ASTM A955/A955M-18

(Specification)Standard Specification for Deformed and Plain Stainless Steel Bars for Concrete Reinforcement

Standard Specification for Deformed and Plain Stainless Steel Bars for Concrete Reinforcement

ABSTRACT

This specification covers deformed and plain stainless steel bars for concrete reinforcement proposed to be used in applications requiring corrosion resistance or controlled magnetic permeability. For each specimen, one tension test, one bend test, if required, and one set of dimensional property tests shall be made. For martensitic materials, two hardness tests shall be performed per lot of material. If the results of the test fail to meet the specified minimum requirements, a retest shall be permitted on two random specimens for each original tension specimen failure from the lot. If a specimen fails a bend test due to reasons other than mechanical or flaws, a retest shall be permitted on two random specimens from the same lot.

SCOPE

1.1 This specification covers deformed and plain stainless steel bars for concrete reinforcement in cut lengths and coils used in applications requiring resistance to corrosion or controlled magnetic permeability. The standard sizes and dimensions of deformed bars and their numerical designation shall be those listed in Table 1. The text of this specification references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification. (A) The 400 and Duplex-Alloy Series is based on a density of 489.59 lb/ft3 [7833.4 kg/m3 ]. The 300 Series is based on a density of 494.78 lb/ft3 [7916.5 kg/m3]. Density varies with alloy content which may result in a variation of several percent.(B) The nominal dimensions of a deformed bar are equivalent to those of a round bar having the same weight [mass] per foot [metre] as the deformed bar.(C) The maximum gap (measured as a chord) between the ends of the deformations shall not exceed 25 %/n of the nominal perimeter of the bar, where n is the number of longitudinal gaps or longitudinal ribs around the perimeter of the bar.

1.1.1 Supplementary requirement (S1) of an optional nature is provided. It shall apply only when specified by the purchaser. In order to obtain a controlled magnetic permeability product, steel conforming to Supplementary Requirement S1 should be ordered.

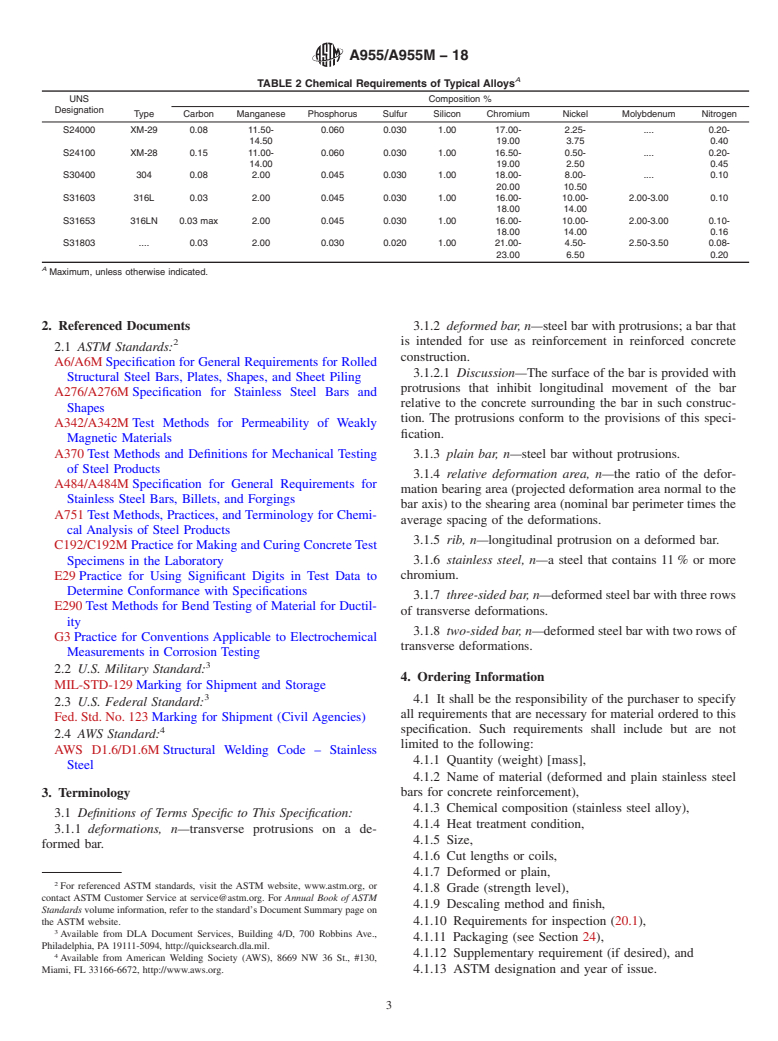

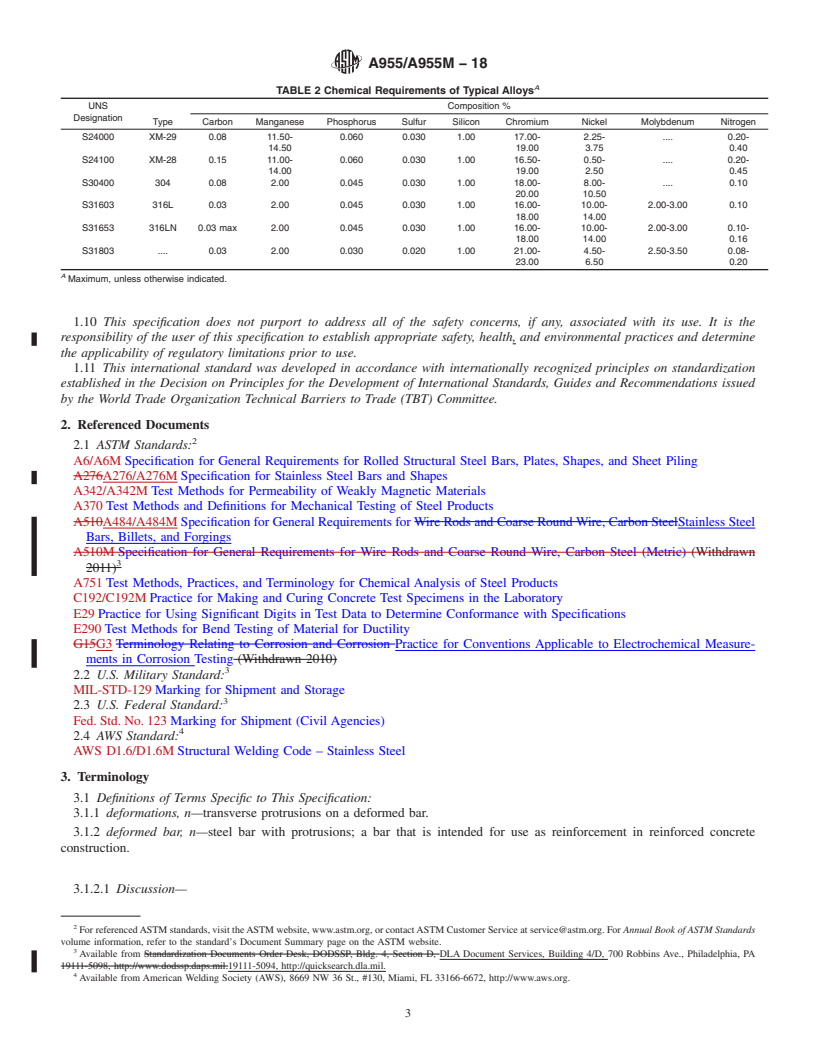

1.2 The chemical composition of the stainless steel alloy shall be selected for suitability to the application involved by agreement between the manufacturer and the purchaser. This is an important consideration in achieving the desired corrosion resistance or controlled magnetic permeability, or both, because these properties are not provided by all stainless steels.

Note 1: The austenitic and austenitic-ferritic (duplex) alloys shown in Table 2 are known to be sold by producers to the requirements of this specification. It provides guidance and is not a mandatory chemical composition table. Other alloys may also provide desired properties; consult with the manufacturer for stainless steel alloy properties and availability. After adoption of Annex A5, a mandatory chemical composition requirements table will be balloted in accordance with its requirements. This note and references to Specification A276/A276M will be simultaneously removed. (A) Maximum, unless otherwise indicated.

1.3 The requirements for introduction of new alloys into a mandatory chemical composition requirements table in this specification are given in Annex A5.

1.4 Requirements for the relative deformation area of three-sided deformed bars are contained in Annex A4.

1.5 Bars are of two minimum yield strength levels, namely, 60 000 psi [420 MPa] and 75 000 psi [520 MPa], designated as Grade 60 [420] and Grade 75 [520], respectively.

1.6 Plain bars in sizes up to and including 2 in. [50.8 mm] in diameter in coils or cut lengths, when ordered, shall be furnished under this specification in Grade 60 [420] and Grade 75 [520], respectively. Bending properties, when required, shall be by agreement between the manufacturer and purchaser. Requirements providing for defo...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A955/A955M −18

Standard Specification for

Deformed and Plain Stainless Steel Bars for Concrete

1

Reinforcement

This standard is issued under the fixed designationA955/A955M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.5 Bars are of two minimum yield strength levels, namely,

60 000 psi [420 MPa] and 75 000 psi [520 MPa], designated as

1.1 This specification covers deformed and plain stainless

Grade 60 [420] and Grade 75 [520], respectively.

steel bars for concrete reinforcement in cut lengths and coils

used in applications requiring resistance to corrosion or con-

1.6 Plain bars in sizes up to and including 2 in. [50.8 mm]

trolled magnetic permeability. The standard sizes and dimen-

in diameter in coils or cut lengths, when ordered, shall be

sionsofdeformedbarsandtheirnumericaldesignationshallbe

furnished under this specification in Grade 60 [420] and Grade

those listed in Table 1. The text of this specification references

75 [520], respectively. Bending properties, when required,

notes and footnotes which provide explanatory material. These

shallbebyagreementbetweenthemanufacturerandpurchaser.

notesandfootnotes(excludingthoseintablesandfigures)shall

Requirements providing for deformations and marking shall

not be considered as requirements of the specification.

not be applicable to plain bars.

1.1.1 Supplementary requirement (S1) of an optional nature

1.7 When stainless steel is to be welded, use a procedure

isprovided.Itshallapplyonlywhenspecifiedbythepurchaser.

suitable for the chemical composition and intended use or

In order to obtain a controlled magnetic permeability product,

service.

steel conforming to Supplementary Requirement S1 should be

ordered.

NOTE 2—Welding of stainless steel reinforcement would occur after

shipment from the producer. Structural welding should be performed in

1.2 The chemical composition of the stainless steel alloy

accordance with the latest edition of AWS D1.6/D1.6M, any other

shall be selected for suitability to the application involved by

internationally accepted stainless steel welding code, or a procedure

agreement between the manufacturer and the purchaser.This is suggested by the material producer. AWS D1.6/D1.6M describes the

proper selection of the filler metals, temperature control, as well as,

an important consideration in achieving the desired corrosion

performance, procedure qualification and inspection requirements.

resistance or controlled magnetic permeability, or both, be-

cause these properties are not provided by all stainless steels.

1.8 This specification is applicable for orders in either

inch-pound units (as Specification A955) or in SI units (as

NOTE 1—The austenitic and austenitic-ferritic (duplex) alloys shown in

Specification A955M).

Table 2 are known to be sold by producers to the requirements of this

specification. It provides guidance and is not a mandatory chemical

1.9 The values stated in either inch-pound or SI units are to

composition table. Other alloys may also provide desired properties;

be regarded separately as standard.Within the text, the SI units

consult with the manufacturer for stainless steel alloy properties and

availability. After adoption of Annex A5, a mandatory chemical compo- are shown in brackets.The values stated in each system are not

sition requirements table will be balloted in accordance with its require-

exact equivalents; therefore, each system shall be used inde-

ments. This note and references to Specification A276/A276M will be

pendentlyoftheother.Combiningvaluesfromthetwosystems

simultaneously removed.

may result in nonconformance with the standard.

1.3 The requirements for introduction of new alloys into a

1.10 This specification does not purport to address all of the

mandatory chemical composition requirements table in this

safety concerns, if any, associated with its use. It is the

specification are given in Annex A5.

responsibility of the user of this specification to establish

1.4 Requirements for the relative deformation area of three-

appropriate safety, health, and environmental practices and

sided deformed bars are contained in Annex A4.

determine the applicability of regulatory limitations prior to

use.

1.11 This international standard was developed in accor-

1

dance with internationally recognized principles on standard-

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

ization established in the Decision on Principles for the

A01.05 on Steel Reinforcement.

Development of In

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A955/A955M − 17a A955/A955M − 18

Standard Specification for

Deformed and Plain Stainless-Steel Stainless Steel Bars for

1

Concrete Reinforcement

This standard is issued under the fixed designation A955/A955M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers deformed and plain stainless-steel stainless steel bars for concrete reinforcement in cut lengths and

coils used in applications requiring resistance to corrosion or controlled magnetic permeability. The standard sizes and dimensions

of deformed bars and their numerical designation shall be those listed in Table 1. The text of this specification references notes

and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be

considered as requirements of the specification.

1.1.1 Supplementary requirement (S1) of an optional nature is provided. It shall apply only when specified by the purchaser.

In order to obtain a controlled magnetic permeability product, steel conforming to Supplementary Requirement S1 should be

ordered.

1.2 The chemical composition of the stainless steel alloy shall be selected for suitability to the application involved by

agreement between the manufacturer and the purchaser. This is an important consideration in achieving the desired corrosion

resistance or controlled magnetic permeability, or both, because these properties are not provided by all stainless steels.

NOTE 1—The austenitic and austenitic-ferritic (duplex) alloys shown in Table 2 have found the most use in North America. are known to be sold by

producers to the requirements of this specification. It provides guidance and is not a mandatory chemical composition table. Other alloys may also provide

desired properties; consult with the manufacturer for stainless steel alloy properties and availability. After adoption of Annex A5, a mandatory chemical

composition requirements table will be balloted in accordance with its requirements. This note and references to Specification A276/A276M will be

simultaneously removed.

1.3 The requirements for introduction of new alloys into a mandatory chemical composition requirements table in this

specification are given in Annex A5.

1.4 Requirements for the relative deformation area of three-sided deformed bars are contained in Annex A4.

1.5 Bars are of two minimum yield strength levels, namely, 60 000 psi [420 MPa] and 75 000 psi [520 MPa], designated as

Grade 60 [420] and Grade 75 [520], respectively.

1.6 Plain bars in sizes up to and including 2 in. [50.8 mm] in diameter in coils or cut lengths, when ordered, shall be furnished

under this specification in Grade 60 [420] and Grade 75 [520], respectively. Bending properties, when required, shall be by

agreement between the manufacturer and purchaser. Requirements providing for deformations and marking shall not be applicable

to plain bars.

1.7 When stainless steel is to be welded, use a procedure suitable for the chemical composition and intended use or service.

NOTE 2—Welding of stainless steel reinforcement would occur after shipment from the producer. Structural welding should be performed in accordance

with the latest edition of AWS D1.6/D1.6M, any other internationally accepted stainless steel welding code, or a procedure suggested by the material

producer. AWS D1.6/D1.6M describes the proper selection of the filler metals, temperature control, as well as, performance, procedure qualification and

inspection requirements.

1.8 This specification is applicable for orders in either inch-pound units (as Specification A955) or in SI units (as Specification

A955M).

1.9 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are

shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently

of the other. Combining values from the two systems may result in nonconformance with the standard.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.05

on Steel Reinforcement.

Current edition approved Sept. 1, 2017Jan. 1, 2018. Published September 2017February 2018. Origin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.