ASTM D6907-05(2016)

(Practice)Standard Practice for Sampling Soils and Contaminated Media with Hand-Operated Bucket Augers

Standard Practice for Sampling Soils and Contaminated Media with Hand-Operated Bucket Augers

SIGNIFICANCE AND USE

5.1 Bucket augers are relatively inexpensive, readily available, available in different types depending on the media to be sampled, and most can be easily operated by one person. They collect a reasonably cylindrical but disturbed sample of surface or subsurface soil or waste. They are generally not suited for sampling gravelly or coarser soil and are unsuitable for sampling rock.

5.2 Bucket augers are commonly used equipment because they are inexpensive to operate, especially compared to powered equipment (that is, direct push and drill rigs). When evaluated against screw augers, bucket augers generally collect larger samples with less chance of mixing with soil from shallow depths because the sample is retained within the auger barrel. Bucket augers are commonly used to depths of 3 m but have been used to much greater depths depending upon the soil or waste characteristics. The sampling depth is limited by the force required to rotate the auger and the depth at which the borehole collapses (unless bore casings or liners are used).

5.3 Bucket augers may not be suitable for the collection of samples for determination of volatile organic compounds because the sample is disturbed during the collection process, which may lead to losses resulting in a chemically unrepresentative sample.

SCOPE

1.1 This practice describes the procedures and equipment used to collect surface and subsurface soil and contaminated media samples for chemical analysis using a hand-operated bucket auger (hereafter referred to as a bucket auger; sometimes referred to as a barrel auger). Several types of bucket augers exist and are designed for sampling various types of soil. All bucket augers collect disturbed samples, but bucket augers can also be used to auger to the desired sampling depth and then, using a core-type sampler, collect a relatively undisturbed sample.

1.2 This practice does not cover the use of large (12-in. or greater diameter) bucket augers mechanically operated by large drill rigs or similar equipment, such as those described in Practice D1452, section 3.2.4.

1.3 The term bucket auger is used to differentiate this type of hand operated auger from others of the solid or hollow stem types that are also hand held or operated.

1.4 This practice does not address sampling objectives (see Practice D5792), general sample planning (see Guide D4687), sampling design (for example, where to collect samples and what depth to sample [see Guide D6044]), sampling for volatile organic compounds (see Guide D4547), equipment cleaning and decontamination (see Practice D5088), sample handling after collection such as compositing and subsampling (see Guide D6051), and sample preservation. For information on other types of augers, see Practice D1452 and Guide D4700.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6907 − 05 (Reapproved 2016)

Standard Practice for

Sampling Soils and Contaminated Media with Hand-

Operated Bucket Augers

This standard is issued under the fixed designation D6907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice describes the procedures and equipment

D1452 Practice for Soil Exploration and Sampling byAuger

used to collect surface and subsurface soil and contaminated

Borings

media samples for chemical analysis using a hand-operated

D4547 Guide for Sampling Waste and Soils for Volatile

bucket auger (hereafter referred to as a bucket auger; some-

Organic Compounds

times referred to as a barrel auger). Several types of bucket

D4687 Guide for General Planning of Waste Sampling

augers exist and are designed for sampling various types of

D4700 Guide for Soil Sampling from the Vadose Zone

soil. All bucket augers collect disturbed samples, but bucket

D5088 Practice for Decontamination of Field Equipment

augers can also be used to auger to the desired sampling depth

Used at Waste Sites

and then, using a core-type sampler, collect a relatively

D5283 Practice for Generation of Environmental Data Re-

undisturbed sample.

lated to Waste ManagementActivities: QualityAssurance

and Quality Control Planning and Implementation

1.2 This practice does not cover the use of large (12-in. or

D5434 Guide for Field Logging of Subsurface Explorations

greaterdiameter)bucketaugersmechanicallyoperatedbylarge

of Soil and Rock

drill rigs or similar equipment, such as those described in

D5681 Terminology for Waste and Waste Management

Practice D1452, section 3.2.4.

D5792 Practice for Generation of Environmental Data Re-

1.3 The term bucket auger is used to differentiate this type

lated to Waste Management Activities: Development of

of hand operated auger from others of the solid or hollow stem

Data Quality Objectives

types that are also hand held or operated.

D6044 Guide for Representative Sampling for Management

of Waste and Contaminated Media

1.4 This practice does not address sampling objectives (see

D6051 Guide for Composite Sampling and Field Subsam-

Practice D5792), general sample planning (see Guide D4687),

pling for Environmental Waste Management Activities

sampling design (for example, where to collect samples and

D6232 Guide for Selection of Sampling Equipment for

what depth to sample [see Guide D6044]), sampling for

WasteandContaminatedMediaDataCollectionActivities

volatile organic compounds (see Guide D4547), equipment

D6282 Guide for Direct Push Soil Sampling for Environ-

cleaning and decontamination (see Practice D5088), sample

mental Site Characterizations

handling after collection such as compositing and subsampling

D6286 Guide for Selection of Drilling Methods for Environ-

(see Guide D6051), and sample preservation. For information

mental Site Characterization

onothertypesofaugers,seePracticeD1452andGuideD4700.

3. Terminology

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.1 Definitions—Except where noted, all terms and symbols

responsibility of the user of this standard to establish appro- in this practice are in accordance with the following publica-

priate safety and health practices and determine the applica- tions. In order of consideration they are:

bility of regulatory limitations prior to use. 3.1.1 Terminology D5681 for Waste and Waste

Management,

3.1.2 Compilation of ASTM Standard Terminology, and

This practice is under the jurisdiction of ASTM Committee D34 on Waste

Management and is the direct responsibility of Subcommittee D34.01.03 on

Sampling Equipment. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 15, 2016. Published October 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2010 as D6907 – 05 (2010). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6907-05R16. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6907 − 05 (2016)

3.1.3 Webster’s New Collegiate Dictionary.

4. Summary of Practice

4.1 Typically, bucket augers are tubular devices with cutting

bits on the bottom that are pushed and twisted into the media

and removed when the tubular “bucket” section is full. The

borehole is advanced one bucket at a time. The practical depth

of investigation using a bucket auger is related to the material

being sampled.

4.2 When a sampling interval starting at the surface is to be

sampled, the same auger can be used to collect all materials to

the bottom of the interval. However, if discrete grab samples

are to be collected to characterize multiple depths or a depth

interval commences below the surface, a clean bucket auger

should be used to collect the sample. The top material in a

bucket should generally be discarded to minimize chances of

cross-contamination of the sample from material that sloughs FIG. 1 Bucket Auger

from the borehole wall.

4.3 All augers collect disturbed samples that are generally

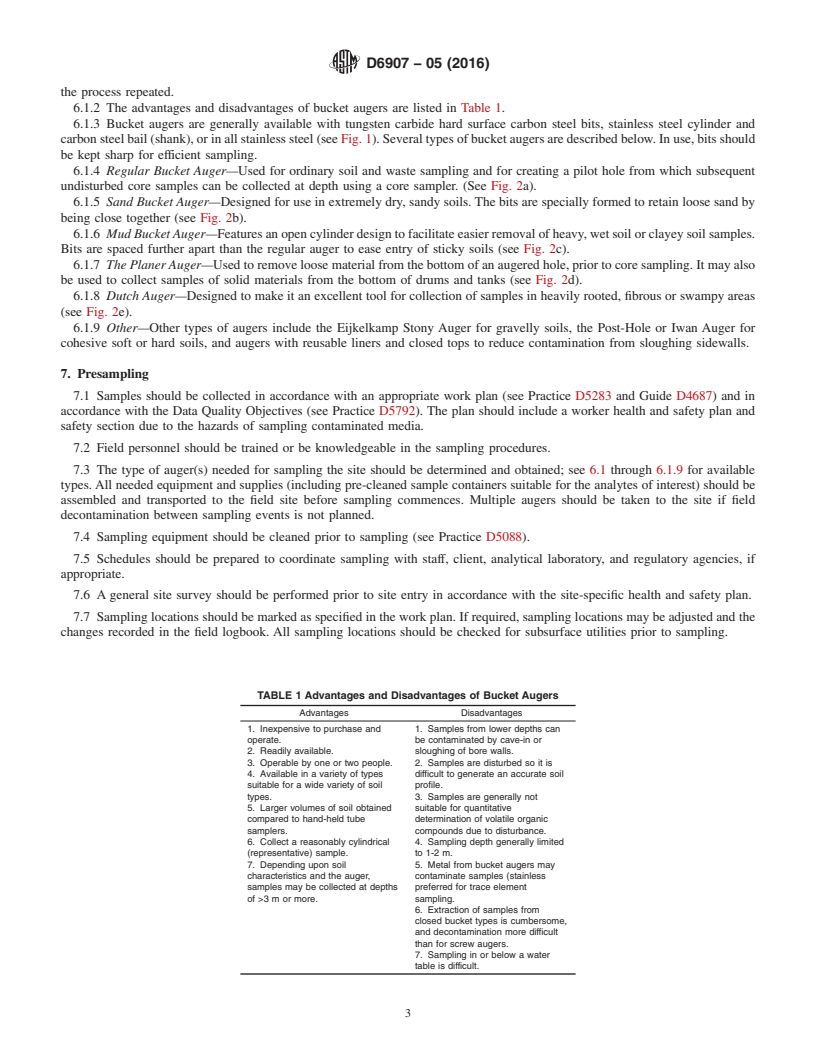

6.1.2 The advantages and disadvantages of bucket augers

not suitable for analysis of volatile organic compounds.

are listed in Table 1.

NOTE 1—Bucket augers may be used to obtain samples of materials

containing volatile organic compounds for field screening purposes. A 6.1.3 Bucket augers are generally available with tungsten

core or tube type sampler can be pushed into undisturbed soil at the

carbide hard surface carbon steel bits, stainless steel cylinder

bottom of an augered hole to collect a relatively undisturbed sample

and carbon steel bail (shank), or in all stainless steel (see Fig.

suitable for chemical analysis.

1). Several types of bucket augers are described below. In use,

bits should be kept sharp for efficient sampling.

5. Significance and Use

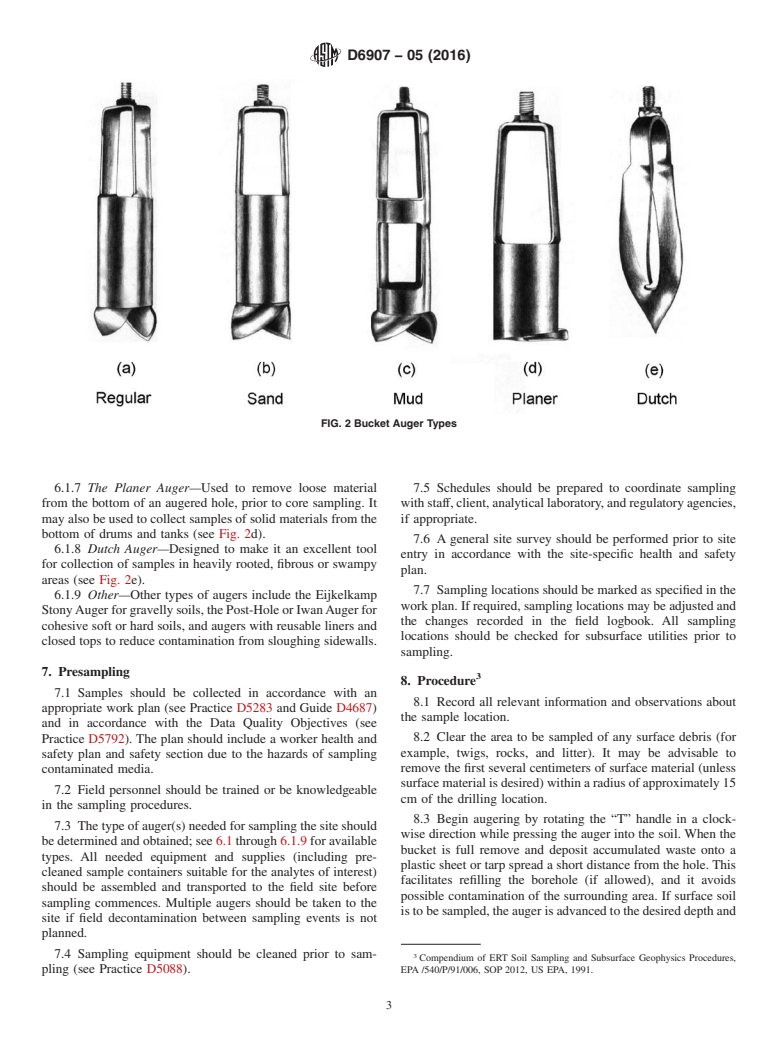

6.1.4 Regular Bucket Auger—Used for ordinary soil and

5.1 Bucket augers are relatively inexpensive, readily

waste sampling and for creating a pilot hole from which

available, available in different types depending on the media

subsequent undisturbed core samples can be collected at depth

to be sampled, and most can be easily operated by one person.

using a core sampler. (See Fig. 2a).

They collect a reasonably cylindrical but disturbed sample of

6.1.5 Sand Bucket Auger—Designed for use in extremely

surface or subsurface soil or waste. They are generally not

dry, sandy soils. The bits are specially formed to retain loose

suited for sampling gravelly or coarser soil and are unsuitable

sand by being close together (see Fig. 2b).

for sampling rock.

6.1.6 Mud Bucket Auger—Features an open cylinder design

5.2 Bucket augers are commonly used equipment because

to facilitate easier removal of heavy, wet soil or clayey soil

they are inexpensive to operate, especially compared to pow-

samples. Bits are spaced further apart than the regular auger to

ered equipment (that is, direct push and drill rigs). When

ease entry of sticky soils (see Fig. 2c).

evaluated against screw augers, bucket augers generally collect

larger samples with less chance of mixing with soil from

shallow depths because the sample is retained within the auger

TABLE 1 Advantages and Disadvantages of Bucket Augers

barrel. Bucket augers are commonly used to depths of3mbut

Advantages Disadvantages

have been used to much greater depths depending upon the soil

1. Inexpensive to purchase and 1. Samples from lower depths can

operate. be contaminated by cave-in or

or waste characteristics. The sampling depth is limited by the

2. Readily available. sloughing of bore walls.

force required to rotate the auger and the depth at which the

3. Operable by one or two people. 2. Samples are disturbed so it is

borehole collapses (unless bore casings or liners are used).

4. Available in a variety of types difficult to generate an accurate soil

suitable for a wide variety of soil profile.

5.3 Bucket augers may not be suitable for the collection of

types. 3. Samples are generally not

samples for determination of volatile organic compounds 5. Larger volumes of soil obtained suitable for quantitative

compared to hand-held tube determination of vol

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6907 − 05 (Reapproved 2010) D6907 − 05 (Reapproved 2016)

Standard Practice for

Sampling Soils and Contaminated Media with Hand-

Operated Bucket Augers

This standard is issued under the fixed designation D6907; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the procedures and equipment used to collect surface and subsurface soil and contaminated media

samples for chemical analysis using a hand-operated bucket auger (hereafter referred to as a bucket auger; sometimes referred to

as a barrel auger). Several types of bucket augers exist and are designed for sampling various types of soil. All bucket augers collect

disturbed samples, but bucket augers can also be used to auger to the desired sampling depth and then, using a core-type sampler,

collect a relatively undisturbed sample.

1.2 This practice does not cover the use of large (12-in. or greater diameter) bucket augers mechanically operated by large drill

rigs or similar equipment, such as those described in Practice D1452, section 3.2.4.

1.3 The term bucket auger is used to differentiate this type of hand operated auger from others of the solid or hollow stem types

that are also hand held or operated.

1.4 This practice does not address sampling objectives (see Practice D5792), general sample planning (see Guide D4687),

sampling design (for example, where to collect samples and what depth to sample [see Guide D6044]), sampling for volatile

organic compounds (see Guide D4547), equipment cleaning and decontamination (see Practice D5088), sample handling after

collection such as compositing and subsampling (see Guide D6051), and sample preservation. For information on other types of

augers, see Practice D1452 and Guide D4700.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1452 Practice for Soil Exploration and Sampling by Auger Borings

D4547 Guide for Sampling Waste and Soils for Volatile Organic Compounds

D4687 Guide for General Planning of Waste Sampling

D4700 Guide for Soil Sampling from the Vadose Zone

D5088 Practice for Decontamination of Field Equipment Used at Waste Sites

D5283 Practice for Generation of Environmental Data Related to Waste Management Activities: Quality Assurance and Quality

Control Planning and Implementation

D5434 Guide for Field Logging of Subsurface Explorations of Soil and Rock

D5681 Terminology for Waste and Waste Management

D5792 Practice for Generation of Environmental Data Related to Waste Management Activities: Development of Data Quality

Objectives

D6044 Guide for Representative Sampling for Management of Waste and Contaminated Media

D6051 Guide for Composite Sampling and Field Subsampling for Environmental Waste Management Activities

D6232 Guide for Selection of Sampling Equipment for Waste and Contaminated Media Data Collection Activities

D6282 Guide for Direct Push Soil Sampling for Environmental Site Characterizations

This practice is under the jurisdiction of ASTM Committee D34 on Waste Management and is the direct responsibility of Subcommittee D34.01.03 on Sampling

Equipment.

Current edition approved Jan. 1, 2010Oct. 15, 2016. Published January 2010October 2016. Originally approved in 2005. Last previous edition approved in 20052010 as

ε1

D6907D6907 – 05 (2010).–05 . DOI: 10.1520/D6907-05E01.10.1520/D6907-05R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6907 − 05 (2016)

D6286 Guide for Selection of Drilling Methods for Environmental Site Characterization

3. Terminology

3.1 Definitions—Except where noted, all terms and symbols in this practice are in accordance with the following publications.

In order of consideration they are:

3.1.1 Terminology D5681 for Waste and Waste Management,

3.1.2 Compilation of ASTM Standard Terminology, and

3.1.3 Webster’s New Collegiate Dictionary.

4. Summary of Practice

4.1 Typically, bucket augers are tubular devices with cutting bits on the bottom that are pushed and twisted into the media and

removed when the tubular “bucket” section is full. The borehole is advanced one bucket at a time. The practical depth of

investigation using a bucket auger is related to the material being sampled.

4.2 When a sampling interval starting at the surface is to be sampled, the same auger can be used to collect all materials to the

bottom of the interval. However, if discrete grab samples are to be collected to characterize multiple depths or a depth interval

commences below the surface, a clean bucket auger should be used to collect the sample. The top material in a bucket should

generally be discarded to minimize chances of cross-contamination of the sample from material that sloughs from the borehole

wall.

4.3 All augers collect disturbed samples that are generally not suitable for analysis of volatile organic compounds.

NOTE 1—Bucket augers may be used to obtain samples of materials containing volatile organic compounds for field screening purposes. A core or tube

type sampler can be pushed into undisturbed soil at the bottom of an augered hole to collect a relatively undisturbed sample suitable for chemical analysis.

5. Significance and Use

5.1 Bucket augers are relatively inexpensive, readily available, available in different types depending on the media to be

sampled, and most can be easily operated by one person. They collect a reasonably cylindrical but disturbed sample of surface or

subsurface soil or waste. They are generally not suited for sampling gravelly or coarser soil and are unsuitable for sampling rock.

5.2 Bucket augers are commonly used equipment because they are inexpensive to operate, especially compared to powered

equipment (that is, direct push and drill rigs). When evaluated against screw augers, bucket augers generally collect larger samples

with less chance of mixing with soil from shallow depths because the sample is retained within the auger barrel. Bucket augers

are commonly used to depths of 3 m but have been used to much greater depths depending upon the soil or waste characteristics.

The sampling depth is limited by the force required to rotate the auger and the depth at which the borehole collapses (unless bore

casings or liners are used).

5.3 Bucket augers may not be suitable for the collection of samples for determination of volatile organic compounds because

the sample is disturbed during the collection process, which may lead to losses resulting in a chemically unrepresentative sample.

6. Apparatus

6.1 Bucket Augers:

6.1.1 Bucket augers for soil sampling generally consist of a tubular auger head with cutting bits, an extension rod or rods, and

a “T” handle (see Fig. 1). The auger is rotated using the “T” handle until the bucket is full, the device retrieved and emptied, and

FIG. 1 Bucket Auger

D6907 − 05 (2016)

the process repeated.

6.1.2 The advantages and disadvantages of bucket augers are listed in Table 1.

6.1.3 Bucket augers are generally available with tungsten carbide hard surface carbon steel bits, stainless steel cylinder and

carbon steel bail (shank), or in all stainless steel (see Fig. 1). Several types of bucket augers are described below. In use, bits should

be kept sharp for efficient sampling.

6.1.4 Regular Bucket Auger—Used for ordinary soil and waste sampling and for creating a pilot hole from which subsequent

undisturbed core samples can be collected at depth using a core sampler. (See Fig. 2a).

6.1.5 Sand Bucket Auger—Designed for use in extremely dry, sandy soils. The bits are specially formed to retain loose sand by

being close together (see Fig. 2b).

6.1.6 Mud Bucket Auger—Features an open cylinder design to facilitate easier removal of heavy, wet soil or clayey soil samples.

Bits are spa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.