ASTM D756-93

(Practice)Practice for Determination of Weight and Shape Changes of Plastics Under Accelerated Service Conditions (Withdrawn 1998)

Practice for Determination of Weight and Shape Changes of Plastics Under Accelerated Service Conditions (Withdrawn 1998)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D756–93

Standard Practice for

Determination of Weight and Shape Changes of Plastics

1

Under Accelerated Service Conditions

This standard is issued under the fixed designation D756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense to replace Method 6011 of Federal Test Method

Standard 406. Consult the DoD Index of Specifications and Standards for the specific year of issue which has been adopted by the

Department of Defense.

1. Scope 2. Referenced Documents

1.1 Thispracticecoversthedeterminationoftheweightand 2.1 ASTM Standards:

shapechangesoccurringinplasticsundervariousconditionsof D618 Practice for Conditioning Plastics and Electrical

2

use, not where exposure to direct sunlight, weathering, corro- Insulating Materials for Testing

2

siveatmospheres,orheataloneisinvolved,butwherechanges D883 Terminology Relating to Plastics

inatmospherictemperatureandhumidityareencountered.This

3. Terminology

embraces the interior of buildings, and the interior of transport

facilitiessuchasmotorvehicles,airplanecargospacesorwing 3.1 Definitions—Definitions of terms applying to this prac-

tice appear in Terminology D883.

interiors, holds of ships, and railroad cars. Procedures are

provided for exposing plastics to combinations of extreme

4. Significance and Use

humidity and temperature that will accelerate the changes

4.1 The test conditions covered in this practice represent a

taking place in the materials kept in sheltered spaces but

start towards organizing a group of test procedures for deter-

subjecttohumidityandtemperaturevariation(seeExplanatory

mining the effects of specified changes of atmospheric tem-

Note).

perature and humidity upon plastic articles. These procedures

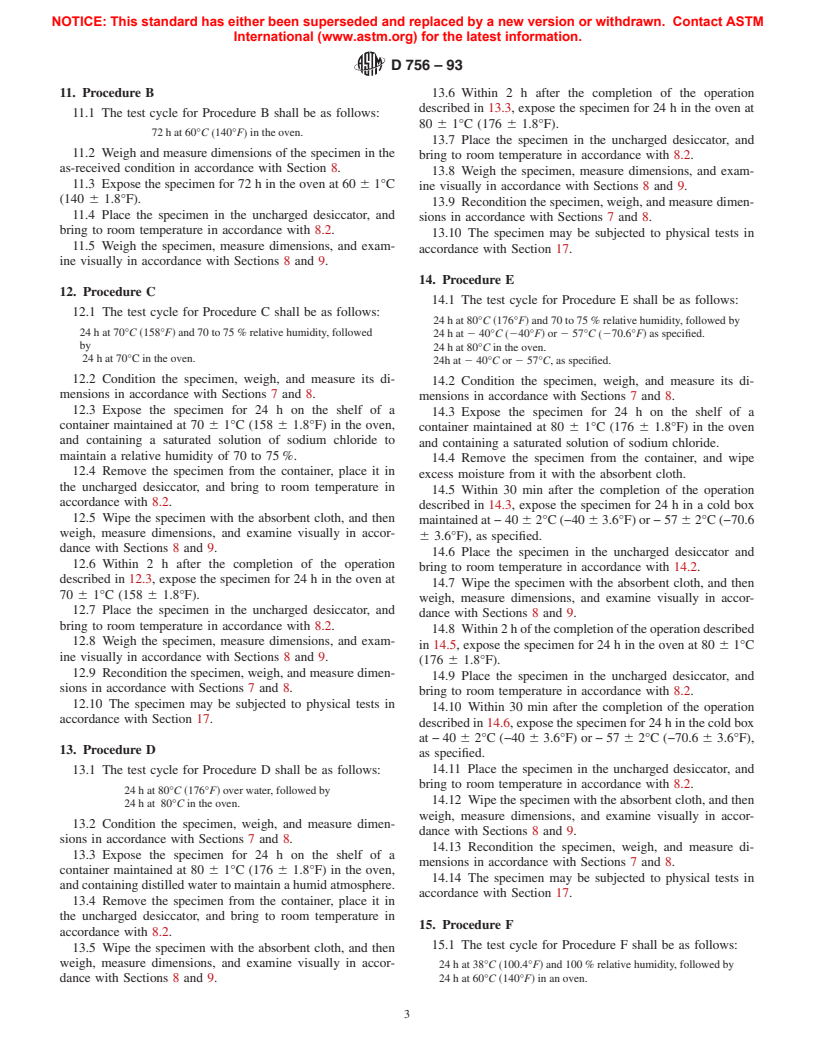

1.2 Seven test procedures are provided which prescribe

have been used for testing both thermosetting and thermoplas-

conditions for different types of exposure. Six of the proce-

tic materials.

dures cover exposures at graduated levels of temperature and

extremes of humidity; the seventh prescribes conditions in-

NOTE 2—The test procedures covered in this practice have been drawn

volving alternate exposure to high and low temperatures.

from various tests used in branches of the plastics industry, and by

Insofar as weight and shape changes, embraced under the

government agencies in procurement of materials.

general term of dimensional stability, are concerned, these

4.2 Whileseveralofthetestingtemperaturesarenotusedin

procedures provide a method of test. Further use of any of the

other ASTM standards, they have a background of several

conditions set up in the procedures is suggested, such as

yearsexperienceinportionsoftheplasticsindustry.Especially

conditioning schedules prior to physical testing of the plastic

in Procedures D and E (Sections 13 and 14) the accelerating

either to test it at the particular condition involved, or to study

effect of temperature in prompting changes caused by a rise in

changes resulting from exposure to that condition.

humidity leads to temperatures that are well above those

1.3 The values stated in SI units are to be regarded as the

encountered in normal service, and they are used simply to

standard. The values given in parentheses are for information

accelerate change.

only.

4.3 Procedure A (Section 10) has been found to develop

1.4 This standard does not purport to address all of the

warping, weight change, and exudation in plastic parts. Proce-

safety problems, if any, associated with its use. It is the

dure B (Section 11) is designed to reveal poorly cured plastics

responsibility of the user of this standard to establish appro-

by developing cracks in them. Procedures C and D are more

priate safety and health practices and determine the applica-

severe measures of the same tendencies developed in Proce-

bility of regulatory limitations prior to use.

dureA; the conditions of Procedure D will produce noticeable

NOTE 1—There is no similar or comparable ISO standard. chemical decomposition in many plastics. Procedure E (Sec-

tion 14) is especially valuable in testing the behavior of plastic

parts with metallic inserts and laminates, for cracking on

1

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

andisthedirectresponsibilityofSubcommitteeD20.50onPermanenceProperties.

Current edition approved Feb. 15, 1993. Published April 1993. Originally

e1 2

published as D756–44T. Last previous edition D756–78 (1983) . Annual Book of ASTM Standards, Vol 08.01.

Copyright © ASTM International, 100 Barr Harbor Drive,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.