ASTM A1007-07

(Specification)Standard Specification for Carbon Steel Wire for Wire Rope

Standard Specification for Carbon Steel Wire for Wire Rope

ABSTRACT

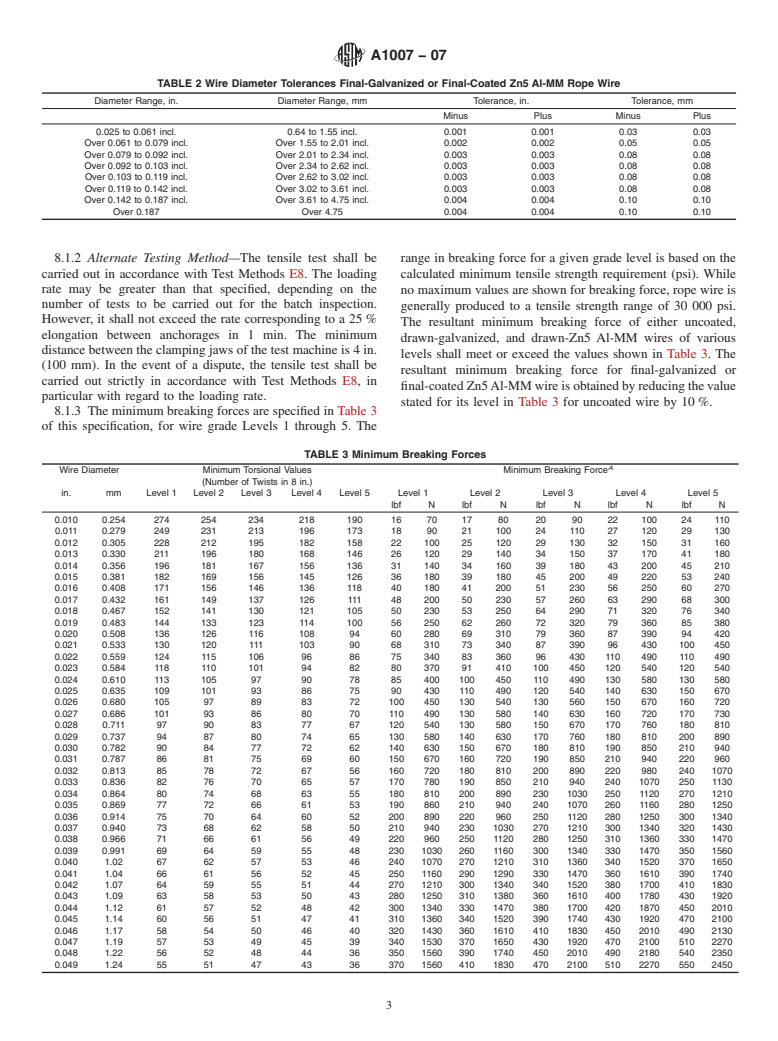

This specification covers uncoated and four classes of round, metallic coated, cold-drawn, carbon steel wire rope in five strength levels. The following materials testing procedures shall be conducted: standard tensile testing; alternate tensile testing; torsion testing; and wrap testing. The wire diameter tolerances of uncoated, drawn-galvanized or drawn-Zn5 Al-MM, and final-galvanized or final-coated Zn5 Al-MM rope wires shall be described. Minimum breakage forces for the carbon steel wire rope shall also be presented. During torsion testing, varying amounts of load shall be applied to the wire being tested.

SCOPE

1.1 This specification covers uncoated and four classes of round, metallic coated, cold-drawn, carbon steel wire for wire rope in five strength levels. This specification specifies:

1.1.1 Dimensional tolerances,

1.1.2 Mechanical characteristics,

1.1.3 Chemical composition requirements,

1.1.4 Coating requirements (if applicable), and

1.1.5 Packaging requirements.

1.2 The values stated for metric equivalents are provided for informational purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1007 −07

StandardSpecification for

1

Carbon Steel Wire for Wire Rope

This standard is issued under the fixed designation A1007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope* 2.3 ISO/EN Standards:

EN10264-1.2 SteelWireandWireProducts—SteelWirefor

1.1 This specification covers uncoated and four classes of

Wire Rope

round, metallic coated, cold-drawn, carbon steel wire for wire

2.4 Industry Standard:

rope in five strength levels. This specification specifies:

4

API 9A Specification for Wire Rope

1.1.1 Dimensional tolerances,

5

2.5 Industry References:

1.1.2 Mechanical characteristics,

AIME/ISS Carbon Steel, Wire and Rods

1.1.3 Chemical composition requirements,

5

AIAG 02.00 Primary Metals Identification TagApplication

1.1.4 Coating requirements (if applicable), and

2.6 Non-Referenced Industry Applicable Standard:

1.1.5 Packaging requirements.

ISO Std. 2232 Drawn Wire for General Purpose Non-Alloy

1.2 Thevaluesstatedformetricequivalentsareprovidedfor

3

Steel Wire Ropes

informational purposes only.

3. Terminology

2. Referenced Documents

3.1 Definitions:

2.1 This specification incorporates, by dated or undated

3.1.1 actual diameter—thearithmeticmeanoftheminimum

reference, provisions from other publications.These normative

and maximum diameter measurements in one location on the

referencesarecitedattheirappropriateplaceinthetextandthe

wire.

publications are listed. For dated references, subsequent

3.1.2 breaking force level (Levels 1,2,3,4 or 5)— a wire

amendments to or revisions of any of these publications apply

strength based on the minimum load carrying capability of a

to this specification only when incorporated in it by amend-

designated wire.

ment or revision. For undated references, the latest edition of

3.1.3 drawn-galvanized—a zinc coating that is applied to

the publication referred to would apply.

the wire prior to the final cold drawing operation by either an

2

2.2 ASTM Standards:

electro-deposition or hot-galvanizing process.

A90/A90M Test Method for Weight [Mass] of Coating on

3.1.4 drawn-Zn5 Al-MM—a zinc-aluminum alloy (misch-

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

metal) coating that is applied to the wire prior to the final cold

A510 Specification for General Requirements forWire Rods

drawing operation by a molten coating process.

and Coarse Round Wire, Carbon Steel

A938 Test Method for Torsion Testing of Wire

3.1.5 final-coated Zn5 Al-MM—a zinc-aluminum alloy

B6 Specification for Zinc (misch-metal) coating that is applied to the wire after the final

B750 Specification for GALFAN (Zinc-5 % Aluminum-

cold drawing operation by a molten coating process.

Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

3.1.6 final-galvanized—a zinc coating that is applied to the

E8 Test Methods for Tension Testing of Metallic Materials

wire after the final cold drawing operation by either an

IEEE/ASTM-SI-10 Standard for Use of the International

electro-deposition or hot-galvanizing process.

System of Units (SI): The Modern Metric System

3.1.7 nominal diameter—the diameter of the wire expressed

in inches (millimetres) and specified by the user to designate

the wire size. It is the basis for the determination of the values

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

of all characteristics of the wire for acceptance purposes.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.03 on Steel Rod and Wire.

Current edition approved Sept. 1, 2007. Published September 2007. Originally

3

approved in 2000. Last previous edition approved in 2002 as A1007 – 02. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/A1007-07. 4th Floor, New York, NY 10036, http://www.ansi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Petroleum Institute (API), 1220 L. St., NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Washington, DC 20005-4070, http://api-ec.api.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAutomotive IndustryAction Group (AIAG), 26200 Lahser Rd.,

the ASTM website. Suite 200, Southfield, MI 48033, http://www.aiag.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1007−07

3.1.8 ovality—the arithmetic difference between the maxi- 5.6.1 Theslabzincusedingalvaniz

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.