ASTM F1587-99(2005)

(Specification)Standard Specification for Head and Face Protective Equipment for Ice Hockey Goaltenders

Standard Specification for Head and Face Protective Equipment for Ice Hockey Goaltenders

ABSTRACT

This document covers specifications and conformity assessment methods for new head and face protectors for ice hockey goaltenders, as offered for initial sale. This specification is intended to reduce the risk of injury associated with playing the position of goaltender in ice hockey. The protectors are classified according to types: Type I and Type II. Optical tests, shock attenuation tests, puck impact tests, penetration resistance tests, and neck strap retention test shall be performed to meet the requirements specified.

SCOPE

1.1 This document covers specifications and conformity assessment methods for new head and face protectors for ice hockey goaltenders, as offered for initial sale.

1.2 This specification is intended to reduce the risk of injury associated with playing the position of goaltender in ice hockey.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F1587 – 99 (Reapproved 2005)

Standard Specification for

Head and Face Protective Equipment for Ice Hockey

Goaltenders

This standard is issued under the fixed designation F1587; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Ice hockey is a contact sport with intrinsic hazards. Participation in this sport implies acceptance of

some risk of injury. The purpose of protective equipment is to reduce this risk. The use of protective

equipment will not eliminate all injuries, but should substantially reduce the severity and frequency

of injury.

This specification was developed to address the unique demands and hazards associated with the

position of goaltender in ice hockey. Two types of protectors are designated. Both types are subject

to impact resistance and shock attenuation requirements. Type I protectors are subject to hockey stick

blade penetration resistance requirements over their entire area of coverage. Type II protectors are

subject to hockey puck penetration resistance requirements within the area of the field of vision, and

hockey stick blade penetration resistance requirements over the remainder of the area of coverage. It

is recommended that Type II protectors be used only by players 18 years of age and older.

This specification is intended to be used with other standards, listed in Section 2, which contain

details of required test procedures.

1. Scope F513 Safety Specification for Eye and Face Protective

Equipment for Hockey Players

1.1 This document covers specifications and conformity

F1446 Test Methods for Equipment and Procedures Used in

assessment methods for new head and face protectors for ice

Evaluating the Performance Characteristics of Protective

hockey goaltenders, as offered for initial sale.

Headgear

1.2 This specification is intended to reduce the risk of injury

associated with playing the position of goaltender in ice

3. Terminology

hockey.

3.1 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as the

3.1.1 back plate—a section of a goaltender’s head and face

standard. The values given in parentheses are for information

protector that covers the posterior of the wearer’s head, in a

only.

style of protector in which a front section and a rear section of

2. Referenced Documents theprotectormoverelativetoeachotherinorderforthewearer

to put on or remove the protector.

2.1 This specification is intended to be used with the

3.1.2 neck strap—a strap that is affixed to the two sides of

following standards:

the helmet and passes under the mandible in close proximity to

2.2 ASTM Standards:

the neck.

3.1.3 shell—the material that gives the helmet its form.

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, and Facilities and is the direct responsibility of Subcommittee F08.15 4. Types of Protectors

on Ice Hockey.

4.1 Type I—Combination head, eye, and face protectors that

Current edition approved May 1, 2005. Published May 2005. Originally

meet requirements for ice hockey stick blade penetration over

approved in 1995. Last previous edition approved in 1999 as F1587 – 99. DOI:

10.1520/F1587-99R05.

the entire area of coverage.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Type II—Combination head, eye, and face protectors

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that meet requirements for ice hockey puck penetration resis-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tance over the area of the field of vision and that meet

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1587 – 99 (2005)

requirements for ice hockey stick blade penetration resistance 5.5 Neck Strap Retention—When tested in accordance with

over the remainder of the area of coverage. 8.5, the force to separate the strap shall be not less than 110 N

(24.7 lbf) nor greater than 500 N (112.4 lbf), and the maximum

5. Performance Requirements displacement of the strap shall not exceed 25.4 mm (1.0 in.) at

a load of 110 N. Retention system requirements shall be met at

5.1 Optical Requirements—Optical requirements shall be as

the ambient conditions specifiedin 12.1ofTest MethodF1446.

stated in 6.3 through 6.4.9 of Specification F513.

5.2 Headform Drop Impact Shock Attenuation Test Require-

6. General Requirements

ments:

5.2.1 Ambient Condition Impacts—The average peak g of

6.1 Component Assemblies—A goaltender head and face

each set of three impacts delivered to the seven specified test

protector may be assembled from a separate helmet and face

locations shall not exceed 275 g.

protector provided that the combination meets all of the

5.2.2 High- and Low-Temperature Condition Impacts—For

requirements of this specification, and provided that the com-

the two impacts delivered to each of the two ambient condition

ponents are designed to be compatible without modification.

test locations with the highest average peak g, no single impact

6.2 Materials:

shall exceed 300 g.

6.2.1 The design of protectors and the choice of materials

5.2.3 Shock Attenuation Impact Damage—The protector

shall be such as to combine mechanical strength and durability

shell shall not suffer any full thickness fractures as a result of

consistent with the intended use of the equipment.

impact testing. Shock-absorbing components (including pad-

6.2.2 Materials coming into contact with the wearer shall

ding and chin cups) shall not suffer any full thickness fractures

not be a type that is known to cause skin irritation or disease,

as a result of impact testing.Aprotector shall fail if any means

and shall not undergo significant loss of strength, flexibility, or

of attachment of any component to any other component, or

other physical change as a result of contact with the wearer.

any closure or retention device, breaks or fails to maintain

6.3 Finishes—All parts shall be well finished and free of

attachment as a result of shock attenuation testing.

any sharp edges or other irregularities that would present the

5.3 Puck Impact Test Requirements:

potential hazards of scratching or cutting the wearer or an

5.3.1 Failure Conditions (All Protectors):

opposing player. Wire components shall have a protective

5.3.1.1 Assembly Integrity—A protector shall fail if any

coating.

means of attachment of any component to any other compo-

nent, or any closure or retention device (excluding positioning 6.4 External Projections—In protectors that incorporate a

devices such as“ j” or “s” hooks), breaks or fails to maintain backplate,theedgeofthefrontsection,whichextendsoverthe

attachment as a result of puck impact testing. back plate, shall not project more than 25.4 mm (1 in.) beyond

the adjacent edges of the back plate, as measured along a

5.3.1.2 ImpactDamage—Theprotectorshellshallnotsuffer

any full thickness fractures as a result of impact testing. square-ended 12.7-mm (0.5-in.) diameter cylindrical rod, when

the rod end is inserted behind the projecting edge of the front

Shock-absorbing components (including padding and chin

cups) shall not suffer any full thickness fractures as a result of section, and along the inner surface of the front section, until

impact testing. the end of the rod is flush with the outer edge of the back plate.

5.3.1.3 Facial Contact—No unpadded portion of the head

6.5 Padding—Padding or cushioning material shall be in-

and face protector shall contact the headform before, during, or

corporated in such a way as to cover all hard surfaces that

after puck impact testing.

could otherwise come into contact with the wearer’s head. The

5.3.2 Failure Conditions (Clear Shield Components)—A

method of securing padding shall not fail to maintain the

protector shall fail if any full thickness fractures occur as a

padding material in position under normal conditions of heat,

result of puck impact testing.

cold, moisture, or force distortion by the wearer.

5.3.3 Failure Conditions (Wire Mesh Components)—Apro-

6.6 Assembly—The methods of assembling protector com-

tector shall fail if any weld completely separates or if any

ponents shall be such as to prevent disengagement of the

fractures in the wire between any two welds occurs as a result

components from each other and from the test headforms as a

of puck impact testing.Aprotector shall fail if fragments of the

result of the tests performed under this specification.

wire coating with a total area greater than 9 mm have

6.7 Access—All protectors shall be so constructed that

completely separated from the wire.

accesstothewearer’sfaceisprovided,withouttheuseoftools,

5.4 Penetration Resistance Test Requirements:

and without causing movement to the cervical spine, in the

5.4.1 Type I Protectors—It shall not be possible to touch the

event of injury. The access provided shall be sufficient for the

test headform to the curved end of the test stick blade within

administration of cardiopulmonary resuscitation to the wearer.

the required area of coverage, excluding the ear opening, with

6.8 Protectors should be designed to minimize rotation on

the test blade oriented in any manner.

the head under the normal stresses encountered in use.

5.4.2 Type II Protectors—It shall not be possible to touch

6.9 Welded Wire Components—All wire ends shall termi-

the face of the headform to the test puck disk within the area

nate at the perimeter of the wire component and must overlap

of the field of vision provided by the protector. Do not touch

the shell material of the protector in such a way as to prevent

the test headform with the curved end of the test stick blade

stick or puck entry between components.

within the remainder of the required area of coverage, exclud-

ing the ear opening, with the test blade oriented in any manner. 6.10 Area of Coverage:

F1587 – 99 (2005)

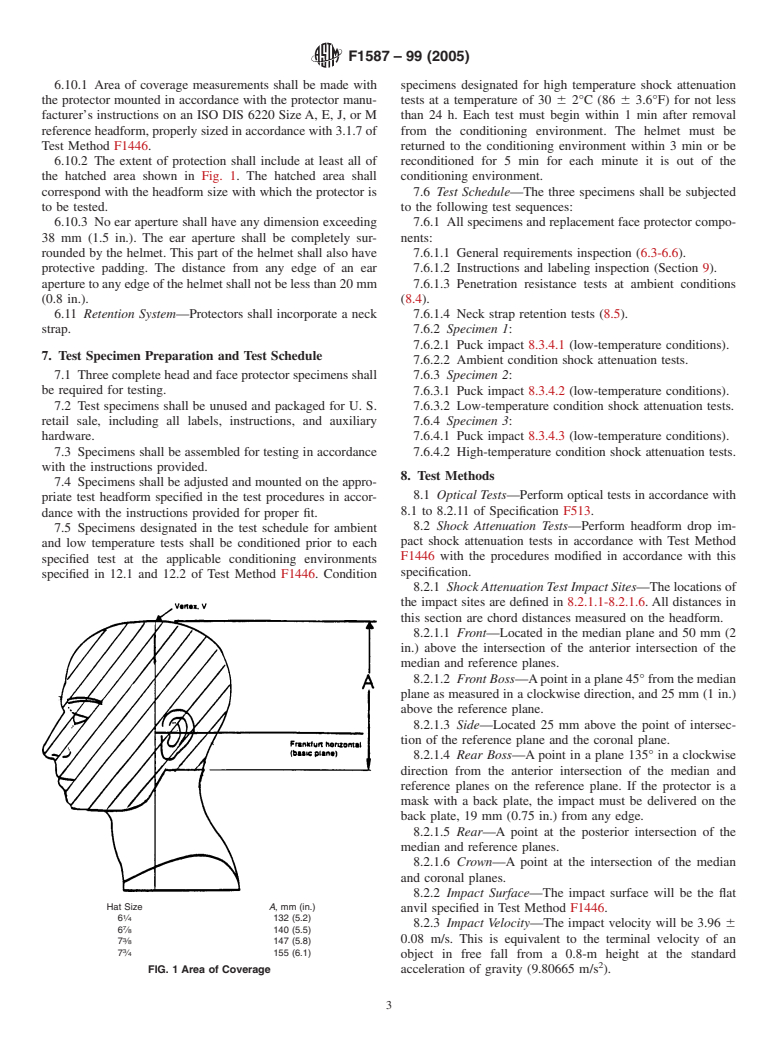

6.10.1 Area of coverage measurements shall be made with specimens designated for high temperature shock attenuation

the protector mounted in accordance with the protector manu- tests at a temperature of 30 6 2°C (86 6 3.6°F) for not less

facturer’s instructions on an ISO DIS 6220 Size A, E, J, or M than 24 h. Each test must begin within 1 min after removal

reference headform, properly sized in accordance with 3.1.7 of from the conditioning environment. The helmet must be

Test Method F1446. returned to the conditioning environment within 3 min or be

6.10.2 The extent of protection shall include at least all of reconditioned for 5 min for each minute it is out of the

the hatched area shown in Fig. 1. The hatched area shall conditioning environment.

correspond with the headform size with which the protector is 7.6 Test Schedule—The three specimens shall be subjected

to be tested. to the following test sequences:

6.10.3 No ear aperture shall have any dimension exceeding 7.6.1 All specimens and replacement face protector compo-

38 mm (1.5 in.). The ear aperture shall be completely sur- nents:

rounded by the helmet. This part of the helmet shall also have 7.6.1.1 General requirements inspection (6.3-6.6).

protective padding. The distance from any edge of an ear 7.6.1.2 Instructions and labeling inspection (Section 9).

aperture to any edge of the helmet shall not be less than 20 mm 7.6.1.3 Penetration resistance tests at ambient conditions

(0.8 in.). (8.4).

6.11 Retention System—Protectors shall incorporate a neck 7.6.1.4 Neck strap retention tests (8.5).

strap. 7.6.2 Specimen 1:

7.6.2.1 Puck impact 8.3.4.1 (low-temperature conditions).

7. Test Specimen Preparation and Test Schedule

7.6.2.2 Ambient condition shock attenuation tests.

7.1 Three complete head and face protector specimens shall 7.6.3 Specimen 2:

be required for testing. 7.6.3.1 Puck impact 8.3.4.2 (low-temperature conditions).

7.2 Test specimens shall be unused and packaged for U. S. 7.6.3.2 Low-temperature condition shock attenuation tests.

retail sale, including all labels, instructions, and auxiliary 7.6.4 Specimen 3:

hardware. 7.6.4.1 Puck impact 8.3.4.3 (low-temperature conditions).

7.3 Specimens shall be assembled for testing in accordance 7.6.4.2 High-temperature condition shock attenuation tests.

with the instructions provided.

8. Test Methods

7.4 Specimens shall be adjusted and mounted on the appro-

8.1 Optical Tests—Perform optical tests in accordance with

priate test headform specified in the test procedures in accor-

8.1 to 8.2.11 of Specification F513.

dance with the instructions provided for proper fit.

8.2 Shock Attenuation Tests—Perform headform drop im-

7.5 Specimens designated in the test schedule for ambient

pact shock attenuation tests in accordance with Test Method

and low temperature tests shall be conditioned prior to each

F1446 with the procedures modified in accordance with this

specified test at the applicable conditioning environments

specification.

specified in 12.1 and 12.2 of Test Method F1446. Condition

8.2.1 Shock Attenuation Test Impact Sites—The locations of

the impact sites are defined in 8.2.1.1-8.2.1.6. All distances in

this section are chord distances measured on the headform.

8.2.1.1 Front—Located in the median plane and 50 mm (2

in.) above the intersection of the anterior intersection of the

median and reference planes.

8.2.1.2 Front Boss—Apoint in a plane 45° from the median

plane as measured in a clockwise direction, and 25 mm (1 in.)

above the reference plane.

8.2.1.3 Side—Located 25 mm above the point of intersec-

tion of the reference plane and the coronal plane.

8.2.1.4 Rear Boss—A point in a plane 135° in a clockwise

direction from the anterior intersection of the median and

reference planes on the reference plane. If the protector is a

mask with a back plate, the impact must be delivered on the

back plate, 19 mm (0.75 in.) from any edge.

8.2.1.5 Rear—A point at the posterior intersection of the

median and reference planes.

8.2.1.6 Crown—A point at the intersection of the median

and coronal planes.

8.2.2 Impact Surface—The impact surface will be the flat

Hat Size A, mm (in.)

anvil specified in Test Method F1446.

6 ⁄4 132 (5.2)

8.2.3 Impact Velocity—The impact velocity will be 3.96 6

6 ⁄8 140 (5.5)

0.08 m/s. This is equivalent to the terminal velocity of an

7 ⁄8 147 (5.8)

7 ⁄4 155 (6.1)

object in free fall from a 0.8-m height at the standard

FIG. 1 Area of Coverage acceleration of gravity (9.80665 m/s ).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.