ASTM C1043-24

(Practice)Standard Practice for Guarded-Hot-Plate Design Using Circular Line-Heat Sources

Standard Practice for Guarded-Hot-Plate Design Using Circular Line-Heat Sources

SIGNIFICANCE AND USE

4.1 This practice describes the design of a guarded hot plate with circular line-heat sources and provides guidance in determining the mean temperature of the meter plate. It provides information and calculation procedures for: (1) control of edge heat loss or gain (Annex A1); (2) location and installation of line-heat sources (Annex A2); (3) design of the gap between the meter and guard plates (Appendix X1); and (4) location of heater leads for the meter plate (Appendix X2).

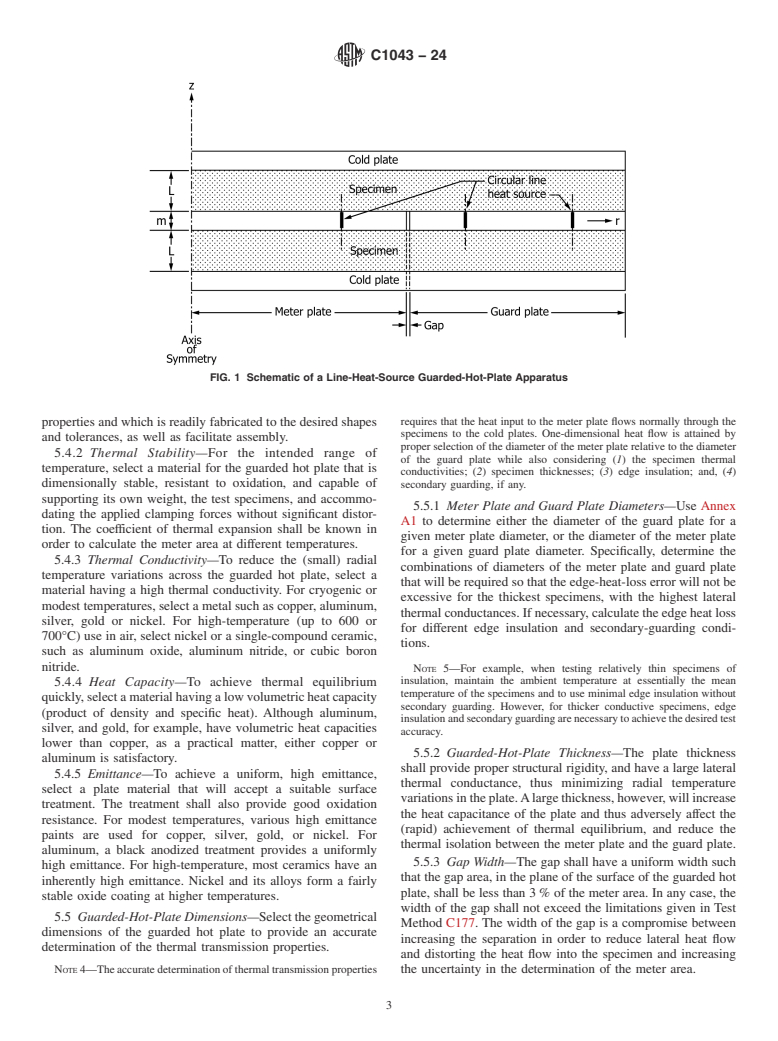

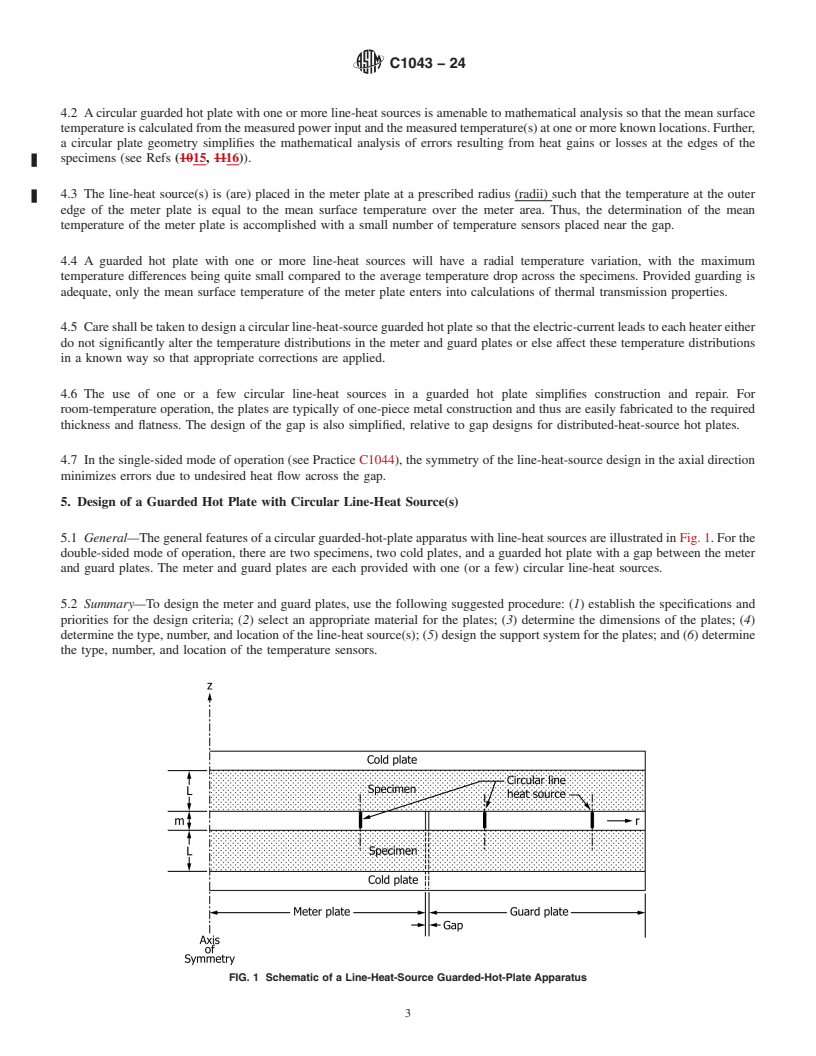

4.2 A circular guarded hot plate with one or more line-heat sources is amenable to mathematical analysis so that the mean surface temperature is calculated from the measured power input and the measured temperature(s) at one or more known locations. Further, a circular plate geometry simplifies the mathematical analysis of errors resulting from heat gains or losses at the edges of the specimens (see Refs (15, 16)).

4.3 The line-heat source(s) is (are) placed in the meter plate at a prescribed radius (radii) such that the temperature at the outer edge of the meter plate is equal to the mean surface temperature over the meter area. Thus, the determination of the mean temperature of the meter plate is accomplished with a small number of temperature sensors placed near the gap.

4.4 A guarded hot plate with one or more line-heat sources will have a radial temperature variation, with the maximum temperature differences being quite small compared to the average temperature drop across the specimens. Provided guarding is adequate, only the mean surface temperature of the meter plate enters into calculations of thermal transmission properties.

4.5 Care shall be taken to design a circular line-heat-source guarded hot plate so that the electric-current leads to each heater either do not significantly alter the temperature distributions in the meter and guard plates or else affect these temperature distributions in a known way so that appropriate corrections are applied.

4.6 The use of one o...

SCOPE

1.1 This practice covers the design of a circular line-heat-source guarded hot plate for use in accordance with Test Method C177.

Note 1: Test Method C177 describes the guarded-hot-plate apparatus and the application of such equipment for determining thermal transmission properties of flat-slab specimens. In principle, the test method includes apparatus designed with guarded hot plates having either distributed- or line-heat sources.

1.2 The guarded hot plate with circular line-heat sources is a design in which the meter and guard plates are circular plates having a relatively small number of heaters, each embedded along a circular path at a fixed radius. In operation, the heat from each line-heat source flows radially into the plate and is transmitted axially through the test specimens.

1.3 The meter and guard plates are fabricated from a continuous piece of thermally conductive material. The plates are made sufficiently thick that, for typical specimen thermal conductances, the radial and axial temperature variations in the guarded hot plate are quite small. By proper location of the line-heat source(s), the temperature at the edge of the meter plate is made equal to the mean temperature of the meter plate, thus facilitating temperature measurements and thermal guarding.

1.4 The line-heat-source guarded hot plate has been used successfully over a mean temperature range from − 10 to + 65°C, with circular metal plates and a single line-heat source in the meter plate. The chronological development of the design for circular line-heat-source guarded hot plates having a single line-heat source in the meter plate is given in Refs (1-9).2

1.5 For high-temperature applications, the line-heat-source guarded hot plate has been used successfully over a mean temperature from 7 to 160°C, with circular metal plates and multiple line-heat sources in the meter plate. The chronological development for circular line-heat-...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1043 − 24

Standard Practice for

Guarded-Hot-Plate Design Using Circular Line-Heat

1

Sources

This standard is issued under the fixed designation C1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope temperature from 7 to 160°C, with circular metal plates and

multiple line-heat sources in the meter plate. The chronological

1.1 This practice covers the design of a circular line-heat-

development for circular line-heat-source guarded hot plates

source guarded hot plate for use in accordance with Test

having multiple line-heat sources in the meter plate is given in

Method C177.

Refs (10-14).

NOTE 1—Test Method C177 describes the guarded-hot-plate apparatus

NOTE 2—Detailed drawings and descriptions for the construction of two

and the application of such equipment for determining thermal transmis-

line-heat-source guarded-hot-plate apparatuses are available in the ad-

sion properties of flat-slab specimens. In principle, the test method

3

junct.

includes apparatus designed with guarded hot plates having either

distributed- or line-heat sources.

1.6 This practice does not preclude (1) lower or higher

1.2 The guarded hot plate with circular line-heat sources is temperatures; (2) plate geometries other than circular; (3)

a design in which the meter and guard plates are circular plates line-heat-source geometries other than circular; or (4) the use

having a relatively small number of heaters, each embedded of plates fabricated from ceramics, composites, or other

along a circular path at a fixed radius. In operation, the heat materials.

from each line-heat source flows radially into the plate and is

1.7 The values stated in SI units are to be regarded as

transmitted axially through the test specimens.

standard. No other units of measurement are included in this

1.3 The meter and guard plates are fabricated from a standard.

continuous piece of thermally conductive material. The plates

1.8 This standard does not purport to address all of the

are made sufficiently thick that, for typical specimen thermal

safety concerns, if any, associated with its use. It is the

conductances, the radial and axial temperature variations in the

responsibility of the user of this standard to establish appro-

guarded hot plate are quite small. By proper location of the

priate safety, health, and environmental practices and deter-

line-heat source(s), the temperature at the edge of the meter

mine the applicability of regulatory limitations prior to use.

plate is made equal to the mean temperature of the meter plate,

1.9 This international standard was developed in accor-

thus facilitating temperature measurements and thermal guard-

dance with internationally recognized principles on standard-

ing.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.4 The line-heat-source guarded hot plate has been used

mendations issued by the World Trade Organization Technical

successfully over a mean temperature range from − 10

Barriers to Trade (TBT) Committee.

to + 65°C, with circular metal plates and a single line-heat

source in the meter plate. The chronological development of

2. Referenced Documents

the design for circular line-heat-source guarded hot plates

4

having a single line-heat source in the meter plate is given in

2.1 ASTM Standards:

2

Refs (1-9).

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measure-

1.5 For high-temperature applications, the line-heat-source

ments and Thermal Transmission Properties by Means of

guarded hot plate has been used successfully over a mean

the Guarded-Hot-Plate Apparatus

C1044 Practice for Using a Guarded-Hot-Plate Apparatus or

Thin-Heater Apparatus in the Single-Sided Mode

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

3

Current edition approved March 1, 2024. Published March 2024. Originally Available from ASTM Headquarters. Order Adjunct: ADJC1043.

4

approved in 1985. Last previous edition approved in 2019 as C1043 – 19. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1043-24. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, ref

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1043 − 19 C1043 − 24

Standard Practice for

Guarded-Hot-Plate Design Using Circular Line-Heat

1

Sources

This standard is issued under the fixed designation C1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the design of a circular line-heat-source guarded hot plate for use in accordance with Test Method C177.

NOTE 1—Test Method C177 describes the guarded-hot-plate apparatus and the application of such equipment for determining thermal transmission

properties of flat-slab specimens. In principle, the test method includes apparatus designed with guarded hot plates having either distributed- or line-heat

sources.

1.2 The guarded hot plate with circular line-heat sources is a design in which the meter and guard plates are circular plates having

a relatively small number of heaters, each embedded along a circular path at a fixed radius. In operation, the heat from each

line-heat source flows radially into the plate and is transmitted axially through the test specimens.

1.3 The meter and guard plates are fabricated from a continuous piece of thermally conductive material. The plates are made

sufficiently thick that, for typical specimen thermal conductances, the radial and axial temperature variations in the guarded hot

plate are quite small. By proper location of the line-heat source(s), the temperature at the edge of the meter plate is made equal

to the mean temperature of the meter plate, thus facilitating temperature measurements and thermal guarding.

1.4 The line-heat-source guarded hot plate has been used successfully over a mean temperature range from − 10 to + 65°C, with

circular metal plates and a single line-heat source in the meter plate. The chronological development of the design offor circular

2

line-heat-source guarded hot plates having a single line-heat source in the meter plate is given in Refs (1-9).

3

NOTE 2—Detailed drawings and descriptions for the construction of two line-heat-source guarded-hot-plate apparatuses are available in the adjunct.

1.5 For high-temperature applications, the line-heat-source guarded hot plate has been used successfully over a mean temperature

from 7 to 160°C, with circular metal plates and multiple line-heat sources in the meter plate. The chronological development for

circular line-heat-source guarded hot plates having multiple line-heat sources in the meter plate is given in Refs (10-14).

3

NOTE 2—Detailed drawings and descriptions for the construction of two line-heat-source guarded-hot-plate apparatuses are available in the adjunct.

1.6 This practice does not preclude (1) lower or higher temperatures; (2) plate geometries other than circular; (3) line-heat-source

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal Measurement.

Current edition approved March 1, 2019March 1, 2024. Published March 2019March 2024. Originally approved in 1985. Last previous edition approved in 20162019 as

C1043 – 16.C1043 – 19. DOI: 10.1520/C1043-19.10.1520/C1043-24.

2

The boldface numbers in parentheses refer to a list of references at the end of this practice.

3

Available from ASTM Headquarters. Order Adjunct: ADJC1043.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1043 − 24

geometries other than circular; or (4) the use of plates fabricated from ceramics, composites, or other materials; or (materials.5)

the use of multiple line-heat sources in both the meter and guard plates.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recom

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.