ASTM D6928-17

(Test Method)Standard Test Method for Resistance of Coarse Aggregate to Degradation by Abrasion in the Micro-Deval Apparatus

Standard Test Method for Resistance of Coarse Aggregate to Degradation by Abrasion in the Micro-Deval Apparatus

SIGNIFICANCE AND USE

5.1 The Micro-Deval abrasion test is a test of coarse aggregate to determine abrasion loss in the presence of water and an abrasive charge. Many aggregates are more susceptible to abrasion when wet than dry, and the use of water in this test incorporates this reduction in resistance to degradation in contrast to some other tests, which are conducted on dry aggregate. The test results are helpful in evaluating the toughness/abrasion resistance of coarse aggregate subject to abrasion when adequate information is not available from service records.

5.2 The Micro-Deval abrasion test is useful for detecting changes in properties of aggregate produced from an aggregate source as part of a quality control or quality assurance process.

SCOPE

1.1 This test method covers a procedure for testing coarse aggregate for resistance to abrasion using the Micro-Deval apparatus.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 The text of this method references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the test method.

1.4 This procedure may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6928 − 17

Standard Test Method for

Resistance of Coarse Aggregate to Degradation by Abrasion

1

in the Micro-Deval Apparatus

This standard is issued under the fixed designation D6928; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for testing coarse 3.1 Definitions:

aggregate for resistance to abrasion using the Micro-Deval 3.1.1 constant mass, n—the condition of a test sample dried

apparatus. at a temperature of 110 6 5 °C such that it will not lose more

than 0.1 % moisture after2hof drying.

1.2 The values stated in SI units are to be regarded as

3.1.1.1 Discussion—Such a condition of dryness can be

standard. No other units of measurement are included in this

verified by determining the mass of the sample before and after

standard.

successive 2-h drying periods. In lieu of such a determination,

1.3 The text of this method references notes and footnotes

samples may be considered to have reached constant mass

which provide explanatory material. These notes and footnotes

when they have been dried at a temperature of 110 6 5 °C for

(excluding those in tables and figures) shall not be considered

an equal or longer period than that previously found adequate

as requirements of the test method.

for producing the desired constant mass condition under equal

1.4 This procedure may involve hazardous materials,

or heavier loading conditions of the oven.

operations, and equipment. This standard does not purport to

4. Summary of Test Method

address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to

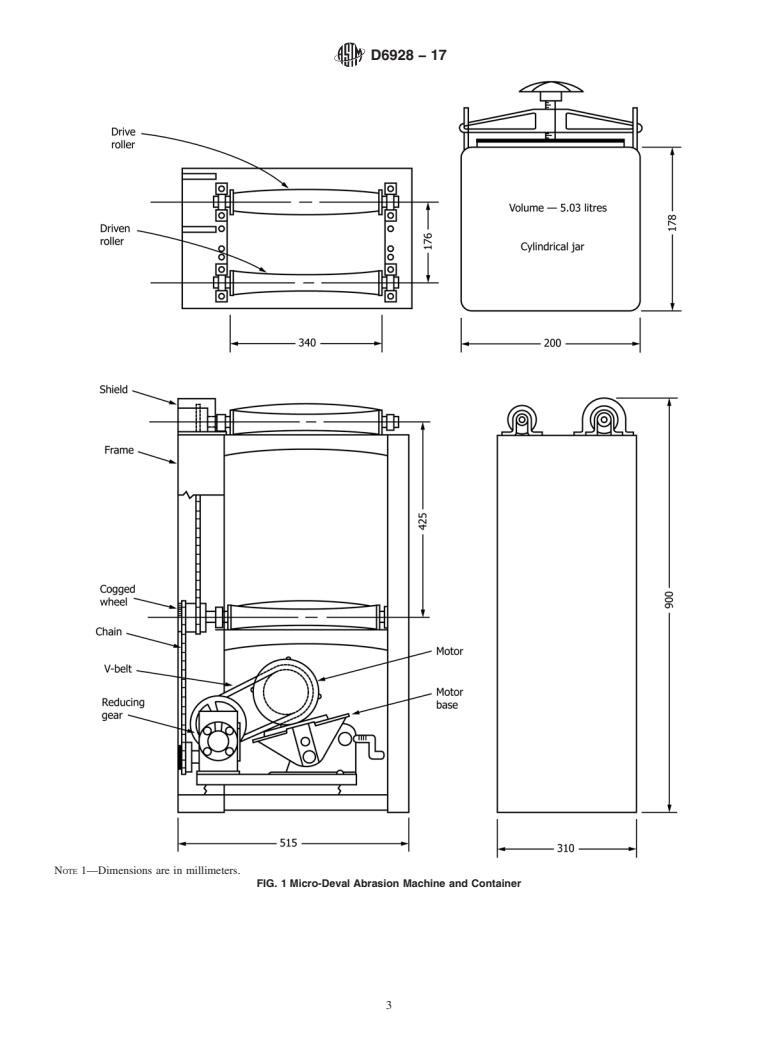

4.1 TheMicro-Devaltestisameasureofabrasionresistance

establish appropriate safety and health practices and deter-

and durability of mineral aggregates resulting from a combi-

mine the applicability of regulatory limitations prior to use.

nation of actions including abrasion and grinding with steel

1.5 This international standard was developed in accor-

balls in the presence of water.Asample with standard grading

dance with internationally recognized principles on standard-

is initially soaked in water for not less than 1 h. The sample is

ization established in the Decision on Principles for the

then placed in a jar mill with 2.0 L of water and an abrasive

Development of International Standards, Guides and Recom-

charge consisting of 5000 g of 9.5-mm diameter steel balls.

mendations issued by the World Trade Organization Technical

The jar, aggregate, water, and charge are revolved at 100 rpm

Barriers to Trade (TBT) Committee.

forupto2h,dependingontheparticlesize.Thesampleisthen

washed and oven dried. The loss is the amount of material

2. Referenced Documents

passing the 1.18-mm sieve expressed as a percent by mass of

2

2.1 ASTM Standards:

the original sample.

C136 Test Method for Sieve Analysis of Fine and Coarse

5. Significance and Use

Aggregates

C670 Practice for Preparing Precision and Bias Statements

5.1 The Micro-Deval abrasion test is a test of coarse

for Test Methods for Construction Materials

aggregate to determine abrasion loss in the presence of water

E11 Specification for Woven Wire Test Sieve Cloth and Test

and an abrasive charge. Many aggregates are more susceptible

Sieves

to abrasion when wet than dry, and the use of water in this test

incorporates this reduction in resistance to degradation in

contrast to some other tests, which are conducted on dry

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

aggregate. The test results are helpful in evaluating the

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

Aggregate Tests.

toughness/abrasion resistance of coarse aggregate subject to

Current edition approved April 1, 2017. Published April 2017. Originally

abrasion when adequate information is not available from

approved in 2003. Last previous edition approved in 2010 as D6928 – 10. DOI:

service records.

10.1520/D6928-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 The Micro-Deval abrasion test is useful for detecting

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

changes in properties of aggregate produced from an aggregate

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. source as part of a quality control or quality assurance process.

Copyright © ASTM

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6928 − 10 D6928 − 17

Standard Test Method for

Resistance of Coarse Aggregate to Degradation by Abrasion

1

in the Micro-Deval Apparatus

This standard is issued under the fixed designation D6928; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for testing coarse aggregate for resistance to abrasion using the Micro-Deval apparatus.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 The text of this method references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the test method.

1.4 This procedure may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C136 Test Method for Sieve Analysis of Fine and Coarse Aggregates

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Terminology

3.1 Definitions:

3.1.1 constant mass, n—the condition of a test sample dried at a temperature of 110 6 5°C5 °C such that it will not lose more

than 0.1 % moisture after 2 h of drying.

1

This test method is under the jurisdiction of ASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.51 on Aggregate

Tests.

Current edition approved June 1, 2010April 1, 2017. Published June 2010April 2017. Originally approved in 2003. Last previous edition approved in 20082010 as D6928 –

ε1

0810. . DOI: 10.1520/D6928-10.10.1520/D6928-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

Such a condition of dryness can be verified by determining the mass of the sample before and after successive 2-h drying periods.

In lieu of such a determination, samples may be considered to have reached constant mass when they have been dried at a

temperature of 110 6 5°C5 °C for an equal or longer period than that previously found adequate for producing the desired constant

mass condition under equal or heavier loading conditions of the oven.

4. Summary of Test Method

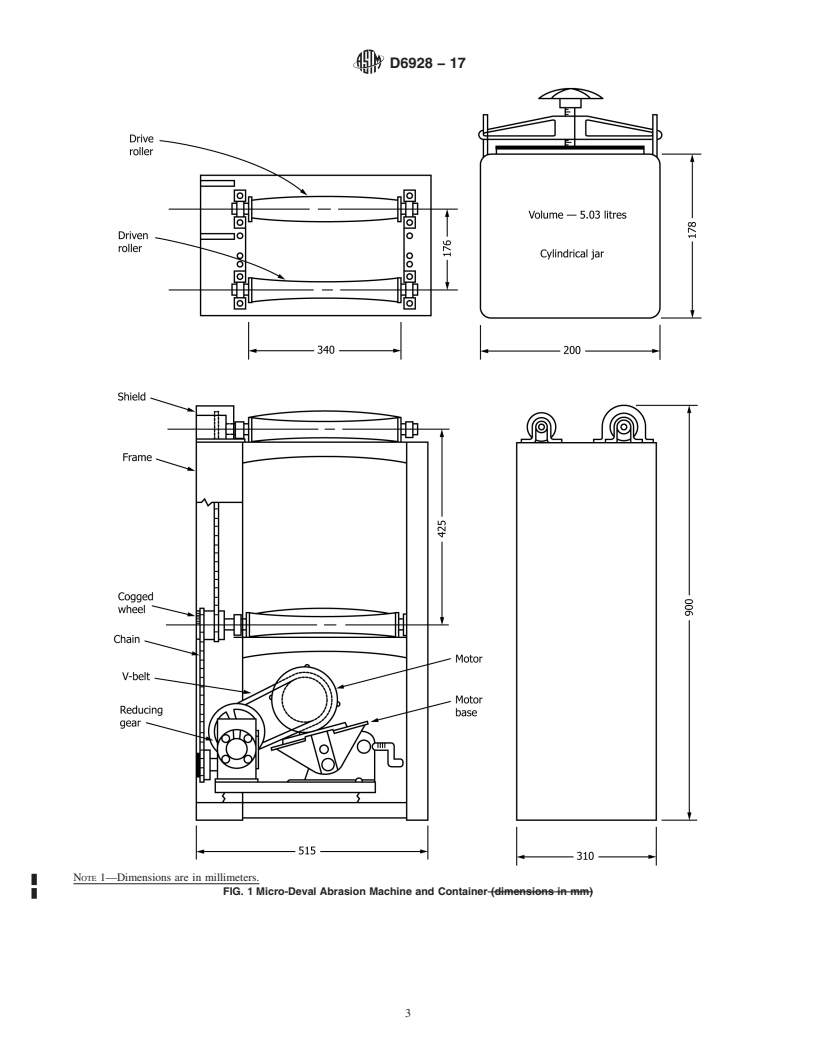

4.1 The Micro-Deval Testtest is a measure of abrasion resistance and durability of mineral aggregates resulting from a

combination of actions including abrasion and grinding with steel balls in the presence of water. A sample with standard grading

is initially soaked in water for not less than one hour.1 h. The sample is then placed in a jar mill with 2.0 L of water and an abrasive

charge consisting of 5000 g of 9.5-mm diameter steel balls. The jar, aggregate, water, and charge are revolved at 100 rpm for up

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6928 − 17

to 2 h, depending on the particle size. The sample is then washed and oven dried. The loss is the amount of material passing the

1.18-mm sieve expressed as a percent by mass of the original sample.

5. Significance and Use

5.1 The Micro-Deval abrasion test is a test of coarse aggregate to determine abrasion loss in the presence of water and an

abrasive charge. Many aggregates are more susceptible to abrasion when wet than dry, and the use of water in this test incorporates

this reduction in resistance to degradation in contrast to some other tests, which are conducte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.