ASTM B520-12(2017)

(Specification)Standard Specification for Tin-Coated, Copper-Clad Steel Wire for Electronic Application

Standard Specification for Tin-Coated, Copper-Clad Steel Wire for Electronic Application

ABSTRACT

This specification covers tin-coated, copper-clad steel wires for electronic applications. The four classes of steel wires considered here are: hard-drawn wires with 30% nominal conductivity (Class T30HS); annealed wires with 30% nominal conductivity (Class T30A); hard-drawn wires with 40% nominal conductivity (Class T40HS); and annealed wires with 40% nominal conductivity (Class T40A). Specimens shall go through tests and shall adhere to specified requirements for dimensions, electrical resistivity, tensile strength, and coating continuity and adherence.

SCOPE

1.1 This specification covers tin-coated copper-clad steel wire for electronic application.

1.2 Four classes of tin-coated copper-clad steel wire are covered as follows:

1.2.1 Class T30HS—Nominal 30 % conductivity, hard-drawn,

1.2.2 Class T30A—Nominal 30 % conductivity, annealed,

1.2.3 Class T40HS—Nominal 40 % conductivity, hard-drawn, and

1.2.4 Class T40A—Nominal 40 % conductivity, annealed.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The SI values for resistivity and volume are to be regarded as standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (Warning—Consideration should be given to toxicity and flammability when selecting solvent cleaners.)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B520 −12 (Reapproved 2017)

Standard Specification for

Tin-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect on date

1.1 This specification covers tin-coated copper-clad steel

of material purchase form a part of this specification to the

wire for electronic application.

extent referenced herein:

1.2 Four classes of tin-coated copper-clad steel wire are

2.2 ASTM Standards:

covered as follows:

B193 Test Method for Resistivity of Electrical Conductor

1.2.1 Class T30HS—Nominal 30 % conductivity, hard-

Materials

drawn,

B258 Specification for Nominal Diameters and Cross-

1.2.2 Class T30A—Nominal 30 % conductivity, annealed,

SectionalAreasofAWGSizesofSolidRoundWiresUsed

1.2.3 Class T40HS—Nominal 40 % conductivity, hard- as Electrical Conductors

drawn, and

B452 Specification for Copper-Clad Steel Wire for Elec-

tronic Application

1.2.4 Class T40A—Nominal 40 % conductivity, annealed.

2.3 National Institute of Standards and Technology:

1.3 The values stated in inch-pound units are to be regarded

NBS Handbook 100 Copper Wire Tables

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only 3. Ordering Information

and are not considered standard.

3.1 Orders for material under this specification shall include

1.3.1 Exception—The SI values for resistivity and volume

the following information:

are to be regarded as standard.

3.1.1 Quantity of each size.

3.1.2 Wire size (see 5.3 and Table 1),

1.4 The following safety hazards caveat pertains only to the

3.1.3 Class of wire (see 1.2),

test method portion, Section 6, of this specification: This

3.1.4 Package size and shipping (see 7.1.7 and Section 9),

standard does not purport to address all of the safety concerns,

packaging inspection if required (see 9.3.3),

if any, associated with its use. It is the responsibility of the user

3.1.5 Special package marking, if required, and

of this standard to establish appropriate safety and health

3.1.6 Place of inspection (see 9.1).

practices and determine the applicability of regulatory limita-

tions prior to use. (Warning—Consideration should be given

4. Material

to toxicity and flammability when selecting solvent cleaners.)

4.1 Thebasismaterialshallconsistofcopper-cladsteelwire

1.5 This international standard was developed in accor-

conforming to the product description, quality and specifica-

dance with internationally recognized principles on standard-

tion requirements of Specification B452.

ization established in the Decision on Principles for the

4.2 Thetin-coatedwireshallconsistofthebasiswirecoated

Development of International Standards, Guides and Recom-

with tin. The tin used for coating shall be commercially pure

mendations issued by the World Trade Organization Technical

(Note 1). For purposes of this specification, the tin shall be

Barriers to Trade (TBT) Committee.

considered“ commercially pure” if the total of other elements,

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Bi-Metallic Conductors. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2017. Published April 2017. Originally the ASTM website.

approved in 1970. Last previous edition approved in 2012 as B520 – 12. DOI: Available from National Institute of Standards and Technology (NIST), 100

10.1520/B0520-12R17. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B520−12 (2017)

TABLE 1 Wire Sizes

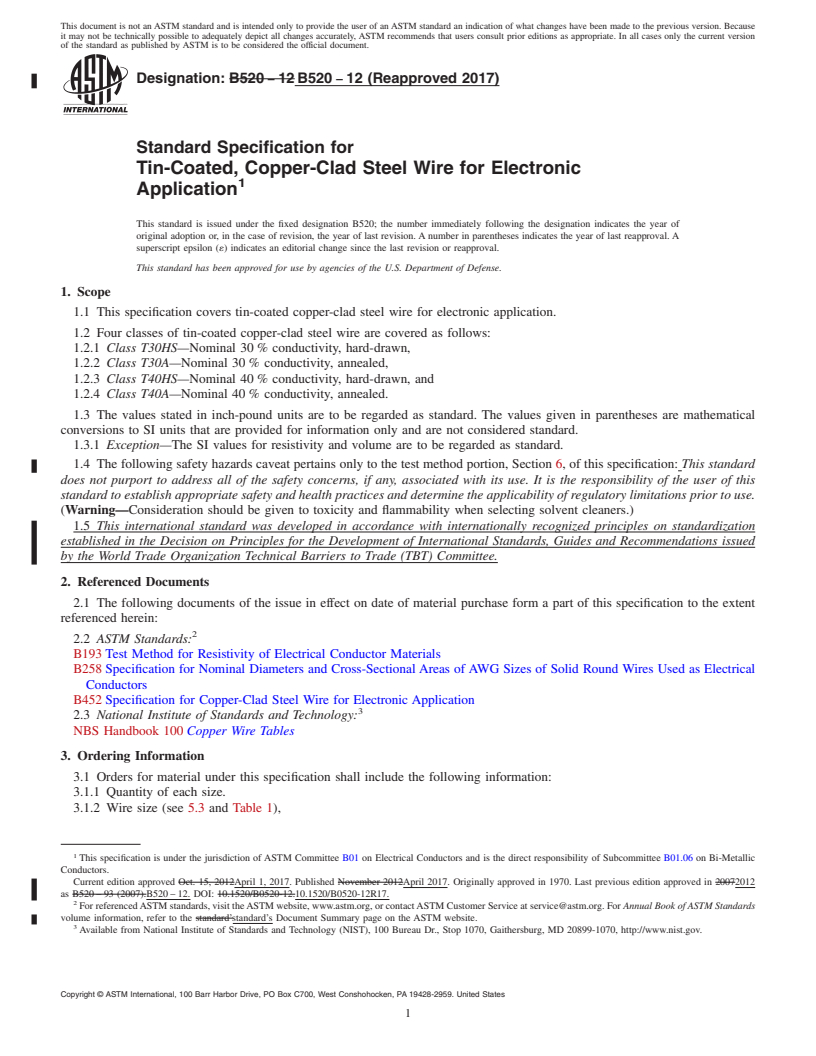

5.2 Resistivity—The electrical resistivity at a temperature of

Diameter Cross-Sectional Area at 20°C (68°F) 20°C shall not exceed the values prescribed in Table 2. See

2 2

in. mm cmil in. mm Note 2 for calculating electrical resistance.

0.0720 1.8129 5180 0.00407 2.63

NOTE2—Relationshipsthatmaybeusefulinconnectionwiththevalues

0.0641 1.6128 4110 0.00323 2.08

of electrical resistivity prescribed in this specification are shown in Table

0.0571 1.450 3260 0.00256 1.65

2 2

3. Resistivity units ⁄58 Ω·mm /m and 0.15328 Ω · g/m at 20°C are

0.0508 1.290 2580 0.00203 1.31

respectively the international equivalent of volume and weight resistivity

0.0453 1.151 2050 0.00161 1.04

0.0403 1.024 1620 0.00128 0.823 of annealed copper equal to 100 % conductivity. The latter term means

that a copper wire1min length and weighing 1 g would have a resistance

0.0359 0.912 1290 0.00101 0.653

of 0.15328 Ω. This is equivalent to a resistivity value of 875.20

0.0320 0.813 1020 0.000804 0.519 2

Ω·lb/mile , which signifies the resistance of a copper wire 1 mile in length

0.0285 0.724 812 0.000638 0.412

weighing 1 lb. It is also equivalent, for example, to 1.7241 µΩ/cm of

0.0253 0.643 640 0.000503 0.324

lengthofacopperbar1cm incrosssection.Acompletediscussionofthis

0.0226 0.574 511 0.000401 0.259

subject is contained in NBS Handbook 100. The use of five significant

0.0201 0.511 404 0.000317 0.205

figures in expressing resistivity does not imply the need for greater

accuracy of measurement than that specified in Test Method

B193. The

0.0179 0.455 320 0.000252 0.162

0.0159 0.404 253 0.000199 0.128 use of five significant figures is required for complete reversible conver-

0.0142 0.361 202 0.000158 0.102 sion from one set of resistivity units to another.

0.0126 0.320 159 0.000125 0.0804

5.3 Dimensions and Permissible Variations—The wire sizes

0.0113 0.287 128 0.000100 0.0647

0.0100 0.254 100 0.0000785 0.0507 shall be expressed as the diameter of the wire in decimal

fractions of an inch to the nearest 0.0001 in. (0.003 mm) (Note

0.0089 0.226 79.2 0.0000622 0.0401

3). For diameters under 0.0100 in. (0.254 mm), the wire shall

0.0080 0.203 64.0 0.0000503 0.0324

0.0071 0.180 50.4 0.0000396 0.0255

not vary from the specified diameter by more than plus 0.0003

0.0063 0.160 39.7 0.0000312 0.0201

in. (0.008 mm) and minus 0.0001 in. (0.003 mm) and for

0.0056 0.142 31.4 0.0000246 0.0159

diameters of 0.0100 in. (0.254 mm) and over, the wire shall not

0.0050 0.127 25.0 0.0000196 0.0127

vary from the specified diameter by more than plus 3 % and

0.0045 0.114 20.2 0.0000159 0.0103

minus 1 %, expressed to the nearest 0.0001 in. (0.003 mm).

0.0040 0.102 16.0 0.0000126 0.00811

0.0035 0.089 12.2 0.00000962 0.00621

NOTE 3—The values of the wire diameters in Table 1 are given to the

0.0031 0.079 9.61 0.00000755 0.00487

nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given

inSpecificationB258.Theuseofgagenumberstospecifywiresizesisnot

recognized in this specification because of the possibility of confusion.An

excellent discussion of wire gages and related subjects is contained in

“Copper Wire Tables” NBS Handbook 100.

exclusive of copper, does not exceed 1 %. Notwithstanding the

5.4 Continuity of Coating—The tin coating shall be continu-

previoussentence,chemicalanalysisofthetincoatingorofthe

ous. The continuity of coating on the wire shall be determined

tin used for coating shall not be required under this specifica-

on representative samples taken before stranding or insulating.

tion.Adequacyofthetincoatingisassuredbythecontinuityof

The continuity of tinning shall be determined by the hydro-

coating and adherence of coating requirements (see 5.4 and

chloric acid-sodium polysulfide test in accordance with 6.2.

5.5). The quality of the tin-coated wire shall be such that the

finished product meets the properties and requirements in this

5.5 Adherence of Coating—The tin coating shall be firmly

specification.

adherent to the surface of the copper-clad steel wire. The

adherence of coating on the wire shall be determined on

NOTE 1—It is necessary that the coating of the tin on the wire be

continuous. The test in the sodium polysulfide is for the purpose of representative samples taken before stranding or insulating.

determining whether or not the wire carries a continuous envelope of pure

The adherence of coating shall be determined by the wrapping

tin. The thickness of the tin coating is necessarily varied. Under the same

and immersion test in accordance with 6.3.

conditions of tinning, the coating on all sizes of wire, excepting on fine

wire, is approximately the same. The coating on fine wire is in general

relatively heavier than that on coarse wire. It is not, therefore, correct to

apply a larger number of cycles in the test on coarse wire than is applied

to fine wire. It is probable that one cycle of the dip test would be sufficient TABLE 2 Resistivity, max at 20°C

to discover defects in tinned wire, but in order to make certain that no

Nominal Diameter, in.

Class of Wire Ω·mm /m

partially covered spots may escape attention, provision has been made for

(mm)

two cycles. It has been found that the tin coating on copper wire consists

T30HS 0.0720 (1.829) to 0.06743

of two parts, an envelope of pure tin on the outside, with an intermediate

0.0201 (0.511) incl (0.067427)

layer of copper-tin alloy. This tin alloy, as well as the amount of tin

and under 0.0201 (0.511) to 0.07315

present, has an effect on the resistivity of the wire. Since the relative

0.0113 (0.287) incl (0.073148)

amount of tin coating and alloy is greater on the small wire than it is on

T30A under 0.0113 (0.287) to 0.07642

0.0031 (0.079) incl (0.076423)

the coarser wire, the resistivity of the wire increases as the size decreases.

This also accounts for the decrease in elongation due to tinning soft wire.

T40HS 0.0720 (1.829) to 0.04874

0.0201 (0.511) incl (0.048742)

5. General Requirements

and under 0.0201 (0.511) to 0.05162

0.0113 (0.287) incl (0.051618)

5.1 Tensile strength and elongation of the tin-coated wire

T40A under 0.0113 (0.287) to 0.05328

shallconformtotherequirementsofSpecificationB452forthe

0.0031 (0.079) incl (0.053280)

applicable size and class of copper-clad steel wire.

B520−12 (2017)

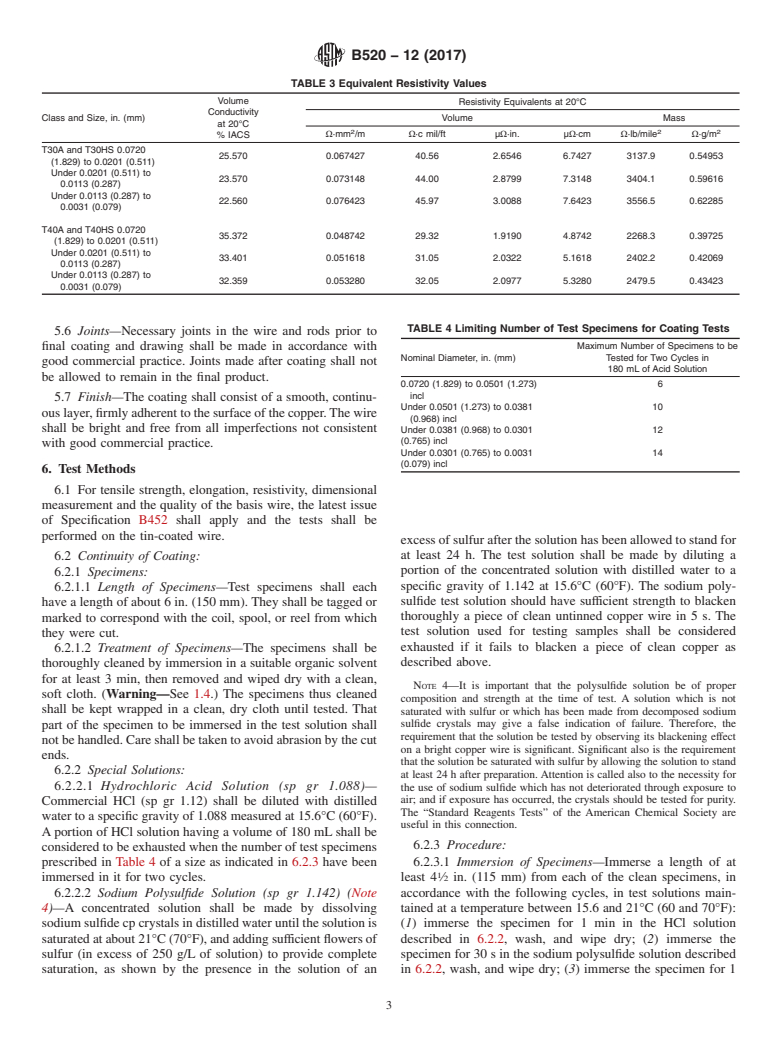

TABLE 3 Equivalent Resistivity Values

Volume Resistivity Equivalents at 20°C

Conductivity

Class and Size, in. (mm) Volume Mass

at 20°C

2 2 2

% IACS Ω·mm /m Ω·c mil/ft µΩ·in. µΩ·cm Ω·lb/mile Ω·g/m

T30A and T30HS 0.0720

25.570 0.067427 40.56 2.6546 6.7427 3137.9 0.54953

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

23.570 0.073148 44.00 2.8799 7.3148 3404.1 0.59616

0.0113 (0.287)

Under 0.0113 (0.287) to

22.560 0.076423 45.97 3.0088 7.6423 3556.5 0.62285

0.0031 (0.079)

T40A and T40HS 0.0720

35.372 0.048742 29.32 1.9190 4.8742 2268.3 0.39725

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

33.401 0.051618 31.05 2.0322 5.1618 2402.2 0.42069

0.0113 (0.287)

Under 0.0113 (0.287) to

32.359 0.053280 32.05 2.0977 5.3280 2479.5 0.43423

0.0031 (0.079)

TABLE 4 Limiting Number of Test Specimens for Coating Tests

5.6 Joints—Necessary joints in the wire and rods prior to

Maximum Number of Specimens to be

final coating and drawing shall be made in accordance with

Nominal Diameter, in. (mm) Tested for Two Cycles in

good commercial practice. Joints made after coating shall not

180 mL of Acid Solution

be allowed to remain in the final product.

0.0720 (1.829) to 0.0501 (1.273) 6

incl

5.7 Finish—The coating shall consist of a smooth, continu-

Under 0.0501 (1.273) to 0.0381 10

ouslayer,firmlyadherenttothesurfaceofthecopper.Thewire

(0.968) incl

shall be bright and free from all imperfections not consistent

Under 0.0381 (0.968) to 0.0301 12

(0.765) incl

with good commercial practice.

Under 0.0301 (0.765) to 0.0031 14

(0.079) incl

6. Test Methods

6.1 For tensile strength, elongation, resistivity, dimensional

measurement and the quality of the basis wire, the latest issue

of Specification B452 shall apply and the tests shall be

performed on the tin-coated wire.

excess of sulfur after the solution has been allowed to stand for

at least 24 h. The test solution shall be made by diluting a

6.2 Continuity of Coating:

portion of the concentrated solution with distilled water to a

6.2.1 Specimens:

specific gravity of 1.142 at 15.6°C (60°F). The sodium poly-

6.2.1.1 Length of Specimens—Test specimens shall each

sulfide test solution should have sufficient strength to blacken

have a length of about 6 in. (150 mm). They shall be tagged or

thoroughly a piece of clean untinned copper wire in 5 s. The

marked to correspond with the coil, spool, or reel from which

test solution used for testing samples shall be considered

they were cut.

exhausted if it fails to blacken a piece of clean copper as

6.2.1.2 Treatment of Specimens—The specimens shall be

described above.

thoroughly cleaned by immersion in a suitable organic solvent

for at least 3 min, then removed and wiped dry with a clean,

NOTE 4—It is important that the polysulfide solution be of proper

soft cloth. (Warning—See 1.4.) The specimens thus cleaned

composition and strength at the time of test. A solution which is not

shall be kept wrapped in a clean, dry cloth until tested. That

saturated with sulfur or which has been made from decomposed sodium

sulfide crystals may give a false indication of failure. Therefore, the

part of the specimen to be immersed in the test solution shall

requirement that the solution be tested by observing its blackening effect

not be handled. Care shall be taken to avoid abrasion by the cut

on a bright copper wire is significant. Significant also is the requirement

ends.

that the solution be saturated with sulfur by allowing the solution to stand

6.2.2 Special Solutions:

at least 24 h after preparation.Attention is called also to the necessity for

6.2.2.1 Hydrochloric Acid Solution (sp gr 1.088)—

the use of sodium sulfide which has not deteriorated through exposure to

air; and if exposure has occurred, the crystals should be tested for purity.

Commercial HCl (sp gr 1.12) shall be diluted with distilled

The “Standard Reagents Tests” of the American Chemical Society are

water to a specific gravity of 1.088 measured at 15.6°C (60°F).

useful in this connection.

Ap

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B520 − 12 (Reapproved 2017)

Standard Specification for

Tin-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 The following documents of the issue in effect on date

1.1 This specification covers tin-coated copper-clad steel

of material purchase form a part of this specification to the

wire for electronic application.

extent referenced herein:

1.2 Four classes of tin-coated copper-clad steel wire are

2.2 ASTM Standards:

covered as follows:

B193 Test Method for Resistivity of Electrical Conductor

1.2.1 Class T30HS—Nominal 30 % conductivity, hard-

Materials

drawn,

B258 Specification for Nominal Diameters and Cross-

1.2.2 Class T30A—Nominal 30 % conductivity, annealed,

Sectional Areas of AWG Sizes of Solid Round Wires Used

1.2.3 Class T40HS—Nominal 40 % conductivity, hard-

as Electrical Conductors

drawn, and B452 Specification for Copper-Clad Steel Wire for Elec-

tronic Application

1.2.4 Class T40A—Nominal 40 % conductivity, annealed.

2.3 National Institute of Standards and Technology:

1.3 The values stated in inch-pound units are to be regarded

NBS Handbook 100 Copper Wire Tables

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

3. Ordering Information

and are not considered standard.

3.1 Orders for material under this specification shall include

1.3.1 Exception—The SI values for resistivity and volume

the following information:

are to be regarded as standard.

3.1.1 Quantity of each size.

3.1.2 Wire size (see 5.3 and Table 1),

1.4 The following safety hazards caveat pertains only to the

3.1.3 Class of wire (see 1.2),

test method portion, Section 6, of this specification: This

3.1.4 Package size and shipping (see 7.1.7 and Section 9),

standard does not purport to address all of the safety concerns,

packaging inspection if required (see 9.3.3),

if any, associated with its use. It is the responsibility of the user

3.1.5 Special package marking, if required, and

of this standard to establish appropriate safety and health

3.1.6 Place of inspection (see 9.1).

practices and determine the applicability of regulatory limita-

tions prior to use. (Warning—Consideration should be given

4. Material

to toxicity and flammability when selecting solvent cleaners.)

4.1 The basis material shall consist of copper-clad steel wire

1.5 This international standard was developed in accor-

conforming to the product description, quality and specifica-

dance with internationally recognized principles on standard-

tion requirements of Specification B452.

ization established in the Decision on Principles for the

4.2 The tin-coated wire shall consist of the basis wire coated

Development of International Standards, Guides and Recom-

with tin. The tin used for coating shall be commercially pure

mendations issued by the World Trade Organization Technical

(Note 1). For purposes of this specification, the tin shall be

Barriers to Trade (TBT) Committee.

considered“ commercially pure” if the total of other elements,

1 2

This specification is under the jurisdiction of ASTM Committee B01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Bi-Metallic Conductors. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2017. Published April 2017. Originally the ASTM website.

approved in 1970. Last previous edition approved in 2012 as B520 – 12. DOI: Available from National Institute of Standards and Technology (NIST), 100

10.1520/B0520-12R17. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B520 − 12 (2017)

TABLE 1 Wire Sizes

5.2 Resistivity—The electrical resistivity at a temperature of

Diameter Cross-Sectional Area at 20°C (68°F) 20°C shall not exceed the values prescribed in Table 2. See

2 2

in. mm cmil in. mm Note 2 for calculating electrical resistance.

0.0720 1.8129 5180 0.00407 2.63

NOTE 2—Relationships that may be useful in connection with the values

0.0641 1.6128 4110 0.00323 2.08

of electrical resistivity prescribed in this specification are shown in Table

0.0571 1.450 3260 0.00256 1.65

2 2

3. Resistivity units ⁄58 Ω · mm /m and 0.15328 Ω · g/m at 20°C are

0.0508 1.290 2580 0.00203 1.31

respectively the international equivalent of volume and weight resistivity

0.0453 1.151 2050 0.00161 1.04

0.0403 1.024 1620 0.00128 0.823 of annealed copper equal to 100 % conductivity. The latter term means

that a copper wire 1 m in length and weighing 1 g would have a resistance

0.0359 0.912 1290 0.00101 0.653

of 0.15328 Ω. This is equivalent to a resistivity value of 875.20

0.0320 0.813 1020 0.000804 0.519

Ω·lb/mile , which signifies the resistance of a copper wire 1 mile in length

0.0285 0.724 812 0.000638 0.412

weighing 1 lb. It is also equivalent, for example, to 1.7241 µΩ/cm of

0.0253 0.643 640 0.000503 0.324

length of a copper bar 1 cm in cross section. A complete discussion of this

0.0226 0.574 511 0.000401 0.259

subject is contained in NBS Handbook 100. The use of five significant

0.0201 0.511 404 0.000317 0.205

figures in expressing resistivity does not imply the need for greater

accuracy of measurement than that specified in Test Method B193. The

0.0179 0.455 320 0.000252 0.162

use of five significant figures is required for complete reversible conver-

0.0159 0.404 253 0.000199 0.128

0.0142 0.361 202 0.000158 0.102

sion from one set of resistivity units to another.

0.0126 0.320 159 0.000125 0.0804

5.3 Dimensions and Permissible Variations—The wire sizes

0.0113 0.287 128 0.000100 0.0647

0.0100 0.254 100 0.0000785 0.0507

shall be expressed as the diameter of the wire in decimal

fractions of an inch to the nearest 0.0001 in. (0.003 mm) (Note

0.0089 0.226 79.2 0.0000622 0.0401

3). For diameters under 0.0100 in. (0.254 mm), the wire shall

0.0080 0.203 64.0 0.0000503 0.0324

0.0071 0.180 50.4 0.0000396 0.0255

not vary from the specified diameter by more than plus 0.0003

0.0063 0.160 39.7 0.0000312 0.0201

in. (0.008 mm) and minus 0.0001 in. (0.003 mm) and for

0.0056 0.142 31.4 0.0000246 0.0159

diameters of 0.0100 in. (0.254 mm) and over, the wire shall not

0.0050 0.127 25.0 0.0000196 0.0127

vary from the specified diameter by more than plus 3 % and

0.0045 0.114 20.2 0.0000159 0.0103

minus 1 %, expressed to the nearest 0.0001 in. (0.003 mm).

0.0040 0.102 16.0 0.0000126 0.00811

0.0035 0.089 12.2 0.00000962 0.00621

NOTE 3—The values of the wire diameters in Table 1 are given to the

0.0031 0.079 9.61 0.00000755 0.00487

nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given

in Specification B258. The use of gage numbers to specify wire sizes is not

recognized in this specification because of the possibility of confusion. An

excellent discussion of wire gages and related subjects is contained in

“Copper Wire Tables” NBS Handbook 100.

exclusive of copper, does not exceed 1 %. Notwithstanding the

5.4 Continuity of Coating—The tin coating shall be continu-

previous sentence, chemical analysis of the tin coating or of the

ous. The continuity of coating on the wire shall be determined

tin used for coating shall not be required under this specifica-

on representative samples taken before stranding or insulating.

tion. Adequacy of the tin coating is assured by the continuity of

The continuity of tinning shall be determined by the hydro-

coating and adherence of coating requirements (see 5.4 and

chloric acid-sodium polysulfide test in accordance with 6.2.

5.5). The quality of the tin-coated wire shall be such that the

finished product meets the properties and requirements in this

5.5 Adherence of Coating—The tin coating shall be firmly

specification.

adherent to the surface of the copper-clad steel wire. The

adherence of coating on the wire shall be determined on

NOTE 1—It is necessary that the coating of the tin on the wire be

representative samples taken before stranding or insulating.

continuous. The test in the sodium polysulfide is for the purpose of

determining whether or not the wire carries a continuous envelope of pure

The adherence of coating shall be determined by the wrapping

tin. The thickness of the tin coating is necessarily varied. Under the same

and immersion test in accordance with 6.3.

conditions of tinning, the coating on all sizes of wire, excepting on fine

wire, is approximately the same. The coating on fine wire is in general

relatively heavier than that on coarse wire. It is not, therefore, correct to

apply a larger number of cycles in the test on coarse wire than is applied

to fine wire. It is probable that one cycle of the dip test would be sufficient TABLE 2 Resistivity, max at 20°C

to discover defects in tinned wire, but in order to make certain that no

Nominal Diameter, in.

Class of Wire Ω·mm /m

partially covered spots may escape attention, provision has been made for

(mm)

two cycles. It has been found that the tin coating on copper wire consists

T30HS 0.0720 (1.829) to 0.06743

of two parts, an envelope of pure tin on the outside, with an intermediate

0.0201 (0.511) incl (0.067427)

layer of copper-tin alloy. This tin alloy, as well as the amount of tin

and under 0.0201 (0.511) to 0.07315

present, has an effect on the resistivity of the wire. Since the relative

0.0113 (0.287) incl (0.073148)

amount of tin coating and alloy is greater on the small wire than it is on T30A under 0.0113 (0.287) to 0.07642

the coarser wire, the resistivity of the wire increases as the size decreases. 0.0031 (0.079) incl (0.076423)

This also accounts for the decrease in elongation due to tinning soft wire.

T40HS 0.0720 (1.829) to 0.04874

0.0201 (0.511) incl (0.048742)

5. General Requirements

and under 0.0201 (0.511) to 0.05162

0.0113 (0.287) incl (0.051618)

5.1 Tensile strength and elongation of the tin-coated wire

T40A under 0.0113 (0.287) to 0.05328

shall conform to the requirements of Specification B452 for the

0.0031 (0.079) incl (0.053280)

applicable size and class of copper-clad steel wire.

B520 − 12 (2017)

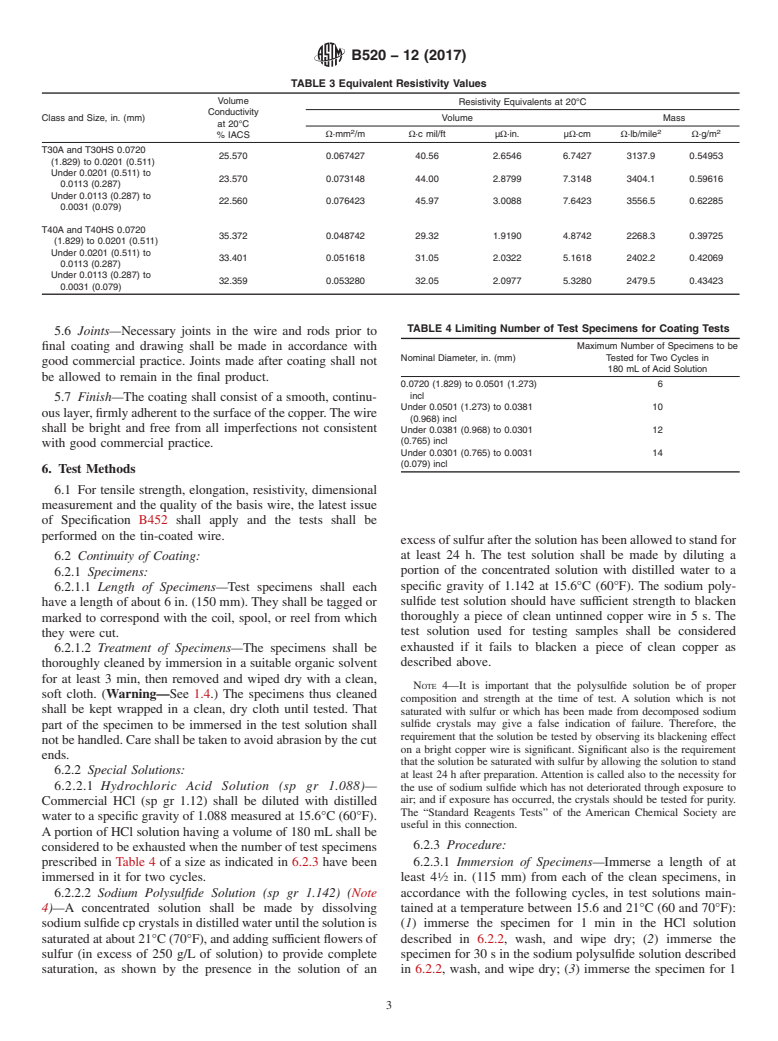

TABLE 3 Equivalent Resistivity Values

Volume

Resistivity Equivalents at 20°C

Conductivity

Class and Size, in. (mm) Volume Mass

at 20°C

2 2 2

Ω·mm /m Ω·c mil/ft µΩ·in. µΩ·cm Ω·lb/mile Ω·g/m

% IACS

T30A and T30HS 0.0720

25.570 0.067427 40.56 2.6546 6.7427 3137.9 0.54953

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

23.570 0.073148 44.00 2.8799 7.3148 3404.1 0.59616

0.0113 (0.287)

Under 0.0113 (0.287) to

22.560 0.076423 45.97 3.0088 7.6423 3556.5 0.62285

0.0031 (0.079)

T40A and T40HS 0.0720

35.372 0.048742 29.32 1.9190 4.8742 2268.3 0.39725

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

33.401 0.051618 31.05 2.0322 5.1618 2402.2 0.42069

0.0113 (0.287)

Under 0.0113 (0.287) to

32.359 0.053280 32.05 2.0977 5.3280 2479.5 0.43423

0.0031 (0.079)

TABLE 4 Limiting Number of Test Specimens for Coating Tests

5.6 Joints—Necessary joints in the wire and rods prior to

Maximum Number of Specimens to be

final coating and drawing shall be made in accordance with

Nominal Diameter, in. (mm) Tested for Two Cycles in

good commercial practice. Joints made after coating shall not

180 mL of Acid Solution

be allowed to remain in the final product.

0.0720 (1.829) to 0.0501 (1.273) 6

incl

5.7 Finish—The coating shall consist of a smooth, continu-

Under 0.0501 (1.273) to 0.0381 10

ous layer, firmly adherent to the surface of the copper. The wire

(0.968) incl

shall be bright and free from all imperfections not consistent

Under 0.0381 (0.968) to 0.0301 12

(0.765) incl

with good commercial practice.

Under 0.0301 (0.765) to 0.0031 14

(0.079) incl

6. Test Methods

6.1 For tensile strength, elongation, resistivity, dimensional

measurement and the quality of the basis wire, the latest issue

of Specification B452 shall apply and the tests shall be

performed on the tin-coated wire.

excess of sulfur after the solution has been allowed to stand for

at least 24 h. The test solution shall be made by diluting a

6.2 Continuity of Coating:

portion of the concentrated solution with distilled water to a

6.2.1 Specimens:

specific gravity of 1.142 at 15.6°C (60°F). The sodium poly-

6.2.1.1 Length of Specimens—Test specimens shall each

sulfide test solution should have sufficient strength to blacken

have a length of about 6 in. (150 mm). They shall be tagged or

thoroughly a piece of clean untinned copper wire in 5 s. The

marked to correspond with the coil, spool, or reel from which

test solution used for testing samples shall be considered

they were cut.

exhausted if it fails to blacken a piece of clean copper as

6.2.1.2 Treatment of Specimens—The specimens shall be

described above.

thoroughly cleaned by immersion in a suitable organic solvent

for at least 3 min, then removed and wiped dry with a clean,

NOTE 4—It is important that the polysulfide solution be of proper

soft cloth. (Warning—See 1.4.) The specimens thus cleaned

composition and strength at the time of test. A solution which is not

shall be kept wrapped in a clean, dry cloth until tested. That

saturated with sulfur or which has been made from decomposed sodium

sulfide crystals may give a false indication of failure. Therefore, the

part of the specimen to be immersed in the test solution shall

requirement that the solution be tested by observing its blackening effect

not be handled. Care shall be taken to avoid abrasion by the cut

on a bright copper wire is significant. Significant also is the requirement

ends.

that the solution be saturated with sulfur by allowing the solution to stand

6.2.2 Special Solutions:

at least 24 h after preparation. Attention is called also to the necessity for

6.2.2.1 Hydrochloric Acid Solution (sp gr 1.088)—

the use of sodium sulfide which has not deteriorated through exposure to

air; and if exposure has occurred, the crystals should be tested for purity.

Commercial HCl (sp gr 1.12) shall be diluted with distilled

The “Standard Reagents Tests” of the American Chemical Society are

water to a specific gravity of 1.088 measured at 15.6°C (60°F).

useful in this connec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B520 − 12 B520 − 12 (Reapproved 2017)

Standard Specification for

Tin-Coated, Copper-Clad Steel Wire for Electronic

Application

This standard is issued under the fixed designation B520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers tin-coated copper-clad steel wire for electronic application.

1.2 Four classes of tin-coated copper-clad steel wire are covered as follows:

1.2.1 Class T30HS—Nominal 30 % conductivity, hard-drawn,

1.2.2 Class T30A—Nominal 30 % conductivity, annealed,

1.2.3 Class T40HS—Nominal 40 % conductivity, hard-drawn, and

1.2.4 Class T40A—Nominal 40 % conductivity, annealed.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The SI values for resistivity and volume are to be regarded as standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 6, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

(Warning—Consideration should be given to toxicity and flammability when selecting solvent cleaners.)

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B258 Specification for Nominal Diameters and Cross-Sectional Areas of AWG Sizes of Solid Round Wires Used as Electrical

Conductors

B452 Specification for Copper-Clad Steel Wire for Electronic Application

2.3 National Institute of Standards and Technology:

NBS Handbook 100 Copper Wire Tables

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size.

3.1.2 Wire size (see 5.3 and Table 1),

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.06 on Bi-Metallic

Conductors.

Current edition approved Oct. 15, 2012April 1, 2017. Published November 2012April 2017. Originally approved in 1970. Last previous edition approved in 20072012

as B520 – 93 (2007).B520 – 12. DOI: 10.1520/B0520-12.10.1520/B0520-12R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’standard’s Document Summary page on the ASTM website.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B520 − 12 (2017)

TABLE 1 Wire Sizes

Diameter Cross-Sectional Area at 20°C (68°F)

2 2

in. mm cmil in. mm

0.0720 1.8129 5180 0.00407 2.63

0.0641 1.6128 4110 0.00323 2.08

0.0571 1.450 3260 0.00256 1.65

0.0508 1.290 2580 0.00203 1.31

0.0453 1.151 2050 0.00161 1.04

0.0403 1.024 1620 0.00128 0.823

0.0359 0.912 1290 0.00101 0.653

0.0320 0.813 1020 0.000804 0.519

0.0285 0.724 812 0.000638 0.412

0.0253 0.643 640 0.000503 0.324

0.0226 0.574 511 0.000401 0.259

0.0201 0.511 404 0.000317 0.205

0.0179 0.455 320 0.000252 0.162

0.0159 0.404 253 0.000199 0.128

0.0142 0.361 202 0.000158 0.102

0.0126 0.320 159 0.000125 0.0804

0.0113 0.287 128 0.000100 0.0647

0.0100 0.254 100 0.0000785 0.0507

0.0089 0.226 79.2 0.0000622 0.0401

0.0080 0.203 64.0 0.0000503 0.0324

0.0071 0.180 50.4 0.0000396 0.0255

0.0063 0.160 39.7 0.0000312 0.0201

0.0056 0.142 31.4 0.0000246 0.0159

0.0050 0.127 25.0 0.0000196 0.0127

0.0045 0.114 20.2 0.0000159 0.0103

0.0040 0.102 16.0 0.0000126 0.00811

0.0035 0.089 12.2 0.00000962 0.00621

0.0031 0.079 9.61 0.00000755 0.00487

3.1.3 Class of wire (see 1.2),

3.1.4 Package size and shipping (see 7.1.7 and Section 9), packaging inspection if required (see 9.3.3),

3.1.5 Special package marking, if required, and

3.1.6 Place of inspection (see 9.1).

4. Material

4.1 The basis material shall consist of copper-clad steel wire conforming to the product description, quality and specification

requirements of Specification B452.

4.2 The tin-coated wire shall consist of the basis wire coated with tin. The tin used for coating shall be commercially pure (Note

1). For purposes of this specification, the tin shall be considered“ commercially pure” if the total of other elements, exclusive of

copper, does not exceed 1 %. Notwithstanding the previous sentence, chemical analysis of the tin coating or of the tin used for

coating shall not be required under this specification. Adequacy of the tin coating is assured by the continuity of coating and

adherence of coating requirements (see 5.4 and 5.5). The quality of the tin-coated wire shall be such that the finished product meets

the properties and requirements in this specification.

NOTE 1—It is necessary that the coating of the tin on the wire be continuous. The test in the sodium polysulfide is for the purpose of determining

whether or not the wire carries a continuous envelope of pure tin. The thickness of the tin coating is necessarily varied. Under the same conditions of

tinning, the coating on all sizes of wire, excepting on fine wire, is approximately the same. The coating on fine wire is in general relatively heavier than

that on coarse wire. It is not, therefore, correct to apply a larger number of cycles in the test on coarse wire than is applied to fine wire. It is probable

that one cycle of the dip test would be sufficient to discover defects in tinned wire, but in order to make certain that no partially covered spots may escape

attention, provision has been made for two cycles. It has been found that the tin coating on copper wire consists of two parts, an envelope of pure tin

on the outside, with an intermediate layer of copper-tin alloy. This tin alloy, as well as the amount of tin present, has an effect on the resistivity of the

wire. Since the relative amount of tin coating and alloy is greater on the small wire than it is on the coarser wire, the resistivity of the wire increases

as the size decreases. This also accounts for the decrease in elongation due to tinning soft wire.

5. General Requirements

5.1 Tensile strength and elongation of the tin-coated wire shall conform to the requirements of Specification B452 for the

applicable size and class of copper-clad steel wire.

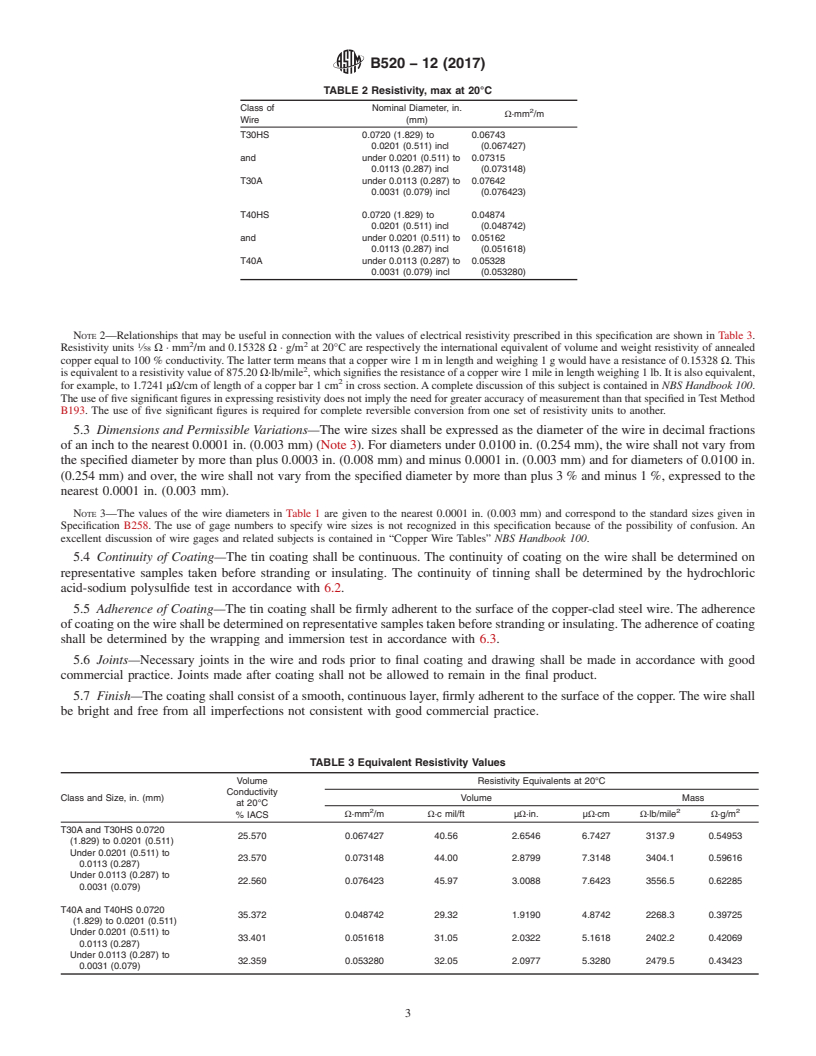

5.2 Resistivity—The electrical resistivity at a temperature of 20°C shall not exceed the values prescribed in Table 2. See Note

2 for calculating electrical resistance.

B520 − 12 (2017)

TABLE 2 Resistivity, max at 20°C

Class of Nominal Diameter, in.

Ω·mm /m

Wire (mm)

T30HS 0.0720 (1.829) to 0.06743

0.0201 (0.511) incl (0.067427)

and under 0.0201 (0.511) to 0.07315

0.0113 (0.287) incl (0.073148)

T30A under 0.0113 (0.287) to 0.07642

0.0031 (0.079) incl (0.076423)

T40HS 0.0720 (1.829) to 0.04874

0.0201 (0.511) incl (0.048742)

and under 0.0201 (0.511) to 0.05162

0.0113 (0.287) incl (0.051618)

T40A under 0.0113 (0.287) to 0.05328

0.0031 (0.079) incl (0.053280)

NOTE 2—Relationships that may be useful in connection with the values of electrical resistivity prescribed in this specification are shown in Table 3.

2 2

Resistivity units ⁄58 Ω · mm /m and 0.15328 Ω · g/m at 20°C are respectively the international equivalent of volume and weight resistivity of annealed

copper equal to 100 % conductivity. The latter term means that a copper wire 1 m in length and weighing 1 g would have a resistance of 0.15328 Ω. This

is equivalent to a resistivity value of 875.20 Ω·lb/mile , which signifies the resistance of a copper wire 1 mile in length weighing 1 lb. It is also equivalent,

for example, to 1.7241 μΩ/cm of length of a copper bar 1 cm in cross section. A complete discussion of this subject is contained in NBS Handbook 100.

The use of five significant figures in expressing resistivity does not imply the need for greater accuracy of measurement than that specified in Test Method

B193. The use of five significant figures is required for complete reversible conversion from one set of resistivity units to another.

5.3 Dimensions and Permissible Variations—The wire sizes shall be expressed as the diameter of the wire in decimal fractions

of an inch to the nearest 0.0001 in. (0.003 mm) (Note 3). For diameters under 0.0100 in. (0.254 mm), the wire shall not vary from

the specified diameter by more than plus 0.0003 in. (0.008 mm) and minus 0.0001 in. (0.003 mm) and for diameters of 0.0100 in.

(0.254 mm) and over, the wire shall not vary from the specified diameter by more than plus 3 % and minus 1 %, expressed to the

nearest 0.0001 in. (0.003 mm).

NOTE 3—The values of the wire diameters in Table 1 are given to the nearest 0.0001 in. (0.003 mm) and correspond to the standard sizes given in

Specification B258. The use of gage numbers to specify wire sizes is not recognized in this specification because of the possibility of confusion. An

excellent discussion of wire gages and related subjects is contained in “Copper Wire Tables” NBS Handbook 100.

5.4 Continuity of Coating—The tin coating shall be continuous. The continuity of coating on the wire shall be determined on

representative samples taken before stranding or insulating. The continuity of tinning shall be determined by the hydrochloric

acid-sodium polysulfide test in accordance with 6.2.

5.5 Adherence of Coating—The tin coating shall be firmly adherent to the surface of the copper-clad steel wire. The adherence

of coating on the wire shall be determined on representative samples taken before stranding or insulating. The adherence of coating

shall be determined by the wrapping and immersion test in accordance with 6.3.

5.6 Joints—Necessary joints in the wire and rods prior to final coating and drawing shall be made in accordance with good

commercial practice. Joints made after coating shall not be allowed to remain in the final product.

5.7 Finish—The coating shall consist of a smooth, continuous layer, firmly adherent to the surface of the copper. The wire shall

be bright and free from all imperfections not consistent with good commercial practice.

TABLE 3 Equivalent Resistivity Values

Volume

Resistivity Equivalents at 20°C

Conductivity

Class and Size, in. (mm) Volume Mass

at 20°C

2 2 2

Ω·mm /m Ω·c mil/ft μΩ·in. μΩ·cm Ω·lb/mile Ω·g/m

% IACS

T30A and T30HS 0.0720

25.570 0.067427 40.56 2.6546 6.7427 3137.9 0.54953

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

23.570 0.073148 44.00 2.8799 7.3148 3404.1 0.59616

0.0113 (0.287)

Under 0.0113 (0.287) to

22.560 0.076423 45.97 3.0088 7.6423 3556.5 0.62285

0.0031 (0.079)

T40A and T40HS 0.0720

35.372 0.048742 29.32 1.9190 4.8742 2268.3 0.39725

(1.829) to 0.0201 (0.511)

Under 0.0201 (0.511) to

33.401 0.051618 31.05 2.0322 5.1618 2402.2 0.42069

0.0113 (0.287)

Under 0.0113 (0.287) to

32.359 0.053280 32.05 2.0977 5.3280 2479.5 0.43423

0.0031 (0.079)

B520 − 12 (2017)

6. Test Methods

6.1 For tensile strength, elongation, resistivity, dimensional measurement and the quality of the basis wire, the latest issue of

Specification B452 shall apply and the tests shall be performed on the tin-coated wire.

6.2 Continuity of Coating:

6.2.1 Specimens:

6.2.1.1 Length of Specimens—Test specimens shall each have a length of about 6 in. (150 mm). They shall be tagged or marked

to correspond with the coil, spool, or reel from which they were cut.

6.2.1.2 Treatment of Specimens—The specimens shall be thoroughly cleaned by immersion in a suitable organic solvent for at

least 3 min, then removed and wiped dry with a clean, soft cloth. (Warning—See 1.4.) The specimens thus cleaned shall be kept

wrapped in a clean, dry cloth until tested. That part of the specimen to be immersed in the test solution shall not be handled. Care

shall be taken to avoid abrasion by the cut ends.

6.2.2 Special Solutions:

6.2.2.1 Hydrochloric Acid Solution (sp gr 1.088)—Commercial HCl (sp gr 1.12) shall be diluted with distilled water to a specific

gravity of 1.088 measured at 15.6°C (60°F). A portion of HCl solution having a volume of 180 mL shall be considered to be

exhausted when the number of test specimens prescribed in Table 4 of a size as indicated in 6.2.3 have been immersed in it for

two cycles.

6.2.2.2 Sodium Polysulfide Solution (sp gr 1.142) (Note 4)—A concentrated solution shall be made by dissolving sodium sulfide

cp crystals in distilled water until the solution is saturated at about 21°C (70°F), and adding sufficient flowers of sulfur (in excess

of 250 g/L of solution) to provide complete saturation, as shown by the presence in the solution of an excess of sulfur after the

solution has been allowed to stand for at least 24 h. The test solution shall be made by diluting a portion of the concentrated

solution with distilled water to a specific gravity of 1.142 at 15.6°C (60°F). The sodium polysulfide test solution should have

sufficient strength to blacken thoroughly a piece of clean untinned copper wire in 5 s. The test solution used for testing samples

shall be considered exhausted if it fails to blacken a piece of clean copper as described above.

NOTE 4—It is important that the polysulfide solution be of proper composition and strength at the time of test. A solution which is not saturated with

sulfur or which has been made from decomposed sodium sulfide crystals may giv

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.