ASTM D6941-03

(Practice)Standard Practice for Measuring Fluidization Segregation Tendencies of Powders

Standard Practice for Measuring Fluidization Segregation Tendencies of Powders

SCOPE

1.1 This practice covers an apparatus and procedure for simulating the segregation tendencies of powders by means of the fluidization mechanism.

1.2 Powders must be capable of being fluidized in order to be tested by this practice.

1.3 Temperature- and humidity-sensitive powders may need to be tested at different temperatures and moisture contents, as would happen in an industrial environment. Further, the gas supply (type, temperature, and humidity) should also match the industrial conditions.

1.4 This standard is not applicable to all bulk solids and segregation mechanisms: while fluidization is a common segregation mechanism experienced by many fine powders, other segregation mechanisms not evaluated by this standard might induce segregation in practice.

1.5 The extent to which segregation will occur in an industrial situation is not only a function of the powder and its tendency to segregate, but also the handling equipment (for example, bin design), process (for example, transfer rates), and environment.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 6941 – 03

Standard Practice for

Measuring Fluidization Segregation Tendencies of Powders

This standard is issued under the fixed designation D 6941; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 fluidization segregation, n—a mechanism that causes

vertical segregation, that is, horizontal layering of fine and

1.1 This practice covers an apparatus and procedure for

coarse particles, as resulting from fluidization of the bulk solid.

simulating the segregation tendencies of powders by means of

3.1.3 segregation, n—a process through which blended or

the fluidization mechanism.

uniform powders or bulk solids become non-uniform, with

1.2 Powders must be capable of being fluidized in order to

regions of varying composition, for example, particle size.

be tested by this practice.

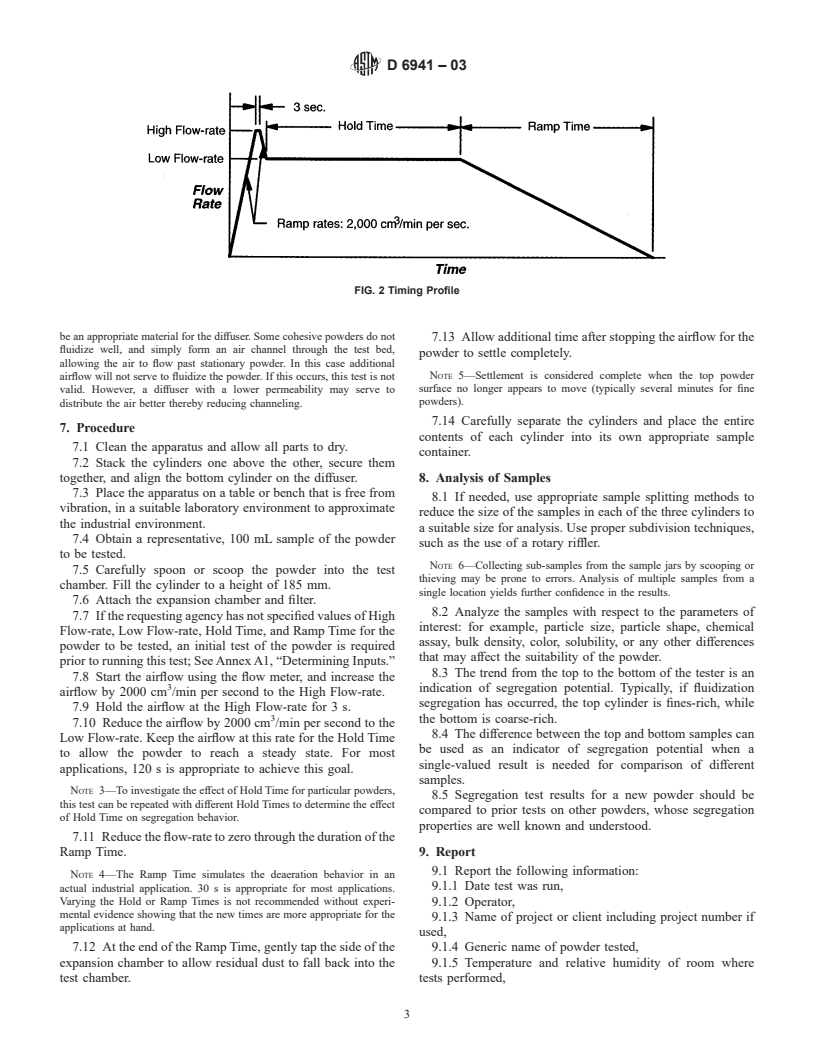

3.2 Definitions of Terms Specific to This Standard:

1.3 Temperature- and humidity-sensitive powders may need

3.2.1 high flow-rate, n—the first stage flow-rate used to

to be tested at different temperatures and moisture contents, as

initiate fluidization.

would happen in an industrial environment. Further, the gas

3.2.2 hold time, n—the time for which the Low Flow-rate is

supply (type, temperature, and humidity) should also match the

held.

industrial conditions.

3.2.3 low flow-rate, n—the second stage flow-rate used to

1.4 This standard is not applicable to all bulk solids and

maintain fluidization.

segregation mechanisms: while fluidization is a common

3.2.4 ramp time, n—the time during which the airflow is

segregation mechanism experienced by many fine powders,

reduced from the Low Flow-rate to zero.

other segregation mechanisms not evaluated by this standard

3.2.5 representative sample, n—a quantity of the bulk solid

might induce segregation in practice.

to be tested that is representative of that solid in an industrial

1.5 The extent to which segregation will occur in an

application being studied. Parameters of interest that may

industrial situation is not only a function of the powder and its

affect whether or not a sample is representative include:

tendency to segregate, but also the handling equipment (for

moisture, particle size distribution, raw material variation,

example, bin design), process (for example, transfer rates), and

method of production, aging, chemical composition.

environment.

1.6 This standard does not purport to address all of the

4. Summary of Practice

safety concerns, if any, associated with its use. It is the

4.1 A representative sample of a powder is placed in the

responsibility of the user of this standard to establish appro-

apparatus.

priate safety and health practices and determine the applica-

4.2 Pressurized gas (usually air) is blown from the bottom at

bility of regulatory limitations prior to use.

a series of flow-rates for specified times, creating a state of

2. Referenced Documents fluidization of the powder.

4.3 Once the airflow is stopped, the powder in the test

2.1 ASTM Standards:

chamber is divided into three samples from the bottom, center,

D 653 Terminology Relating to Soil, Rock, and Contained

and top of the column.

Fluids

4.4 The samples are then available to be tested for differ-

3. Terminology

ences relevant to the application, for example, particle size or

chemical assay.

3.1 Definitions—Definitions of terms used in this test

method shall be in accordance with Terminology D 653.

5. Significance and Use

3.1.1 fluidization, n—the state in which a powder exhibits

5.1 Fluidization segregation can cause vertical segregation

fluid-like properties.

within bins used to hold and transport powders. This can affect

final product quality in industrial applications.

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

5.2 By measuring a powder’s segregation tendency, one can

Rock and is the direct responsibility of Subcommittee D18.24 on Characterization

compare results to other powders with known history, or

and Handling of Powders and Bulk Solids.

determine if the given powder may have a tendency to

Current edition approved July 10, 2003. Published August 2003.

Annual Book of ASTM Standards, Vol 04.08. segregate in a given process.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6941–03

5.3 Fine powders generally have a lower permeability than cylinders. The bottom cylinder sits against the diffuser in the

coarse bulk solids and therefore tend to retain air longer. Thus, air supply plenum. The top cylinder mates to the expansion

when a bin is being filled with a fluidizable powder, the coarser chamber. When the cylinders are stacked together, they make

particles settle or are driven into the bed while the finer up the test chamber, where the powder is placed. The as-

particles remain fluidized near the surface. sembled test chamber dimensions are 24 mm I.D. by at least

5.4 Fluidization, which serves as a driving force for this 185 mm tall. The test chamber should have at least 25 mm

mechanism of segregation, is likely to occur when fine pow- additional height to allow expansion of the powder bed. The

ders are pneumatically conveyed into a bin, the bin is filled or cylinders must be held together so they do not separate during

discharged at high rates, or if sufficient air flow counter to the the tests and so leakage does not occur, while still able to be

flow of powder is present within the bin. separated at the end of the test in a way to allow for sample

recovery. This can be done a number of ways, including taping

6. Apparatus

the sections together.

6.1 The apparatus including critical dimensions is shown in

6.4 Expansion Chamber—The expansion chamber allows

Fig. 1. It consists of the following:

the powder to disengage from the air stream.

6.2 Gas Supply with Flow Meter—A gas supply capable of

6.5 Filter—The filter prevents powder from being blown

fluidizing the powder is required (15 to 30 psig [100 to 200

out of the apparatus. The filter material should be appropriate

kPa] range, 25 psig [170 kPa] recommended, maximum flow

for the application and should not contaminate the powder

rate 10 000 cm /min). The gas flow rate must be adjustable

(which may affect the analysis of the samples), and should

during the test-an automated controller may be used for this

provide sufficient containment of the powder (from both a

purpose.

safety perspective and a loss of powder perspective).

6.6 Diffuser—The diffuser distributes the air uniformly into

NOTE 1—Generally, clean, dry air is used. If air is not suitable (that is,

the test chamber; therefore, a sufficient pressure drop across the

it reacts with or adversely affects the powder being tested) another gas,

such as nitrogen, may be used. diffuser is required.

6.3 Cylinders—Three transparent cylinders are stacked,

NOTE 2—A sintered metal disk, such as 5 μm filtration grade porous

stainless steel sheet available from Mott Industrial, Farmington CT, may

identified (from the bottom) as the bottom, center, and top

FIG. 1 Apparatus

D6941–03

FIG. 2 Timing Profile

be an appropriate material for the diffuser. Some cohesive powders do not

7.13 Allow additional time after stopping the airflow for the

fluidize well, and simply form an air channel through the test bed,

powder to settle completely.

allowing the air to flow past stationary powder. In this case additional

NOTE 5—Settlement is considered complete when the top powder

airflow will not serve to fluidize the powder. If this occurs, this test is not

surface no longer appears to move (typically several minutes for fine

valid. However, a diffuser with a lower pe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.