ASTM D2412-02(2008)

(Test Method)Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

SIGNIFICANCE AND USE

The external loading properties of plastic pipe obtained by this test method are used for the following:

To determine the stiffness of the pipe. This is a function of the pipe dimensions and the physical properties of the material of which the pipe is made.

To determine the load-deflection characteristics and pipe stiffness which are used for engineering design (see Appendix X1).

To compare the characteristics of various plastics in pipe form.

To study the interrelations of dimensions and deflection properties of plastic pipe and conduit.

To measure the deflection and load-resistance at any of several significant events if they occur during the test.

SCOPE

1.1 This test method covers the determination of load-deflection characteristics of plastic pipe under parallel-plate loading.

1.2 This test method covers thermoplastic resin pipe, reinforced thermosetting resin pipe (RTRP), and reinforced polymer mortar pipe (RPMP).

1.3 The characteristics determined by this test method are pipe stiffness, stiffness factor, and load at specific deflections.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1—While this test method can be used in measuring the pipe stiffness of corrugated plastic pipe or tubing, special conditions and procedures are used. These details are included in the product standards, for example, Specification F 405.

1.5 The text of this test method references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the test method.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D2412–02 (Reapproved 2008)

Standard Test Method for

Determination of External Loading Characteristics of Plastic

Pipe by Parallel-Plate Loading

This standard is issued under the fixed designation D2412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D695 Test Method for Compressive Properties of Rigid

Plastics

1.1 This test method covers the determination of load-

D1600 Terminology for Abbreviated Terms Relating to

deflection characteristics of plastic pipe under parallel-plate

Plastics

loading.

D2122 Test Method for Determining Dimensions of Ther-

1.2 This test method covers thermoplastic resin pipe, rein-

moplastic Pipe and Fittings

forced thermosetting resin pipe (RTRP), and reinforced poly-

E177 Practice for Use of the Terms Precision and Bias in

mer mortar pipe (RPMP).

ASTM Test Methods

1.3 The characteristics determined by this test method are

E691 Practice for Conducting an Interlaboratory Study to

pipe stiffness, stiffness factor, and load at specific deflections.

Determine the Precision of a Test Method

1.4 The values stated in inch-pound units are to be regarded

F405 Specification for Corrugated Polyethylene (PE) Pipe

as standard. The values given in parentheses are mathematical

and Fittings

conversions to SI units that are provided for information only

F412 Terminology Relating to Plastic Piping Systems

and are not considered standard.

NOTE 1—While this test method can be used in measuring the pipe 3. Terminology

stiffness of corrugated plastic pipe or tubing, special conditions and

3.1 Definitions: Definitions are in accordance with Termi-

procedures are used. These details are included in the product standards,

nology F412, and abbreviations are in accordance with Termi-

for example, Specification F405.

nology D1600, unless otherwise specified.

1.5 The text of this test method references notes and

3.2 Definitions of Terms Specific to This Standard:

footnotes that provide explanatory material. These notes and

3.2.1 Dy—measured change of the inside diameter in the

footnotes (excluding those in tables and figures) shall not be

direction of load application expressed in inches (millimetres).

considered as requirements of the test method.

3.2.2 initial inside diameter (d)—the average of the inside

1.6 This standard does not purport to address all of the

diameters as determined for the several test specimens and

safety concerns, if any, associated with its use. It is the

expressed in inches (millimetres).

responsibility of the user of this standard to establish appro-

3.2.3 load (F)—the load applied to the pipe to produce a

priate safety and health practices and determine the applica-

givenpercentagedeflection.Expressedasnewtonspermetreor

bility of regulatory limitations prior to use.

pounds-force per linear inch.

3.2.4 mean radius (r)—the mid-wall radius determined by

2. Referenced Documents

subtractingtheaveragewallthicknessfromtheaverageoutside

2.1 ASTM Standards:

diameter and dividing the difference by two. Expressed as

inches (millimetres).

3.2.5 pipe deflection (P)—the ratio of the reduction in pipe

This test method is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test

inside diameter to the initial inside diameter expressed as the

Methods.

percentage of the initial inside diameter.

Current edition approved July 15, 2008. Published July 2008. Originally

3.2.6 pipe significant events:

approved in 1965. Last previous edition approved in 2002 as D2412 – 02. DOI:

3.2.6.1 liner cracking or crazing—theoccurrenceofabreak

10.1520/D2412-02R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

or network of fine breaks in the liner visible to the unaided eye.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.6.2 rupture—a crack or break extending entirely or

Standards volume information, refer to the standard’s Document Summary page on

partly through the pipe wall.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2412–02 (2008)

NOTE 2—The significant events listed may or may not occur in a NOTE 5—For some types of testing machines a greater plate thickness

specific pipe material. may be required to limit plate bending.

3.2.6.3 wall cracking—the occurence of a break in the pipe

6.3 Deformation (Deflection) Indicator— The change in

wall visible to the unaided eye.

inside diameter, or deformation parallel to the direction of

3.2.6.4 wall delamination—the occurrence of any separa-

loading, shall be measured with a suitable instrument meeting

tion in the components of the pipe wall visible to the unaided

the requirements of Test Method D695, except that the instru-

eye.

ment shall be accurate to the nearest 0.010 in. (0.25 mm). The

3.2.7 pipe stiffness (PS)—the value obtained by dividing the

instrument shall not support the pipe test specimen or the plate

force per unit length of specimen by the resulting deflection in

or affect in any way the load deflection measurements.

the same units at the prescribed percentage deflection.

Changes in diameter are measured during loading by continu-

3.2.8 stiffness factor (SF)—the product of pipe stiffness and

ously recording plate travel or by periodically computing it.

the quantity 0.149 r .

7. Test Specimens

3.2.9 Discussion—The “pipe stiffness” and “stiffness fac-

tor” are related as follows:

7.1 For thermoplastic pipe, the test specimen shall be a

piece of pipe 6 6 ⁄8 in. (150 6 3 mm) long.

PS 5 F/Dy (1)

7.2 For reinforced thermosetting resin pipe, the minimum

3 3

SF 5 EI 5 0.149 Fr /Dy 5 0.149 r ~PS! (2)

test specimen length shall be three times the nominal pipe

NOTE 3—See Appendix X2 for information relating PS, E, and Dy.

diameter or 12.0 in. (300 mm), whichever is smaller. For pipe

larger than 60 in. (1524 mm) in diameter, the minimum

4. Summary of Test Method

specimen length shall be 20 % of the nominal diameter

4.1 A short length of pipe is loaded between two rigid

adjusted to the nearest 1 in. (25.4 mm).

parallel flat plates at a controlled rate of approach to one

7.3 The ends of specimens shall be cut square and shall be

another. Load-deflection (of the pipe diameter) data are ob-

free of burrs and jagged edges.

tained. If cracking, crazing, delamination, or rupture occurs,

7.4 No less than three specimens shall be tested for each

the corresponding load and deflection are recorded.

sample of pipe.

5. Significance and Use

NOTE 6—For quality control testing a single specimen may be used

with the thinnest wall at the top.

5.1 The external loading properties of plastic pipe obtained

by this test method are used for the following:

7.5 Certain RTRP pipes exhibit surface irregularity because

5.1.1 To determine the stiffness of the pipe. This is a

the production process is inside diameter controlled. To assure

function of the pipe dimensions and the physical properties of

accurate test results by parallel-plate loading, the test specimen

the material of which the pipe is made.

must be uniformly loaded along its entire bearing surface. If

5.1.2 To determine the load-deflection characteristics and

surface irregularities (resin-rich areas) along the outside diam-

pipe stiffness which are used for engineering design (see

eter prevent the bearing load from being uniformly distributed

Appendix X1). along the length of the specimen, the outside surface along the

5.1.3 To compare the characteristics of various plastics in

loading line shall be sanded smooth by hand. This sanding

pipe form. shall only be done if the reinforcement is not damaged. Note

5.1.4 To study the interrelations of dimensions and deflec-

that sanding shall be done only along the plate contact lines.

tion properties of plastic pipe and conduit.

8. Conditioning

5.1.5 Tomeasurethedeflectionandload-resistanceatanyof

several significant events if they occur during the test.

8.1 Condition pipe for at least4hinair,ata temperature of

73.4 6 3.6°F (23 6 2°C), and conduct the test in a room

6. Apparatus

maintained at the same temperature.

6.1 Testing Machine—A properly calibrated compression

8.2 When a referee test is required, condition specimens for

testing machine of the constant-rate-of-crosshead movement

at least 40 h at 73.4 6 3.6°F (23 6 2°C) and 50 6 5 % relative

type meeting the requirements of Test Method D695 shall be

humidity and conduct the test under the same conditions.

used to make the tests. The rate of head approach shall be 0.50

6 0.02 in. (12.5 6 0.5 mm)/min.

9. Procedure

9.1 Make the following measurements on each specimen:

NOTE 4—Hydraulic testing machines that may vary slightly from these

rate limits are commonly used and are satisfactory for testing RTRP and

9.1.1 Determine the length of each specimen to the nearest

RPMP pipe 24-in. (610-mm) size and larger. 1

⁄32 in. (1 mm) or better, by making and averaging at least four

6.2 Loading Plates—The load shall be applied to the equally spaced measurements around the perimeter.

specimen through two parallel steel bearing plates. The plates 9.1.2 Measure the wall thickness of each specimen in

shall be flat, smooth, and clean. The thickness of the plates accordance with Test Method D2122. Make at least eight

shall be sufficient so that no bending or deformation occurs measurements equally spaced around one end and calculate the

during the test, but it shall not be less than 0.25 in. (6.0 mm). average wall thickness.

The plate length shall equal or exceed the specimen length and 9.1.3 Determine whether a line of minimum wall thickness

the plate width shall not be less than the pipe contact width at exists along the length of the specimen and if so mark it for use

maximum pipe deflection plus 6.0 in. (150 mm). in 9.2.1.

D2412–02 (2008)

NOTE 7—OnRTRPandRPMPpipemeasurementsmaybemadeatboth

9.7 Record type and position of each event with respect to

ends.

the corresponding load and deflection. Discontinue the test

when either of the following occur:

9.1.4 Determine the average outside diameter to the nearest

9.7.1 The load on the specimen fails to increase with

0.01 in. (0.2 mm) using a circumferential wrap tape or by

increasing deflection (maximum point on load-deflection plot

averaging the maximum and minimum outside diameters as

has been reached).

measured with a micrometer or caliper.

9.7.2 The specimen deflection reaches 30 % of the average

9.1.5 For OD-controlled pipe calculate the average pipe

inside diameter or the required maximum deflection.

insidediamete

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D 2412–96a Designation:D 2412–02 (Reapproved 2008)

Standard Test Method for

Determination of External Loading Characteristics of Plastic

Pipe by Parallel-Plate Loading

This standard is issued under the fixed designation D 2412; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of load-deflection characteristics of plastic pipe under parallel-plate loading.

1.2 This test method covers thermoplastic resin pipe, reinforced thermosetting resin (RTRP) pipe,pipe (RTRP), and reinforced

plasticpolymer mortar (RPMP) pipe. pipe (RPMP).

1.3 The characteristics determined by this test method are pipe stiffness, stiffness factor, and load at specific deflections.

1.4The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 1—While this test method can be used in measuring the pipe stiffness of corrugated plastic pipe or tubing, special conditions and procedures

are used. These details are included in the product standards, for example, Specification F 405.

1.5 The text of this test method references notes and footnotes that provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the test method.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 695 Test Method for Compressive Properties of Rigid Plastics

D 1600 Terminology for Abbreviated Terms Relating to Plastics

D 2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F 405 Specification for Corrugated Polyethylene (PE) TubingPipe and Fittings

F 412 Terminology Relating to Plastic Piping Systems

3. Terminology

3.1 Definitions: Definitions are in accordance with Terminology F 412, and abbreviations are in accordance with Terminology

D 1600, unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Dy—measured change of the inside diameter in the direction of load application expressed in inches (millimetres).

3.2.2 initial inside diameter (d)—the average of the inside diameters as determined for the several test specimens and expressed

in inches (millimetres).

3.2.3 load (F)—the load applied to the pipe to produce a given percentage deflection. Expressed as newtons per metre or

pounds-force per linear inch.

This test method is under the jurisdiction ofASTM Committee F–17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Methods.

Current edition approved Oct. 10, 1996. Published November 1997. Originally published as D2412–65T. Last previous edition D2412–96.

This test method is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Methods.

Current edition approved July 15, 2008. Published July 2008. Originally approved in 1965. Last previous edition approved in 2002 as D 2412 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2412–02 (2008)

3.2.4 mean radius (r)—the mid-wall radius determined by subtracting the average wall thickness from the average outside

diameter and dividing the difference by two. Expressed as inches (millimetres).

3.2.5 pipe deflection (P)—the ratio of the reduction in pipe inside diameter to the initial inside diameter expressed as the

percentage of the initial inside diameter.

3.2.6 pipe significant events:

3.2.6.1 liner cracking or crazing—the occurrence of a break or network of fine breaks in the liner visible to the unaided eye.

3.2.6.2 rupture—a crack or break extending entirely or partly through the pipe wall.

NOTE 2—The significant events listed may or may not occur in a specific pipe material.

3.2.6.3 wall cracking— the occurence of a break in the pipe wall visible to the unaided eye.

3.2.6.4 wall delamination—the occurrence of any separation in the components of the pipe wall visible to the unaided eye.

3.2.7 pipe stiffness (PS)—the value obtained by dividing the force per unit length of specimen by the resulting deflection in the

same units at the prescribed percentage deflection.

3.2.8 stiffness factor (SF)—the product of pipe stiffness and the quantity 0.149 r r .

3.2.9 Discussion—The “pipe stiffness” and “stiffness factor” are related as follows:

PS 5 F/Dy (1)

3 3

SF 5 EI 5 0.149 Fr /Dy 5 0.149 r ~PS! (2)

NOTE 3—See Appendix X2 for information relating PS, E, and Dy.

4. Summary of Test Method

4.1 A short length of pipe is loaded between two rigid parallel flat plates at a controlled rate of approach to one another.

Load-deflection (of the pipe diameter) data are obtained. If cracking, crazing, delamination, or rupture occurs, the corresponding

load and deflection are recorded.

5. Significance and Use

5.1 The external loading properties of plastic pipe obtained by this test method are used for the following:

5.1.1 To determine the stiffness of the pipe. This is a function of the pipe dimensions and the physical properties of the material

of which the pipe is made.

5.1.2 To determine the load-deflection characteristics and pipe stiffness which are used for engineering design (see Appendix

X1).

5.1.3 To compare the characteristics of various plastics in pipe form.

5.1.4 To study the interrelations of dimensions and deflection properties of plastic pipe and conduit.

5.1.5 To measure the deflection and load-resistance at any of several significant events if they occur during the test.

6. Apparatus

6.1 Testing Machine—A properly calibrated compression testing machine of the constant-rate-of-crosshead movement type

meeting the requirements of Test Method D 695 shall be used to make the tests. The rate of head approach shall be 0.50 6 0.02

in. (12.5 6 0.5 mm)/min.

NOTE 4—Hydraulic testing machines that may vary slightly from these rate limits are commonly used and are satisfactory for testing RTRPand RPMP

pipe 24-in. (610-mm) size and larger.

6.2 Loading Plates—The load shall be applied to the specimen through two parallel steel bearing plates.The plates shall be flat,

smooth, and clean. The thickness of the plates shall be sufficient so that no bending or deformation occurs during the test, but it

shall not be less than 0.25 in. (6.0 mm). The plate length shall equal or exceed the specimen length and the plate width shall not

be less than the pipe contact width at maximum pipe deflection plus 6.0 in. (150 mm).

NOTE 5—For some types of testing machines a greater plate thickness may be required to limit plate bending.

6.3 Deformation (Deflection) Indicator— The change in inside diameter, or deformation parallel to the direction of loading,

shall be measured with a suitable instrument meeting the requirements of Test Method D 695, except that the instrument shall be

accurate to the nearest 0.010 in. (0.25 mm). The instrument shall not support the pipe test specimen or the plate or affect in any

way the load deflection measurements. Changes in diameter are measured during loading by continuously recording plate travel

or by periodically computing it.

7. Test Specimens

7.1 For thermoplastic pipe, the test specimen shall be a piece of pipe 6 6 ⁄8 in. (150 6 3 mm) long.

7.2 For reinforced thermosetting resin pipe, the minimum test specimen length shall be three times the nominal pipe diameter

or 12.0 in. (300 mm), whichever is smaller. For pipe larger than 60 in. (1524 mm) in diameter, the minimum specimen length shall

be 20 % of the nominal diameter adjusted to the nearest 1 in. (25.4 mm).

D 2412–02 (2008)

7.3 The ends of specimens shall be cut square and shall be free of burrs and jagged edges.

7.4 No less than three specimens shall be tested for each sample of pipe.

NOTE 6—For quality control testing a single specimen may be used with the thinnest wall at the top.

7.5 Certain RTRP pipes exhibit surface irregularity because the production process is inside diameter controlled. To assure

accuratetestresultsbyparallel-plateloading,thetestspecimenmustbeuniformlyloadedalongitsentirebearingsurface.Ifsurface

irregularities (resin-rich areas) along the outside diameter prevent the bearing load from being uniformly distributed along the

length of the specimen, the outside surface along the loading line shall be sanded smooth by hand.This sanding shall only be done

if the reinforcement is not damaged. Note that sanding shall be done only along the plate contact lines.

8. Conditioning

8.1 Condition pipe for at least4hinair,ata temperature of 73.4 6 3.6°F (23 6 2°C), and conduct the test in a room maintained

at the same temperature.

8.2 When a referee test is required, condition specimens for at least 40 h at 73.4 6 3.6°F (23 6 2°C) and 50 6 5 % relative

humidity and conduct the test under the same conditions.

9. Procedure

9.1 Make the following measurements on each specimen:

9.1.1 Determine the length of each specimen to the nearest ⁄32 in. (1 mm) or better, by making and averaging at least four

equally spaced measurements around the perimeter.

9.1.2 Measure the wall thickness of each specimen in accordance with Test Method D 2122. Make at least eight measurements

equally spaced around one end and calculate the average wall thickness.

9.1.3 Determine whether a line of minimum wall thickness exists along the length of the specimen and if so mark it for use in

9.2.1.

NOTE 7—On RTRP and RPMP pipe measurements may be made at both ends.

9.1.4 Determine the average outside diameter to the nearest 0.01 in. (0.2 mm) using a circumferential wrap tape or by averaging

the maximum and minimum outside diameters as measured with a micrometer or caliper.

9.1.5 For OD-controlled pipe calculate the average pipe inside diameter (ID) by subtracting two times the average of all wall

thicknesses(9.1.2)fromtheaverageofalloutsidediameters(9.1.4).ForID-controlledpipedeterminetheaverageIDbymeasuring

the maximum and minimum inside diameters. Use this average ID as the basis for computing the percentage of deflection for all

specimens in that lot of pipe.

9.2 Locate the pipe section with its longitudinal axis parallel to the bearing plates and center it laterally in the testing machine.

9.2.1 If an orientation of minimum wall thickness has been found, place the first specimen so the thinnest wall is at the top and

rotate successive specimens 35 and 70°. If no minimum wall thickness was identified, use any base line.

9.3 With the deflection indicator in place, bring the upper plate into contact with the specimen with no more load than is

necessary to hold it in place. This establishes the beginning point for subsequent deflection measurements.

9.4 Compress the specimen at a constant rate of 0.50 6 0.02 in. (12.5 6 0.5 mm)/min.

NOTE 8—For larger sizes of pipe made from relatively low-modulus materials, creep may affect the results of this test because of the loading rate

specified.

9.5 Record load-deflection measurements continuously or intermittently with reference to the relative movement of the bearing

plates. If measurements are made intermittently, make and record such measurements at increments of not more than 5 % of the

average inside diameter of the specimen. Refer to Annex A1.

9.6 Observe and note the load and deflection at the first evidence of each of the following significant events when and if they

occur:

9.6.1 Liner cracking or crazing.

9.6.2 Wall cracking.

9.6.3 Wall delamination.

9.6.4 Rupture.

9.7 Record type and position of each event with respect to the corresponding load and deflection. Discontinue the test when

either of the following occur:

9.7.1 The load on the specimen fails to increase with increasing deflection (maximum point on load-deflection plot has been

reached).

9.7.2 The specimen deflection reaches 30 % of the average inside diameter or the required maximum deflection.

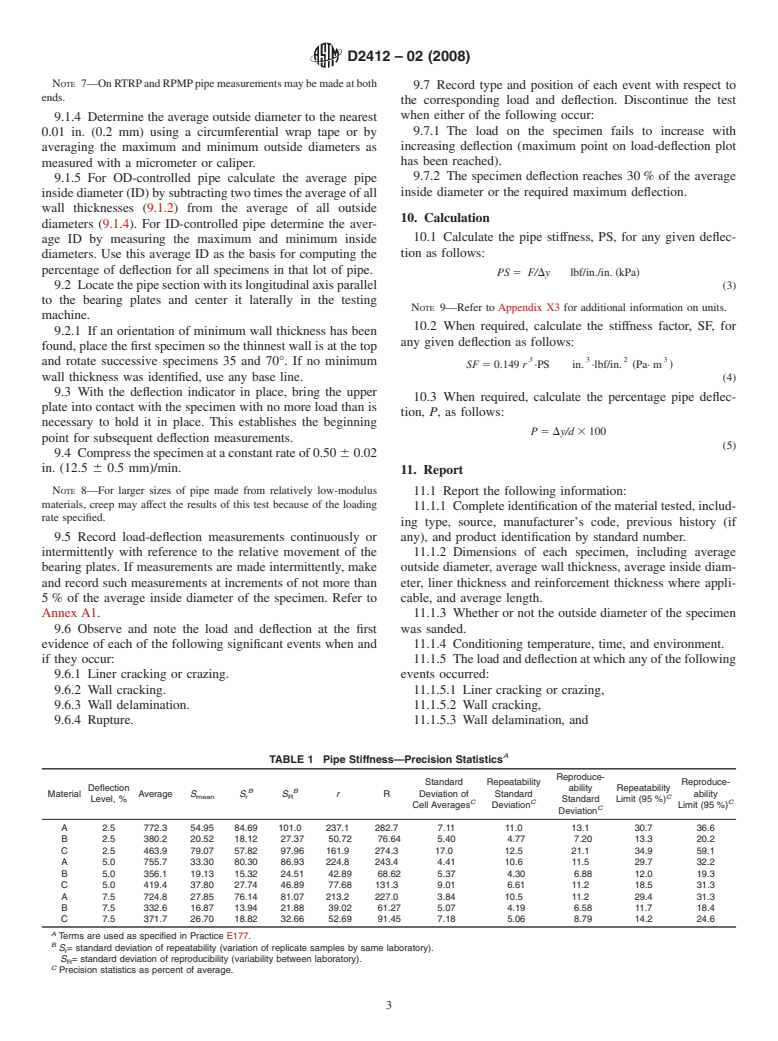

10. Calculation

10.1 Calculate the pipe stiffness, PS, for any given deflection as follows:

PS 5 F/Dy lbf/in./in. ~kPa!

(3)

D 2412–02 (2008)

NOTE 9—Refer to Appendix X3 for additional information on units.

10.2 When required, calculate the stiffness factor, SF, for any given deflection as follows:

3 3 2 3

SF 5 0.149 r ·PS in. ·lbf/in. ~Pa· m !

(4)

10.3 When required, calculate the percentage pipe deflection, P, as follows:

P5Dy/d 3 100

(5)

11. Report

11.1 Report the following information:

11.1.1 Complete identification of the material tested, including type, source, manufacturer’s code, previous history (if any), and

product identification by standard number.

11.1.2 Dimensions of each specimen, including average outside diameter, average wall thickness, average inside diameter, liner

thickness and reinforcement thickness where applicable, and average length.

11.1.3 Whether or not the outside diameter of the specimen was sanded.

11.1.4 Conditioning temperature, time, and environment.

11.1.5 The load and deflection at which any of the following events occurred:

11.1.5.1 Liner cracking or crazing,

11.1.5.2 Wall cracking,

11.1.5.3 Wall delamination, and

11.1.5.4 Rupture.

11.1.6 The reason for terminating the test.

11.1.7 If required, a plot on cartesian coordinates of the load in p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.