ASTM D1675-18

(Test Method)Standard Test Methods for Polytetrafluoroethylene Tubing

Standard Test Methods for Polytetrafluoroethylene Tubing

SIGNIFICANCE AND USE

4.1 The test methods in this standard are considered important to characterize polytetrafluoroethylene tubing. They are intended primarily for, but not limited to polytetrafluoroethylene tubing.

4.2 Variations in these methods or alternate contemporary methods of measurement may be used to determine the values for the properties in this standard provided such methods ensure quality levels and measurement accuracy equal to or better than those prescribed herein. It is the responsibility of the organizations using alternate test methods to be able to demonstrate this condition. In cases of dispute, the methods specified herein shall be used.

Note 2: Provision for alternate methods is necessary because of (1) the desire to simplify procedures for specific applications, and (2) the desire to eliminate redundant testing and use data generated during manufacturing process control, including that generated under Statistical Process Control (SPC) conditions, using equipment and methods other than those specified herein. An example would be the use of laser micrometers or optical comparators to measure dimensions.

SCOPE

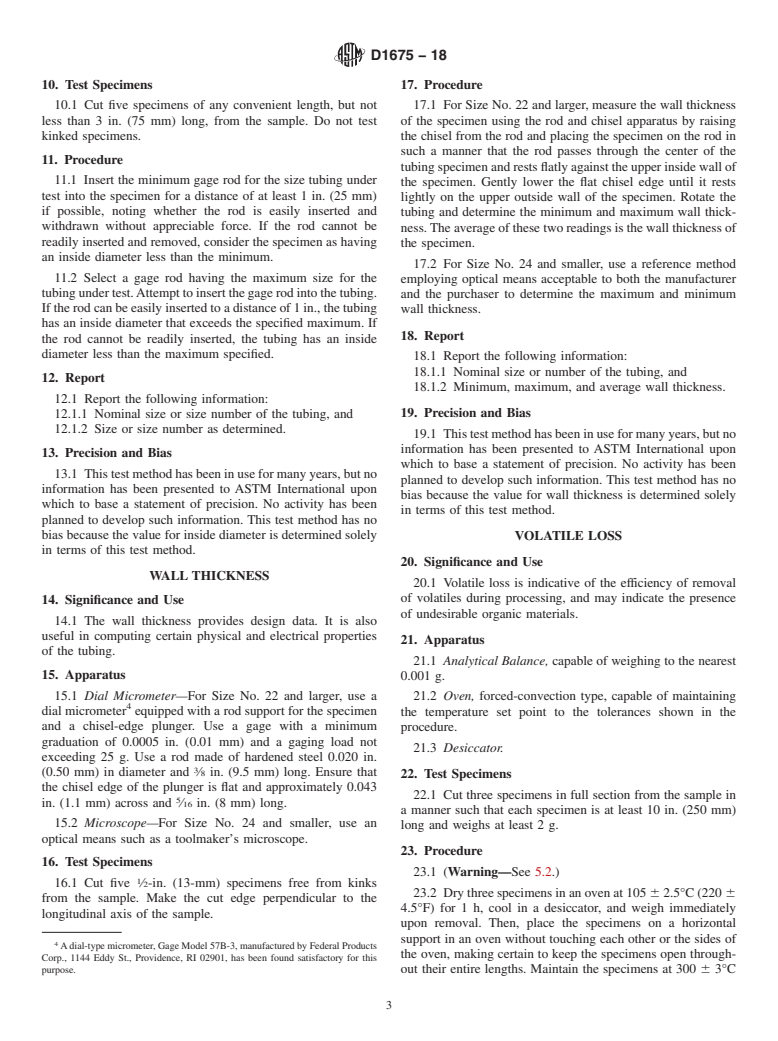

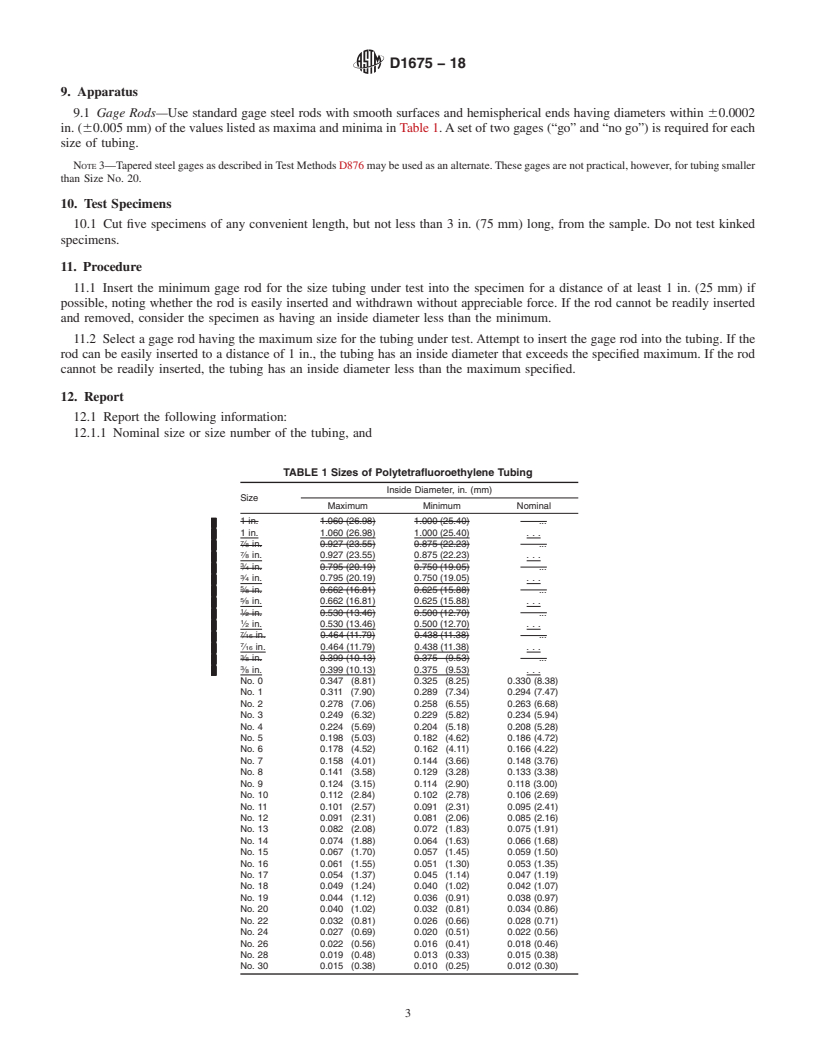

1.1 These test methods cover procedures for testing polytetrafluoroethylene tubing for use as electrical insulation. The procedures appear in the following sections:

Procedure

Sections

ASTM

Methods

Conditioning

7

...

Dielectric Breakdown Voltage

28 – 30

D149, D876

Inside Diameter

8 – 13

D876

Mandrel Bend Test

46 – 52

D149, D876

Melting Point

41 – 45

D3418, D4895

Penetration Test

26 and 27

D876

Specific Gravity

36 – 40

D792, D1505

Strain Relief

31 – 35

...

Volatile Loss

20 – 25

...

Wall Thickness

14 – 19

...

Note 1: These test methods are similar but not identical to those in IEC 60684–2.

1.2 The values stated in inch-pound units are the standard except for temperature, which is stated in degrees Celsius. Values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1675 −18

Standard Test Methods for

1

Polytetrafluoroethylene Tubing

This standard is issued under the fixed designation D1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 These test methods cover procedures for testing poly- 2.1 ASTM Standards:

tetrafluoroethylene tubing for use as electrical insulation. The D149 Test Method for Dielectric Breakdown Voltage and

procedures appear in the following sections: Dielectric Strength of Solid Electrical Insulating Materials

at Commercial Power Frequencies

ASTM

Procedure Sections Methods

D792 Test Methods for Density and Specific Gravity (Rela-

tive Density) of Plastics by Displacement

Conditioning 7 .

D876 Test Methods for Nonrigid Vinyl Chloride Polymer

Dielectric Breakdown Voltage 28 – 30 D149, D876

Inside Diameter 8 – 13 D876

Tubing Used for Electrical Insulation

Mandrel Bend Test 46 – 52 D149, D876

D1505 Test Method for Density of Plastics by the Density-

Melting Point 41 – 45 D3418, D4895

Gradient Technique

Penetration Test 26 and 27 D876

Specific Gravity 36 – 40 D792, D1505

D1711 Terminology Relating to Electrical Insulation

Strain Relief 31–35 .

D3418 Test Method for Transition Temperatures and En-

Volatile Loss 20–25 .

thalpies of Fusion and Crystallization of Polymers by

Wall Thickness 14–19 .

Differential Scanning Calorimetry

NOTE 1—These test methods are similar but not identical to those in

D3487 Specification for Mineral Insulating Oil Used in

IEC 60684–2.

Electrical Apparatus

1.2 The values stated in inch-pound units are the standard

D4895 Specification for Polytetrafluoroethylene (PTFE)

except for temperature, which is stated in degrees Celsius.

Resin Produced From Dispersion

Values in parentheses are for information only.

E176 Terminology of Fire Standards

1.3 This standard does not purport to address all of the

2.2 IEC Standards

safety concerns, if any, associated with its use. It is the

60684–2 Flexible Insulating Sleeves—Part 2: Methods of

responsibility of the user of this standard to establish appro- 3

Test

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3. Terminology

For specific warning statements, see Section 5.

3.1 Definitions:

1.4 This international standard was developed in accor-

3.1.1 For definitions pertaining to electrical insulation, refer

dance with internationally recognized principles on standard-

to Terminology D1711.

ization established in the Decision on Principles for the

3.1.2 For definitions pertaining to fire standards, refer to

Development of International Standards, Guides and Recom-

Terminology E176.

mendations issued by the World Trade Organization Technical

3.2 Definitions of Terms Specific to This Standard:

Barriers to Trade (TBT) Committee.

1 2

These test methods are under the jurisdiction of ASTM Committee D09 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical and Electronic Insulating Materials and are the direct responsibility of contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Subcommittee D09.07 on Electrical Insulating Materials. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2018. Published May 2018. Originally the ASTM website.

3

approved in 1959. Last previous edition approved in 2011 as D1675 – 03 (2011). Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/D1675-18. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1675 − 18

3.2.1 apparent melting point, n—the temperature at which 6.2 In the case of material offered in cut lengths, do not

the appearance of the plastic changes from opaque to transpar- prepare specimens from samples of material closer than 1 in.

ent. (25 mm) from each end.

3.2.2 strain relief, n—a dimensional change brought about

6.3 Do not use specimens with obvious defects unless the

by subjecting the tubing to an elevated temperature.

purpose of the test is to determine the effects of these defects.

3.2.3 volatile

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1675 − 03 (Reapproved 2011) D1675 − 18

Standard Test Methods for

1

Polytetrafluoroethylene Tubing

This standard is issued under the fixed designation D1675; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 These test methods cover procedures for testing polytetrafluoroethylene tubing for use as electrical insulation. The

procedures appear in the following sections:

ASTM

Procedure Sections Methods

Conditioning 7 .

Dielectric Breakdown Voltage 28 – 30 D149, D876

Inside Diameter 8 – 13 D876

Mandrel Bend Test 46 – 52 D149, D876

Melting Point 41 – 45 D3418, D4895

Penetration Test 26 and 27 D876

Specific Gravity 36 – 40 D792, D1505

Strain Relief 31 – 35 .

Volatile Loss 20 – 25 .

Wall Thickness 14 – 19 .

NOTE 1—These test methods are similar but not identical to those in IEC 60684–2.

1.2 The values stated in inch-pound units are the standard except for temperature, which is stated in degrees Celsius. Values in

parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific warning statements, see Section 5.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D876 Test Methods for Nonrigid Vinyl Chloride Polymer Tubing Used for Electrical Insulation

D1505 Test Method for Density of Plastics by the Density-Gradient Technique

D1711 Terminology Relating to Electrical Insulation

D3418 Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential

Scanning Calorimetry

D3487 Specification for Mineral Insulating Oil Used in Electrical Apparatus

D4895 Specification for Polytetrafluoroethylene (PTFE) Resin Produced From Dispersion

E176 Terminology of Fire Standards

1

These test methods are under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and are the direct responsibility of Subcommittee

D09.07 on Flexible and Rigid Electrical Insulating Materials.

Current edition approved Aug. 1, 2011May 1, 2018. Published August 2011May 2018. Originally approved in 1959. Last previous edition approved in 20032011 as

D1675 – 03.D1675 – 03 (2011). DOI: 10.1520/D1675-03R11.10.1520/D1675-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1675 − 18

2.2 IEC Standards

3

60684–2 Flexible Insulating Sleeves—Part 2: Methods of Test

3. Terminology

3.1 Definitions:

3.1.1 For definitions pertaining to electrical insulation, refer to Terminology D1711.

3.1.2 For definitions pertaining to fire standards, refer to Terminology E176.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 apparent melting point, n—the temperature at which the appearance of the plastic changes from opaque to transparent.

3.2.2 strain relief, n—a dimensional change brought about by subjecting the tubing to an elevated temperature.

3.2.3 volatile loss, n—the reduction in weight by vaporization under controlled conditions.

4. Significance and Use

4.1 The test methods in this standard are considered important

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.