ASTM E1084-86(1996)

(Test Method)Standard Test Method for Solar Transmittance (Terrestrial) of Sheet Materials Using Sunlight

Standard Test Method for Solar Transmittance (Terrestrial) of Sheet Materials Using Sunlight

SCOPE

1.1 This test method covers the measurement of solar transmittance (terrestrial) of materials in sheet form by using a pyranometer, an enclosure, and the sun as the energy source.

1.2 This test method also allows measurement of solar transmittance at angles other than normal incidence.

1.3 This test method is applicable to sheet materials that are transparent, translucent, textured, or patterned.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1084 – 86 (Reapproved 1996)

Standard Test Method for

Solar Transmittance (Terrestrial) of Sheet Materials Using

Sunlight

This standard is issued under the fixed designation E 1084; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the measurement of solar 4.1 Using a pyranometer to measure the solar irradiance, the

transmittance (terrestrial) of materials in sheet form by using a test specimen is inserted in the path of the rays from the sun to

pyranometer, an enclosure, and the sun as the energy source. the pyranometer. An enclosure with a nonreflecting bottom is

1.2 This test method also allows measurement of solar used to avoid measuring flux from around the edges of the

transmittance at angles other than normal incidence. specimen or from multiple reflections between the box and the

1.3 This test method is applicable to sheet materials that are specimen. The transmittance is the ratio of the flux measured

transparent, translucent, textured, or patterned. with the specimen in the light path to the flux measured without

1.4 This standard does not purport to address all of the the specimen in the path.

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Solar transmittance is an important factor in the admis-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. sion of energy through fenestration, collector glazing, and

protective envelopes. This test method provides a means of

2. Referenced Documents

measuring this factor under fixed conditions. While the data

2.1 ASTM Standards: may be of assistance to designers in the selection and specifi-

E 284 Terminology of Appearance cation of glazing materials, the solar transmittance is not

E 772 Terminology Relating to Solar Energy Conversion sufficient to define the rate of net heat transfer without

2.2 Other Document: information on other important factors.

ASHRAE Handbook of Fundamentals 5.2 This test method has been found practical for both

transparent and translucent materials, as well as for those with

3. Terminology

transmittance reduced by highly reflective coatings. This test

3.1 Definitions:

method is particularly applicable to the measurement of

3.1.1 pyranometer, n—a radiometer used to measure the transmittance of inhomogeneous, fiber reinforced, patterned, or

total solar radiant energy incident upon a surface per unit time

corrugated materials since the transmittance is averaged over a

per unit area. This energy includes the direct radiant energy, large area.

diffuse radiant energy, and reflected radiant energy from the 5.3 This test method may be used to measure transmittance

background.

of glazing materials at angles up to 60° off normal incidence.

3.1.2 solar reflectance, n—the ratio of reflected to incident

NOTE 1—A technique similar to the one described but using a pyrhe-

solar flux.

liometer has been used for the measurement of specular solar reflectance;

3.1.3 solar transmittance, n—the ratio of transmitted to

however, there is insufficient experience with this technique for standard-

incident solar flux.

ization at present.

3.2 Definitions of Terms Specific to This Standard:

6. Apparatus

3.2.1 solar flux, n—the total radiation from the sun, both

direct and diffuse. 6.1 Enclosure—The required apparatus is a box capable of

supporting a 0.60 m (24 in.) square specimen. The box shall

have a square, clear aperture of no less than 0.50 m by 0.50 m

These test methods are under the jurisdiction of ASTM Committee E44 on

Solar, Geothermal, and Other Alternative Energy Sources and is the direct (20 in. by 20 in.). The enclosure shall have provisions to hold

responsibility of Subcommittee E44.05 on Solar Heating and Cooling Subsystems

specimens planar across the aperture with the additional

and Systems.

capability to remove and replace the specimen easily during the

Current edition approved Feb. 21, 1986. Published April 1986.

measurement process. It shall also have the capability to move

Annual Book of ASTM Standards, Vol 06.01.

Annual Book of ASTM Standards, Vol 12.02.

the specimen across the aperture in a systematic way. Light

Available from American Society of Heating, Refrigerating, and Air Condi-

baffled air vents at the top and bottom of the enclosure are

tioning Engineers, 1791 Tullie Circle N.E., Atlanta, GA 30329.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1084

ventionally mirrored glass. For highly diffusing materials, a box with the

recommended to aid cooling of all components when a

specified aperture and blackened side walls, the test method could

specimen is in place. The inside of the box shall have side walls

underestimate the transmittance by up to 0.03. Using highly reflecting side

covered with mirrors having specular, solar reflectance greater

walls on the interior of the enclosure reduces this error for such materials

than 0.85 that extend from the opening down to the plane of the

to less than 0.01 transmittance unit. For highly specular materials, this

sensor element. Therest of the inside of the box shall be

error is negligible.

blackened so that its solar reflectance is less than 0.10. A

NOTE 3—For an enclosure with a highly reflecting bottom, the mea-

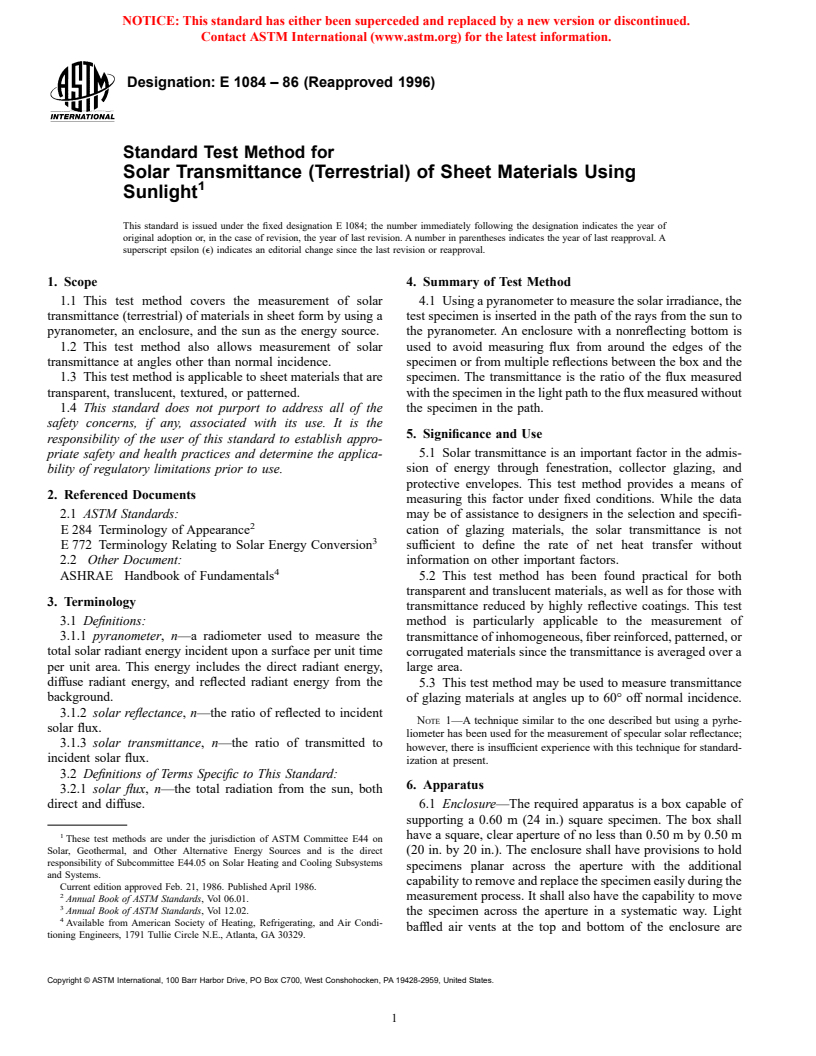

typical unit is shown in Fig. 1.

sured transmittance could be greater than 0.05 too high due to multiple

NOTE 2—Mirrors having the necessary specular reflectance are bright reflections. A blackened bottom having less than 0.10 reflectance will hold

anodized aluminum lighting sheet, aluminized polymer films, and con-

(A) Specular mirror, 500 3 50 mm. (J) Standard 2 3 4 in. wood framing, 75 mm long (bottom to center of hole)

(B) Nonreflecting, black bottom. Nontransmitting louvers or multiple layers of grill (K) Rectangular, ⁄4 in. plywood, 500 3 75 mm.

cloth that allow air circulation into the enclosure are preferable.

(C) Pyranometer (L) ⁄2 3 2 in. carriage bolt with wing and washer.

(D) Support shelf for pyranometer. The height of the shelf will depend on the (M) ⁄4 in. iron pipe.

pyranometer used.

(E) Semicircular disk 538 mm diameter out of ⁄4in plywood. (N) U-bolts.

(F) Semicircular tracker with scale (P) Primary tracking axis, aligned parallel to earth’s axis of rotation. The axis shall

make an angle with the vertical equal to the local latitude and point toward the

North Star.

(G) Lip of flange turned up to 20 mm to help support specimens (Q) C-clamp attached to arm to lock equatorial angle during measurements.

(H) 50 mm flange bent out of sheet metal or cut from wood. Top surface is (R) Vertical support post approximately 1 m long. Made from standard 2 36ft

painted back to prevent light entering enclosure due to multiple reflections from lumber.

around the specimen edges.

NOTE 1—This apparatus consisting of enclosure, detector, and equatorial mount has been found acceptable for measuring solar transmittance of sheet

materials. The majority of the pieces are cut from standard 2.4, 2 by 6, and ⁄4 in. plywood construction materials.

FIG. 1 Apparatus Consisting of Enclosure, Detector, and Equatorial Mount

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1084

this error to less than 0.005 transmittance units.

6.3.1.2 sensitivity that is isotropic except for the usual

cosine response with altitude angle; and

6.2 Tracking:

6.3.1.3 output linear to within 62 % from 0 to 1000 W/m2

6.2.1 The enclosure shall be mounted in a manner that

or calibration curves accurate to within 62 % over the same

allows repositioning approximately every 15 min in order to

range. Additional desirable characteristics are relative short-

track the sun. The use of an equitorial or altazmuth mount is

time constants of a few seconds and good temperature stability.

recommended and automatic solar tracker is optional.

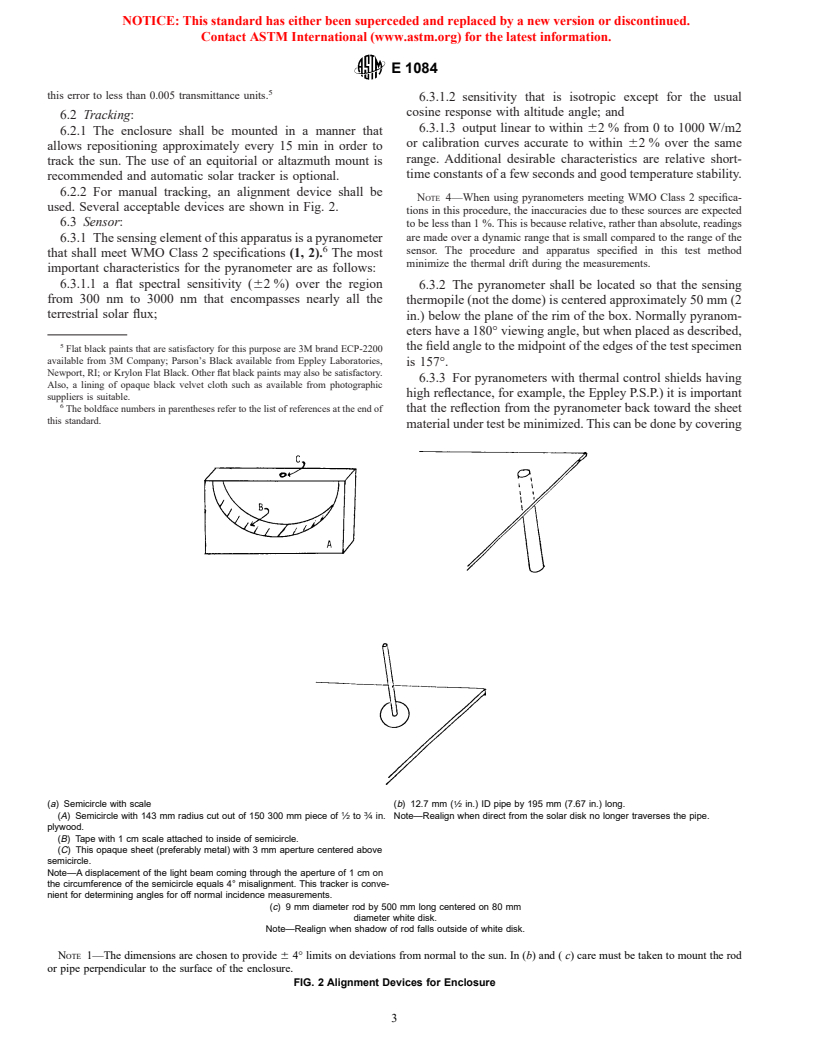

6.2.2 For manual tracking, an alignment device shall be

NOTE 4—When using pyranometers meeting WMO Class 2 specifica-

used. Several acceptable devices are shown in Fig. 2.

tions in this procedure, the inaccuracies due to these sources are expected

6.3 Sensor:

to be less than 1 %. This is because relative, rather than absolute, readings

are made over a dynamic range that is small compared to the range of the

6.3.1 The sensing element of this apparatus is a pyranometer

sensor. The procedure and apparatus specified in this test method

that shall meet WMO Class 2 specifications (1, 2). The most

minimize the thermal drift during the measurements.

important characteristics for the pyranometer are as follows:

6.3.1.1 a flat spectral sensitivity (62 %) over the region

6.3.2 The pyranometer shall be located so that the sensing

from 300 nm to 3000 nm that encompasses nearly all the

thermopile (not the dome) is centered approximately 50 mm (2

terrestrial solar flux;

in.) below the plane of the rim of the box. Normally pyranom-

eters have a 180° viewing angle, but when placed as described,

the field angle to the midpoint of the edges of the test specimen

Flat black paints that are satisfactory for this purpose are 3M brand ECP-2200

available from 3M Company; Parson’s Black available from Eppley Laboratories,

is 157°.

Newport, RI; or Krylon Flat Black. Other flat black paints may also be satisfactory.

6.3.3 For pyranometers with thermal control shields having

Also, a lining of opaque black velvet cloth such as available from photographic

high reflectance, for example, the Eppley P.S.P.) it is important

suppliers is suitable.

The boldface numbers in parentheses refer to the list of references at the end of

that the reflection from the pyranometer back toward the sheet

this standard.

material under test be minimized. This can be done by covering

(a) Semicircle with scale (b) 12.7 mm ( ⁄2 in.) ID pipe by 195 mm (7.67 in.) long.

1 3

(A) Semicircle with 143 mm radius cut out of 150 300 mm piece of ⁄2 to ⁄4 in. Note—Realign when direct from the solar disk no longer traverses the pipe.

plywood.

(B) Tape with 1 cm scale attached to inside of semicircle.

(C) This opaque sheet (preferably metal) with 3 mm aperture centered above

semicircle.

Note—A displacement of the light beam coming through the aperture of 1 cm on

the circumference of the semicircle equals 4° misalignment. This tracker is conve-

nient for determining angles for off normal incidence measurements.

(c) 9 mm diameter rod by 500 mm long centered on 80 mm

diameter white disk.

Note—Realign when shadow of rod falls outside of white disk.

NOTE 1—The dimensions are chosen to provide 6 4° limits on deviations from normal to the sun. In (b) and ( c) care must be taken to mount the rod

or pipe perpendicular to the surface of the enclosure.

FIG. 2 Alignment Devices for Enclosure

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E 1084

the shield with a nonreflecting material or by mounting the

j = the jth individual measurement of the transmittance,

pyranometer outside the enclosure with only the dome and

and

sensor element projecting into the box.

n = the number of individual measurements made.

8.8 Align the apparatus, at least every 15 min.

NOTE 5—Mounting the pyranometer outside of the enclosure also

8.9 When measuring corrugated or nonuniformly transmit-

reduces the heating load and cooling requirements for the pyranometer.

ting specimens, translate the specimen in such a way as to

obtain an average value for the transmittance. Since a system-

7. Specimens

atic translation over one period of structure is required, it is

7.1 The test specimens shall not be less than 0.60 by 0.60 m

permissible to perform the step in 8.3. Then take several

(24 by 24 in.). Care must be taken to prevent light leaks at the

measurements with sample on the box (8.4) before repeating

edges, especially if the cross-sectional shape of the specimen is

the step in 8.3, provided these before and after readings are in

not flat. Also, if the cross-sectional shape is not flat or if the

close agreement.

specimen is patterned, a specimen enough larger to allow

translation across the pyranometer by at least one period of the NOTE 8—Do not leave the specimens on the box for periods longer than

10 min since it may cause overheating of the sensor, resulting in nonlinear

shape or pattern is required.

response or even permanent damage.

8. Procedure

8.10 Measurement of the solar transmittance of sheet mate-

rials at angles up to 60° off normal incidence is also permitted

8.1 Conduct the tests on a sunny day with no cloud cover

by this test method. To do this, align the box aperture with

within6 15° of the sun and a minimum normal solar irradiance

respect to the solar angle to provide the desired incidence

of 700 W/m2 and constant to within 1 % during the individual

angle, and follow the steps in 8.4 to 8.7.

tests. Conduct testing as close to solar noon as possible but no

more than 3 h before or after solar noon.

9. Report

8.2 Set up apparatus at a location where no prominent

9.1 The report shall include the following information:

structure or vegetation is nearby in the pyranometer’s field of

9.1.1 The source and identity of the test specimen,

view.

9.1.2 A complete description of the test specimen, that is,

8.3 Align the box aperture to within 4° of the normal to the

thickness, cross-sectional shape, color, size, translucent or

sun’s rays, and measure the solar flux with no specimen in

transparent, type of material.

place. Allow adequate time for the trace or reading to stabilize.

9.1.3 The orientation of the sample based on any nonuni-

8.4 Place the test specimen on the box and measure the

formity or anisotropy such as surface coatings, exposed surface

transmitted solar flux, again allowing adequate time for the

fiber orientation, color bands, etc. during each measurement.

trace or reading to stabilize.

9.1.4 For each angle of incidence used, report the following

NOTE 6—Operate the pyranometer as directed by its manufacture inf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.