ASTM B452-09

(Specification)Standard Specification for Copper-Clad Steel Wire for Electronic Application

Standard Specification for Copper-Clad Steel Wire for Electronic Application

ABSTRACT

This specification covers bare round copper-clad steel wire for electronic application. Four classes of copper-clad steel wire are covered as Class 30HS, 30A, 40HS, and 40A. The wire shall consist of a core of homogeneous open-hearth, electric-furnace, or basic-oxygen steel with a continuous outer cladding of copper thoroughly bonded to the core throughout. The copper-lad steel wire shall conform to the tensile strength and elongation requirements. Electrical resistivity test shall be performed at a specified temperature of each class of wire and shall not exceed the values prescribed in this specification. Dimensional measurements shall be made with a micrometer caliper and shall withstand torsion test without fracturing. Copper cladding to the steel of each of the four specimens shall conform to the adhesion criterion. Surface finish shall meet the required allowable number of defects.

SCOPE

1.1 This specification covers bare round copper-clad steel wire for electronic application.

1.2 Four classes of copper-clad steel wire are covered as follows:

1.2.1 Class 30HS—Nominal 30 % conductivity hard-drawn,

1.2.2 Class 30A—Nominal 30 % conductivity annealed,

1.2.3 Class 40HS—Nominal 40 % conductivity hard-drawn, and

1.2.4 Class 40A—Nominal 40 % conductivity annealed.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are in SI units.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B452 −09

StandardSpecification for

1

Copper-Clad Steel Wire for Electronic Application

This standard is issued under the fixed designation B452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

3.1.3 Class of wire (see 1.2 and Table 1),

1.1 This specification covers bare round copper-clad steel

3.1.4 Packaging and shipping (Section 10),

wire for electronic application.

3.1.5 If inspection is required (see 6.3.3), and

1.2 Four classes of copper-clad steel wire are covered as

3.1.6 Place of inspection (see 6.1).

follows:

1.2.1 Class 30HS—Nominal 30 % conductivity hard-drawn,

4. Material

1.2.2 Class 30A—Nominal 30 % conductivity annealed,

4.1 The wire shall consist of a core of homogeneous

1.2.3 Class 40HS—Nominal 40 % conductivity hard-drawn,

open-hearth, electric-furnace, or basic-oxygen steel with a

and

continuous outer cladding of copper thoroughly bonded to the

1.2.4 Class 40A—Nominal 40 % conductivity annealed.

core throughout and shall be of such quality as to meet the

1.3 The values stated in inch-pound units are to be regarded

requirements of this specification (Note 1).

as the standard.The values given in parentheses are in SI units.

NOTE 1—The copper-clad steel wire provides a high-strength conductor

for use in wire and cable where greater strength is required and a lower

2. Referenced Documents

conductivity can be tolerated.At high frequencies the reduced conductiv-

ity is less pronounced due to concentration of the current in the outer

2.1 The following documents of the issue in effect on the

periphery of the wire. Minimum thickness of 6 % and 10 % of the radius

date of material purchase form a part of this specification to the

for 30 and 40 % conductivity material, respectively, has been established

extent referenced herein:

to facilitate the inspection of thickness on fine wires.

2

2.2 ASTM Standards:

5. General Requirements

B193 Test Method for Resistivity of Electrical Conductor

2

Materials

5.1 Tensile Strength and Elongation—The copper-clad steel

B258 Specification for Nominal Diameters and Cross-

wire shall conform to the tensile strength and elongation

SectionalAreasofAWGSizesofSolidRoundWiresUsed

requirements of Table 1. For intermediate sizes not listed in

2

as Electrical Conductors

Table 1, the elongation requirements of the next smaller size

2.3 National Institute of Standards and Technology: shall apply; in the case of tensile strength, the requirements of

3

NBS Handbook 100—Copper Wire Tables

the next larger size shall apply.

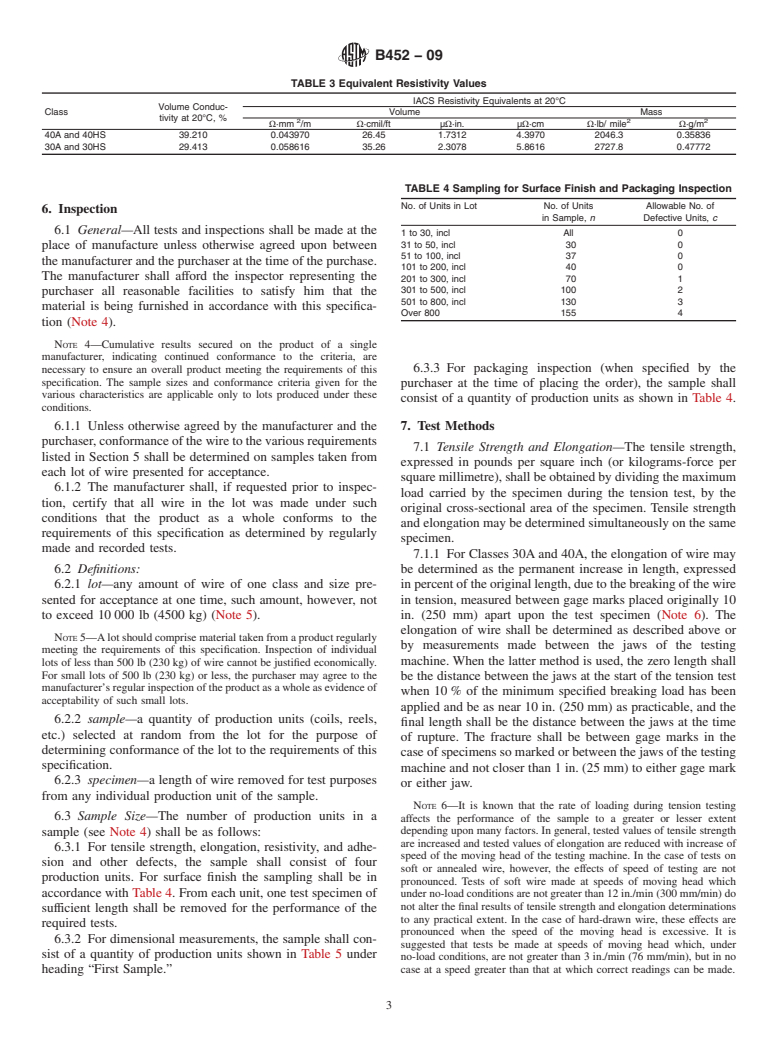

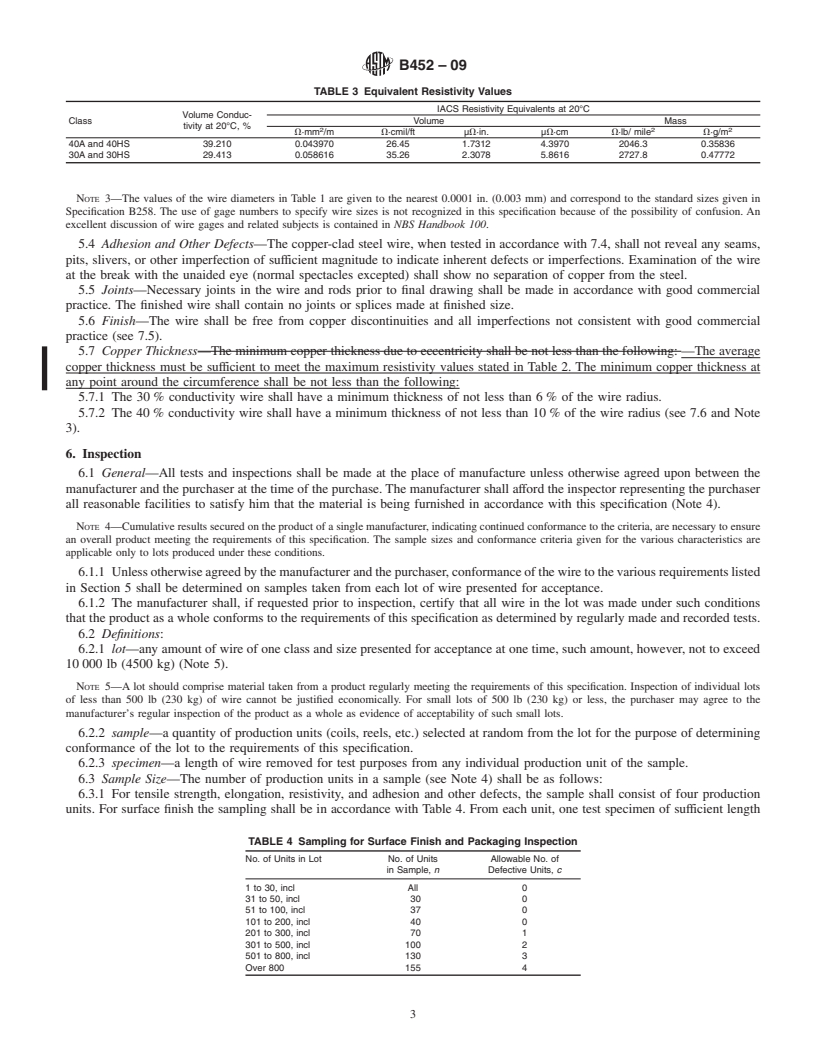

5.2 Resistivity—The electrical resistivity at a temperature of

3. Ordering Information

20°C shall not exceed the values prescribed in Table 2. See

3.1 Orders for material under this specification shall include

Note 2 for calculating electrical resistance.

the following information:

NOTE 2—Relationships which may be useful in connection with the

3.1.1 Quantity of each size and class,

values of electrical resistivity prescribed in this specification are shown in

Table 3. Resistivity units are based on the International Annealed Copper

2

1

Standard (IACS) adopted by IEC in 1913, which is ⁄58Ω·mm /m at 20°C

1

This specification is under the jurisdiction of ASTM Committee B01 on

2

for100 %conductivity.Thevalueof0.017241Ω·mm /mandthevalueof

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on

2

0.15328 Ω·g/m at 20°C are respectively the international equivalent of

Composite Conductors.

volume and weight resistivity of annealed copper equal to 100 %

Current edition approved Oct. 1, 2009. Published November 2009. Originally

conductivity. The latter term means that a copper wire 1 in. in length and

approved in 1967. Last previous edition approved in 2002 as B452 – 02. DOI:

weighing 1 g would have a resistance of 0.15328Ω. This is equivalent to

10.1520/B0452-09.

2

2 a resistivity value of 875.20Ω· lb/mile , which signifies the resistance of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

a copper wire 1 mile in length weighing 1 lb. It is also equivalent, for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

example,to1.7241µΩ/cmoflengthofacopperbar1cm incrosssection.

Standards volume information, refer to the standard’s Document Summary page on

Acomplete discussion of this subject is contained in NBS Handbook 100.

the ASTM website.

3

Available from National Institute of Standards and Technology (NIST), 100 The use of five significant figure

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B452–02 Designation: B452 – 09

Standard Specification for

1

Copper-Clad Steel Wire for Electronic Application

This standard is issued under the fixed designation B452; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers bare round copper-clad steel wire for electronic application.

1.2 Four classes of copper-clad steel wire are covered as follows:

1.2.1 Class 30HS—Nominal 30 % conductivity hard-drawn,

1.2.2 Class 30A—Nominal 30 % conductivity annealed,

1.2.3 Class 40HS—Nominal 40 % conductivity hard-drawn, and

1.2.4 Class 40A—Nominal 40 % conductivity annealed.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are in SI units.

2. Referenced Documents

2.1 The following documents of the issue in effect on the date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

2

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-SectionalAreas ofAWG Sizes of Solid Round Wires Used as Electrical

Conductors

2.3 National Institute of Standards and Technology:

3

NBS Handbook 100—Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size and class,

3.1.2 Wire size, diameter in inches (see 5.3 and Table 1),

3.1.3 Class of wire (see 1.2 and Table 1),

3.1.4 Packaging and shipping (Section 10),

3.1.5 If inspection is required (see 6.3.3), and

3.1.6 Place of inspection (see 6.1).

4. Material

4.1 Thewireshallconsistofacoreofhomogeneousopen-hearth,electric-furnace,orbasic-oxygensteelwithacontinuousouter

cladding of copper thoroughly bonded to the core throughout and shall be of such quality as to meet the requirements of this

specification (Note 1).

NOTE 1—The copper-clad steel wire provides a high-strength conductor for use in wire and cable where greater strength is required and a lower

conductivity can be tolerated.At high frequencies the reduced conductivity is less pronounced due to concentration of the current in the outer periphery

of the wire. Minimum thickness of 6 % and 10 % of the radius for 30 and 40 % conductivity material, respectively, has been established to facilitate the

inspection of thickness on fine wires.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Composite

Conductors.

´1

Current edition approved April 10, 2002. Published April 2002. Originally published as B452–67. Last previous edition B452–93(1998) . DOI: 10.1520/B0452-02.

Current edition approved Oct. 1, 2009. Published November 2009. Originally approved in 1967. Last previous edition approved in 2002 as B452 – 02. DOI:

10.1520/B0452-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 02.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from the National Institute of Standards and Technology (NIST), Gaithersburg, MD 20899.

3

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B452 – 09

TABLE 1 Tensile and Elongation Requirements

Elongation, min.

2

Diameter Cross-Sectional Area at 20°C Tensile Strength, psi (kgf/mm ) %in10in.

(250 mm)

Class Class

2 2

in. mm cmil in. mm Class 30HS, min Class 30A, min Class 40HS, min Class 40A, min 30HS and 30A and

40HS 40A

0.0720 1.83 5180 0.00407 2.63 127 000 (89.3) 50 000 (35.2) 110 000 (77.3) 45 000 (31.6) 1.5 15

0.0641 1.63 4110 0.00323 2.08 127 000 (89.3) 50 000 (35.2) 110 000 (77.3) 45 000 (31.6) 1.5 15

0.0571 1.45 3260 0.00256 1.65 127 000 (89.3) 50 000 (35.2) 110 000 (77.3) 45 000 (31.6) 1.5 15

0.0508 1.29 2580 0.00203 1.31 127 000 (89.3) 50 000 (35.2) 110 000 (77.3) 45 000 (31.6) 1.5 15

0.0453 1.15

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.