ASTM B555-86(1997)

(Guide)Standard Guide for Measurement of Electrodeposited Metallic Coating Thicknesses by the Dropping Test

Standard Guide for Measurement of Electrodeposited Metallic Coating Thicknesses by the Dropping Test

SCOPE

1.1 This guide covers the use of the dropping test to measure the thickness of electrodeposited zinc, cadmium, copper, and tin coatings.

Note 1—Under most circumstances this method of measuring coating thicknesses is not as reliable or as convenient to use as an appropriate coating thickness gage (see Test Methods B 499, B 504, and B 568).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 555 – 86 (Reapproved 1997)

Standard Guide for

Measurement of Electrodeposited Metallic Coating

Thicknesses by the Dropping Test

This standard is issued under the fixed designation B 555; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This guide covers the use of the dropping test to 4.1 The thickness of a metal coating is often critical to its

measure the thickness of electrodeposited zinc, cadmium, performance.

copper, and tin coatings. 4.2 This procedure is useful for an approximate determina-

tion when the best possible accuracy is not required. For more

NOTE 1—Under most circumstances this method of measuring coating

reliable determinations, the following methods are available:

thicknesses is not as reliable or as convenient to use as an appropriate

Test Methods B 487, B 499, B 504, and B 568.

coating thickness gage (see Test Methods B 499, B 504, and B 568).

4.3 This test assumes that the rate of dissolution of the

1.2 This standard does not purport to address all of the

coating by the corrosive reagent under the specified conditions

safety concerns, if any, associated with its use. It is the

is always the same.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Factors Affecting the Accuracy

bility of regulatory limitations prior to use.

5.1 The following factors will affect the accuracy of a

coating thickness measurement made by this method:

2. Referenced Documents

5.1.1 Cleanliness of Surface—Any foreign material on the

2.1 ASTM Standards:

surface to be tested, including lacquer, grease, corrosion

B 487 Test Method for Measurement of Metal and Oxide

products, and conversion coatings, will interfere with the test

Coating Thicknesses by Microscopical Examination of a

and must be removed. Tarnish and conversion coatings can

Cross Section

often be removed by mild burnishing with a soft, clean pencil

B 499 Test Method for Measurement of Coating Thick-

eraser.

nesses by the Magnetic Method: Nonmagnetic Coatings on

5.1.2 Concentration of Test Solution—Variation from the

Magnetic Basis Metals

stated concentrations will introduce an error unless the thick-

B 504 Test Method for Measurement of Thickness of Me-

ness factor is adjusted accordingly. Test solutions cannot be

tallic Coatings by the Coulometric Method

reused.

B 568 Test Method for Measurement of Coating Thickness

5.1.3 Temperature—The thickness factor for a given solu-

by X-Ray Spectrometry

tion, being a function of the temperature, must be known for

D 1193 Specification for Reagent Water

the temperature at which the test is made. Specimens to be

tested should be allowed to reach room temperature before

3. Summary of Guide

testing.

3.1 A dropping test consists of applying dropwise a corro-

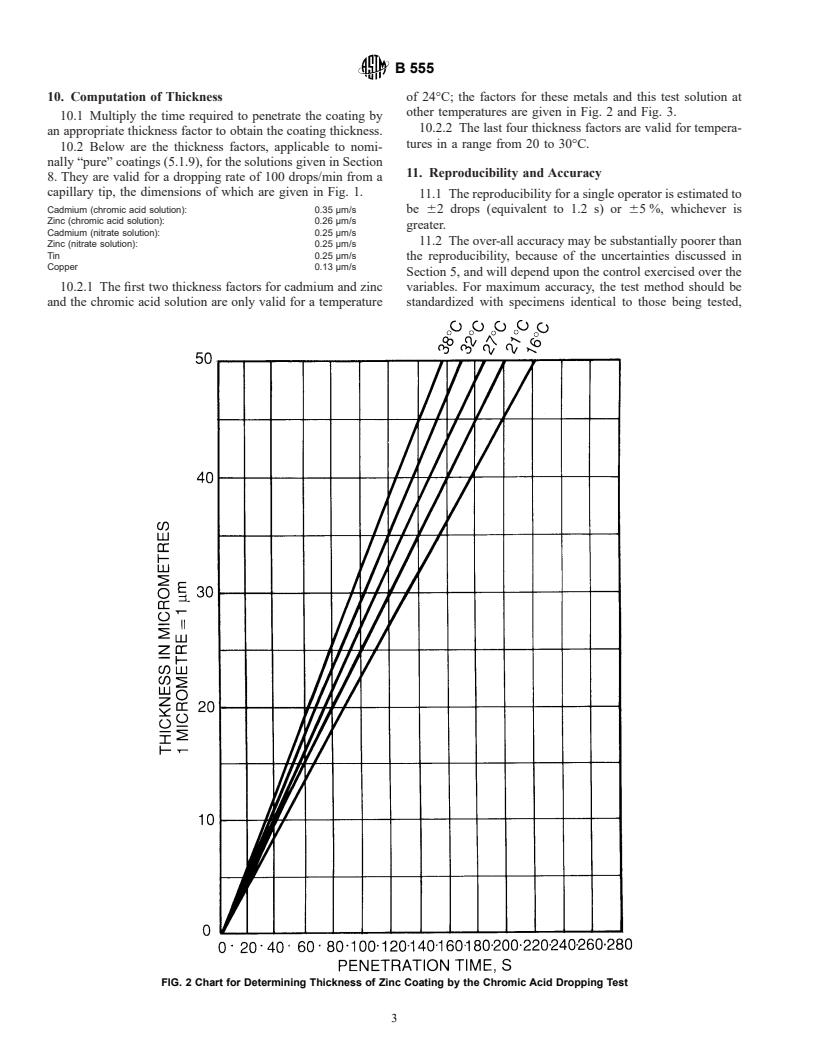

5.1.4 Dropping Rate—The thickness factor is also a func-

sive solution, at a constant rate, to the electroplated surface,

tion of the dropping rate. The thickness factors given in Section

and measuring the time required to penetrate the coating and

10 are for a dropping rate of 100 drops/min and will remain

expose the substrate; this time is proportional to the coating

valid for the range of 95 to 105 drops/min.

thickness.

5.1.5 Solution Drainage—The thickness factors given in

Section 10 are valid only if the test solution is rapidly drained

1 off, as from a flat surface inclined 45° from the horizontal. The

This guide is under the jurisdiction of ASTM Committee B08 on Metallic and

Inorganic Coatings and is the direct responsibility of Subcommittee B08.10 on test cannot be made on a horizontal surface or at a location that

General Test Methods.

does not permit rapid drainage.

Current edition approved January 31, 1986. Published March 1986. Originally

5.1.6 Drop Size—Variation in drop size may alter the

e1

published as B 555 – 71. Last previous edition B 555 – 75 (1980) .

penetration rate. The tip of the dropping apparatus should

Annual Book of ASTM Standards, Vol 02.05.

Annual Book of ASTM Standards, Vol 11.01.

conform to the dimensions given in Fig. 1 and should be kept

Such tests were described by Hull, R. O., and Strausser, P., Monthly Review,

clean.

American Electroplaters Society, MRAEA, Vol 22, 1935, p. 9, and by Brenner, A.,

5.1.7 Alloy Layer—The presence of an alloy layer at the

Proceedings, American Electroplaters Society, AEPPB, Vol 27, 1939, p. 204.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 555

A—Glass tube with one end open to atmosphere and one end submerged in the test

solution in funnel, C.

B—Rubber stopper forms air tight seal between tube, A, and funnel, C.

C—Separatory funnel.

D—Wide-bore rubber tubing (75 to 125 mm in length) or sealed glass joints.

E—Capillary tubing (140 mm in length, 0.64-mm bore).

F—Rubber tubing or sealed glass joints.

G—Capillary glass tip (with 12.7-mm taper to outside diameter of 3.5 mm).

H—Specimen.

I—Collector of spent solution.

NOTE 1—Solution head is constant as long as air is being drawn through tube, A.

FIG. 1 Dropping Funnel

coating-substrate interface may obscure the end point and 8. Test Solutions

introduce an uncertainty as to the amount of alloy included in

8.1 Solution for Cadmium and Zinc:

the thickness measurement.

Chromic acid (CrO ) 200 g/L

5.1.8 Detection of End Point—The end point (the time at

Sulfuric acid (96 % H SO , sp gr 1.84) 50 g/L or 27 mL/L

2 4

which the coating has been penetrated and the substrate

NOTE 2—Sulfuric acid is added slowly with stirring to at least 20 times

exposed) is characterized b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.