ASTM F1508-96

(Specification)Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas and Liquid Services

Standard Specification for Angle Style, Pressure Relief Valves for Steam, Gas and Liquid Services

SCOPE

1.1 This specification covers spring-loaded, angle style, pressure relief valves for steam, gas, and liquid system applications (excluding boiler safety and hydraulic system relief valves).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1508 – 96

Standard Specification for

Angle Style, Pressure Relief Valves for Steam, Gas, and

Liquid Services

This standard is issued under the fixed designation F 1508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 351/A351M Specification for Castings, Austenitic,

Austenitic-Ferritic (Duplex), for Pressure-Containing

1.1 This specification covers spring-loaded, angle style,

Parts

pressure relief valves for steam, gas, and liquid system

A 479/A479M Specification for Stainless and Heat-

applications (excluding boiler safety and hydraulic system

Resisting Steel Bars and Shapes for Use in Boilers and

relief valves).

Other Pressure Vessels

2. Referenced Documents

A 494/A494M Specification for Castings, Nickel and

Nickel Alloy

2.1 ASTM Standards:

A 689 Specification for Carbon and Alloy Steel Bars for

A 105 Specification for Forgings, Carbon Steel, for Piping

Springs

Components

B 21 Specification for Naval Brass Rod, Bar, and Shapes

A 125 Specification for Steel Springs, Helical, Heat

B 61 Specification for Steam or Valve Bronze Castings

Treated

B 62 Specification for Composition Bronze or Ounce Metal

A 182 Specification for Forged or Rolled Alloy-Steel Pipe

Castings

Flanges, Forged Fittings, and Valves and Parts for High-

B 148 Specification for Aluminum Bronze Castings

Temperature Service

B 164 Specification for Nickel-Copper Alloy Rod, Bar, and

A 193 Specification for Alloy-Steel and Stainless Steel

Wire

Bolting Materials for High-Temperature Service

B 637 Specification for Precipitation Hardening Nickel-

A 194 Specification for Carbon and Alloy Steel Nuts for

Alloy Bars, Forgings, and Forging Stock for High-

Bolts for High-Pressure and High-Temperature Service

Temperature Service

A 216/A216M Specification for Steel Castings, Carbon,

D 5204 Specification for Polyamide-Imide (PAI) Molding

Suitable for Fusion Welding for High-Temperature Ser-

and Extrusion Materials

vice

F 467 Specification for Nonferrous Nuts for General Use

A 217/A217M Specification for Steel Castings, Martensitic

F 468 Specification for Nonferrous Bolts, Hex Cap Screws,

Stainless and Alloy, for Pressure-Containing Parts, Suit-

and Studs for General Use

able for High-Temperature Service

2.2 ANSI Standards:

A 227/A227M Specification for Steel Wire, Cold-Drawn for

ANSI B.1 Unified Screw Threads

Mechanical Springs

ANSI B16.5 Pipe Flanges and Flanged Fittings

A 229/A229M Specification for Steel Wire, Oil-Tempered

ANSI B16.34 Valves—Flanged, Threaded, and Welding

for Mechanical Springs

End

A 231/A231M Specification for Chromium-Vanadium Al-

2.3 ASME Standard:

loy Steel Spring Wire

Boiler and Pressure Vessel Code

A 276 Specification for Stainless and Heat-Resisting Steel

2.4 API Standards:

Bars and Shapes

A 313 Specification for Chromium-Nickel Stainless and

Heat-Resisting Steel Spring Wire

Annual Book of ASTM Standards, Vol 02.01.

Annual Book of ASTM Standards, Vol 02.04.

1 8

This specification is under the jurisdiction of ASTM Committee F25 on Ships Annual Book of ASTM Standards, Vol 08.03.

and Marine Technology and is the direct responsibility of Subcommittee F25.11 on Annual Book of ASTM Standards, Vol 15.08.

Machinery and Piping Systems. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Current edition approved Nov. 10, 1996. Published October 1997. 4th Floor, New York, NY 10036.

2 11

Annual Book of ASTM Standards, Vol 01.01. Available from American Society of Mechanical Engineers (ASME), ASME

Annual Book of ASTM Standards, Vol 01.05. International Headquarters, Three Park Ave., New York, NY 10016-5990.

4 12

Annual Book of ASTM Standards, Vol 01.02. Available from The American Petroleum Institute (API), 1220 L. St., NW,

Annual Book of ASTM Standards, Vol 01.03. Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1508 – 96

API Standard 526 Flanged Steel Safety-Relief Valves 3.1.5 built-up backpressure—the static discharge pressure at

API Standard RP 520, Part 1 Recommended Practice for the outlet of a pressure relief valve caused by the pressure drop

the Design and Installation of Pressure-Relieving Systems in the discharge piping while the valve is discharging.

in Refineries

3.1.6 gagging device—a device, normally a screw (also

2.5 Federal Specifications:

called test gag), used to prevent the pressure relief valve from

QQ-N-281 Nickel-Copper Alloy Bar, Rod, Plate, Sheet,

opening during a hydrostatic pressure test of the equipment on

Strip, Wire, Forgings, and Structural and Special Shaped

which it is installed.

Sections

3.1.7 inlet piping—when used in this specification, refers to

QQ-N-286 Nickel-Copper-Aluminum Alloy, Wrought

all piping and fittings between the source and the inlet

(UNS N05500)

connection to the pressure relief valve.

2.6 Military Standards and Specifications:

3.1.8 instability (chatter, flutter)—an unstable operation of

MIL-STD-167-1 Mechanical Vibrations of Shipboard

the pressure relief valve characterized by rapid seating and

Equipment (Type I—Environmental and Type II—

unseating of the disk during discharge. This hammering of the

Internally Excited)

disk on the seat can cause high loading forces which can lead

MIL-STD-1330 Cleaning and Testing of Shipboard Oxy-

to damage and rapid failure of the seating and sliding surfaces.

gen, Nitrogen and Hydrogen Gas Piping Systems

3.1.9 maximum system operating pressure—the highest

MIL-F-1183 Fittings, Pipe, Cast Bronze, Silver Brazing,

pressure which can exist in a system, vessel, or component

General Specification for

under normal (noncasualty) operating conditions. This is a

MIL-F-20042 Flanges, Pipe and Bulkhead, Bronze (Silver

normal (noncasualty) pressure which the pressure relief valve

Brazing)

is not intended to protect against. This pressure can be the

MIL-P-46122 Plastic Molding Material and Plastic Extru-

result of influences such as pump or compressor shutoff

sion Material, Polyvinylidene Fluoride Polymer and Co-

pressure, pressure regulating valve lockup (no flow) pressure,

polymer

and so forth.

MIL-R-17131 Rods, Welding, Surfacing

3.1.10 opening pressure—the value of increasing inlet

MIL-S-901 Shock Tests, H.I. (High-Impact); Shipboard

static pressure of a pressure relief valve at which there is a

Machinery, Equipment and Systems, Requirements for

measurable lift, or at which the discharge becomes continuous

MS 16142 Boss, Gasket-Seal Straight Thread Tube Fitting,

by seeing, feeling, or hearing.

Standard Dimensions for

3.1.11 outlet piping (or discharge piping)—when used in

MS 51840 Plug, Machine Thread, O-ring

2.7 Naval Sea Systems Command (NAVSEA): this specification, refers to all piping and fittings between the

pressure relief valve outlet connection and the main, tank, or

Drawings:

803-1385884 Unions, Fittings and Adapters, Butt and atmosphere to which the pressure relief valve relieves.

Socket Welding, 6000 PSI, WOG IPS

3.1.12 popping pressure—the value of increasing inlet static

803-1385943 Unions, Silver Brazing, 3000 PSI, WOG IPS,

pressure at which the disk moves in the opening direction at a

for UT Inspection

faster rate as compared with the corresponding movement at

803-1385946 Unions, Bronze Silver Brazing, WOG, for UT

higher or lower pressures. It generally applies to valves with

Inspection

compressible fluid service such as steam, gas, and so forth.

3.1.13 pressure relief valve—an automatic pressure reliev-

3. Terminology

ing device actuated by the static pressure upstream of the valve

3.1 Definitions:

and characterized by either rapid opening (pop action for gas,

3.1.1 accumulation—the increase in static pressure above

vapor, or steam) or gradual opening (for liquids).

the set pressure during discharge through the valve, when the

3.1.14 primary and secondary pressure zones of pressure

valve passes the rated flow. Accumulation is expressed in

relief valve—primary pressure zone refers to all portions of the

pound-force per square inch or as a percent of the set pressure.

pressure-containing envelope subject to inlet pressure; second-

3.1.2 accumulation pressure—the set pressure plus the ac-

ary pressure zone refers to all portions of the pressure-

cumulation. Accumulation pressure is expressed in pound-

containing envelope subject to outlet or discharge pressure

force per square inch gage.

(includes spring housing of nonvented valves).

3.1.3 blowdown—the difference between the set pressure

3.1.15 relieving capacity (also called flow capacity)—the

and the reseating pressure. Blowdown is expressed in pound-

pressure relief valve is defined as the quantity of pressure

force per square inch or a percent of the set pressure. The

medium relieving through the pressure relief valve at the

accumulation and blowdown establish the operating band of

accumulation pressure such as: pound per hour of steam, gallon

the pressure relief valve at a particular set pressure.

per minute of water at 70°F, or SCFM (standard cubic feet per

3.1.4 blowdown pressure—the set pressure minus the blow-

minute at 60°F and 14.7 psia) of air, as applicable.

down. Blowdown pressure is expressed in pound-force per

3.1.16 set pressure—the value of increasing inlet static

square inch gage.

pressure at which a pressure relief valve displays one of the

operational characteristics as defined under opening pressure,

or start-to-leak pressure. Set pressure is expressed in pound-

Available from Standardization Documents Order Desk, Bldg. 4 Section D,

700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. force per square inch gage.

F 1508 – 96

3.1.17 set pressure range—the range over which the set 5.1.8 Blowdown limits, if different than specified in 7.7.

pressure can be adjusted with the installed spring. 5.1.9 Envelope dimensions, if not covered in Table 13 and

3.1.18 set pressure tolerance—the permissible plus or mi- Table 14.

nus deviation from the specified set pressure. Set pressure 5.1.10 Supplementary requirements, if any (see S1 through

tolerance is expressed in pound-force per square inch or as a S5).

percent of the set pressure.

6. Valve Coding And Construction

3.1.19 source—when used in this specification, refers to the

6.1 Valves shall incorporate the design features specified in

pressure container being protected from overpressure by the

6.2 and 6.3.

pressure relief valve, for example, piping main, pressure vessel

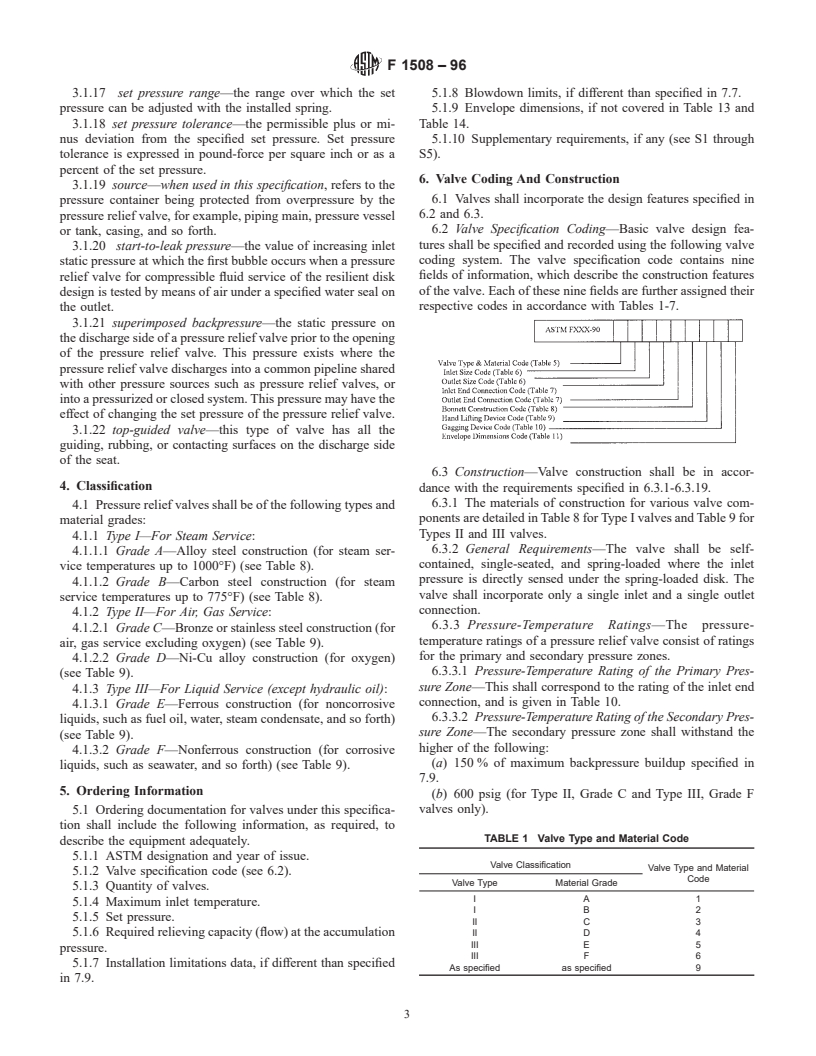

6.2 Valve Specification Coding—Basic valve design fea-

or tank, casing, and so forth.

tures shall be specified and recorded using the following valve

3.1.20 start-to-leak pressure—the value of increasing inlet

coding system. The valve specification code contains nine

static pressure at which the first bubble occurs when a pressure

fields of information, which describe the construction features

relief valve for compressible fluid service of the resilient disk

of the valve. Each of these nine fields are further assigned their

design is tested by means of air under a specified water seal on

respective codes in accordance with Tables 1-7.

the outlet.

3.1.21 superimposed backpressure—the static pressure on

the discharge side of a pressure relief valve prior to the opening

of the pressure relief valve. This pressure exists where the

pressure relief valve discharges into a common pipeline shared

with other pressure sources such as pressure relief valves, or

into a pressurized or closed system. This pressure may have the

effect of changing the set pressure of the pressure relief valve.

3.1.22 top-guided valve—this type of valve has all the

guiding, rubbing, or contacting surfaces on the discharge side

of the seat.

6.3 Construction—Valve construction shall be in accor-

4. Classification

dance with the requirements specified in 6.3.1-6.3.19.

6.3.1 The materials of construction for various valve com-

4.1 Pressure relief valves shall be of the following types and

ponents are detailed in Table 8 for Type I valves and Table 9 for

material grades:

Types II and III valves.

4.1.1 Type I—For Steam Service:

6.3.2 General Requirements—The valve shall be self-

4.1.1.1 Grade A—Alloy steel construction (for steam ser-

contained, single-seated, and spring-loaded where the inlet

vice temperatures up to 1000°F) (see Table 8).

pressure is directly sensed under the spring-loaded disk. The

4.1.1.2 Grade B—Carbon steel construction (for steam

valve shall incorporate only a single inlet and a single outlet

service temperatures up to 775°F) (see Table 8).

connection.

4.1.2 Type II—For Air, Gas Service:

6.3.3 Pressure-Temperature Ratings—The pressure-

4.1.2.1 Grade C—Bronze or stainless steel construction (for

temperature ratings of a pressure relief valve consist of ratings

air, gas service excluding oxygen) (see Table 9).

for the primary and secondary pressure zones.

4.1.2.2 Grade D—Ni-Cu alloy construction (for oxygen)

6.3.3.1 Pressure-Temperature Rating of the Primary Pres-

(see Table 9).

sure Zone—This shall correspond to the rating of the inlet end

4.1.3 Type III—For Liquid Service (except hydraulic oil):

connection, and is given in Table 10.

4.1.3.1 Grade E—Ferrous construction (for noncorrosive

6.3.3.2 Pressure-Temperature Rating of the Secondary Pres-

liquids, such as fuel oil, water, steam condensate, and so forth)

sure Zone—The secondary pressure zone shall withstand the

(see Table 9).

higher of the following:

4.1.3.2 Grade F—Nonferrous construction (for corrosive

(a) 150 % of maximum backpressure buildup specified in

liquids, such as seawater, and so forth) (see Table 9).

7.9.

5. Ordering Information

(b) 600 psig (for Type II, Grade C and Type III, Grade F

valves only).

5.1 Ordering documentation for valves under this specifica-

tion shall include the following information, as required, to

TABLE 1 Valve Type and Material Code

describe the equipment adequately.

5.1.1 ASTM designation and year of issue.

Valve Classification

Valve Type and Material

5.1.2 Valve specification code (see 6.2).

Code

Valve Type Material Grade

5.1.3 Quantity of valves.

IA 1

5.1.4 Maximum inlet temperature.

IB 2

5.1.5 Set pressure.

IIC3

5.1.6 Required relieving capacity (flow) at the accumulation IID4

III E 5

pressure.

III F 6

5.1.7 Installation limitations data, if different than specified

As specified as specified 9

in 7.9.

F 1508 – 96

TABLE 2 Codes for Valve Inlet/Outlet Pipe Size

Nominal valve inlet or

As

outlet pipe size, in. 0.25 0.38 0.50 0.75

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.