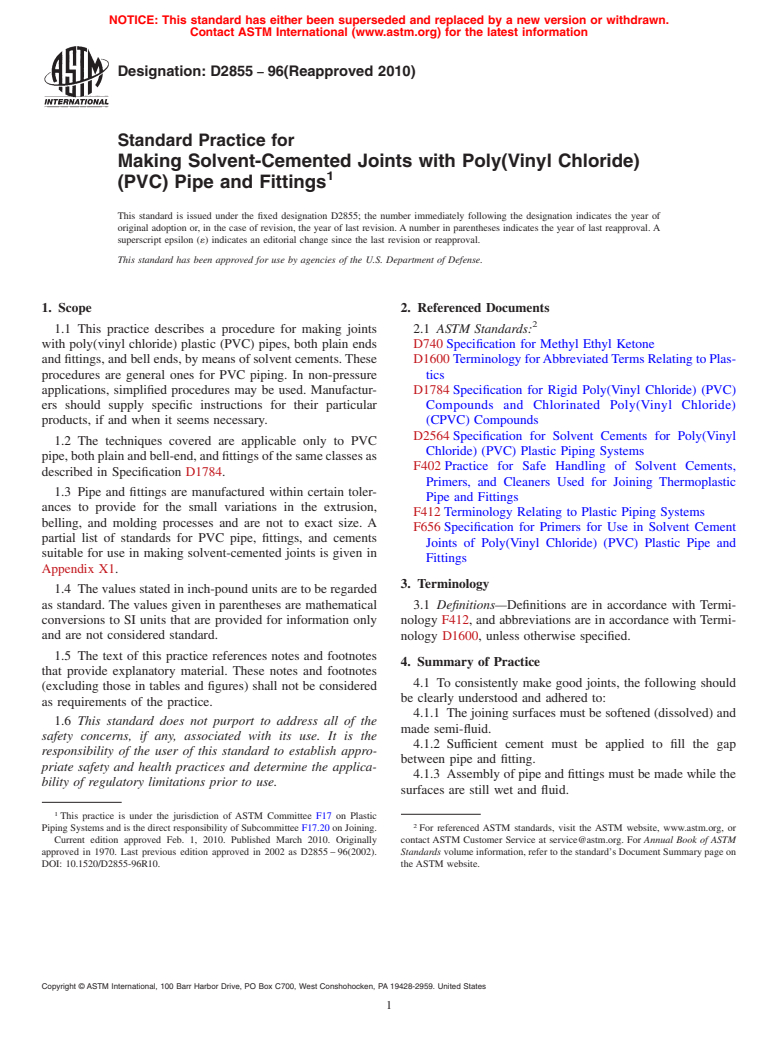

7.1 Cutting the Pipe—Cutpipesquarewiththeaxis,usinga (12-mm) brush or dauber for nominal pipe size ⁄2-in. and less,

fine-toothhandsawandamiterbox,orafine-toothpowersaw a 1-in. (25-mm) brush or dauber for pipe up through 2-in.

nominalpipesize,andabrushwidthatleast ⁄2ofnominalpipe

with a suitable guide (see Fig. 5). Wood-working blades may

be used. A rotary cutter may be used if the cutting blades are size for sizes above 2 in., except that for pipe sizes 6 in. and

larger a 2 ⁄2-in. (60-mm) brush is adequate. Other applicators

specifically designed for cutting plastic pipe in such a way as

not to raise a burr or ridge (flare) at the cut end of the pipe. If maybeusedprovidedtheiruseresultsinanequivalentamount

of cement being applied to the joining surfaces.

othertoolsarenotavailable,astandardrotarymetalpipecutter

may be used, provided great care is taken to remove all the 7.5.3 Application of Primer and Cement—PVC solvent

ridgeraisedatthepipeendbythewedgingactionofthecutting cementisfastdrying,andthereforethecementshallbeapplied

wheels.Failuretoremovetheridgewillresultinthecementin as quickly as possible, consistent with good workmanship. It

FIG. 5 Apparatus for Cutting Pipe

D2855 − 96 (2010)

FIG. 6 Chamfer and Deburring of Pipe Edges

FIG. 9 Application of Primer to Inside Socket Surface

FIG. 7 Pipe Entering Dry Fitting

7.5.3.2 Next, soften surface of male end of pipe, to be

inserted into socket, to depth of fitting socket by uniformly

applying a liberal coat of primer. Be sure entire surface is well

softened (dissolved) (see Fig. 10).

7.5.3.3 Again,brushinsidesocketsurfacewithprimer;then,

without delay, apply cement to pipe while the surfaces are still

wet with primer (see Fig. 11).

7.5.3.4 Apply cement lightly but uniformly to inside of

socket,takingcaretokeepexcesscementoutofsocket.Thisis

to prevent solvent damage to pipe (see Fig. 12). Time is

FIG. 8 Cleaning of Pipe with Dry Cloth to Remove Foreign Matter

important at this stage. Apply a second coat of cement to the

pipe end (see Fig. 11).

maybenecessaryfortwoworkerstoperformthisoperationfor

larger sizes of pipe. Under conditions of high atmospheric

humidity, quick application is important to minimize conden-

sation of moisture from the air on the cement surface. The

surface temperature of the mating surfaces should not exceed

110°F (45°C) at the time of assembly. In direct sunlight or in

ambient temperatures above 110°F, the pipe surface may

exceed 110°F. The pipe temperature may be reduced by

swabbing the surface to be cemented with clean wet rags

provided the pipe is thoroughly dried before the primer and

cement are applied.

7.5.3.1 Firstapplyprimertoinsidesocketsurface(see7.5.2

for applicator or brush size). Use a scrubbing motion to ensure

penetration. Repeated applications may be necessary (see Fig.

FIG. 10 Liberal Application of Primer to Soften Surface of End of

9). Pipe

D2855 − 96 (2010)

(3) Take special care to remove moisture, including ice

and snow, from pipe and fitting surfaces before applying

primer or cement.

(4) Always use primer to soften the joining surfaces

before applying cement. More than one application may be

necessary.

(5) Allow a longer cure time before the system is used.

This is necessary because the solvents evaporate more slowly

at cold temperatures. Refer to Table X2.1.

7.6 Special Instructions for Bell-End Pipe—T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.