ASTM E2945-14(2021)

(Test Method)Standard Test Method for Film Permeability Determination Using Static Permeability Cells

Standard Test Method for Film Permeability Determination Using Static Permeability Cells

SIGNIFICANCE AND USE

5.1 This test method provides a simple approach for determining the transmission properties of film membranes and sheeting over a range of permeability exceeding four orders of magnitude. This test method is described here to measure the permeability of films used in soil fumigation, but it is also appropriate for other gases and membranes if the analytical methods are appropriately modified.

5.2 This test method can be used for single or mixed compounds. This test method uses small quantities of test chemicals in vapor form, and microgram to milligram quantities of each chemical may produce a sufficient amount of vapor for each test depending on the analytical methods.

5.3 Interlaboratory testing showed that the MTC estimated by this test method is relatively insensitive to the laboratory procedures. The interlaboratory testing involved measuring the MTC for several soil fumigant compounds and a wide range of film permeability. Analysts with prior experience handling and analyzing gaseous fumigant compounds had lower coefficients of variation (10 % to 20 %) compared to less experienced analysts (20 % to 50 %) based on triplicate tests. The coefficient of variation between laboratories was higher for less permeable film materials than for films with high MTC. This was attributed to the additional length of the experiments and potential for increased leakage from the apparatus and was most pronounced for less experienced analysts.

SCOPE

1.1 This test method covers the measurement of the transmission of a gas through plastic membranes, sheeting, films, and fabric materials using a static sealed diffusion chamber. The test method monitors gas diffusion across a film membrane and provides measurements of (1) gas concentrations on each side of the film membrane and (2) estimates of the mass transfer coefficient (MTC) for the tested gas and film material. The MTC represents the film permeability and is independent of the concentration gradient used during testing, which simplifies some aspects of the experimental design.

1.2 This test method permits the loading of mixed vapors and simultaneous determination of the permeability of one film to various gases.

1.3 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2945 − 14 (Reapproved 2021)

Standard Test Method for

Film Permeability Determination Using Static Permeability

Cells

This standard is issued under the fixed designation E2945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1898Practice for Sampling of Plastics (Withdrawn 1998)

E691Practice for Conducting an Interlaboratory Study to

1.1 This test method covers the measurement of the trans-

Determine the Precision of a Test Method

mission of a gas through plastic membranes, sheeting, films,

and fabric materials using a static sealed diffusion chamber.

3. Terminology

Thetestmethodmonitorsgasdiffusionacrossafilmmembrane

3.1 Definitions:

and provides measurements of (1) gas concentrations on each

3.1.1 concentration, C, n—chemical mass divided by the

side of the film membrane and (2) estimates of the mass

chamber volume.

transfer coefficient (MTC) for the tested gas and film material.

3.1.1.1 Discussion—C is the initial (t = 0) concentration in

The MTC represents the film permeability and is independent

o

the source chamber. The SI unit of concentration is µg/cm .

of the concentration gradient used during testing, which

simplifies some aspects of the experimental design.

3.1.2 concentration gradient, n—difference in the concen-

tration of gases across the film membrane divided by the

1.2 This test method permits the loading of mixed vapors

transport distance between the source and collection chambers

andsimultaneousdeterminationofthepermeabilityofonefilm

(for example, usually considered to be the film thickness).

to various gases.

3.1.2.1 Discussion—The SI unit of the concentration gradi-

1.3 Units—The values stated in SI units are to be regarded

ent is µg/cm -cm.

as the standard. No other units of measurement are included in

3.1.3 mass transfer coeffıcient, MTC, n—gas diffusion rate

this standard.

constant that relates the mass transfer rate, distance, and

1.4 This standard does not purport to address all of the

concentration gradient as the driving force through a film

safety concerns, if any, associated with its use. It is the

membrane under the test conditions.

responsibility of the user of this standard to establish appro-

3.1.3.1 Discussion—TheSIunitoftheMTCiscm/hour.The

priate safety, health, and environmental practices and deter-

MTC expresses the ease of transmission of a gas through a

mine the applicability of regulatory limitations prior to use.

membrane under test conditions. The test conditions shall be

1.5 This international standard was developed in accor-

stated, which include the ambient temperature, relative

dance with internationally recognized principles on standard-

humidity, film conditioning, sampling, and handling.

ization established in the Decision on Principles for the

3.1.4 mass transfer rate, J, n—mass transfer rate, or flux

Development of International Standards, Guides and Recom-

density,ofagasdiffusingthroughafilmmembraneisthemass

mendations issued by the World Trade Organization Technical

of gas passing through a unit area (for example, 1 cm)offilm

Barriers to Trade (TBT) Committee.

membraneperunittimeinterval(forexample,1h).TheSIunit

2. Referenced Documents

of J is µg/cm hour.

2.1 ASTM Standards:

4. Summary of Test Method

D618Practice for Conditioning Plastics for Testing

4.1 This test method uses a static sealed apparatus consist-

This test method is under the jurisdiction of ASTM Committee E35 on

ing of two chambers separated by the test-film membrane.The

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct

testchemicalinthevaporphaseisaddedtothechamberonone

responsibility of Subcommittee E35.22 on Pesticide Formulations and Delivery

side of the film and the apparatus is incubated at constant

Systems.

Current edition approved April 1, 2021. Published April 2021. Originally temperature during which the chemical diffuses through the

approved in 2014. Last previous edition approved in 2014 as E2945–14 DOI:

test membrane. This test method requires determination of the

10.1520/E2945-21.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2945 − 14 (2021)

FIG. 1 Schematic of Static Film Permeability Apparatus Consisting of Two Parts: A Source and Collection Chamber with a Film Mem-

brane between Them

relative chemical concentrations on both sides of the mem- cient of variation between laboratories was higher for less

brane at several time points during the incubation. Concentra- permeable film materials than for films with high MTC. This

tions are monitored until equilibrium is reached or some other

was attributed to the additional length of the experiments and

practical stoppage time. For permeable films, more frequent potential for increased leakage from the apparatus and was

sampling is necessary because equilibrium may be reached

most pronounced for less experienced analysts.

within minutes or hours. For films with very low permeability,

longer incubation times (weeks) may be necessary to reach

6. Apparatus

equilibrium.Linearregressionofdatamaybeusedtocalculate

6.1 Asealed apparatus is constructed of inert and imperme-

the mass transfer coefficient (MTC). Alternatively, an analyti-

able material (for example, stainless steel) such that a sample

cal solution to a mathematical model may be used to calculate

oftestmembraneisheldbetweenthetwochambersinaclosed

MTC (see Appendix X1) for which a nonlinear least-square

system. The selection of material is dependent on the gases

algorithm is available to fit concentrations derived from the

being considered. The apparatus (see Fig. 1) enables sampling

mathematical model to the observed concentrations. See Pa-

4,5

of the time rate of change in the gas concentration in each

piernik et al for additional details.

chamber and the mass transfer coefficient. The apparatus is

5. Significance and Use

configured as shown in Fig. 1.

5.1 This test method provides a simple approach for deter- 6.1.1 Permeability Apparatus—Stainless steel pipe (for

mining the transmission properties of film membranes and

example, 0.3cm to 0.6cm thick, 10cm to 15cm diameter) is

sheeting over a range of permeability exceeding four orders of cut to form cylinders with height 2cm to 6cm.The volume of

magnitude. This test method is described here to measure the

the chamber affects the time to reach equilibrium; therefore,

permeability of films used in soil fumigation, but it is also

taller cylinders are appropriate for testing permeable films,

appropriate for other gases and membranes if the analytical

shortercylindersforlesspermeablefilms.Theendsofthepipe

methods are appropriately modified.

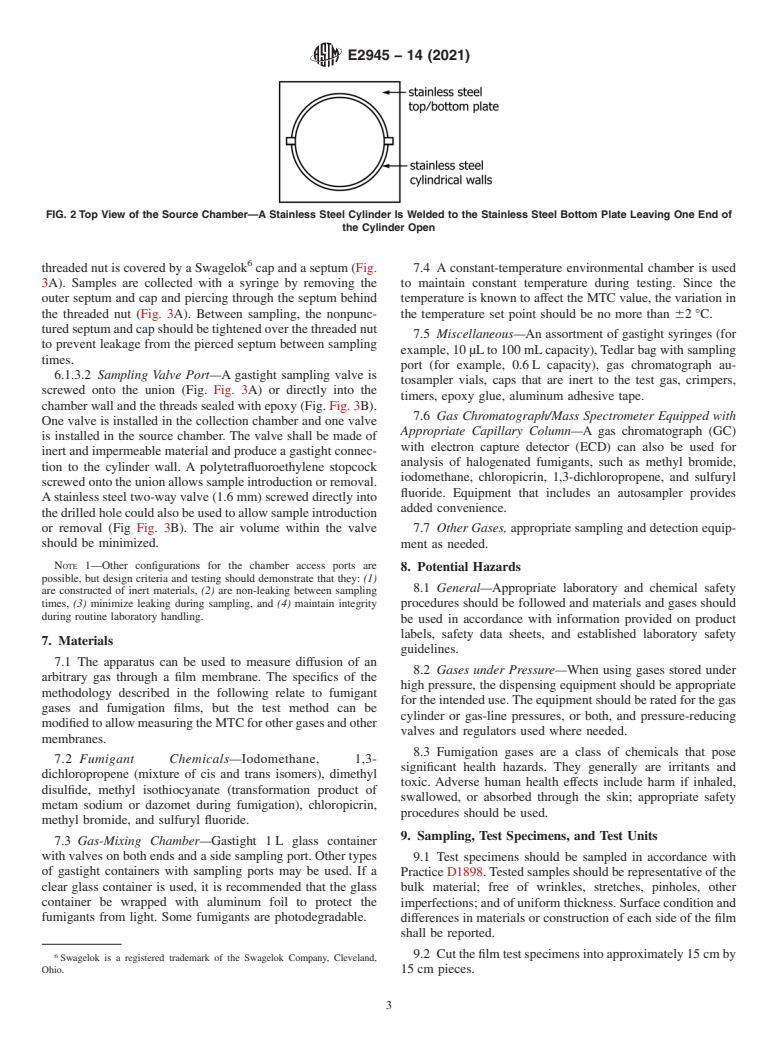

are trued and the mating surfaces smoothed. Each cylinder is

welded to a flat steel plate (for example, 0.3 cm thick) at one

5.2 This test method can be used for single or mixed

end, as shown in Fig. 2.

compounds. This test method uses small quantities of test

chemicals in vapor form, and microgram to milligram quanti-

6.1.2 Sampling Ports—Holesaredrilledandthreadedonthe

tiesofeachchemicalmayproduceasufficientamountofvapor

side of each cylinder to allow installation of sampling ports.

for each test depending on the analytical methods.

The holes should be located near the mid-point height of the

cylinder (Figs. 1 and 2).

5.3 Interlaboratory testing showed that the MTC estimated

by this test method is relatively insensitive to the laboratory 6.1.3 The purpose of the ports is to allow access to the

procedures.Theinterlaboratorytestinginvolvedmeasuringthe inside of the chamber for spiking and sampling. During other

MTCforseveralsoilfumigantcompoundsandawiderangeof times, ports should be sealed to prevent leakage. This can be

film permeability.Analysts with prior experience handling and accomplished using a septum port or sampling valve as

analyzing gaseous fumigant compounds had lower coefficients

described in 6.1.3.1 and 6.1.3.2.

of variation (10% to 20%) compared to less experienced

6.1.3.1 Septum Port—A 1.6mm steel (or brass) union con-

analysts (20% to 50%) based on triplicate tests. The coeffi-

nector is installed in each hole. Before installation, the threads

of the union are coated with epoxy to ensure a gastight seal.

One port is installed in the collection chamber and two ports

Papiernik, S. K., Yates, S. R., and Gan, J., “An approach for estimating the

permeability of agricultural films,” Environmental Science and Technology, Vol 35,

(on opposite sides of the cylinder) are installed in the source

2001, pp. 1240-1246.

chamber. The second port is used to vent the source chamber

Papiernik, S. K., Ernst, F. F., andYates, S. R., “An apparatus for measuring the

during spiking. A septum and threaded nut are installed onto

gas permeability of films,” Journal of Environmental Quality, Vol 31, 2002, pp.

358-361. the1.6mmunionandtheunionthreadscoatedwithepoxy.The

E2945 − 14 (2021)

FIG. 2 Top View of the Source Chamber—A Stainless Steel Cylinder Is Welded to the Stainless Steel Bottom Plate Leaving One End of

the Cylinder Open

threadednutiscoveredbyaSwagelok capandaseptum(Fig. 7.4 A constant-temperature environmental chamber is used

3A). Samples are collected with a syringe by removing the to maintain constant temperature during testing. Since the

outer septum and cap and piercing through the septum behind temperature is known to affect the MTC value, the variation in

the threaded nut (Fig. 3A). Between sampling, the nonpunc- the temperature set point should be no more than 62°C.

turedseptumandcapshouldbetightenedoverthethreadednut

7.5 Miscellaneous—An assortment of gastight syringes (for

to prevent leakage from the pierced septum between sampling

example,10µLto100mLcapacity),Tedlarbagwithsampling

times.

port (for example, 0.6L capacity), gas chromatograph au-

6.1.3.2 Sampling Valve Port—A gastight sampling valve is

tosampler vials, caps that are inert to the test gas, crimpers,

screwed onto the union (Fig. Fig. 3A) or directly into the

timers, epoxy glue, aluminum adhesive tape.

chamberwallandthethreadssealedwithepoxy(Fig.Fig.3B).

7.6 Gas Chromatograph/Mass Spectrometer Equipped with

One valve is installed in the collection chamber and one valve

Appropriate Capillary Column—A gas chromatograph (GC)

is installed in the source chamber. The valve shall be made of

with electron capture detector (ECD) can also be used for

inertandimpermeablematerialandproduceagastightconnec-

analysis of halogenated fumigants, such as methyl bromide,

tion to the cylinder wall. A polytetrafluoroethylene stopcock

iodomethane, chloropicrin, 1,3-dichloropropene, and sulfuryl

screwedontotheunionallowssampleintroductionorremoval.

fluoride. Equipment that includes an autosampler provides

Astainlesssteeltwo-wayvalve(1.6mm)screweddirectlyinto

added convenience.

thedrilledholecouldalsobeusedtoallowsampleintroduction

or removal (Fig Fig. 3B). The air volume within the valve 7.7 Other Gases, appropriate sampling and detection equip-

should be minimized.

ment as needed.

NOTE 1—Other configurations for the chamber access ports are

8. Potential Hazards

possible, but design criteria and testing should demonstrate that they: (1)

8.1 General—Appropriate laboratory and chemical safety

are constructed of inert materials, (2) are non-leaking between sampling

times, (3) minimize leaking during sampling, and (4) maintain integrity

procedures should be followed and materials and gases should

during routine laboratory handling.

be used in accordance with information provided on product

labels, safety data sheets, and established laboratory safety

7. Materials

guidelines.

7.1 The apparatus can be used to measure diffusion of an

8.2 Gases under Pressure—When using gases stored under

arbitrary gas through a film membrane. The specifics of the

high pressure, the dispensing equipment should be appropriate

methodology described in the following relate to fumigant

fortheintendeduse.Theequipmentshouldberatedforthegas

gases and fumigation films, but the test method can be

cylinder or gas-line pressures, or both, and pressure-reducing

modifiedtoallowmeasuringtheMTCforothergasesandother

valves and regulators used where needed.

membranes.

8.3 Fumigation gases are a class of chemicals that pose

7.2 Fumigant Chemicals—Iodomethane, 1,3-

significant health hazards. They generally are irritants and

dichloropropene (mixture of cis and trans isomers), dimethyl

toxic. Adverse human health effects include harm if inhaled,

disulfide, methyl isothiocyanate (transformation product of

swallowed, or absorbed through the skin; appropriate safety

metam sodium or dazomet during fumigation), chloropicrin,

procedures should be used.

methyl bromide, and sulfuryl fluoride.

9. Sampling, Test Specimens, and Test Units

7.3 Gas-Mixing Chamber—Gastight 1L glass container

withvalvesonbothendsandasidesamplingport.Othertypes

9.1 Test specimens should be sampled in accordance with

of gastight containers with sampling ports may be used. If a PracticeD1898.Testedsamplesshouldberepresentativeofthe

clear glass container is used, it is recommended that the glass

bulk material; free of wrinkles, stretches, pinholes, other

container be wrapped with aluminum foil to protect the imperfections;andofuniformthickness.Surfaceconditionand

fumigants from light. Some fumigants are photodegradable.

differences in materials or construction of each side of the film

shall be reported.

9.2 Cutthefilmtestspecimensintoapproximately15cmby

Swagelok is a registered trademark of the Swagelok Company, Cleveland,

Ohio. 15cm pieces.

E2945 − 14 (2021)

3A Sampling Port Design

3b Sampling Port Design

FIG. 3 Sampling Port Design

9.3 Information concerning the film composition (for 10.3 Replication—In general, triplicate permeability appa-

example, thickness, presence of ultraviolet [UV] stabilizers, ratuses are constructed for each test film and the MTC is

barrier polymers and additives, and so forth) and manufactur- calculated for each replicate. The average and st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.