ASTM D3169-89(2001)

(Specification)Standard Specification for Refined Sunflower Oil (Withdrawn 2007)

Standard Specification for Refined Sunflower Oil (Withdrawn 2007)

SCOPE

1.1 This specification covers once-refined sunflower oil, technical grade, suitable for use in protective coatings.

WITHDRAWN RATIONALE

This specification covers once-refined sunflower oil, technical grade, suitable for use in protective coatings.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this specification was withdrawn in February 2007. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3169 – 89 (Reapproved 2001)

Standard Specification for

Refined Sunflower Oil

This standard is issued under the fixed designation D 3169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1967 Test Method for Color After Heating of Drying

Oils

1.1 This specification covers once-refined sunflower oil,

D 2090 Test Method for Clarity and Cleanness of Paint and

technical grade, suitable for use in protective coatings.

Ink Liquids

2. Referenced Documents

3. Properties

2.1 ASTM Standards:

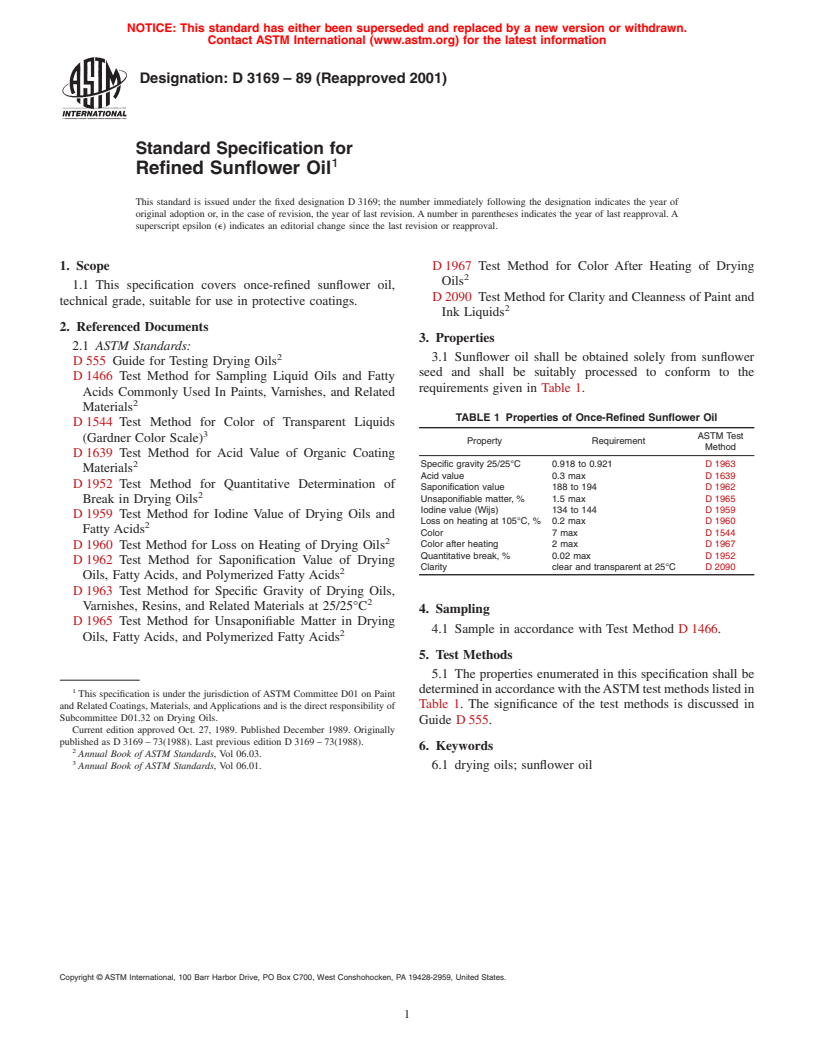

2 3.1 Sunflower oil shall be obtained solely from sunflower

D 555 Guide for Testing Drying Oils

seed and shall be suitably processed to conform to the

D 1466 Test Method for Sampling Liquid Oils and Fatty

requirements given in Table 1.

Acids Commonly Used In Paints, Varnishes, and Related

Materials

TABLE 1 Properties of Once-Refined Sunflower Oil

D 1544 Test Method for Color of Transparent Liquids

ASTM Test

(Gardner Color Scale)

Property Requirement

Method

D 1639 Test Method for Acid Value of Organic Coating

2 Specific gravity 25/25°C 0.918 to 0.921 D 1963

Materials

Acid value 0.3 max D 1639

D 1952 Test Method for Quantitative Determination of

Saponification value 188 to 194 D 1962

Unsaponifiable matter, % 1.5 max D 1965

Break in Drying Oils

Iodine value (Wijs) 134 to 144 D 1959

D 1959 Test Method for Iodine Value of Drying Oils and

Loss on heating at 105°C, % 0.2 max D 1960

Fatty Acids

Color 7 max D 1544

Color after heating 2 max D 1967

D 1960 Test Method for Loss on Heating of Drying Oils

Quantitative break, % 0.02 max D 1952

D 1962 Test Method for Saponification Value of Drying

Clarity clear and transparent at 25°C D 2090

Oils, Fatty Acids, and Polymerized Fatty Acids

D 1963 Test Method for Specific Gravity of Drying Oils,

Varnishes, Resins, and Related Materials at 25/25°C

4. Sampling

D 1965 Test Method for Unsaponifiable Matter in Drying

4.1 Sample in accordanc

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 The testing procedures described in these test methods have been in use for many years and emphasize the physical properties of pine oil rather than its chemical composition. Test Methods D6387 describe a capillary gas chromatography method which is suitable for determining both the major and minor components found in pine oils.

SCOPE

1.1 These test methods cover procedures for sampling and testing pine oils, and are applicable to both natural pine oils derived from pine stumps either by the steam and solvent process or by destructive distillation, and also to synthetic pine oils obtained by the chemical hydration of terpene hydrocarbons.

1.2 The procedures given in these test methods appear in the following order:

Section

Sampling

4

Appearance

5

Color

6

Specific Gravity

7

Refractive Index

8

Composition

9

Moisture

10

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Tall oil fractionated products derived from tall oil are important commercial materials, primarily composed of fatty acids and rosin acids, but also containing some neutral material (see Terminology D804). For many applications, it is necessary to know the level of the individual fatty acids and rosin acids present in these products. Gas chromatography has proven to be a useful tool for such determinations (see Test Methods D509), and capillary chromatography, described in these test methods, is considered to be the most effective gas chromatographic technique currently available. In particular situations, other techniques may be more suitable than gas chromatography. For example, the presence of fatty acid esters in the sample would result in transesterification during the derivatization step that may affect the results.

3.2 Due to hydrogen bonding, unmodified tall oil fatty acids and rosin acids cannot be volatilized at atmospheric pressure without undergoing decomposition. So, it is necessary to convert the free acids to the more volatile and more stable methyl esters, prior to chromatographic separation.

3.3 These test methods describe four ways to prepare methyl esters. The classic method is through the use of diazomethane, but diazomethane is a hazardous and toxic material, and so is no longer the preferred agent. The use of diazomethane is detailed in Appendix X1.

3.3.1 TMAH causes isomerization of a sample’s di- and polyunsaturated fatty acids, when it is used in even a slight excess. This leads to inaccurate results for the individual fatty acid components. TMAH should be used for materials containing only rosin acids, or when the identification or quantitation of individual fatty acid components is not important.

3.3.2 TMPAH is the recommended methylating agent when the identification or quantitation of individual di- and polyunsaturated fatty acids is required. TMPAH produces results that are very similar to those of diazomethane, but with...

SCOPE

1.1 These test methods cover the determination of the amounts of the individual fatty acids and rosin acids in fractionated tall oil products, using capillary gas chromatographic separation of the volatile methyl esters of these acids.

1.2 Four methods for forming the methyl esters, and two methods for determining the amounts of the individual fatty acids and rosin acids are described.

1.2.1 The classic method for the formation of methyl esters is through the use of diazomethane, but diazomethane is a hazardous and toxic material, and so is no longer the preferred reagent. The use of diazomethane is detailed in the Appendix. Methyl esters may be formed through the use of tetramethylammonium hydroxide (TMAH), trimethylphenylammonium hydroxide (TMPAH), or N,N-dimethylformamide dimethyl acetal (DMF-DMA).

1.2.2 The two methods for determining the amount of the individual fatty acids and rosin acids are the “internal standard” method, which yields absolute values, and the “area percent” method, which yields relative values.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

2.1 This test method is intended for the determination of the free fatty acids contained in animal, marine, and vegetable fats and oils for the purpose of quality assurance.

SCOPE

1.1 This test method covers the determination of the free fatty acid content of fats and oils.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This practice is designed for use by the oil processor or research laboratory for evaluation by a trained sensory panel, or for use by quality control (QC) and quality assurance (QA) personnel for sampling from a tank truck, car, or any other bulk transportation container, or by both.

4.2 The consistent use of this practice will provide representative samples for all sensory, chemical and physical analyses and will protect the oil from oxidation.

4.3 The objective of this practice is to ensure that the sample is representative of the sample source from the time of sampling until the time of evaluation and to protect oil quality during that time.

4.4 This practice addresses neither evaluation and scaling techniques, nor the sampling, handling, and preparing of solid fats.

SCOPE

1.1 This practice covers the recommended procedures for bulk sampling, handling, and preparing edible vegetable oil (liquid at room temperature) prior to sensory evaluation.

1.2 This practice is consistent with the background information presented in ASTM STP 433, ASTM Manual 26, and ASTM STP 758. These should be consulted for supplemental guidance.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The testing procedures described in these test methods have been in use for many years and emphasize the physical properties of pine oil rather than its chemical composition. Test Methods D6387 describe a capillary gas chromatography method which is suitable for determining both the major and minor components found in pine oils.

SCOPE

1.1 These test methods cover procedures for sampling and testing pine oils, and are applicable to both natural pine oils derived from pine stumps either by the steam and solvent process or by destructive distillation, and also to synthetic pine oils obtained by the chemical hydration of terpene hydrocarbons.

1.2 The procedures given in these test methods appear in the following order:

Section

Sampling

4

Appearance

5

Color

6

Specific Gravity

7

Refractive Index

8

Composition

9

Moisture

10

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 This test method is intended to determine the melting point of all normal animal and vegetable fats.

3.2 The natural fats and oils, that is, those of animal and vegetable origin, are mixtures of glycerides and other substances and consist of a number of components. They do not exhibit either a definite or sharp melting point. Fats pass through a stage of gradual softening before they become completely liquid. The melting point then shall be defined by the specific conditions of the method by which it is determined and, in this case, it shall be the temperature at which the sample becomes perfectly clear and liquid.

SCOPE

1.1 This test method is intended to determine the melting point of all normal animal and vegetable fats and oils. This test method was derived from ALCA H-16.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Tall oil fractionated products derived from tall oil are important commercial materials, primarily composed of fatty acids and rosin acids, but also containing some neutral material (see Terminology D804). For many applications, it is necessary to know the level of the individual fatty acids and rosin acids present in these products. Gas chromatography has proven to be a useful tool for such determinations (see Test Methods D509), and capillary chromatography, described in these test methods, is considered to be the most effective gas chromatographic technique currently available. In particular situations, other techniques may be more suitable than gas chromatography. For example, the presence of fatty acid esters in the sample would result in transesterification during the derivatization step that may affect the results.

3.2 Due to hydrogen bonding, unmodified tall oil fatty acids and rosin acids cannot be volatilized at atmospheric pressure without undergoing decomposition. So, it is necessary to convert the free acids to the more volatile and more stable methyl esters, prior to chromatographic separation.

3.3 These test methods describe four ways to prepare methyl esters. The classic method is through the use of diazomethane, but diazomethane is a hazardous and toxic material, and so is no longer the preferred agent. The use of diazomethane is detailed in Appendix X1.

3.3.1 TMAH causes isomerization of a sample’s di- and polyunsaturated fatty acids, when it is used in even a slight excess. This leads to inaccurate results for the individual fatty acid components. TMAH should be used for materials containing only rosin acids, or when the identification or quantitation of individual fatty acid components is not important.

3.3.2 TMPAH is the recommended methylating agent when the identification or quantitation of individual di- and polyunsaturated fatty acids is required. TMPAH produces results that are very similar to those of diazomethane, but with...

SCOPE

1.1 These test methods cover the determination of the amounts of the individual fatty acids and rosin acids in fractionated tall oil products, using capillary gas chromatographic separation of the volatile methyl esters of these acids.

1.2 Four methods for forming the methyl esters, and two methods for determining the amounts of the individual fatty acids and rosin acids are described.

1.2.1 The classic method for the formation of methyl esters is through the use of diazomethane, but diazomethane is a hazardous and toxic material, and so is no longer the preferred reagent. The use of diazomethane is detailed in the Appendix. Methyl esters may be formed through the use of tetramethylammonium hydroxide (TMAH), trimethylphenylammonium hydroxide (TMPAH), or N,N-dimethylformamide dimethyl acetal (DMF-DMA).

1.2.2 The two methods for determining the amount of the individual fatty acids and rosin acids are the “internal standard” method, which yields absolute values, and the “area percent” method, which yields relative values.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The application of this practice will help ensure consistency in procedures used for the sensory evaluation of edible oils and fats.

SCOPE

1.1 This practice covers the recommended procedures for the sensory evaluation of edible oils and fats.

1.2 This practice covers techniques for evaluating appearance, odor, and flavor in fats and oils, for determining overall odor and flavor intensity, and the intensity of individual odors or flavors.

1.3 The techniques used in this practice are applicable to oils (liquid at room temperature) and liquified fats (solid at room temperature).

1.4 The values in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method is useful when oils and fats are suspected as an ignition source or a fuel source in a fire.

4.1.1 The identification of oil and fat residues in samples from a fire scene can support the field investigator’s opinion regarding the origin and cause of the fire.

4.1.2 The positive identification of fatty acid(s) does not necessarily mean that the fire was caused by self heating.

4.2 This test method specifically identifies fatty acid derivatives. Oils and fats are comprised primarily of triglycerides (which are fatty acids attached to a glycerol backbone), and some free fatty acids. Free fatty acids and triglycerides are not easily analyzed by the traditional ignitable liquid extraction techniques. Solvent extraction and derivatization to FAME will enable identification by GC-MS.

4.2.1 The identification of an individual fatty acid in fire debris samples does not confirm the presence of oils or fats; however, there are times when large quantities of the oil or fat may be extracted. In such cases a more positive identification can be made.

4.2.2 Oils and fats containing fatty acids with no double bonds will generally have no tendency to self-heat. With increasing unsaturation (1, 2, and 3 double bonds), the tendency to self-heat also increases, such that polyunsaturated fatty acids (PUFAs), such as C18:3, have a high tendency to self-heat.

4.3 This test method is a sensitive separation technique and can detect quantities as small as 3 µL of oil or fat residue in an extract from a debris sample.

4.4 This test method shall be performed after all required traditional testing for ignitable liquid residues is completed.

4.5 This test method extracts liquids and residues from porous and nonporous materials of various sizes.

4.6 This test method can be hampered by coincident extraction of interfering compounds present in the fire debris samples.

4.7 This is a destructive technique and whenever possible the entire sample should...

SCOPE

1.1 This test method covers the extraction, derivatization, and identification of fatty acids indicative of vegetable oils and fats in fire debris and liquid samples. This procedure will also extract animal oils and fats, as these are similar in chemical composition to vegetable oils and fats. Herein, the phrase “oils and fats” will be used to refer to both animal and vegetable derived oils and fats.

1.2 This test method is suitable for successfully extracting oil and fat residues having 8 to 24 carbon atoms.

1.3 The identification of a specific type of oil (for example, olive, corn, linseed) requires a quantitative analysis of the fatty acid esters and is beyond the scope of this test method.

1.4 This test method cannot replace the requisite knowledge, skills, or abilities acquired through appropriate education, training, and experience and should be used in conjunction with sound professional judgment.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard7 pagesEnglish languagesale 15% off

- Standard7 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers SEBS (styrene-ethylenebutylene-styrene)-modified mopping asphalt intended for use in built-up roof construction, construction of some modified bitumen systems, construction of bituminous vapor retarder systems, and for adhering insulation boards used in various types of roofing systems. This specification is intended as a material specification and issues regarding the suitability of specific roof constructions or application techniques are beyond its scope. The specified tests and property values are intended to establish minimum properties. In place system design criteria or performance attributes are factors beyond the scope of this specification. The base asphalt shall be prepared from crude petroleum and the SEBS-modified asphalt shall incorporate sufficient SEBS as the primary polymeric modifier. The SEBS modified asphalt shall be homogeneous and free of water and shall conform to the prescribed physical properties including (1) softening point before and after heat exposure, (2) softening point change, (3) flash point, (4) penetration before and after heat exposure, (5) penetration change, (6) solubility in trichloroethylene, (7) tensile elongation, (8) elastic recovery, and (9) low temperature flexibility. The sampling and test methods to determine compliance with the specified physical properties, as well as the evaluation for stability during heat exposure are detailed.

SCOPE

1.1 This specification covers SEBS (styrene-ethylene-butylene-styrene)-modified asphalt intended for use in built-up roof construction, construction of some modified bitumen systems, construction of bituminous vapor retarder systems, and for adhering insulation boards used in various types of roof systems.

1.2 This specification is intended as a material specification. Issues regarding the suitability of specific roof constructions or application techniques are beyond its scope.

1.3 The specified tests and property values used to characterize SEBS-modified asphalt are intended to establish minimum properties. In-place system design criteria or performance attributes are factors beyond the scope of this specification.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.