ASTM D4639-86(1996)

(Test Method)Standard Test Method for Volatile Content in Phenolic Resins (Withdrawn 2004)

Standard Test Method for Volatile Content in Phenolic Resins (Withdrawn 2004)

SCOPE

1.1 This test method covers the determination of matter in a solid phenolic resin that is volatile at 300°F (150°C).

1.2 This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the determination of matter in a solid phenolic resin that is volatile at 300F (150C).

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in December 2004 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

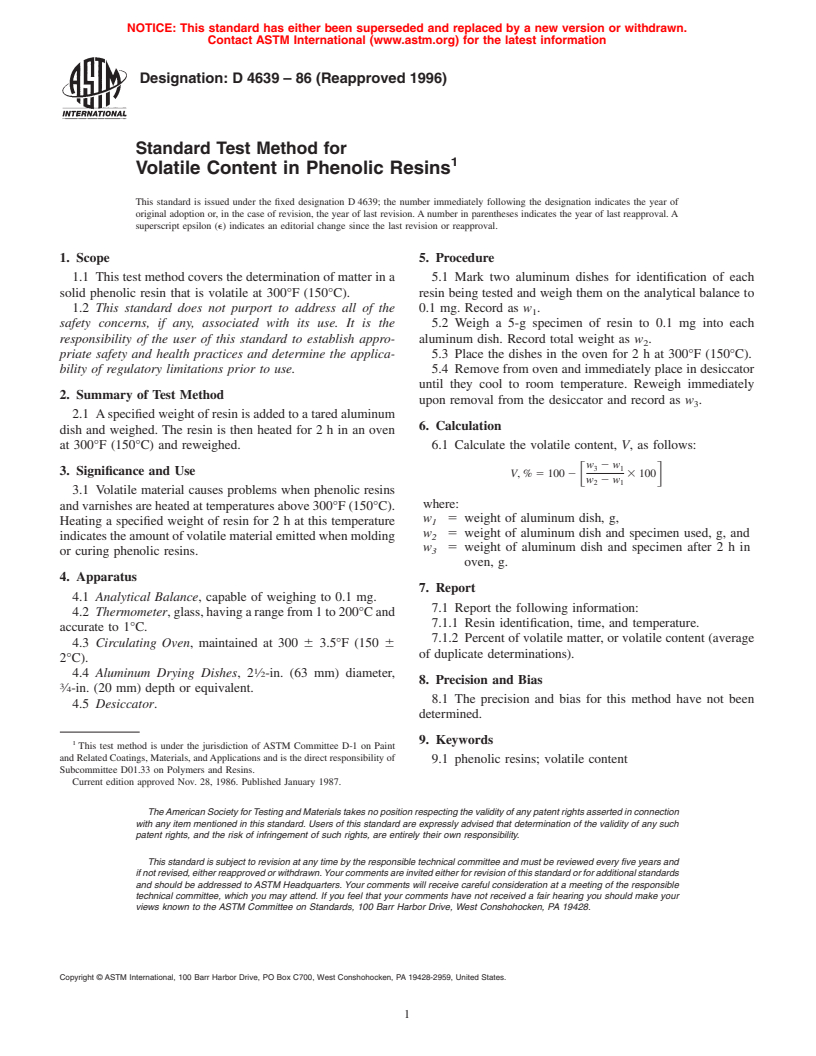

Designation:D4639–86(Reapproved1996)

Standard Test Method for

Volatile Content in Phenolic Resins

This standard is issued under the fixed designation D 4639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Procedure

1.1 This test method covers the determination of matter in a 5.1 Mark two aluminum dishes for identification of each

solid phenolic resin that is volatile at 300°F (150°C). resin being tested and weigh them on the analytical balance to

1.2 This standard does not purport to address all of the 0.1 mg. Record as w .

safety concerns, if any, associated with its use. It is the 5.2 Weigh a 5-g specimen of resin to 0.1 mg into each

responsibility of the user of this standard to establish appro- aluminum dish. Record total weight as w .

priate safety and health practices and determine the applica- 5.3 Place the dishes in the oven for2hat 300°F (150°C).

bility of regulatory limitations prior to use. 5.4 Remove from oven and immediately place in desiccator

until they cool to room temperature. Reweigh immediately

2. Summary of Test Method

upon removal from the desiccator and record as w .

2.1 Aspecified weight of resin is added to a tared aluminum

6. Calculation

dish and weighed. The resin is then heated for2hinan oven

at 300°F (150°C) and reweighed. 6.1 Calculate the volatile content, V, as follows:

w 2 w

3 1

3. Significance and Use

V,% 5 100 2 3 100

F G

w 2 w

2 1

3.1 Volatile material causes problems when phenolic resins

where:

and varnishes are heated at temperatures above 300°F (150°C).

w 5 weight of aluminum dish, g,

Heating a specified weight of resin for2hat this temperature 1

w 5 weight of aluminum dish and specimen used, g, and

indicates the amount of volatile material emitted w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.