ASTM B902/B902M-13(2018)

(Specification)Standard Specification for Compressed Round Stranded Copper Conductors, Hard, Medium-Hard, or Soft Using Single Input Wire Construction

Standard Specification for Compressed Round Stranded Copper Conductors, Hard, Medium-Hard, or Soft Using Single Input Wire Construction

ABSTRACT

This specification covers stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use in insulated conductor assemblies for electrical purposes. These conductors shall be composed of one or more roller shaped or die closed layers of helically laid wires using the single input wire. For stranded conductors, the direction of lay of the outer layer shall be leeft hand and may be reversed or unidirectional/unilay in successive layers. Test for the physical and electrical properties of wires composing conductors made from hard-drawn or medium-hard-drawn wires, uncoated or coated, shall be made before but not after stranding. For the purpose of calculating mass, cross sections, and so forth, the density of the copper shall be taken. The mass and electrical resistance of a unit length of stranded unsealed conductor are a function of the lenght of lay shall be calculated.

SCOPE

1.1 This specification covers stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use in insulated conductor assemblies for electrical purposes. These conductors shall be composed of one or more roller shaped or die closed layers of helically laid wires using the single input wire (SIW) methodology. (see Note 1 and Explanatory Note 1)

Note 1: Sealed conductors which are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within the guidelines of this specification.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B902/B902M −13 (Reapproved 2018)

Standard Specification for

Compressed Round Stranded Copper Conductors, Hard,

Medium-Hard, or Soft Using Single Input Wire Construction

This standard is issued under the fixed designation B902/B902M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B189 Specification for Lead-Coated and Lead-Alloy-Coated

Soft Copper Wire for Electrical Purposes

1.1 This specification covers stranded conductors made

B193 Test Method for Resistivity of Electrical Conductor

from round copper wires, either uncoated or coated with tin,

Materials

lead, or lead alloy for general use in insulated conductor

B246 Specification for Tinned Hard-Drawn and Medium-

assemblies for electrical purposes. These conductors shall be

Hard-Drawn Copper Wire for Electrical Purposes

composed of one or more roller shaped or die closed layers of

B263 Test Method for Determination of Cross-Sectional

helically laid wires using the single input wire (SIW) method-

Area of Stranded Conductors

ology. (see Note 1 and Explanatory Note 1)

B354 Terminology Relating to Uninsulated Metallic Electri-

NOTE 1—Sealed conductors which are intended to prevent longitudinal

cal Conductors

water propagation and are further covered/insulated, are also permitted

2.2 Other Standard:

within the guidelines of this specification.

NBS Handbook 100 —Copper Wire Tables

1.2 The values stated in inch-pound or SI units are to be

3. Classification

regarded separately as standard. The values in each system are

not exact equivalents; therefore, each system shall be used

3.1 The conductors described in this specification are in-

independently of the other. Combining values from the two

tendedforsubsequentinsulationorcovering.Theclassification

systems may result in nonconformance with the specification.

of these conductors is SIW compressed.

1.2.1 For density, resistivity, and temperature, the values

4. Ordering Information

stated in SI units are to be regarded as standard.

1.3 This international standard was developed in accor- 4.1 Orders for material under this specification shall include

dance with internationally recognized principles on standard- the following information:

ization established in the Decision on Principles for the

4.1.1 Quantity of each size,

Development of International Standards, Guides and Recom- 4.1.2 Conductorsize:circular-milareaorAWG(seeSection

mendations issued by the World Trade Organization Technical

7),

Barriers to Trade (TBT) Committee. 4.1.3 Class: SIW compressed (see 1.2 and Table 1),

4.1.4 Temper (see 5.3),

2. Referenced Documents

4.1.5 Whether coated or uncoated; if coated (see 5.1 and

5.2).

2.1 ASTM Standards:

4.1.6 Details of special-purpose lays, if required (see 7.3).

B1 Specification for Hard-Drawn Copper Wire

4.1.7 When physical tests shall be made (see Sections 9 and

B2 Specification for Medium-Hard-Drawn Copper Wire

10).

B3 Specification for Soft or Annealed Copper Wire

4.1.8 Package size (see 16.1).

B33 Specification for Tin-Coated Soft or Annealed Copper

4.1.9 Lagging, if required (see 16.2).

Wire for Electrical Purposes

4.1.10 Special package marking, if required (see Section

16.3), and

This specification is under the jurisdiction of ASTM Committee B01 of

4.1.11 Place of inspection (see Section 15).

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

5. Requirements for Wires

Current edition approved Oct. 1, 2018. Published October 2018. Originally

ɛ1

5.1 The purchaser shall designate the type of wire and the

approved in 2000. Last previous edition approved in 2013 as B902/B902M – 13 .

DOI: 10.1520/B0902_B0902M-13R18.

kind of coating, if any, to be used in the conductor.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from National Technical Information Service (NTIS), 5301 Shawnee

the ASTM website. Rd., Alexandria, VA 22312, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B902/B902M−13 (2018)

TABLE 1 Construction Requirements of Compressed Round SIW Standard Copper Conductors

Compressed Strand Dimensions

Conductor Size Nominal Nominal

Diameter Diameter

of SIW of SIW

Minimum Compressed Compressed

Number of Conductor, Conductor, Mass DC Resistance at 20°C

cmils AWG mm Wires in. mm. lb/1000ft kg/km Ω/1000ft Ω/km

5 000 000 2534 217 2.424 61.57 15890 23649 0.00218 0.00715

4 500 000 2280 217 2.300 58.41 14300 21283 0.00242 0.00794

4 000 000 2027 217 2.168 55.07 12590 18738 0.00270 0.00886

3 500 000 1773 169 2.028 51.51 11020 16401 0.00308 0.01010

3 000 000 1520 169 1.878 47.69 9353 13920 0.00365 0.01197

2 500 000 1267 127 1.714 43.54 7794 11600 0.00428 0.01404

2 000 000 1013 127 1.533 38.94 6175 9190 0.00529 0.01735

1 900 000 962.7 127 1.494 37.95 5866 8730 0.00557 0.01827

1 800 000 912.1 127 1.454 36.93 5558 8272 0.00588 0.01929

1 750 000 886.7 127 1.434 36.42 5403 8041 0.00604 0.01981

1 700 000 861.4 127 1.413 35.89 5249 7812 0.00622 0.02040

1 600 000 810.7 127 1.371 34.82 4940 7352 0.00661 0.02168

1 500 000 760.1 90 1.327 33.71 4631 6892 0.00705 0.02312

1 400 000 709.4 90 1.282 32.56 4323 6434 0.00756 0.02480

1 300 000 658.7 90 1.236 31.39 4014 5974 0.00814 0.02670

1 250 000 633.4 90 1.212 30.78 3859 5743 0.00847 0.02778

1 200 000 608.0 90 1.187 30.15 3705 5514 0.00882 0.02893

1 100 000 557.4 90 1.137 28.88 3396 5054 0.00962 0.03155

1 000 000 506.7 53 1.084 27.53 3088 4596 0.0106 0.0348

900 000 456.0 53 1.028 26.11 2779 4136 0.0118 0.3087

800 000 405.4 53 0.969 24.61 2470 3676 0.0132 0.0433

750 000 380.0 53 0.939 23.85 2316 3447 0.0141 0.0462

700 000 354.7 34 0.907 23.04 2161 3216 0.0151 0.0495

650 000 329.4 34 0.874 22.20 2007 2987 0.0163 0.0535

600 000 304.0 34 0.840 21.34 1883 2802 0.0177 0.0581

550 000 278.7 34 0.804 20.42 1698 2527 0.0192 0.0630

500 000 253.4 30 0.766 19.46 1544 2298 0.0212 0.0695

450 000 228.0 30 0.727 18.47 1389 2067 0.0235 0.0771

400 000 202.7 24 0.685 17.40 1235 1838 0.0264 0.0866

350 000 177.3 24 0.641 16.28 1081 16.09 0.3002 0.0991

300 000 152.0 18 0.594 15.09 926.3 1379 0.0353 0.1158

250 000 126.7 18 0.542 13.77 771.9 1149 0.0423 0.1387

211 600 0000 107.2 17 0.498 12.65 653.1 972.0 0.0500 0.1640

167 800 000 85.03 15 0.443 11.25 518.1 771.1 0.0630 0.2066

133 100 00 67.44 12 0.395 10.03 410.9 611.5 0.0795 0.2607

105 600 0 53.51 7 0.352 8.94 325.8 484.9 0.100 0.328

83 690 1 42.41 7 0.313 7.95 258.4 384.6 0.127 0.417

66 360 2 33.63 6 0.283 7.19 204.9 305.0 0.159 0.521

52 620 3 26.66 6 0.252 6.40 162.5 241.8 0.201 0.659

41 740 4 21.15 6 0.225 5.72 128.9 191.8 0.253 0.830

33 090 5 16.77 6 0.200 5.08 102.2 152.1 0.319 1.046

26 240 6 13.30 6 0.178 4.52 81.05 120.6 0.403 1.322

20 820 7 10.55 6 0.159 4.04 64.28 95.67 0.509 1.669

16 510 8 8.366 6 0.142 3.61 50.97 75.86 0.640 2.099

13 090 9 6.633 6 0.126 3.20 40.42 60.16 0.809 2.653

10 380 10 5.260 6 0.113 2.87 32.06 47.71 1.02 3.35

6 530 12 3.309 6 0.089 2.26 20.16 30.00 1.63 5.35

4 110 14 2.083 6 0.071 1.80 12.68 18.87 2.58 8.46

2 580 16 1.307 6 0.054 1.37 7.974 11.87 4.10 13.45

1 620 18 0.8209 6 0.043 1.09 5.015 7.464 6.54 21.45

1 020 20 0.5168 6 0.034 0.86 3.154 4.694 10.3 33.8

640 22 0.3243 6 0.027 0.69 1.992 2.965 16.4 53.8

404 24 0.2047 6 0.022 0.56 1.249 1.859 26.1 85.6

5.2 Before stranding, the copper wire used shall meet all of 5.3 In SIWcompressed conductors, the central core shall be

the requirements of the following specifications ofASTM that made of wire of the same type and temper as the concentric

are applicable to its type: layers, unless otherwise specified.

5.2.1 Specification B3,

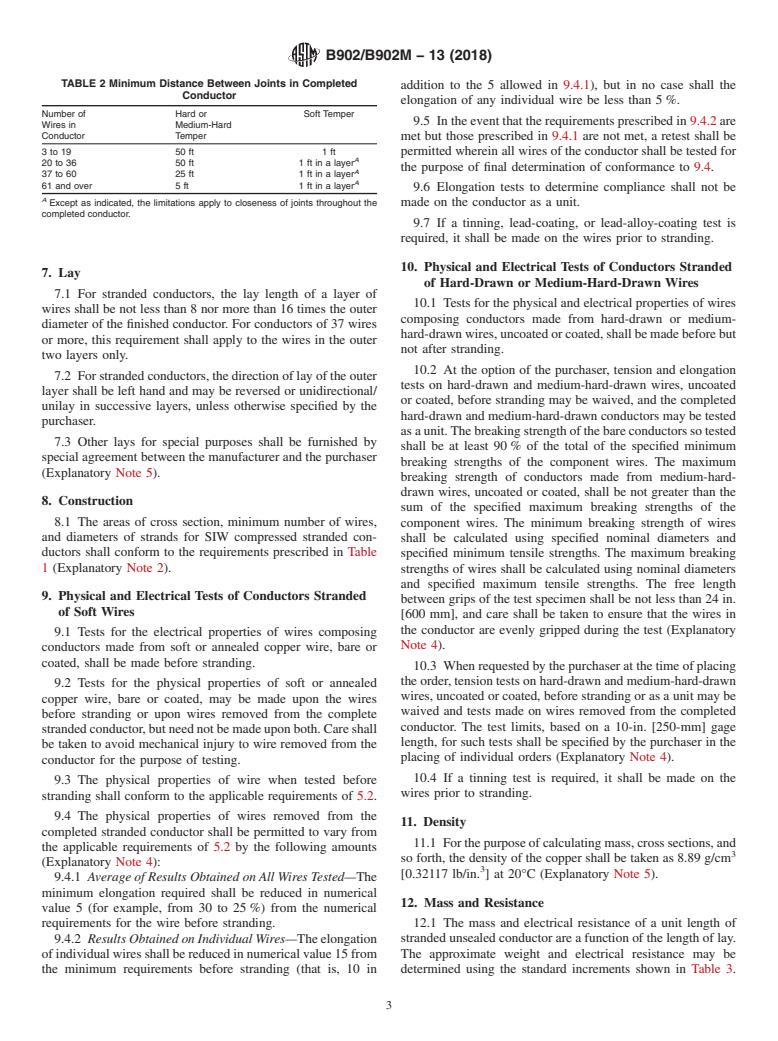

6. Joints

5.2.2 Specification B33,

5.2.3 Specification B2, 6.1 Welds and brazes may be made in rods or in wires prior

5.2.4 Specification B1, to final drawing.Welds and brazes may be made in the finished

5.2.5 Specification B189, and individual wires composing the conductor, but shall not be

5.2.6 Specification B246. closer together than prescribed in Table 2.

B902/B902M−13 (2018)

TABLE 2 Minimum Distance Between Joints in Completed

addition to the 5 allowed in 9.4.1), but in no case shall the

Conductor

elongation of any individual wire be less than 5 %.

Number of Hard or Soft Temper

9.5 In the event that the requirements prescribed in 9.4.2 are

Wires in Medium-Hard

Conductor Temper

met but those prescribed in 9.4.1 are not met, a retest shall be

3to19 50ft 1ft permitted wherein all wires of the conductor shall be tested for

A

20 to 36 50 ft 1 ft in a layer

the purpose of final determination of conformance to 9.4.

A

37 to 60 25 ft 1 ft in a layer

A

61 and over 5 ft 1 ft in a layer

9.6 Elongation tests to determine compliance shall not be

A

Except as indicated, the limitations apply to closeness of joints throughout the

made on the conductor as a unit.

completed conductor.

9.7 If a tinning, lead-coating, or lead-alloy-coating test is

required, it shall be made on the wires prior to stranding.

10. Physical and Electrical Tests of Conductors Stranded

7. Lay

of Hard-Drawn or Medium-Hard-Drawn Wires

7.1 For stranded conductors, the lay length of a layer of

10.1 Tests for the physical and electrical properties of wires

wires shall be not less than 8 nor more than 16 times the outer

composing conductors made from hard-drawn or medium-

diameter of the finished conductor. For conductors of 37 wires

hard-drawnwires,uncoatedorcoated,shallbemadebeforebut

or more, this requirement shall apply to the wires in the outer

not after stranding.

two layers only.

10.2 At the option of the purchaser, tension and elongation

7.2 For stranded conductors, the direction of lay of the outer

tests on hard-drawn and medium-hard-drawn wires, uncoated

layer shall be left hand and may be reversed or unidirectional/

or coated, before stranding may be waived, and the completed

unilay in successive layers, unless otherwise specified by the

hard-drawn and medium-hard-drawn conductors may be tested

purchaser.

asaunit.Thebreakingstrengthofthebareconductorssotested

7.3 Other lays for special purposes shall be furnished by

shall be at least 90 % of the total of the specified minimum

special agreement between the manufacturer and the purchaser

breaking strengths of the component wires. The maximum

(Explanatory Note 5).

breaking strength of conductors made from medium-hard-

drawn wires, uncoated or coated, shall be not greater than the

8. Construction

sum of the specified maximum breaking strengths of the

8.1 The areas of cross section, minimum number of wires,

component wires. The minimum breaking strength of wires

and diameters of strands for SIW compressed stranded con- shall be calculated using specified nominal diameters and

ductors shall conform to the requirements prescribed in Table

specified minimum tensile strengths. The maximum breaking

1 (Explanatory Note 2). strengths of wires shall be calculated using nominal diameters

and specified maximum tensile strengths. The free length

9. Physical and Electrical Tests of Conductors Stranded

between grips of the test specimen shall be not less than 24 in.

of Soft Wires

[600 mm], and care shall be taken to ensure that the wires in

the conductor are evenly gripped during the test (Explanatory

9.1 Tests for the electrical properties of wires composing

Note 4).

conductors made from soft or annealed copper wire, bare or

coated, shall be made before stranding.

10.3 When requested by the purchaser at the time of placing

the order, tension tests on hard-drawn and medium-hard-drawn

9.2 Tests for the physical properties of soft or annealed

wires, uncoated or coated, before stranding or as a unit may be

copper wire, bare or coated, may be made upon the wires

waived and tests made on wires removed from the completed

before stranding or upon wires removed from the complete

conductor. The test limits, based on a 10-in. [250-mm] gage

strandedconductor,butneednotbemadeuponboth.Careshall

length, for such tests shall be specified by the purchaser in the

be taken to avoid mechanical injury to wire removed from the

placing of individual orders (Explanatory Note 4).

conductor for the purpose of testing.

10.4 If a tinning test is required, it shall be made on the

9.3 The physical properties of wire when tested before

wires prior to stranding.

stranding shall conform to the applicable requirements of 5.2.

9.4 The physical properties of wires removed from the

11. Density

completed stranded conductor shall be permitted to vary from

11.1 Forthepurposeofcalculatingmass,crosssections,and

the applicable requirements of 5.2 by the following amounts

so forth, the density of the copper shall be taken as 8.89 g/cm

(Explanatory Note 4):

[0.32117 lb/in. ] at 20°C (Explanatory Note 5).

9.4.1 AverageofResultsObtainedonAllWiresTested—The

minimum elongation required shall be reduced in numerical

12. Mass and Resistance

value 5 (for example, from 30 to 25 %) from the numerical

requirements for the wire before stranding. 12.1 The mass and electrical resistance of a unit length of

9.4.2 ResultsObtainedonIndividualWires—Theelongation stranded unsealed conductor are a function of the length of lay.

ofindividualwiresshallbereducedinnumericalvalue15from The approximate weight and electrical resistance may be

the minimum requirements before stranding (that is, 10 in determined using the standard increments shown in Table 3.

B902/B902M−13 (2018)

TABLE 3 Standard Increments Due to Stranding

13.1.1 The area of cross section of a conductor may be

SIW Compressed Conductor Increment of Resistance and Mass % determined by calculations from diameter measurements, ex-

A

Classes AA , B, C, and D, 2000 2 pressed to four decimal places, of its component wires at any

cmil and under

point when measured perpendicularly to their axes.

Over 2000 to 3000 cmil 3

13.1.2 The area of cross section of a conductor may be

Over 3000 to 4000 cmil 4

Over 4000 to 5000 cmil 5

determinedbyTestMethodB263.Inapplyingthattestmethod,

A

No. 0 AWG and larger. the increment in mass resulting from stranding may be the

applicable value specified in 12.1 or may be calculated from

the measured component dimensions of the sample under test.

Incaseofqu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.