ASTM F3125/F3125M-19

(Specification)Standard Specification for High Strength Structural Bolts and Assemblies, Steel and Alloy Steel, Heat Treated, Inch Dimensions 120 ksi and 150 ksi Minimum Tensile Strength, and Metric Dimensions 830 MPa and 1040 MPa Minimum Tensile Strength

Standard Specification for High Strength Structural Bolts and Assemblies, Steel and Alloy Steel, Heat Treated, Inch Dimensions 120 ksi and 150 ksi Minimum Tensile Strength, and Metric Dimensions 830 MPa and 1040 MPa Minimum Tensile Strength

SCOPE

1.1 This specification covers chemical, physical and mechanical requirements for quenched and tempered bolts manufactured from steel and alloy steel, in inch and metric dimensions, in two strength grades, two types and two styles.

1.1.1 This specification is a consolidation and replacement of six ASTM standards, including; A325, A325M, A490, A490M, F1852 and F2280.

1.1.2 This consolidated standard is to ensure alignment between standards with the same intended end use and to simplify the use and maintenance of structural bolt specifications.

1.2 Intended Use:

1.2.1 Bolts manufactured under this specification are intended for use in structural connections covered in the Specification for Structural Joints Using High-Strength Bolts, as approved by the Research Council on Structural Connections.

1.2.2 Bolts in this specification are furnished in sizes from 1/2 to 1-1/2 in. inclusive and from M12 to M36 inclusive.

1.3 Classification, Table 1:

1.3.1 Bolts are designated by grade, which indicates inch or metric strength and style.

1.3.2 Bolts are designated by type denoting raw material chemical composition.

1.3.3 Bolts are designated by style denoting Heavy Hex bolts or “Twist-Off” Style assemblies.

1.4 Terms used in this specification are defined in F1789.

1.5 Units—The values stated in either SI units or inch pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 Table footnotes are requirements. Notes are advisory.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F3125/F3125M −19

Standard Specification for

High Strength Structural Bolts and Assemblies, Steel and

Alloy Steel, Heat Treated, Inch Dimensions 120 ksi and 150

ksi Minimum Tensile Strength, and Metric Dimensions 830

1

MPa and 1040 MPa Minimum Tensile Strength

ThisstandardisissuedunderthefixeddesignationF3125/F3125M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ing values from the two systems may result in non-

conformance with the standard.

1.1 This specification covers chemical, physical and me-

chanical requirements for quenched and tempered bolts manu- 1.6 Table footnotes are requirements. Notes are advisory.

factured from steel and alloy steel, in inch and metric

1.7 This standard does not purport to address all of the

dimensions, in two strength grades, two types and two styles.

safety concerns, if any, associated with its use. It is the

1.1.1 This specification is a consolidation and replacement

responsibility of the user of this standard to establish appro-

of six ASTM standards, including; A325, A325M, A490,

priate safety, health, and environmental practices and deter-

A490M, F1852 and F2280.

mine the applicability of regulatory limitations prior to use.

1.1.2 This consolidated standard is to ensure alignment

1.8 This international standard was developed in accor-

between standards with the same intended end use and to

dance with internationally recognized principles on standard-

simplify the use and maintenance of structural bolt specifica-

ization established in the Decision on Principles for the

tions.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.2 Intended Use:

Barriers to Trade (TBT) Committee.

1.2.1 Bolts manufactured under this specification are in-

tended for use in structural connections covered in the Speci-

2. Referenced Documents

fication for Structural Joints Using High-Strength Bolts, as

2

approved by the Research Council on Structural Connections.

2.1 ASTM Standards:

1.2.2 Bolts in this specification are furnished in sizes from

A194/A194MSpecification for Carbon Steel, Alloy Steel,

1 1

⁄2 to 1- ⁄2 in. inclusive and from M12 to M36 inclusive.

and Stainless Steel Nuts for Bolts for High Pressure or

High Temperature Service, or Both

1.3 Classification, Table 1:

A354Specification for Quenched and TemperedAlloy Steel

1.3.1 Bolts are designated by grade, which indicates inch or

Bolts, Studs, and Other Externally Threaded Fasteners

metric strength and style.

A449Specification for Hex Cap Screws, Bolts and Studs,

1.3.2 Bolts are designated by type denoting raw material

Steel, Heat Treated, 120/105/90 ksi Minimum Tensile

chemical composition.

Strength, General Use

1.3.3 Bolts are designated by style denoting Heavy Hex

A563Specification for Carbon and Alloy Steel Nuts

bolts or “Twist-Off” Style assemblies.

A563MSpecificationforCarbonandAlloySteelNuts(Met-

1.4 Terms used in this specification are defined in F1789.

ric)

1.5 Units—ThevaluesstatedineitherSIunitsorinchpound A751Test Methods, Practices, and Terminology for Chemi-

units are to be regarded separately as standard. The values cal Analysis of Steel Products

stated in each system may not be exact equivalents; therefore, B695Specification for Coatings of Zinc Mechanically De-

each system shall be used independently of the other. Combin- posited on Iron and Steel

E709Guide for Magnetic Particle Testing

E1444/E1444MPractice for Magnetic Particle Testing

1

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts,

2

Nuts, Rivets and Washers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2019. Published December 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

published in 2015. Last previous edition published in 2018 as F3125–18. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3125_F3125M–19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3125/F3125M−19

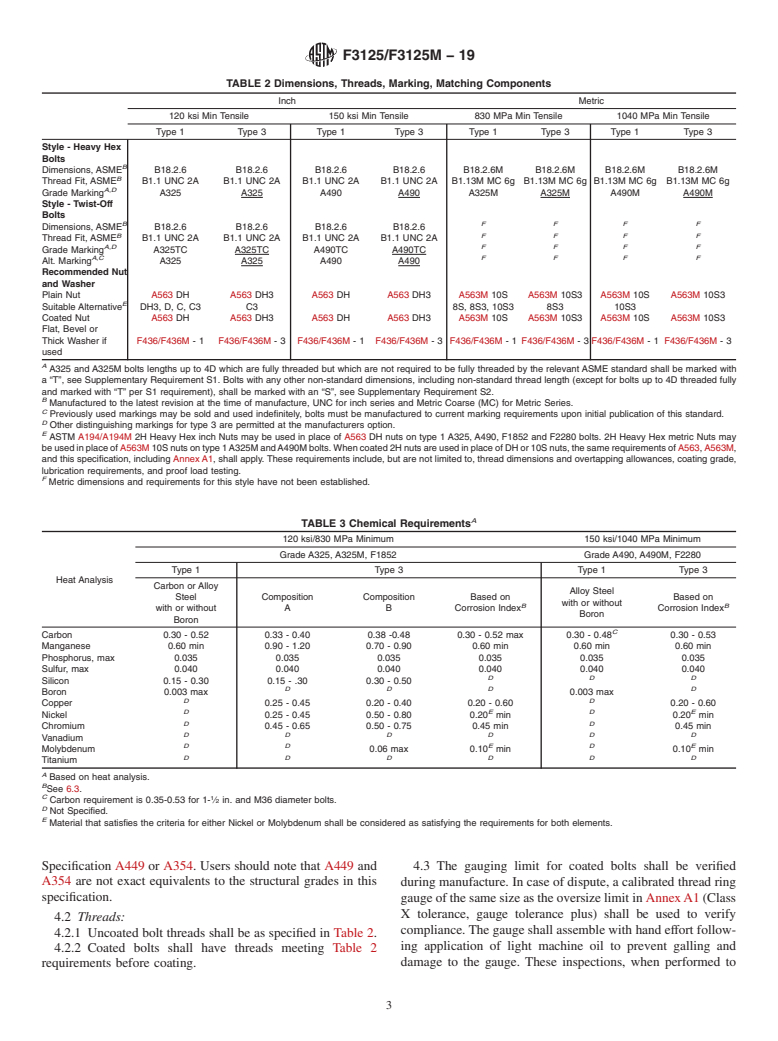

4

TABLE 1 Classification

2.3 IFI Standard:

A

Grade Min. Strength Type Style IFI 144Test Evaluation Procedures for Coating Qualifica-

A325 120 ksi 1 3 Heavy Hex Head tion

A490 150 ksi 1 3 Heavy Hex Head 5

2.4 RCSC Standard:

F1852 120 ksi 1 3 Twist-Off

SpecificationforStructuralJointsUsingHigh-StrengthBolts

F2280 150 ksi 1 3 Twist-Off

A325M

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3125/F3125M − 18 F3125/F3125M − 19

Standard Specification for

High Strength Structural Bolts and Assemblies, Steel and

Alloy Steel, Heat Treated, Inch Dimensions 120 ksi and 150

ksi Minimum Tensile Strength, and Metric Dimensions 830

1

MPa and 1040 MPa Minimum Tensile Strength

This standard is issued under the fixed designation F3125/F3125M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers chemical, physical and mechanical requirements for quenched and tempered bolts manufactured

from steel and alloy steel, in inch and metric dimensions, in two strength grades, two types and two styles.

1.1.1 This specification is a consolidation and replacement of six ASTM standards, including; A325, A325M, A490, A490M,

F1852 and F2280.

1.1.2 This consolidated standard is to ensure alignment between standards with the same intended end use and to simplify the

use and maintenance of structural bolt specifications.

1.2 Intended Use:

1.2.1 Bolts manufactured under this specification are intended for use in structural connections covered in the Specification for

Structural Joints Using High-Strength Bolts, as approved by the Research Council on Structural Connections.

1 1

1.2.2 Bolts in this specification are furnished in sizes from ⁄2 to 1- ⁄2 in. inclusive and from M12 to M36 inclusive.

1.3 Classification, Table 1:

1.3.1 Bolts are designated by grade, which indicates inch or metric strength and style.

1.3.2 Bolts are designated by type denoting raw material chemical composition.

1.3.3 Bolts are designated by style denoting Heavy Hex bolts or “Twist-Off” Style assemblies.

1.4 Terms used in this specification are defined in F1789.

1.5 Units—The values stated in either SI units or inch pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.6 Table footnotes are requirements. Notes are advisory.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A194/A194M Specification for Carbon Steel, Alloy Steel, and Stainless Steel Nuts for Bolts for High Pressure or High

Temperature Service, or Both

A354 Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners

1

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved Dec. 1, 2018Dec. 1, 2019. Published February 2019December 2019. Originally published in 2015. Last previous edition published in 20152018

as F3125–15.–18. DOI: 10.1520/F3125_F3125M–15A.10.1520/F3125_F3125M–19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3125/F3125M − 19

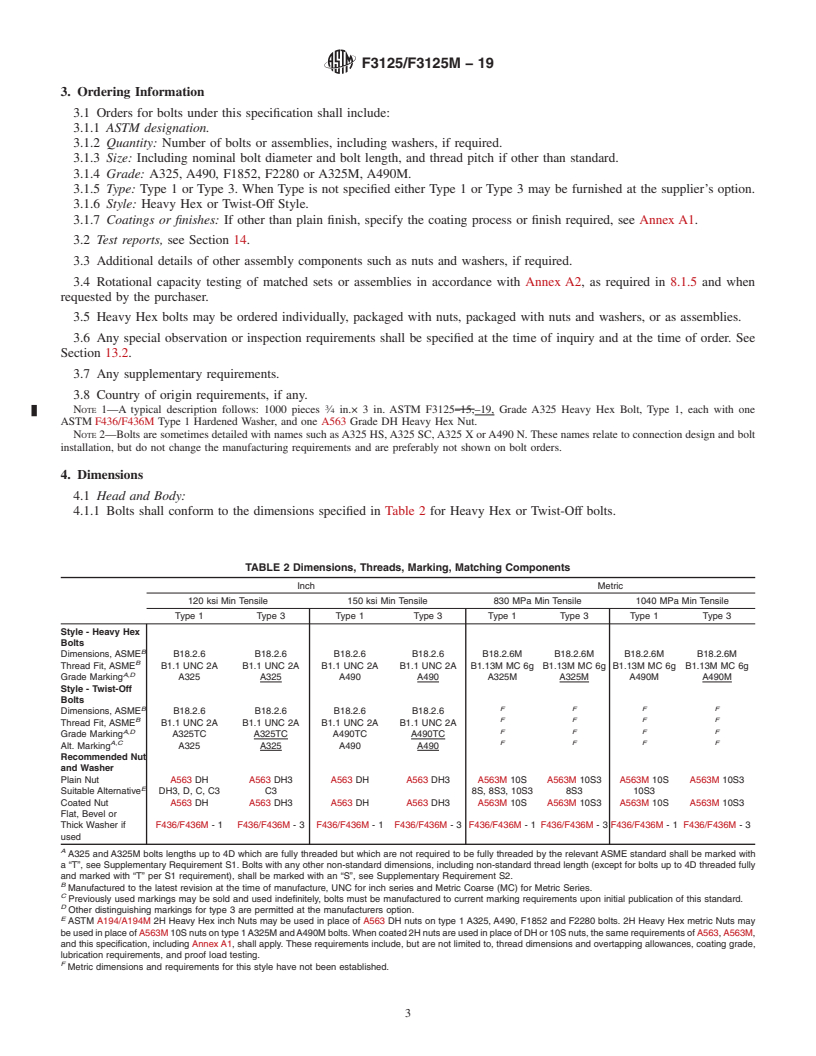

TABLE 1 Classification

A

Grade Min. Strength Type Style

A325 120 ksi 1 3 Heavy Hex Head

A490 150 ksi 1 3 Heavy Hex Head

F1852 120 ksi 1 3 Twist-Off

F2280 150 ksi 1 3 Twist-Off

A325M 830 MPa 1 3 Heavy Hex Head

A490M 1040 MPa 1 3 Heavy Hex Head

A

Type 1 - 120 ksi (830 MPa) - carbon steel, carbon boron steel, alloy steel or alloy

steel with boron addition

Type 3 - 120 ksi (830 MPa) or 150 ksi (1040 MPa) - weathering steel

Type 1 - 150 ksi (1040 MPa) - alloy st

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.