ASTM D3487-00(2006)

(Specification)Standard Specification for Mineral Insulating Oil Used in Electrical Apparatus

Standard Specification for Mineral Insulating Oil Used in Electrical Apparatus

ABSTRACT

This specification covers two types of new mineral insulating oils of petroleum origin for use as an insulating and cooling medium in new and existing power and distribution electrical apparatus, such as transformers, regulators, reactors, circuit breakers, switchgear, and attendant equipment. It is the intension of this specification to define a mineral insulating oil that is functionally interchangeable and miscible with existing oils, is compatible with existing apparatus and with appropriate field maintenance, and will satisfactorily maintain its functional characteristics in its application in electrical equipment. Type I mineral oils are used for apparatus where normal oxidation resistance is required, where as, Type II mineral oils are used for apparatus where greater oxidation resistance is required. When examined with corresponding test methods, sampled specimens shall conform accordingly to physical (aniline point, color, flash point, interfacial tension, pour point, relative density or specific gravity, viscosity, and appearance), electrical (dielectric breakdown voltage, gassing tendency, and dissipation or power factor), and chemical (oxidation stability, oxidation inhibitor content, corrosive sulfur content, water content, neutralization number, and PCB content) property requirements.

SCOPE

1.1 This specification covers new mineral insulating oil of petroleum origin for use as an insulating and cooling medium in new and existing power and distribution electrical apparatus, such as transformers, regulators, reactors, circuit breakers, switchgear, and attendant equipment.

1.2 This specification is intended to define a mineral insulating oil that is functionally interchangeable and miscible with existing oils, is compatible with existing apparatus and with appropriate field maintenance, and will satisfactorily maintain its functional characteristics in its application in electrical equipment. This specification applies only to new insulating oil as received prior to any processing.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3487 – 00 (Reapproved 2006)

Standard Specification for

Mineral Insulating Oil Used in Electrical Apparatus

This standard is issued under the fixed designation D 3487; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D877 Test Method for Dielectric Breakdown Voltage of

Insulating Liquids Using Disk Electrodes

1.1 This specification covers new mineral insulating oil of

D923 Practices for Sampling Electrical Insulating Liquids

petroleum origin for use as an insulating and cooling medium

D924 TestMethodforDissipationFactor(orPowerFactor)

innewandexistingpoweranddistributionelectricalapparatus,

and Relative Permittivity (Dielectric Constant) of Electri-

such as transformers, regulators, reactors, circuit breakers,

cal Insulating Liquids

switchgear, and attendant equipment.

D971 Test Method for Interfacial Tension of Oil Against

1.2 This specification is intended to define a mineral insu-

Water by the Ring Method

latingoilthatisfunctionallyinterchangeableandmisciblewith

D974 Test Method for Acid and Base Number by Color-

existing oils, is compatible with existing apparatus and with

2 Indicator Titration

appropriate field maintenance, and will satisfactorily main-

D1275 Test Method for Corrosive Sulfur in Electrical

tain its functional characteristics in its application in electrical

Insulating Oils

equipment.Thisspecificationappliesonlytonewinsulatingoil

D1298 TestMethodforDensity,RelativeDensity(Specific

as received prior to any processing.

Gravity), or API Gravity of Crude Petroleum and Liquid

2. Referenced Documents

Petroleum Products by Hydrometer Method

D1500 Test Method for ASTM Color of Petroleum Prod-

2.1 ASTM Standards:

ucts (ASTM Color Scale)

D88 Test Method for Saybolt Viscosity

D1524 Test Method for Visual Examination of Used Elec-

D92 Test Method for Flash and Fire Points by Cleveland

trical Insulating Oils of Petroleum Origin in the Field

Open Cup Tester

D1533 Test Method for Water in Insulating Liquids by

D97 Test Method for Pour Point of Petroleum Products

Coulometric Karl Fischer Titration

D445 Test Method for Kinematic Viscosity of Transparent

D1816 Test Method for Dielectric Breakdown Voltage of

and Opaque Liquids (and Calculation of Dynamic Viscos-

InsulatingOilsofPetroleumOriginUsingVDEElectrodes

ity)

D1903 Test Method for Coefficient of Thermal Expansion

D611 Test Methods for Aniline Point and Mixed Aniline

of Electrical Insulating Liquids of Petroleum Origin, and

Point of Petroleum Products and Hydrocarbon Solvents

Askarels

D2112 Test Method for Oxidation Stability of Inhibited

Mineral Insulating Oil by Pressure Vessel

This specification is under the jurisdiction of ASTM Committee D27 on

D2300 Test Method for Gassing of Electrical Insulating

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

Liquids Under Electrical Stress and Ionization (Modified

mittee D27.01 on Mineral.

Current edition approved Sept. 1, 2006. Published September 2006. Originally Pirelli Method)

approved in 1976. Last previous edition approved in 2000 as D3487–00.

D2440 Test Method for Oxidation Stability of Mineral

Refer to American National Standard C57.106. Guide for Acceptance and

Insulating Oil

Maintenance of Insulating Oil in Equipment (IEEE Standard64). Available from

D2668 Test Method for 2,6-di-tert-Butyl- p-Cresol and

AmericanNationalStandardsInstitute(ANSI),25W.43rdSt.,4thFloor,NewYork,

NY 10036, http://www.ansi.org.

2,6-di-tert-Butyl Phenol in Electrical Insulating Oil by

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Infrared Absorption

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D2717 Test Method for Thermal Conductivity of Liquids

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. D2766 TestMethodforSpecificHeatofLiquidsandSolids

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3487 – 00 (2006)

If temperatures higher than those recommended for the operating

D3300 Test Method for Dielectric Breakdown Voltage of

pressure are used, the oil should be tested for inhibitor content and

Insulating Oils of Petroleum Origin Under Impulse Con-

inhibitor added as necessary to return inhibitor content to its initial value.

ditions

Attempts to dry apparatus containing appreciable amounts of free water

D4059 TestMethodforAnalysisofPolychlorinatedBiphe-

may result in a significant loss of inhibitor even at the conditions

nyls in Insulating Liquids by Gas Chromatography

recommended above.

D4768 Test Method for Analysis of 2,6-Ditertiary-Butyl

3.3 additives—chemical substances that are added to min-

Para-Cresol and 2,6-Ditertiary-Butyl Phenol in Insulating

eral insulating oil to achieve required functional properties.

Liquids by Gas Chromatography

3.4 properties—those properties of the mineral insulating

D5837 Test Method for Furanic Compounds in Electrical

oil which are required for the design, manufacture, and

Insulating Liquids by High-Performance Liquid Chroma-

operation of the apparatus. These properties are listed in

tography (HPLC)

Section 5.

3. Terminology Definitions

4. Sampling and Testing

3.1 Type I Mineral Oil—an oil for apparatus where normal

4.1 Take all oil samples in accordance with Test Methods

oxidation resistance is required. Some oils may require the

D923.

addition of a suitable oxidation inhibitor to achieve this.

4.2 Make each test in accordance with the latest revision of

3.2 Type II Mineral Oil—an oil for apparatus where greater

the ASTM test method specified in Section 5.

oxidation resistance is required. This is usually achieved with

4.3 The oil shall meet the requirements of Section 5 at the

the addition of a suitable oxidation inhibitor.

unloading point.

NOTE 1—During processing of inhibited mineral oil under vacuum and

NOTE 2—Because of the different needs of the various users, items

elevated temperatures, partial loss of inhibitor and volatile portions of

relatingtopackaging,labeling,andinspectionareconsideredtobesubject

mineral oil may occur. The common inhibitors, 2,6-ditertiary-butyl

to buyer-seller agreement.

para-cresol and 2,6-ditertiary-butyl phenol, are more volatile than trans-

NOTE 3—In addition to all other tests listed herein, it is sound

former oil. If processing conditions are too severe, oxidation stability of

engineering practice for the apparatus manufacturer to perform an

the oil may be decreased due to loss of inhibitor. The selectivity for

evaluation of new types of insulating oils in insulation systems, prototype

removal of moisture and air in preference to loss of inhibitor and oil is

structures, or full-scale apparatus, or any combination thereof, to assure

improved by use of a low processing temperature.

suitable service life.

Conditions that have been found satisfactory for most inhibited mineral

oil processing are:

4.4 Make known to the user the generic type and amount of

Minimum Pressure

any additive used, for assessing any potential detrimental

Temperature, °C Pa Torr, Approximate

reaction with other materials in contact with the oil.

40 5 0.04

50 10 0.075

60 20 0.15 5. Property Requirements

70 40 0.3

5.1 Mineral insulating oil conforming to this specification

80 100 0.75

90 400 3.0 shallmeetthepropertylimitsgiveninTable1.Thesignificance

100 1000 7.5

of these properties is discussed in Appendix X2.

D 3487 – 00 (2006)

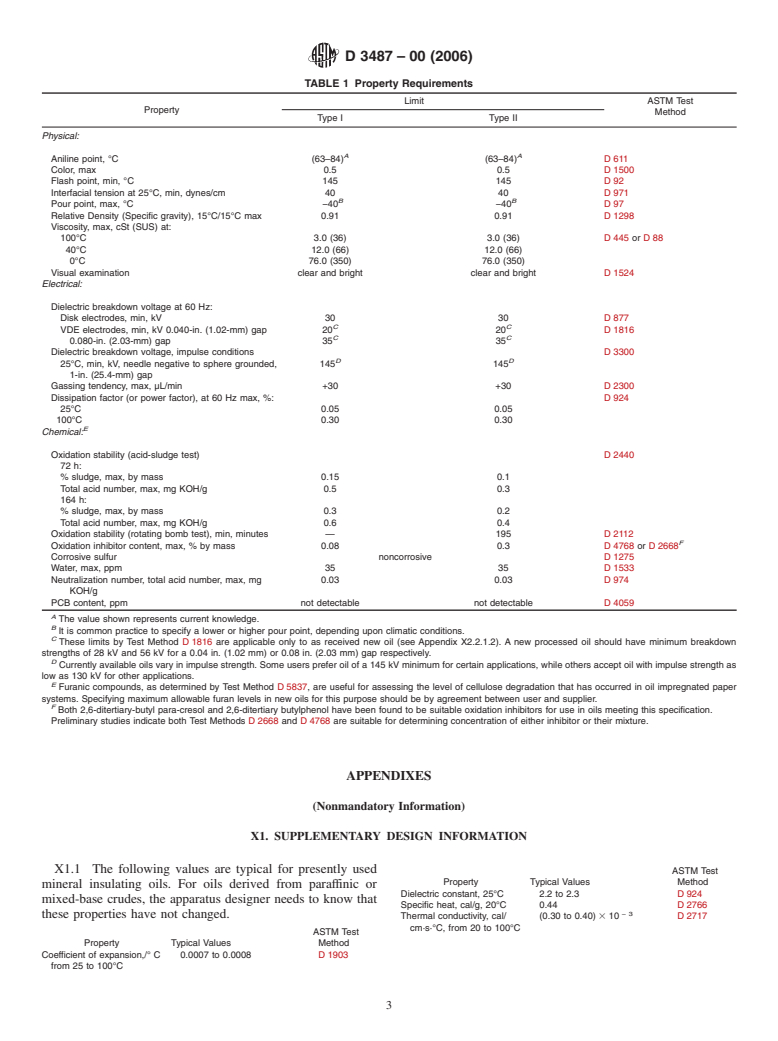

TABLE 1 Property Requirements

Limit ASTM Test

Property

Method

Type I Type II

Physical:

A A

Aniline point, °C (63–84) (63–84) D611

Color, max 0.5 0.5 D 1500

Flash point, min, °C 145 145 D92

Interfacial tension at 25°C, min, dynes/cm 40 40 D 971

B B

Pour point, max, °C −40 −40 D97

Relative Density (Specific gravity), 15°C/15°C max 0.91 0.91 D 1298

Viscosity, max, cSt (SUS) at:

100°C 3.0 (36) 3.0 (36) D 445 or D88

40°C 12.0 (66) 12.0 (66)

0°C 76.0 (350) 76.0 (350)

Visual examination clear and bright clear and bright D 1524

Electrical:

Dielectric breakdown voltage at 60 Hz:

Disk electrodes, min, kV 30 30 D 877

C C

VDE electrodes, min, kV 0.040-in. (1.02-mm) gap 20 20 D 1816

C C

0.080-in. (2.03-mm) gap 35 35

Dielectric breakdown voltage, impulse conditions D 3300

D D

25°C, min, kV, needle negative to sphere grounded, 145 145

1-in. (25.4-mm) gap

Gassing tendency, max, µL/min +30 +30 D 2300

Dissipation factor (or power factor), at 60 Hz max, %: D 924

25°C 0.05 0.05

100°C 0.30 0.30

E

Chemical:

Oxidation stability (acid-sludge test) D 2440

72 h:

% sludge, max, by mass 0.15 0.1

Total acid number, max, mg KOH/g 0.5 0.3

164 h:

% sludge, max, by mass 0.3 0.2

Total acid number, max, mg KOH/g 0.6 0.4

Oxidation stability (rotating bomb test), min, minutes — 195 D2112

F

Oxidation inhibitor content, max, % by mass 0.08 0.3 D 4768 or D 2668

Corrosive sulfur noncorrosive D 1275

Water, max, ppm 35 35 D 1533

Neutralization number, total acid number, max, mg 0.03 0.03 D 974

KOH/g

PCB content, ppm not detectable not detectable D 4059

A

The value shown represents current knowledge.

B

It is common practice to specify a lower or higher pour point, depending upon climatic conditions.

C

These limits by Test Method D 1816 are applicable only to as received new oil (see Appendix X2.2.1.2). A new processed oil should have minimum breakdown

strengths of 28 kV and 56 kV for a 0.04 in. (1.02 mm) or 0.08 in. (2.03 mm) gap respectively.

D

Currently available oils vary in impulse strength. Some users prefer oil of a 145 kV minimum for certain applications, while others accept oil with impulse strength as

low as 130 kV for other applications.

E

Furanic compounds, as determined by Test Method D 5837, are useful for assessing the level of cellulose degradation that has occurred in oil impregnated paper

systems. Specifying maximum allowable furan levels in new oils for this purpose should be by agreement between user and supplier.

F

Both 2,6-ditertiary-butyl para-cresol and 2,6-ditertiary butylphenol have been found to be suitable oxidation inhibitors for use in oils meeting this specification.

Preliminary studies indicate both Test Methods D 2668 and D 4768 are suitable for determining concentration of either inhibitor or their mixture.

APPEN

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.