ASTM D1696-95(2006)

(Test Method)Standard Test Method for Solubility of Cellulose in Sodium Hydroxide

Standard Test Method for Solubility of Cellulose in Sodium Hydroxide

SIGNIFICANCE AND USE

The measurement of soluble oxidizable components of cellulose in sodium hydroxide is indicative of the purity of the cellulose sample, since pure cellulose is insoluble in sodium hydroxide. The extracted components are typically hemicelluloses, which are naturally present in the wood. Differences in pulp purity can have a dramatic impact on the processing and properties of the cellulose derivatives produced from the pulp.

SCOPE

1.1 This test method is intended for application to dissolving-type cellulose pulps prepared from cotton or wood. The procedure is not directly applicable to unrefined pulps for use in chemical conversion processes because solubility equilibrium may not be attained within the specified extraction time.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1696–95(Reapproved2006)

Standard Test Method for

Solubility of Cellulose in Sodium Hydroxide

This standard is issued under the fixed designation D1696; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Summary of Test Method

1.1 This test method is intended for application to 3.1 Pulp is steeped in a sodium hydroxide solution of a

dissolving-type cellulose pulps prepared from cotton or wood. specified concentration for1hat 20°C. The soluble fraction is

The procedure is not directly applicable to unrefined pulps for estimated by dichromate oxidation of the filtered steeping

use in chemical conversion processes because solubility equi- alkali.The concentration of sodium hydroxide used in the pulp

librium may not be attained within the specified extraction extraction process must be reported as part of the analytical

time. result. Sodium hydroxide concentrations of 10, 18, and 21.5%

1.2 The values stated in SI units are to be regarded as are most frequently used. Data are reported as percent of dry

standard. No other units of measurement are included in this sample weight.

standard. 3.2 Theextractionprocedureavoidsdilutionsequences,and

1.3 This standard does not purport to address all of the therefore,theresultsarenotcomparabletodataobtainedbythe

safety concerns, if any, associated with its use. It is the alpha, beta, gamma methods of pulp fractionation (see TAPPI

responsibility of the user of this standard to consult and Method T429). The terms “alpha-,” “beta-,” or “gamma-”

establish appropriate safety and health practices and deter- cellulosemustnotbeappliedtoanytestvaluesobtainedbythis

mine the applicability of regulatory limitations prior to use. procedure since they are defined only by the method of their

determination.

2. Referenced Documents

3.3 Theessentialfeatureofthemethodistopreparesodium

2.1 ASTM Standards: hydroxide extracts and oxidize the soluble material with

D1193 Specification for Reagent Water

dichromate as described. Alternative methods of estimating

D1347 Test Methods for Methylcellulose dichromate by titration with ferrous ammonium sulfate and

D1348 Test Methods for Moisture in Cellulose

sodium thiosulfate are described.

2.2 TAPPI Standard:

4. Significance and Use

T 429 Method for Alpha-Cellulose in Paper

4.1 The measurement of soluble oxidizable components of

cellulose in sodium hydroxide is indicative of the purity of the

cellulose sample, since pure cellulose is insoluble in sodium

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

hydroxide. The extracted components are typically hemicellu-

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

loses, which are naturally present in the wood. Differences in

Current edition approved April 1, 2006. Published April 2006. Originally

pulp purity can have a dramatic impact on the processing and

approved in 1959. Last previous edition approved in 2000 as D1696–95(2000).

DOI: 10.1520/D1696-95R06. properties of the cellulose derivatives produced from the pulp.

This test method is an adaptation of the method designated CCA 8:55 by the

Analysis Committee of the Central Committee of the Cellulose Industry of the

5. Apparatus

Swedish Association of Pulp and Paper Engineers. This test method is also

5.1 Constant-Temperature Bath—A water bath maintained

comparable with the TAPPI Tentative Standard T235 m-58, Solubility of Pulp in

Cold Sodium Hydroxide.

at 20 6 0.2°C.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

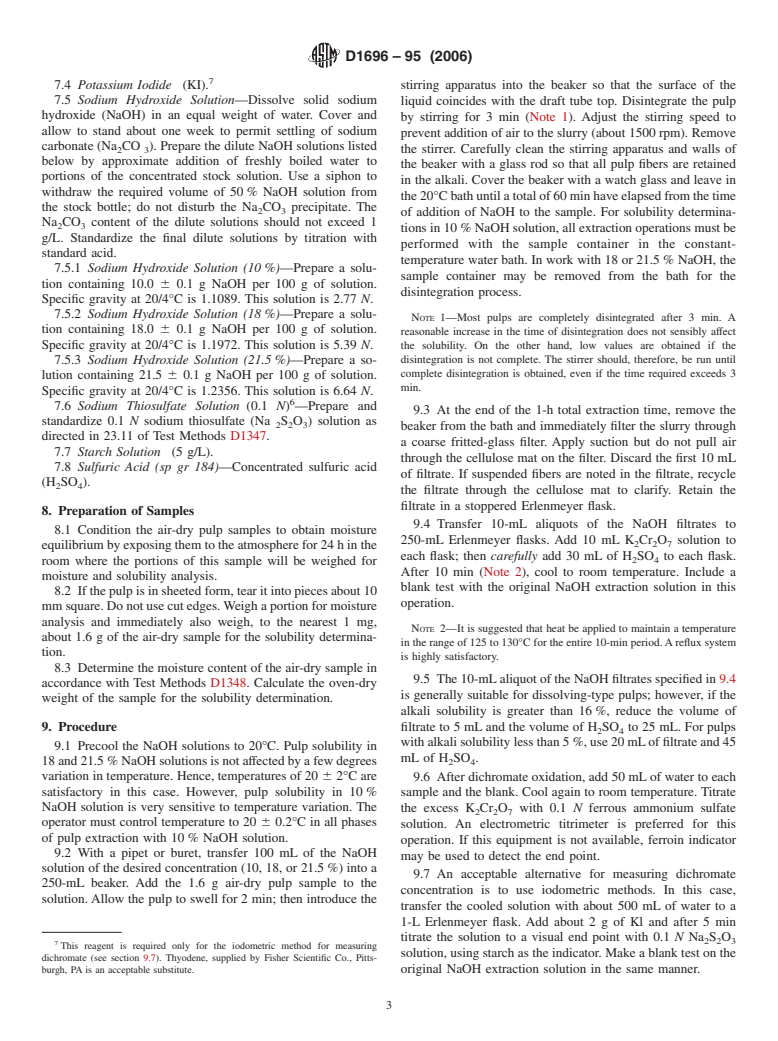

5.2 Stirrer—Mechanical stirrer as shown in Fig. 1.All parts

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in contact with solutions must be of stainless steel. The stirrer

Standards volume information, refer to the standard’s Document Summary page on

motor shall be a variable speed laboratory motor with 1500

the ASTM website.

Withdrawn. The last approved version of this historical standard is referenced

rpm max speed.

on www.astm.org.

5.3 Fritted-Glass Filter Crucible— A fritted-glass filter

Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

crucible, coarse porosity (pore size 40 to 60 µm), of 30-mL

P.O.Box105113,Atlanta,GA30348;15TechnologyParkwaySouth,Norcross,GA

30092. capacity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1696–95 (2006)

Metric Equivalents

1 1 1 3 1 1 5

in. ⁄8 ⁄4 ⁄2 ⁄4 1 3 ⁄4 6 ⁄2 8 ⁄8

mm 3.2 6.4 12.7 19.0 25.4 82.6 165.1 219.1

FIG. 1 Design Details of Mechanical Stirrer

5.4 Electrometric Titration Apparatus— For estimation of 6.2 Unless otherwise indicated, references to water shall be

dichromate by titration with ferrous ammonium sulfate. An understood to mean reagent water conforming to Specification

indicator may be used as described in 8.6, but for rapid, D1193.

accurate analysis an electrometric apparatus is recommended.

7. Reagents

6. Purity of Reagents

7.1 Ferroin (0.025 M)—Dissolve 1.48 g of orthophenan-

6.1 Reagent grade chemicals shall be used in all tests.

throline monohydrate (or 1.624 g of the hydrochloride) with

Unlessotherwiseindicated,itisintendedthatallreagentsshall

0.695 g of ferrous sulfate (FeSO ) in water and dilute to 100

conform to the specifications of the Committee on Analytical

6 mL.

Reagents of the American Chemical Society, where such

7.2 Ferrous Ammonium Sulfate Solution (0.1 N)—Dissolve

specifications are available. Other grades may be used, pro-

40 to 41 g of ferrous ammonium sulfate (FeSO (NH ) -SO

vided it is first ascertained that the reagent is of sufficiently

4 4 2

4·6H O) in water containing 10 mL of H SO and dilute to 1

high purity to permit its use without lessening the accuracy of

2 2 4

the determination. litre in a volumetric flask. Standardize the solution daily

against potassium permanganate (KMnO ).

7.3 Potassium Dichromate Solution (20 g/L)—Weigh20.0g

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

of potassium dichromate (K Cr O ), transfer to a 2-L beaker,

2 2 7

listed by the American Chemical Society, see Analar Standards for Laboratory

and dissolve in approximately 700 mL of water. Add, with

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

constant stirring, 150 mL of H SO . Allow to cool to room

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, 2 4

MD. temperature. Dilute to 1 L with water.

D1696–95 (2006)

7.4 Potassium Iodide (KI). stirring apparatus into the beaker so that the surface of the

7.5 Sodium Hydroxide Solution—Dissolve solid sodium liquid coincides with the draft tube top. Disintegrate the pulp

hydroxide (NaOH) in an equal weight of water. Cover and

by stirring for 3 min (Note 1). Adjust the stirring speed to

allow to stand about one week to permit settling of sodium

prevent addition of air to the slurry (about 1500 rpm). Remove

carbonate (Na CO ). Prepare the dilute NaOH solutions listed

2 3 the stirrer. Carefully clean the stirring apparatus and walls of

below by approximate addition of freshly boiled water to

the beaker with a glass rod so that all pulp fibers are retained

portions of the concentrated stock solution. Use a siphon to

in the alkali. Cover the beaker with a watch glass and leave in

withdraw the required volume of 50% NaOH solution from

the20°Cbathuntilatotalof60minhaveelapsedfromthetime

the stock bottle; do not disturb the Na CO precipitate. The

2 3

of addition of NaOH to the sample. For solubility determina-

Na CO content of the dilute solutions should not exceed 1

2 3

tionsin10%NaOHsolution,allextractionoperationsmustbe

g/L. Standardize the final dilute solutions by titration with

performed with the sample container in the constant-

standard acid.

temperature water bath. In work with 18 or 21.5% NaOH, the

7.5.1 Sodium Hydroxide Solution (10 %)—Prepare a solu-

sample container may be removed from the bath for the

tion containing 10.0 6 0.1 g NaOH per 100 g of solution.

disintegration

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.