ASTM F1282-03e1

(Specification)Standard Specification for Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite Pressure Pipe

Standard Specification for Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite Pressure Pipe

SCOPE

1.1 This specification covers a coextruded polyethylene composite pressure pipe with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer polyethylene layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the polyethylene-aluminum-polyethylene (PE-AL-PE) pipes, the requirements and test methods for materials, the dimensions and strengths of the component tubes and finished pipe, adhesion tests, and the burst and sustained pressure performance. Also given are the requirements and methods of marking. The pipe covered by this specification is intended for use in potable water distribution systems for residential and commercial applications, water service, underground irrigation systems, and radient panel heating systems, baseboard, snow- and ice-melt systems, and gases that are compatible with composite pipe and fittings.

1.2 This specification relates only to metal and plastic composite pipes incorporating a welded metallic tube. The welded metallic tube of itself is capable of sustaining internal pressures. Pipes consisting of metallic layers not welded together are outside the scope of this specification.

1.3 Specifications for connectors for use with pipe meeting the requirements of this specification are given in Annex A1.

1.4 This specification excludes crosslinked polyethylene-aluminum-crosslinked polyethylene pipes (see Specification F 1281).

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The following precautionary caveat pertains only to the test methods portion, Section 9, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: F 1282 – 03

Standard Specification for

Polyethylene/Aluminum/Polyethylene (PE-AL-PE) Composite

1

Pressure Pipe

This standard is issued under the fixed designation F 1282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Tables 1–5 and Table A2.1 were editorially corrected and 5.3.3.2 was editorially reinstated in July 2005.

1. Scope of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory limita-

1.1 This specification covers a coextruded polyethylene

tions prior to use.

composite pressure pipe with a welded aluminum tube rein-

forcement between the inner and outer layers. The inner and

2. Referenced Documents

outer polyethylene layers are bonded to the aluminum tube by

2.1 ASTM Standards:

a melt adhesive. Included is a system of nomenclature for the

D618 Practice for Conditioning Plastics for Testing

polyethylene-aluminum-polyethylene (PE-AL-PE) pipes, the

D1248 Specification for Polyethylene Plastics Extrusion

requirements and test methods for materials, the dimensions

Materials for Wire and Cable

and strengths of the component tubes and finished pipe,

D1598 Test Method for Time-to-Failure of Plastic Pipe

adhesion tests, and the burst and sustained pressure perfor-

Under Constant Internal Pressure

mance. Also given are the requirements and methods of

D1599 Test Method for Resistance to Short-Time Hydrau-

marking.The pipe covered by this specification is intended for

lic Pressure of Plastic Pipe, Tubing, and Fittings

use in potable water distribution systems for residential and

D1600 Terminology for Abbreviated Terms Relating to

commercialapplications,waterservice,undergroundirrigation

Plastics

systems, and radient panel heating systems, baseboard, snow-

D1898 Practice for Sampling of Plastics

and ice-melt systems, and gases that are compatible with

D2104 Specification for Polyethylene (PE) Plastic Pipe,

composite pipe and fittings.

Schedule 40

1.2 This specification relates only to metal and plastic

D2122 Test Method for Determining Dimensions of Ther-

composite pipes incorporating a welded metallic tube. The

moplastic Pipe and Fittings

welded metallic tube of itself is capable of sustaining internal

D2837 Test Method for Obtaining Hydrostatic Design

pressures. Pipes consisting of metallic layers not welded

Basis for Thermoplastic Pipe Materials

together are outside the scope of this specification.

D3035 Specification for Polyethylene (PE) Plastic Pipe

1.3 Specifications for connectors for use with pipe meeting

(DR-PR) Based on Controlled Outside Diameter

the requirements of this specification are given in Annex A1.

D3350 Specification for Polyethylene Plastics Pipe and

1.4 This specification excludes crosslinked polyethylene-

Fittings Materials

aluminum-crosslinked polyethylene pipes (see Specification

E8 Test Methods for Tension Testing of Metallic Materials

F1281).

F412 Terminology Relating to Plastic Piping Systems

1.5 The values stated in SI units are to be regarded as the

F 1281 Specification for Crosslinked Polyethylene/

standard. The values given in parentheses are for information

Aluminum/Crosslinked Polyethylene (PEX-AL-PEX)

only.

Pressure Pipe

1.6 The following precautionary caveat pertains only to the

F 1974 Specification for Metal Insert Fittings for

test methods portion, Section 9, of this specification: This

Polyethylene/Aluminum/Polyethylene and Crosslinked

standard does not purport to address all of the safety concerns,

Polyethylene/Aluminum/Crosslinked Polyethylene Com-

if any, associated with its use. It is the responsibility of the user

posite Pressure Pipe

2.2 NSF Standard:

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standard No. 14 Plastics Piping System Components and

2

Piping Systems and is the direct responsibility of Subcommittee F17.11 on

Related Materials

Composite.

Standard No. 61 Drinking Water System Components—

Current edition approved Oct. 1, 2003. Published November 2003. Originally

2

e3

Health Effects

approved in 1990. Last previous edition approved in 2002 as F1282–02 .

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

F 1282 – 03

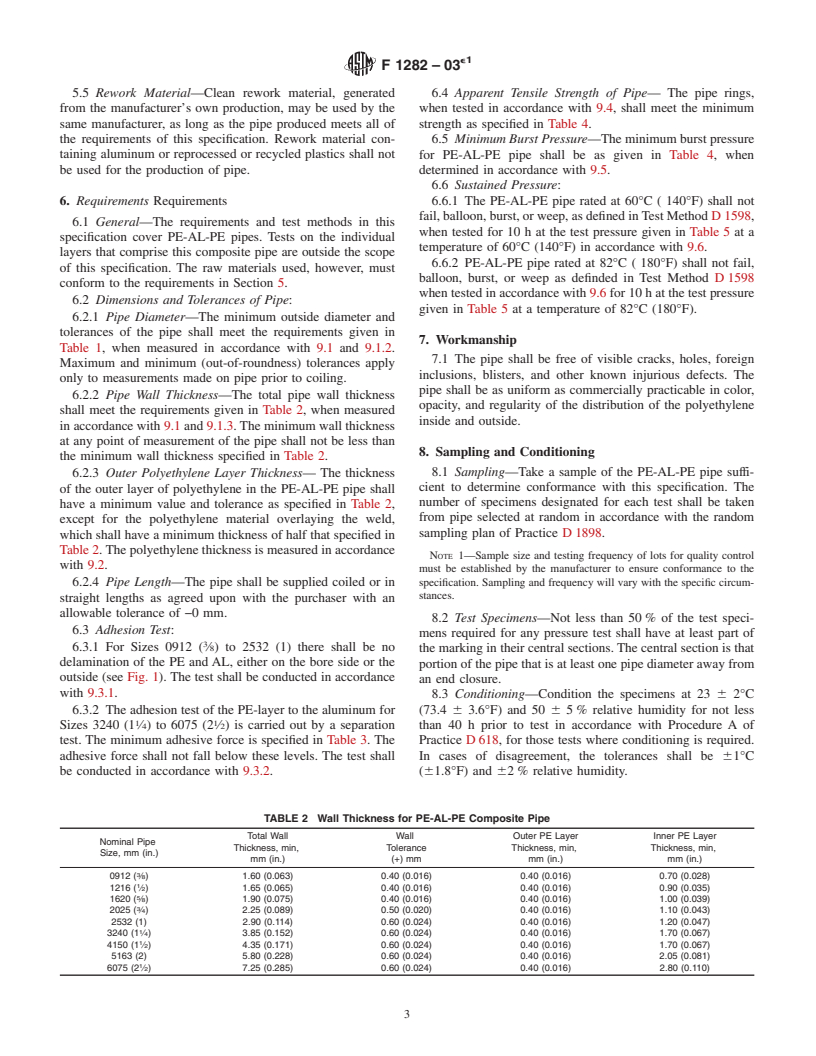

2.3 Uniform Classification Committee Standard: 4.2 Pipe Dimension Ratio—The concept of dimension ratio

3

Uniform Freight Classification is not relevant to PE-AL-PE laminated pipes, and cannot be

2.4 National Motor Freight Association Standard: used to relate pressure rating with total

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.