ASTM C1371-15(2022)

(Test Method)Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers

Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers

SIGNIFICANCE AND USE

5.1 Surface Emittance Testing:

5.1.1 Heat transfer from a surface by radiation transfer is reduced if the surface of a material has a low emittance. Since the controlling factor in the use of insulation is sometimes condensation control or personnel protection, it is important to understand that a low emittance will change the surface temperature of a material. One possible criterion in the selection of these materials is the question of the effect of aging on the surface emittance. If the initial low surface emittance of a material is not maintained during service, then the long-term value of the material is diminished.

5.1.2 This test method provides a means for comparative periodic testing of low emittance surfaces in the field. In this way the effects of aging on the reflective properties can be monitored.

5.1.3 This test method determines the total hemispherical emittance with a precision of better than ±0.02 units.(1) The emittances of the calibration standards shall have been obtained from accurate independent measurements of total hemispherical emittance. This test method shall not be used for specimens that are highly anisotropic or transparent to infrared radiation. This test method also shall not be used for specimens with significant thermal resistance (see 7.3.4).

5.1.4 Once a reliable emittance measurement has been determined, the value is available to be used to calculate radiative heat flow from the subject surface. For example, if the temperature of the surface, T1, and the temperature of the surroundings, T2, are known, then the radiative heat flow, Qrad, is given by:

where A is the area of the surface, and either A is assumed to be much smaller than the area of the surroundings or the emittance of the surroundings is assumed to be unity. This radiative heat flow when combined with convective and conductive heat flows provides the total heat flow from the surface (a method for calculating total heat flow is described in Practic...

SCOPE

1.1 This test method covers a technique for determination of the emittance of opaque and highly thermally conductive materials using a portable differential thermopile emissometer. The purpose of the test method is to provide a comparative means of quantifying the emittance of materials near room temperature.

1.2 This test method does not supplant Test Method C835, which is an absolute method for determination of total hemispherical emittance, or Test Method E408, which includes two comparative methods for determination of total normal emittance. Because of the unique construction of the portable emissometer, it can be calibrated to measure the total hemispherical emittance. This is supported by comparison of emissometer measurements with those of Test Method C835 (1).2

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1371 − 15 (Reapproved 2022)

Standard Test Method for

Determination of Emittance of Materials Near Room

Temperature Using Portable Emissometers

This standard is issued under the fixed designation C1371; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thistestmethodcoversatechniquefordeterminationof

the emittance of opaque and highly thermally conductive C168Terminology Relating to Thermal Insulation

C680Practice for Estimate of the Heat Gain or Loss and the

materials using a portable differential thermopile emissometer.

The purpose of the test method is to provide a comparative Surface Temperatures of Insulated Flat, Cylindrical, and

Spherical Systems by Use of Computer Programs

means of quantifying the emittance of materials near room

temperature. C835Test Method for Total Hemispherical Emittance of

Surfaces up to 1400°C

1.2 This test method does not supplant Test Method C835,

E177Practice for Use of the Terms Precision and Bias in

which is an absolute method for determination of total hemi-

ASTM Test Methods

spherical emittance, orTest Method E408, which includes two

E408Test Methods for Total Normal Emittance of Surfaces

comparative methods for determination of total normal emit-

Using Inspection-Meter Techniques

tance. Because of the unique construction of the portable

E691Practice for Conducting an Interlaboratory Study to

emissometer, it can be calibrated to measure the total hemi-

Determine the Precision of a Test Method

spherical emittance. This is supported by comparison of

emissometer measurements with those of Test Method C835

3. Terminology

(1).

3.1 Definitions—For definitions of some terms used in this

1.3 The values stated in SI units are to be regarded as

test method, refer to Terminology C168.

standard. No other units of measurement are included in this

3.2 Definitions of Terms Specific to This Standard:

standard.

3.2.1 diffuse surface—a surface that emits or reflects equal

radiation intensity, or both, in all directions (2).

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.2 emissive power—the rate of radiative energy emission

responsibility of the user of this standard to establish appro-

per unit area from a surface (2).

priate safety, health, and environmental practices and deter-

3.2.3 emissometer—an instrument used for measurement of

mine the applicability of regulatory limitations prior to use.

emittance.

1.5 This international standard was developed in accor-

3.2.4 Lambert’s cosine law—the mathematical relation de-

dance with internationally recognized principles on standard-

scribing the variation of emissive power from a diffuse surface

ization established in the Decision on Principles for the

asvaryingwiththecosineoftheanglemeasuredawayfromthe

Development of International Standards, Guides and Recom-

normal of the surface (2).

mendations issued by the World Trade Organization Technical

3.2.5 normal emittance—the directional emittance perpen-

Barriers to Trade (TBT) Committee.

dicular to the surface.

3.2.6 radiative intensity—radiative energy passing through

an area per unit solid angle, per unit of the area projected

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal normal to the direction of passage, and per unit time (2).

Measurement.

Current edition approved May 1, 2022. Published June 2022. Originally

approved in 1997. Last previous edition approved in 2015 as C1371–15. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1371-15R22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1371 − 15 (2022)

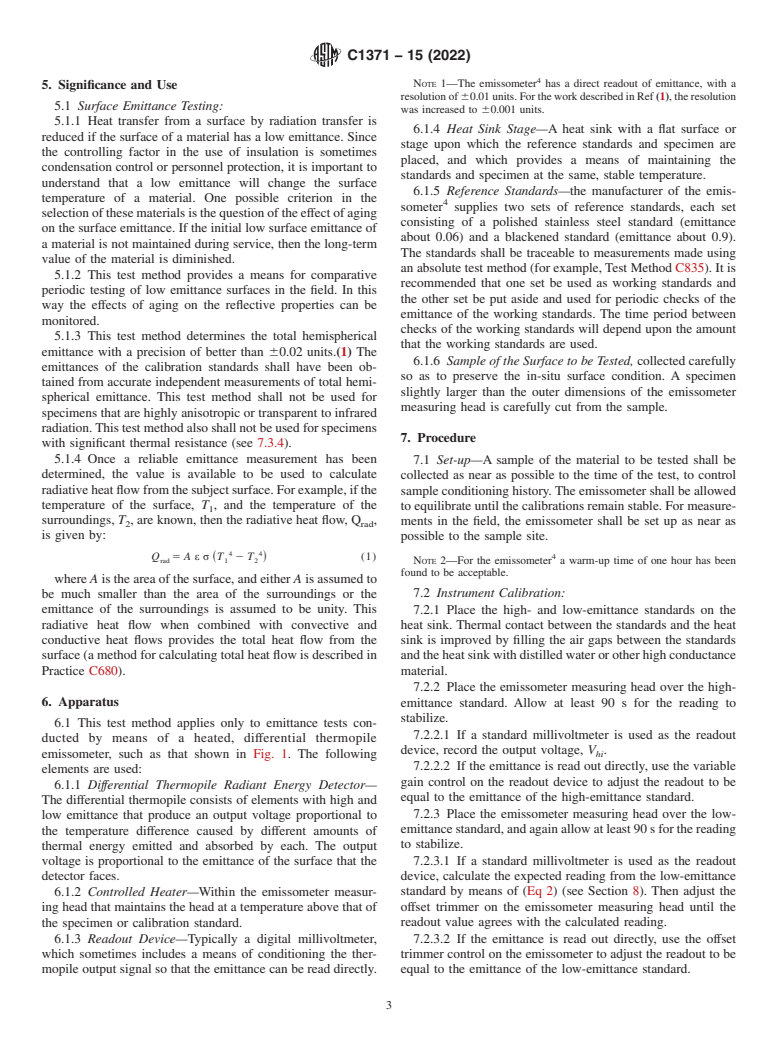

NOTE 1—(a) Emissometer measuring head on high-emittance standard during calibration, showing heat sink and cable to readout device. (b) Bottom

view of emissometer measuring head showing high- and low-emittance detector elements. The diameter of the emissometer measuring head is about 50

mm and the detector elements are recessed about 3 mm into the measuring head.

FIG. 1 Schematic of Emissometer

3.2.7 spectral—having a dependence on wavelength; radia- T =temperature of the test surface, K

tion within a narrow region of wavelength (2). T =temperature of the radiant background, K

T =temperature of the detector, K

d

3.2.8 specular surface—mirrorlike in reflection behavior

T =temperature of the surface of specimen, K

s

(2).

V =voltage output of the detector when stabilized on

hi

3.3 Symbols:

high-emittance calibration standard

3.3.1 For standard symbols used in this test method, see

V =voltage output of the detector when stabilized on

low

Terminology C168. Additional symbols are listed here:

low-emittance calibration standard

α=total absorptance, dimensionless

V =voltageoutputofthedetectorwhenstabilizedontest

spec

α =spectral absorptance, dimensionless

λ

specimen

ε = total emittance of the high-emittance calibration

hi

standard, dimensionless

4. Summary of Test Method

ε = total emittance of the low-emittance calibration

low

4.1 This test method employs a differential thermopile

standard, dimensionless

emissometer for total hemispherical emittance measurements.

ε =apparent total emittance of the test specimen, dimen-

spec

The detector thermopiles are heated in order to provide the

sionless

necessary temperature difference between the detector and the

ε=apparent total emittance of the surface, dimensionless

surface. Thedifferentialthermopileconsistsofonethermopile

ε =apparent total emittance of the surface 1, dimensionless

that is covered with a black coating and one that is covered

ε =apparent total emittance of the surface 2, dimensionless

with a reflective coating. The instrument is calibrated using

ε =apparent total emittance of the surface of detector,

d

two standards, one with a high emittance and the other with a

dimensionless

low emittance, which are placed on the flat surface of a heat

ε =apparent total emittance of the surface of specimen,

s

sink (the stage) as shown in Fig. 1. A specimen of the test

dimensionless

materialisplacedonthestageanditsemittanceisquantifiedby

ε =spectral emittance, dimensionless

λ

comparison to the emittances of the standards. The calibration

λ=wavelength, µm

shallbecheckedrepeatedlyduringthetestasprescribedin7.2.

ρ=total reflectance, dimensionless

−8 2 4

σ=Stefan-Boltzmann constant, 5.6696×10 W/m ·K

τ=total transmittance, dimensionless

2 4

Thesolesourceofsupplyofemissometersknowntothecommitteeatthistime

A =area of surface, m

2 is Devices & Services Co., 10024 Monroe Drive, Dallas, TX 75229. If you are

k =proportionality constant, V·m /W

aware of alternative suppliers, please provide this information toASTM Headquar-

Q =radiation heat transfer, W

rad ters. Your comments will receive careful consideration at a meeting of the

q =radiative heat flux, W/m responsible technical committee, which you may attend.

rad

C1371 − 15 (2022)

NOTE 1—The emissometer has a direct readout of emittance, with a

5. Significance and Use

resolutionof 60.01units.FortheworkdescribedinRef (1),theresolution

5.1 Surface Emittance Testing:

was increased to 60.001 units.

5.1.1 Heat transfer from a surface by radiation transfer is

6.1.4 Heat Sink Stage—A heat sink with a flat surface or

reduced if the surface of a material has a low emittance. Since

stage upon which the reference standards and specimen are

the controlling factor in the use of insulation is sometimes

placed, and which provides a means of maintaining the

condensation control or personnel protection, it is important to

standards and specimen at the same, stable temperature.

understand that a low emittance will change the surface

6.1.5 Reference Standards—the manufacturer of the emis-

temperature of a material. One possible criterion in the

someter supplies two sets of reference standards, each set

selectionofthesematerialsisthequestionoftheeffectofaging

consisting of a polished stainless steel standard (emittance

on the surface emittance. If the initial low surface emittance of

about 0.06) and a blackened standard (emittance about 0.9).

a material is not maintained during service, then the long-term

The standards shall be traceable to measurements made using

value of the material is diminished.

an absolute test method (for example,Test MethodC835). It is

5.1.2 This test method provides a means for comparative

recommended that one set be used as working standards and

periodic testing of low emittance surfaces in the field. In this

the other set be put aside and used for periodic checks of the

way the effects of aging on the reflective properties can be

emittance of the working standards. The time period between

monitored.

checks of the working standards will depend upon the amount

5.1.3 This test method determines the total hemispherical

that the working standards are used.

emittance with a precision of better than 60.02 units.(1) The

6.1.6 Sample of the Surface to be Tested,collected carefully

emittances of the calibration standards shall have been ob-

so as to preserve the in-situ surface condition. A specimen

tained from accurate independent measurements of total hemi-

slightly larger than the outer dimensions of the emissometer

spherical emittance. This test method shall not be used for

measuring head is carefully cut from the sample.

specimensthatarehighlyanisotropicortransparenttoinfrared

radiation.Thistestmethodalsoshallnotbeusedforspecimens

7. Procedure

with significant thermal resistance (see 7.3.4).

5.1.4 Once a reliable emittance measurement has been

7.1 Set-up—A sample of the material to be tested shall be

determined, the value is available to be used to calculate collected as near as possible to the time of the test, to control

radiativeheatflowfromthesubjectsurface.Forexample,ifthe

sampleconditioninghistory.Theemissometershallbeallowed

temperature of the surface, T , and the temperature of the toequilibrateuntilthecalibrationsremainstable.Formeasure-

surroundings, T ,areknown,thentheradiativeheatflow,Q ,

ments in the field, the emissometer shall be set up as near as

2 rad

is given by: possible to the sample site.

4 4

Q 5 Aεσ ~T 2 T ! (1)

rad 1 2

NOTE 2—For the emissometer a warm-up time of one hour has been

found to be acceptable.

where Aistheareaofthesurface,andeither Aisassumedto

7.2 Instrument Calibration:

be much smaller than the area of the surroundings or the

emittance of the surroundings is assumed to be unity. This 7.2.1 Place the high- and low-emittance standards on the

radiative heat flow when combined with convective and heat sink. Thermal contact between the standards and the heat

conductive heat flows provides the total heat flow from the sink is improved by filling the air gaps between the standards

surface(amethodforcalculatingtotalheatflowisdescribedin andtheheatsinkwithdistilledwaterorotherhighconductance

Practice C680). material.

7.2.2 Place the emissometer measuring head over the high-

6. Apparatus

emittance standard. Allow at least 90 s for the reading to

stabilize.

6.1 This test method applies only to emittance tests con-

7.2.2.1 If a standard millivoltmeter is used as the readout

ducted by means of a heated, differential thermopile

device, record the output voltage, V .

emissometer, such as that shown in Fig. 1. The following hi

7.2.2.2 If the emittance is read out directly, use the variable

elements are used:

gain control on the readout device to adjust the readout to be

6.1.1 Differential Thermopile Radiant Energy Detector—

equal to the emittance of the high-emittance standard.

The differential thermopile consists of elements with high and

7.2.3 Place the emissometer measuring head over the low-

low emittance that produce an output voltage proportional to

emittancestandard,andagainallowatleast90sforthereading

the temperature difference caused by different amounts of

to stabilize.

thermal energy emitted and absorbed by each. The output

voltage is proportional to the emittance of the surface that the 7.2.3.1 If a standard millivoltmeter is used as the readout

detector faces. device, calculate the expected reading from the low-emittance

6.1.2 Controlled Heater—Within the emissometer measur- standard by means of (Eq 2) (see Section 8). Then adjust the

offset trimmer on the emissometer measuring head until the

ingheadthatmaintainstheheadatatemperatureabovethatof

the specimen or calibration standard. readout value agrees with the calculated reading.

6.1.3 Readout Device—Typically a digital millivoltmeter, 7.2.3.2 If the emittance is read out directly, use the offset

which sometimes includes a means of conditioning the ther- trimmer control on the emissometer to adjust the readout to be

mopile output signal so that the emittance can be read directly. equal to the emittance of the low-emittance standard.

C1371 − 15 (2022)

7.2.4 Place the emissometer measuring head over the high- 9. Report

emittance standard again, and repeat the procedure in 7.2.1 –

9.1 Report the following information:

7.2.3, until the measuring head can be moved from one

9.1.1 Name and any other pertinent identification of the

standard to the other without requiring any adjustment to

material, including a physical description.

obtain the expected reading.

9.1.2 Description of the specimen and its relationship to the

7.3 Specimen Collection:

sample, including a brief history of the specimen, if known.

7.3.1 The specimen collection procedure depends on the

9.1.3 Thickness of the specimen as received and as tested.

nature of the material. In general, the procedure shall ensure

9.1.4 Temperature of the room in which the measurements

minimum alteration of the specimen surface. For example, if

were conducted, °C.

the emittance of a dust-covered specimen is to be determined,

9.1.5 Source and assigned emittance values of the calibra-

the dust shall not be removed.

tion standards.

7.3.2 All contact with the specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.