ASTM D6549-06

(Test Method)Standard Test Method for Determination of Cooling Characteristics of Quenchants by Cooling Curve Analysis with Agitation (Drayton Unit)

Standard Test Method for Determination of Cooling Characteristics of Quenchants by Cooling Curve Analysis with Agitation (Drayton Unit)

SIGNIFICANCE AND USE

This test method provides a cooling time versus temperature curve (profile) that can be related to physical properties, such as the hardness obtainable upon quenching of a metal. The results obtained by this test method may be used as a guide in quenchant selection or as a comparison of quench severities of different quenchants, new or used.

SCOPE

1.1 This test method covers the equipment and the procedure for evaluation of quenching characteristics of a quenching fluid by cooling rate determination.

1.2 This test method is designed to evaluate quenching fluids with agitation, using the Drayton Agitation Unit.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6549–06

Standard Test Method for

Determination of Cooling Characteristics of Quenchants by

1

Cooling Curve Analysis with Agitation (Drayton Unit)

This standard is issued under the fixed designation D6549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.4 ASTM Adjuncts:

ADJD6300 D2PP, Determination of Precision and Bias

1.1 This test method covers the equipment and the proce-

Data for Use in Test Methods for Petroleum Products and

dure for evaluation of quenching characteristics of a quenching

5

Lubricants

fluid by cooling rate determination.

1.2 This test method is designed to evaluate quenching

3. Terminology

fluids with agitation, using the Drayton Agitation Unit.

3.1 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as

3.1.1 aqueous polymer quenchant—an aqueous polymer

standard. The values given in parentheses are for information

quenchant is an aqueous solution containing a water soluble

only.

polymer, typically including poly(alkylene glycol), poly(ethyl

1.4 This standard does not purport to address all of the

oxazoline), poly(sodium acrylate), and poly(vinyl pyrrolidone)

safety concerns, if any, associated with its use. It is the

6

(1,2,3). The quenchant solution also typically contains addi-

responsibility of the user of this standard to establish appro-

tives for corrosion and foam control, if needed. Quench

priate safety and health practices and determine the applica-

severity of aqueous polymer quenchants is dependent on

bility of regulatory limitations prior to use.

concentration and molecular weight of the specific polymer

2. Referenced Documents being evaluated, quenchant temperature, and agitation rate as

2

shown in Fig. 1, Fig. 2, and Fig. 3, respectively.

2.1 ASTM Standards:

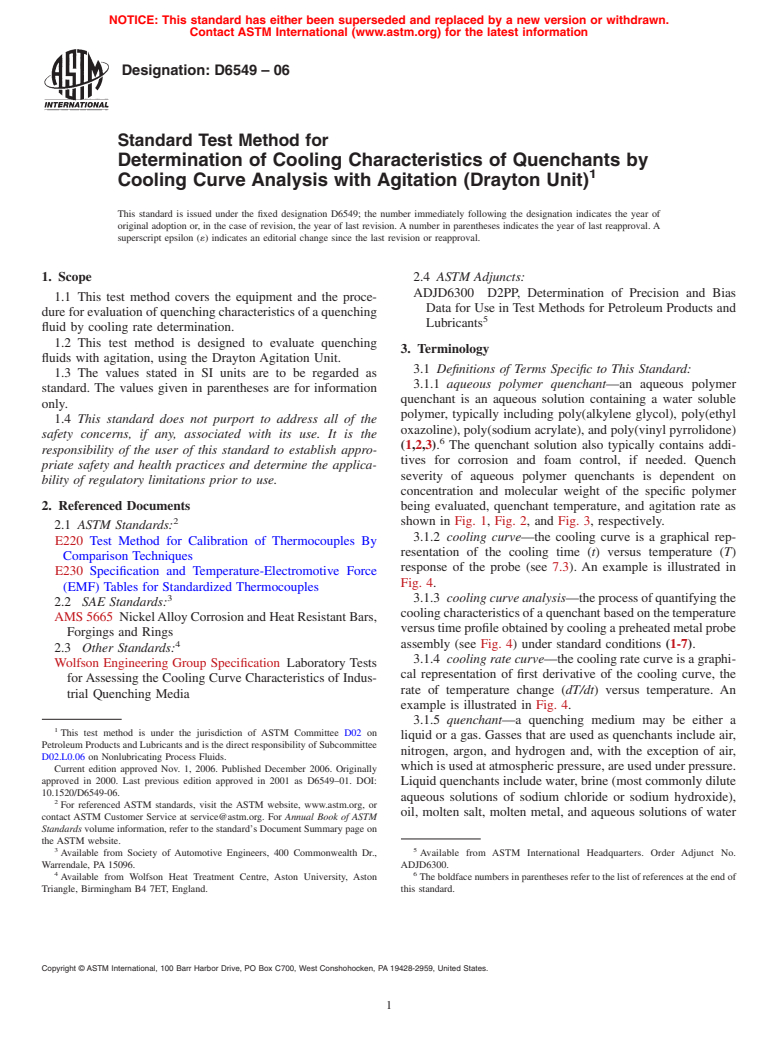

3.1.2 cooling curve—the cooling curve is a graphical rep-

E220 Test Method for Calibration of Thermocouples By

resentation of the cooling time (t) versus temperature (T)

Comparison Techniques

response of the probe (see 7.3). An example is illustrated in

E230 Specification and Temperature-Electromotive Force

Fig. 4.

(EMF) Tables for Standardized Thermocouples

3 3.1.3 cooling curve analysis—theprocessofquantifyingthe

2.2 SAE Standards:

coolingcharacteristicsofaquenchantbasedonthetemperature

AMS5665 NickelAlloyCorrosionandHeatResistantBars,

versustimeprofileobtainedbycoolingapreheatedmetalprobe

Forgings and Rings

4

assembly (see Fig. 4) under standard conditions (1-7).

2.3 Other Standards:

3.1.4 cooling rate curve—the cooling rate curve is a graphi-

Wolfson Engineering Group Specification Laboratory Tests

cal representation of first derivative of the cooling curve, the

forAssessing the Cooling Curve Characteristics of Indus-

rate of temperature change (dT/dt) versus temperature. An

trial Quenching Media

example is illustrated in Fig. 4.

3.1.5 quenchant—a quenching medium may be either a

1

This test method is under the jurisdiction of ASTM Committee D02 on

liquid or a gas. Gasses that are used as quenchants include air,

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

nitrogen, argon, and hydrogen and, with the exception of air,

D02.L0.06 on Nonlubricating Process Fluids.

whichisusedatatmosphericpressure,areusedunderpressure.

Current edition approved Nov. 1, 2006. Published December 2006. Originally

approved in 2000. Last previous edition approved in 2001 as D6549–01. DOI:

Liquid quenchants include water, brine (most commonly dilute

10.1520/D6549-06.

aqueous solutions of sodium chloride or sodium hydroxide),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

oil, molten salt, molten metal, and aqueous solutions of water

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 5

Available from Society of Automotive Engineers, 400 Commonwealth Dr., Available from ASTM International Headquarters. Order Adjunct No.

Warrendale, PA 15096. ADJD6300.

4 6

Available from Wolfson Heat Treatment Centre, Aston University, Aston The boldface numbers in parentheses refer to the list of references at the end of

Triangle, Birmingham B4 7ET, England. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6549–06

FIG. 1 Effect of Quenchant Concentration on Cooling Curve Performance for a Poly(Alkylene Glycol) Quenchant at 30°C and 0.5 m/s

FIG. 2 Effect of Bath Tem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.