ASTM G78-01(2007)

(Guide)Standard Guide for Crevice Corrosion Testing of Iron-Base and Nickel-Base Stainless Alloys in Seawater and Other Chloride-Containing Aqueous Environments

Standard Guide for Crevice Corrosion Testing of Iron-Base and Nickel-Base Stainless Alloys in Seawater and Other Chloride-Containing Aqueous Environments

SIGNIFICANCE AND USE

This guide covers procedures for crevice-corrosion testing of iron-base and nickel-base stainless alloys in seawater. The guidance provided may also be applicable to crevicecorrosion testing in other chloride containing natural waters and various laboratory prepared aqueous chloride environments.

This guide describes the use of a variety of crevice formers including the nonmetallic, segmented washer design referred to as the multiple crevice assembly (MCA) as described in 9.2.2.

In-service performance data provide the most reliable determination of whether a material would be satisfactory for a particular end use. Translation of laboratory data from a single test program to predict service performance under a variety of conditions should be avoided. Terms, such as immunity, superior resistance, etc., provide only a general and relatively qualitative description of an alloy’corrosion performance. The limitations of such terms in describing resistance to crevice corrosion should be recognized.

While the guidance provided is generally for the purpose of evaluating sheet and plate materials, it is also applicable for crevice-corrosion testing of other product forms, such as tubing and bars.

The presence or absence of crevice corrosion under one set of conditions is no guarantee that it will or will not occur under other conditions. Because of the many interrelated metallurgical, environmental, and geometric factors known to affect crevice corrosion, results from any given test may or may not be indicative of actual performance in service applications where the conditions may be different from those of the test.

SCOPE

1.1 This guide covers information for conducting crevice-corrosion tests and identifies factors that may affect results and influence conclusions.

1.2 These procedures can be used to identify conditions most likely to result in crevice corrosion and provide a basis for assessing the relative resistance of various alloys to crevice corrosion under certain specified conditions.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific warning statement, see 7.1.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G78 − 01(Reapproved 2007)

Standard Guide for

Crevice Corrosion Testing of Iron-Base and Nickel-Base

Stainless Alloys in Seawater and Other Chloride-Containing

Aqueous Environments

ThisstandardisissuedunderthefixeddesignationG78;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Crevice corrosion of iron-base and nickel-base stainless alloys can occur when an occlusion or

crevice limits access of the bulk environment to a localized area of the metal surface. Localized

environmental changes in this stagnant area can result in the formation of acidic/high chloride

conditions that may result in initiation and propagation of crevice corrosion of susceptible alloys.

In practice, crevices can generally be classified into two categories: (1) naturally occurring, that is,

those created by biofouling, sediment, debris, deposits, etc. and (2) man-made, that is, those created

during manufacturing, fabrication, assembly, or service. Crevice formers utilized in laboratory and

field studies can represent actual geometric conditions encountered in some service applications. Use

of such crevice formers in service-type environments are not considered accelerated test methods.

The geometry of a crevice can be described by the dimensions of crevice gap and crevice depth.

Crevice gap is identified as the width or space between the metal surface and the crevice former.

Crevice depth is the distance from the mouth to the center or base of the crevice.

1. Scope bility of regulatory limitations prior to use. For a specific

warning statement, see 7.1.1.

1.1 This guide covers information for conducting crevice-

corrosion tests and identifies factors that may affect results and

2. Referenced Documents

influence conclusions.

2.1 ASTM Standards:

1.2 These procedures can be used to identify conditions

G1Practice for Preparing, Cleaning, and Evaluating Corro-

mostlikelytoresultincrevicecorrosionandprovideabasisfor

sion Test Specimens

assessing the relative resistance of various alloys to crevice

G4Guide for Conducting Corrosion Tests in Field Applica-

corrosion under certain specified conditions.

tions

1.3 The values stated in SI units are to be regarded as

G15Terminology Relating to Corrosion and CorrosionTest-

standard. The values given in parentheses are for information ing (Withdrawn 2010)

only.

G46Guide for Examination and Evaluation of Pitting Cor-

rosion

1.4 This standard does not purport to address all of the

G48Test Methods for Pitting and Crevice Corrosion Resis-

safety concerns, if any, associated with its use. It is the

tance of Stainless Steels and Related Alloys by Use of

responsibility of the user of this standard to establish appro-

Ferric Chloride Solution

priate safety and health practices and determine the applica-

1 2

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metals and is the direct responsibility of Subcommittee G01.09 on Corrosion in contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Natural Waters. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved May 1, 2007. Published May 2007. Originally the ASTM website.

approved in 1983. Last previous edition approved in 2001 as G78–01. DOI: The last approved version of this historical standard is referenced on

10.1520/G0078-01R07. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G78 − 01 (2007)

3. Terminology 5. Apparatus

3.1 Definitions of related terms can be found in Terminol- 5.1 Laboratory tests utilizing filtered, natural seawater, or

ogy G15. other chloride containing aqueous environments are frequently

conductedintanksortroughsunderlowvelocity(forexample,

;0.5 m/s (1.64 ft/s) or less) or quiescent conditions. Contain-

4. Significance and Use

ers should be resistant to the test media.

4.1 This guide covers procedures for crevice-corrosion test-

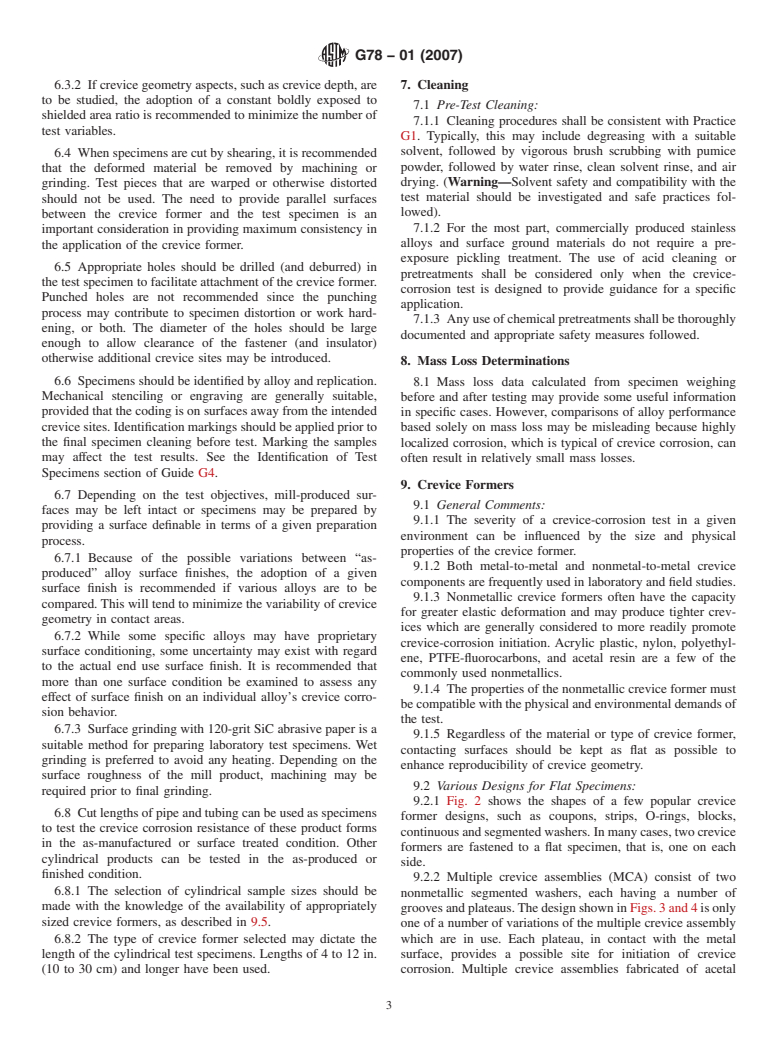

5.2 Fig. 1 shows a typical test apparatus for conducting

ing of iron-base and nickel-base stainless alloys in seawater.

crevice-corrosiontestsundercontrolledtemperatureconditions

The guidance provided may also be applicable to crevicecor-

with provisions for recirculation or refreshment of the aqueous

rosion testing in other chloride containing natural waters and

environment, or both, at a constant level.

various laboratory prepared aqueous chloride environments.

5.3 The apparatus should be suitably sized to provide

4.2 This guide describes the use of a variety of crevice

complete immersion of the test panel. Vertical positioning of

formers including the nonmetallic, segmented washer design

the crevice-corrosion specimens facilitates visual inspection

referred to as the multiple crevice assembly (MCA) as de-

without the need to remove them from the environments.

scribed in 9.2.2.

4.3 In-service performance data provide the most reliable

6. Test Specimens

determination of whether a material would be satisfactory for

a particular end use. Translation of laboratory data from a 6.1 Becauseofthenumberofvariableswhichmayaffectthe

test results, a minimum of three specimens are suggested for

single test program to predict service performance under a

variety of conditions should be avoided. Terms, such as each set of environmental, metallurgical, or geometric condi-

tions to be evaluated. If reproducibility is unsatisfactory,

immunity, superior resistance, etc., provide only a general and

relatively qualitative description of an alloy’s corrosion per- additional specimens should be tested.

formance. The limitations of such terms in describing resis-

6.2 Dimensions of both the test specimen and crevice

tance to crevice corrosion should be recognized.

former should be determined and recorded.

4.4 While the guidance provided is generally for the pur-

6.3 Variations in the boldly exposed (crevice-free) to

pose of evaluating sheet and plate materials, it is also appli-

shielded(crevice)arearatioofthetestspecimenmayinfluence

cableforcrevice-corrosiontestingofotherproductforms,such

crevicecorrosion.Allspecimensinatestseriesshouldhavethe

as tubing and bars.

samenominalsurfacearea.Whilenospecificspecimendimen-

sions are recommended, test panels measuring up to 300 by

4.5 The presence or absence of crevice corrosion under one

300 mm (11.81 by 11.81 in.) have been used in seawater tests

set of conditions is no guarantee that it will or will not occur

with both naturally occurring and man-made crevice formers.

under other conditions. Because of the many interrelated

For laboratory studies, the actual size of the specimen may be

metallurgical, environmental, and geometric factors known to

limited by the dimensions of the test apparatus and this should

affect crevice corrosion, results from any given test may or

be taken into consideration in making comparisons.

may not be indicative of actual performance in service appli-

cationswheretheconditionsmaybedifferentfromthoseofthe 6.3.1 A test program may be expanded to assess any effect

test. of boldly exposed to shielded area ratio.

FIG. 1 Positioning of Crevice-Corrosion Test Specimens—Typical Arrangement in Controlled Environment Apparatus

G78 − 01 (2007)

6.3.2 Ifcrevicegeometryaspects,suchascrevicedepth,are 7. Cleaning

to be studied, the adoption of a constant boldly exposed to

7.1 Pre-Test Cleaning:

shielded area ratio is recommended to minimize the number of

7.1.1 Cleaning procedures shall be consistent with Practice

test variables.

G1. Typically, this may include degreasing with a suitable

solvent, followed by vigorous brush scrubbing with pumice

6.4 Whenspecimensarecutbyshearing,itisrecommended

powder, followed by water rinse, clean solvent rinse, and air

that the deformed material be removed by machining or

drying. (Warning—Solvent safety and compatibility with the

grinding. Test pieces that are warped or otherwise distorted

test material should be investigated and safe practices fol-

should not be used. The need to provide parallel surfaces

lowed).

between the crevice former and the test specimen is an

7.1.2 For the most part, commercially produced stainless

important consideration in providing maximum consistency in

alloys and surface ground materials do not require a pre-

the application of the crevice former.

exposure pickling treatment. The use of acid cleaning or

6.5 Appropriate holes should be drilled (and deburred) in

pretreatments shall be considered only when the crevice-

thetestspecimentofacilitateattachmentofthecreviceformer.

corrosion test is designed to provide guidance for a specific

Punched holes are not recommended since the punching

application.

process may contribute to specimen distortion or work hard-

7.1.3 Anyuseofchemicalpretreatmentsshallbethoroughly

ening, or both. The diameter of the holes should be large

documented and appropriate safety measures followed.

enough to allow clearance of the fastener (and insulator)

otherwise additional crevice sites may be introduced.

8. Mass Loss Determinations

6.6 Specimens should be identified by alloy and replication. 8.1 Mass loss data calculated from specimen weighing

Mechanical stenciling or engraving are generally suitable,

before and after testing may provide some useful information

providedthatthecodingisonsurfacesawayfromtheintended

in specific cases. However, comparisons of alloy performance

crevicesites.Identificationmarkingsshouldbeappliedpriorto

based solely on mass loss may be misleading because highly

the final specimen cleaning before test. Marking the samples

localized corrosion, which is typical of crevice corrosion, can

may affect the test results. See the Identification of Test

often result in relatively small mass losses.

Specimens section of Guide G4.

9. Crevice Formers

6.7 Depending on the test objectives, mill-produced sur-

9.1 General Comments:

faces may be left intact or specimens may be prepared by

9.1.1 The severity of a crevice-corrosion test in a given

providing a surface definable in terms of a given preparation

environment can be influenced by the size and physical

process.

properties of the crevice former.

6.7.1 Because of the possible variations between “as-

9.1.2 Both metal-to-metal and nonmetal-to-metal crevice

produced” alloy surface finishes, the adoption of a given

components are frequently used in laboratory and field studies.

surface finish is recommended if various alloys are to be

9.1.3 Nonmetallic crevice formers often have the capacity

compared.This will tend to minimize the variability of crevice

for greater elastic deformation and may produce tighter crev-

geometry in contact areas.

ices which are generally considered to more readily promote

6.7.2 While some specific alloys may have proprietary

crevice-corrosion initiation. Acrylic plastic, nylon, polyethyl-

surface conditioning, some uncertainty may exist with regard

ene, PTFE-fluorocarbons, and acetal resin are a few of the

to the actual end use surface finish. It is recommended that

commonly used nonmetallics.

more than one surface condition be examined to assess any

9.1.4 The properties of the nonmetallic crevice former must

effect of surface finish on an individual alloy’s crevice corro-

becompatiblewiththephysicalandenvironmentaldemandsof

sion behavior.

the test.

6.7.3 Surface grinding with 120-grit SiC abrasive paper is a

9.1.5 Regardless of the material or type of crevice former,

suitable method for preparing laboratory test specimens. Wet

contacting surfaces should be kept as flat as possible to

grinding is preferred to avoid any heating. Depending on the

enhance reproducibility of crevice geometry.

surface roughness of the mill product, machining may be

9.2 Various Designs for Flat Specimens:

required prior to final grinding.

9.2.1 Fig. 2 shows the shapes of a few popular crevice

6.8 Cutlengthsofpipeandtubingcanbeusedasspecimens

former designs, such as coupons, strips, O-rings, blocks,

to test the crevice corrosion resistance of these product forms

continuousandsegmentedwashers.Inmanycases,twocrevice

in the as-manufactured or surface treated condition. Other

formers are fastened to a flat specimen, that is, one on each

cylindrical products can be tested in the as-produced or

side.

finished condition.

9.2.2 Multiple crevice assemblies (MCA) consist of two

6.8.1 The selection of cylindrical sample sizes should be

nonmetallic segmented washers, each having a number of

made with the knowledge of the availability of appropriately

groovesandplateaus.ThedesignshowninFigs.3and4isonly

sized crevice formers, as described in 9.5.

one of a number of variations of the multiple crevice assembly

6.8.2 The type of crevice former selected may dictate the which are in use. Each plateau, in contact with the metal

length of the cylindrical test specimens. Lengths of 4 to 12 in. surface, provides a possible site for initiation of crevice

(10 to 30 cm) and longer have been used. corrosion. Multiple crevice assemblies fabricated of acetal

G78 − 01 (2007)

NOTE 1—Various crevice former designs utilized in laboratory and field test crevice-corrosion studies. Severity of the test may vary as a function of

crevice geometry, that is, size of the crevice former and degree of tightness

FIG. 2 Crevice Former Designs

FIG. 4 Multiple Crevice Assembly with Sheet Specimen

resin have been shown to be suitable for seawater exposures.

Other nonmetallics, such as PTFE-fluorocarbon and ceramic,

have also been used (see 9.1.4).

9.2.3 For metal-to-metal crevice-corrosion tests, flat wash-

ers or coupons are often fastened to a larger test specimen.All

components should be of the same material and prepared for

exposure in the same manner.

9.2.3.1 Crevice testing with metal to metal components

NOTE 1—Inch-pound equivalents for SI units:

assembled with either nonmetal or metal fasteners (with

0.5 mm=0.0197 in.

insulator) will necessarily result in the formation of secondary

1 mm=0.039 in

2.5 mm=0.098 in. crevice sites where the fastener contacts the metallic crevice

7 mm=0.25 in.

former. In some cases, the geometry of these secondary sites

13 mm=0.512 in.

may be more severe than the intended primary crevice site.

17 mm=0.669 in.

19 mm=0.748 in.

9.3 Method of Attachment:

22 mm=0.866 in.

9.3.1 Either metallic or nonmetallic fasteners, for example,

25.4 mm=1 in.

nut-andbolt-type,canbeusedtosecurethecreviceformersto

FIG. 3 Details of Multiple Crevice Washer (not to scale)

the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.