ASTM F1227-89(1999)

(Test Method)Test Method for Total Mass Loss of Materials and Condensation of Outgassed Volatiles on Microelectronics-Related Substrates (Withdrawn 2000)

Test Method for Total Mass Loss of Materials and Condensation of Outgassed Volatiles on Microelectronics-Related Substrates (Withdrawn 2000)

SCOPE

1.1 This test method covers various thermoplastics and thermosets routinely used in the microelectronics industry. This test method covers a screening technique to determine volatile content of these materials when exposed to a vacuum environment. Two parameters are measured: total mass loss (TML) and collected volatile condensable materials (CVCM).

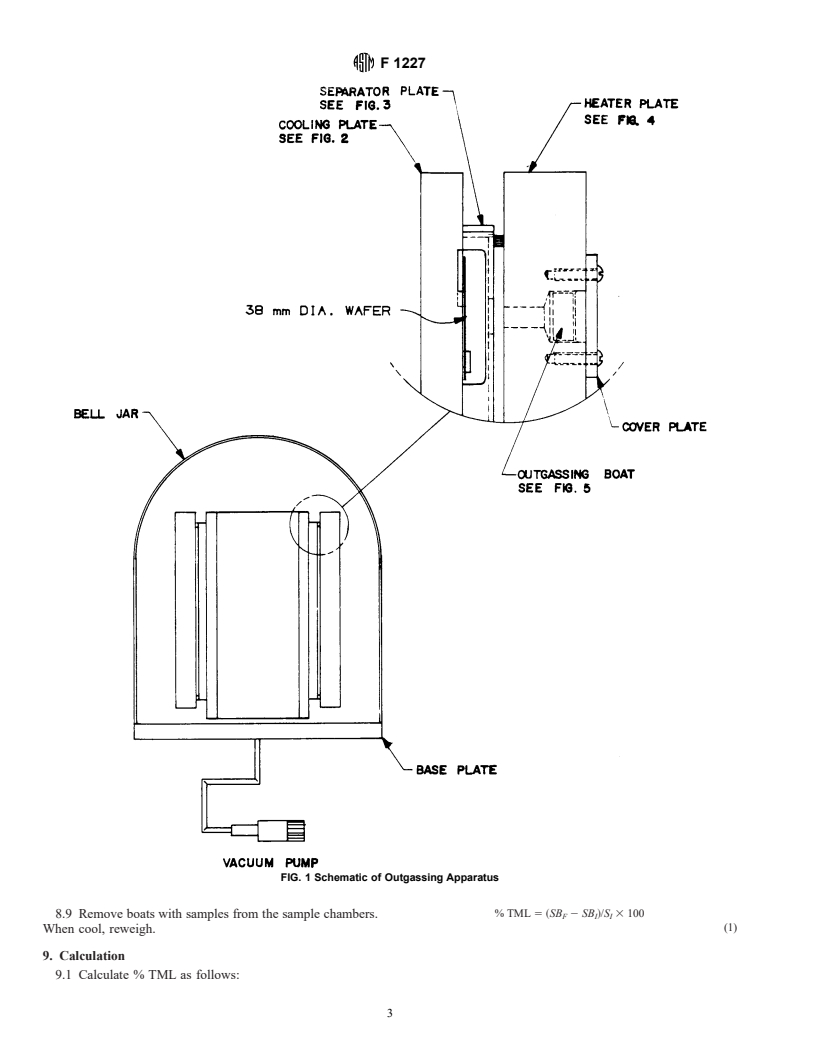

1.2 This test method describes the test apparatus and related operating procedures for evaluating the mass loss of materials being subjected to 25°, 70° or 125°C at less than 5 Pa (0.05 mbars) for 24 h. The lowest temperature simulates storage conditions, while the middle and upper temperatures simulate soft bake and hard bake conditions encountered during microelectronics manufacturing. The overall mass loss can be classified into noncondensables and condensables. The latter are characterized herein as being capable of condensing on a silicon wafer, glass plate, aluminum disk or other substrate, maintained at a temperature of 18°C. Note 1-Unless otherwise noted, the tolerances are 18°C + 3°C, 25°C + 1°C, 70°C + 1°C, and 125°C + 1°C.

1.3 Any thermoplastic or thermoset can be tested. The materials may be tested in the "as-received" condition or prepared for test after various curing or manufacturing steps.

1.4 This test method is primarily a screening technique for materials and is not necessarily valid for computing actual contamination on a system or component because of possible differences in configuration, temperatures, and material processing. The three temperatures allow testing with respect to maximum expected service temperature. Also, many polymers cannot be tested at 125°C as they melt or undergo glass transition above 70°C.

1.5 The use of materials that are deemed acceptable in accordance with this test method does not ensure that the system or component will remain uncontaminated. Therefore, subsequent functional, developmental, and qualification tests should be used, as necessary, to ensure that material performance is satisfactory.

1.6 No data is yet available to evaluate minimum sample sizes. Sample sizes as small as 130 mg have been used.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: F 1227 – 89 (Reapproved 1999)

Standard Test Method for

Total Mass Loss of Materials and Condensation of

Outgassed Volatiles on Microelectronics-Related

1

Substrates

This standard is issued under the fixed designation F 1227; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 No data is yet available to evaluate minimum sample

sizes. Sample sizes as small as 130 mg have been used.

1.1 This test method covers various thermoplastics and

1.7 The values stated in SI units are to be regarded as the

thermosets routinely used in the microelectronics industry. This

standard. The values given in parentheses are for information

test method covers a screening technique to determine volatile

only.

content of these materials when exposed to a vacuum environ-

1.8 This standard does not purport to address all of the

ment. Two parameters are measured: total mass loss (TML)

safety concerns, if any, associated with its use. It is the

and collected volatile condensable materials (CVCM).

responsibility of the user of this standard to establish appro-

1.2 This test method describes the test apparatus and related

priate safety and health practices and determine the applica-

operating procedures for evaluating the mass loss of materials

bility of regulatory limitations prior to use.

being subjected to 25, 70, or 125°C at less than 5 Pa (0.05

mbars) for 24 h. The lowest temperature simulates storage

2. Referenced Documents

conditions, while the middle and upper temperatures simulate

2.1 ASTM Standards:

soft bake and hard bake conditions encountered during micro-

E 595 Test Method for Total Mass Loss and Collected

electronics manufacturing. The overall mass loss can be

Volatile Condensable Materials from Outgassing in a

classified into noncondensables and condensables. The latter

2

Vacuum Environment

are characterized herein as being capable of condensing on a

silicon wafer, glass plate, aluminum disk or other substrate,

3. Terminology

maintained at a temperature of 18°C.

3.1 Definitions:

NOTE 1—Unless otherwise noted, the tolerances are 18°C 6 3°C, 25°C

3.1.1 collected volatile condensable material (CVCM)—the

6 1°C, 70°C 6 1°C, and 125°C 6 1°C.

quantity of outgassed matter from a test specimen that con-

1.3 Any thermoplastic or thermoset can be tested. The denses on a silicon wafer maintained at a specific constant

materials may be tested in the “as-received” condition or

temperature for a specified time. CVCM is expressed as a

prepared for test after various curing or manufacturing steps. percentage of the initial specimen mass and is calculated from

1.4 This test method is primarily a screening technique for

the condensate mass determined from the difference in mass of

materials and is not necessarily valid for computing actual the silicon wafer before and after the test.

contamination on a system or component because of possible

3.1.2 total mass loss (TML)—total mass of material out-

differences in configuration, temperatures, and material pro-

gassed from a specimen that is maintained at a specified

cessing. The three temperatures allow testing with respect to constant temperature and operating pressure for a specified

maximum expected service temperature. Also, many polymers

time. TML is calculated from the mass of the specimen as

cannot be tested at 125°C as they melt or undergo glass measured before and after the test and is expressed as a

transition above 70°C.

percentage of the initial specimen mass.

1.5 The use of materials that are deemed acceptable in

4. Summary of Test Method

accordance with this test method does not ensure that the

system or component will remain uncontaminated. Therefore, 4.1 The test specimen may be a raw material or cut from a

subsequent functional, developmental, and qualification tests device. It may be preferable to obtain samples from completed

should be used, as necessary, to ensure that material perfor- devices, so that any volatiles that are released during the

mance is satisfactory. manufacturing process are not included in TML. A specimen is

added to a clean, preweighed boat and boat and specimen are

weighed. The loaded boat is then inserted into a sample

1

This test method is under the jurisdiction of ASTM Committee E-21 on Space chamber in the copper heating bar. Up to 16 specimens can be

Simulation and Applications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

2

Current edition approved May 26, 1989. Published July 1989. Annual Book of ASTM Standards, Vol 15.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1227

tested simultaneously in the apparatus. The sample chambers

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.