ASTM C472-99

(Test Method)Standard Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete

Standard Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete

SCOPE

1.1 These test methods cover the physical testing of gypsum, gypsum plasters, and gypsum concrete.

1.2 The test methods appear in the following sections: Sections Precautions for Physical Tests 4 Reagents and Materials 5 Free Water 6 to 9 Fineness 10 to 14 Normal Consistency of Gypsum Plaster 15 to 19 Normal Consistency of Gypsum Concrete 20 to 24 Setting Time 25 to 29 Setting Time (Alternate Temperature Rise Method) 30 to 35 Compressive Strength 36 to 41 Density 42 to 46

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see X1.2.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 472 – 99

Standard Test Methods for

Physical Testing of Gypsum, Gypsum Plasters and Gypsum

Concrete

This standard is issued under the fixed designation C 472; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope E 11 Specification for Wire-Cloth Sieves for Testing Pur-

poses

1.1 These test methods cover the physical testing of gyp-

sum, gypsum plasters, and gypsum concrete.

3. Terminology

1.2 The test methods appear in the following sections:

3.1 Definitions:

Sections

3.1.1 For useful definitions refer to Terminology C 11.

Precautions for Physical Tests 4

Reagents and Materials 5 4. Precautions for Physical Tests

Free Water 6

4.1 Gypsum products are greatly affected by small amounts

Fineness 7

Normal Consistency of Gypsum Plaster 8

of impurities introduced by careless laboratory manipulation.

Normal Consistency of Gypsum Concrete 9

In order to obtain accurate results, it is absolutely essential to

Setting Time 10

observe the following precautions:

Setting Time (Temperature Rise Method) 11

Compressive Strength 12

4.1.1 Keep all apparatus thoroughly clean. Remove all

Density 13

traces of set plaster.

1.3 The values regarded as the standard are either in

NOTE 1—For mixing pastes and mortars, a 500-ml rubber dental bowl

inch-pound units or SI (metric). The values stated first shall be

is a convenience.

regarded as the standard. Values following in parentheses are

NOTE 2—Use care when drying gypsum, gypsum plasters, or gypsum

approximate and are provided for information purposes only.

concrete. Exceeding the specified drying temperatures may calcine the

specimens, which will cause inaccurate test results.

1.4 The text of this standard references notes and footnotes

which provide explanatory material. These notes and footnotes

5. Reagents and Materials

(excluding those in tables and figures) are not requirements of

5.1 Distilled or Deionized Water—free of chlorides and

the standard.

sulfates at a temperature of 21 61°C (70 62°F).

1.5 This standard does not purport to address all of the

5.2 Standard Sand— Specification C 778, 20–30 sand.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

6. Free Water

priate safety and health practices and determine the applica-

6.1 Significance and Use—This test method determines the

bility of regulatory limitations prior to use. For a specific

free water contained in gypsum, gypsum plasters, and gypsum

precautionary statement, see X1.2.1.

concrete samples, and prepares the sample for subsequent

2. Referenced Documents

testing.

6.2 Apparatus:

2.1 ASTM Standards:

6.2.1 Balance, capable of weighing not less than 500 g at

C 11 Terminology Relating to Gypsum and Related Build-

a precision of 0.1 g.

ing Materials and Systems

6.2.2 Drying Oven, set at 45 6 3°C.

C 778 Specification for Standard Sand

6.2.3 Desiccator, containing calcium chloride or equiva-

lent desiccant.

These test methods are under the jurisdiction of ASTM Committee C-11 on

6.3 Procedure:

Gypsum and Related Building Materials and Systems and are the direct responsi-

6.3.1 Weigh a sample of not less than 500 g of the material

bility of Subcommittee C11.01 on Specifications and Test Methods for Gypsum

as received to the nearest 0.1 g and spread it to a thin layer in

Products.

Current edition approved May 10, 1999. Published June 1999. Originally

published as C 472–61. Last previous edition C 472–98.

2 3

Annual Book of ASTM Standards, Vol 04.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 472

a suitable-vessel. Place in an oven (6.2.2) and dry for 2 h; then 8. Normal Consistency of Gypsum Plaster

cool in a desiccator (6.2.3) and weigh again.

8.1 Significance and Use—This test method is used to

6.3.2 Retain the dried sample in an airtight container until

determine the volume of water required for mixing gypsum

used for the fineness test (Section 7).

plaster when performing the setting time and compressive

6.4 Report—Report the loss in weight as a percentage of the strength tests.

original weight of the sample as received to a precision of

8.2 Apparatus:

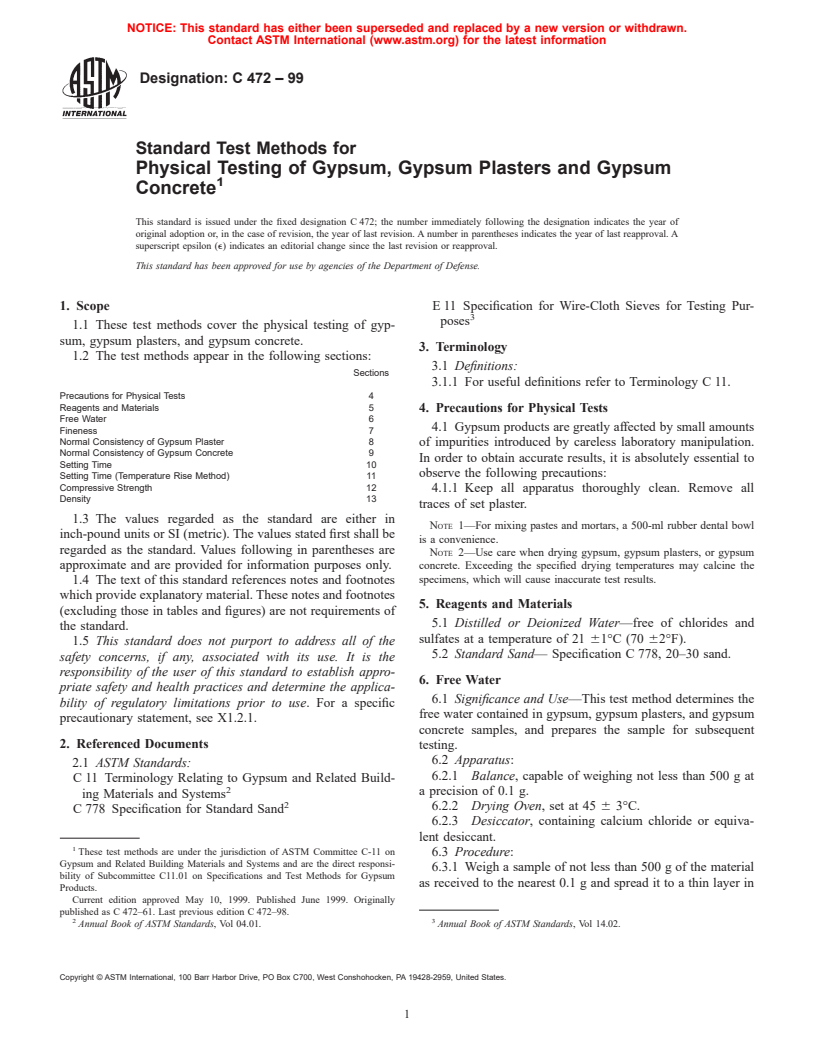

0.1%. 8.2.1 Modified Vicat Apparatus—The modified Vicat appa-

ratus (Fig. 1) shall consist of a bracket, A, bearing a movable

6.5 Precision and Bias—The precision and bias of the free

brass rod, B, 6.3 mm in diameter and of suitable length to fit the

water test method have not been determined.

Vicat Bracket. A conical plunger made of aluminum with an

apex angle of 53° 08 min and a height of 45 mm shall be

7. Fineness

attached to the lower end of the rod. The total weight of the rod

7.1 Significance and Use—This test method covers a pro-

and plunger shall be 35 g. A means shall be provided for adding

cedure for determining the fineness of gypsum and gypsum

a weight, G, to the rod, increasing the total weight to 50 g. The

plasters and is used to determine compliance with gypsum and

rod shall be capable of being held in any position by a screw,

gypsum plaster specifications. The degree of correlation be-

E. The rod shall have a mark, D, midway between the ends

tween the results of this test method and service performance

which moves under a scale, F, graduated in millimetres,

has not been determined.

attached to the bracket, A.

7.2 Apparatus:

8.2.2 Mold—The conical ring mold shall be made of a

7.2.1 Sieves, as required by a particular gypsum or gypsum

noncorroding, nonabsorbent material, and shall have an inside

plaster specification, in accordance with Specification E 11.

diameter of 60 mm at the base and 70 mm at the top and a

7.2.2 Balance, capable of weighing not less than 1000 g at

height of 40 mm.

a precision of 0.1 g.

7.2.3 Mechanical Sieving Machine

7.3 Procedure:

This method is described by Kuntze, R. A., “An Improved Method for the

Normal Consistency of Gypsum Plasters,” ASTM Bulletin No. 246, ASTM, May

7.3.1 Determine fineness by sieving a known weight of the

1960, p. 35.

dried sample through sieves of the specified sizes (Note 3 and

Note 4). The size of the sample to be used in determining

fineness depends upon the particle size of the material. If the

material will pass a 6.3-mm ( ⁄4-in.) sieve, a 100-g sample will

be sufficient; if the largest particles are more than 25 mm (1 in.)

in diameter, use not less than a 1000-g sample. With these

limitations the size of sample to be used is left to the discretion

of the operator. Shake the sample through each sieve with as

little abrasion as possible (Note 5). Weigh the amount of

material retained on each sieve and calculate the fineness,

expressed as a percentage of the weight of the original sample.

7.3.2 If a mechanical sieving machine is used, make a series

of tests at one minute intervals, with each type of material and

sieve size combination to be used. When not more than 0.5 g

passes each sieve in a one minute interval, use that time as the

standard sieving time for that test procedure on that machine.

NOTE 3—For suggested method of sieving gypsum through a 45-μm

(No. 325) sieve, see Appendix X1.

NOTE 4—The sizes of the sieves to be used are given in the specifica-

tions of ASTM covering the particular product in question.

NOTE 5—When sieving by hand through a 150–μm (No. 100) sieve, use

a lateral motion, and tap the side of the sieve with the palm of the hand.

Continue without brushing until not more than 0.5 g passes through during

1 min of sieving. If the sieve openings become clogged, transfer the

retained material temporarily to another vessel, invert the sieve over a

sheet of paper on the table and tap it sharply against the table. Then

transfer all the retained material back into the sieve and continue sieving.

7.4 Report—Report the percent by weight retained on each

A—Hinged support bracket D—Graduation mark

sieve or passing particular sieves in accordance with the

B—Plunger support rod E—Lock screw

material specification to the nearest full percentage point.

C—Conical plunger F—Modified scale

G—Weight

7.5 Precision and Bias—The precision and bias of the

fineness test method have not been determined. FIG. 1 Modified Vicat Apparatus (Conical Plunger Method)

C 472

8.2.3 Base Plate—The base plate for supporting the ring 8.3.3 Test gypsum molding plaster and gypsum gauging

mold shall be of plate glass and about 100 mm square. plaster with different amounts of water until a penetration of 30

6 2 mm is obtained. Use the rod and plunger for this

8.2.4 Balance, capable of weighing not less than 500 g at a

determination weighing 35 g.

precision of 0.1 g.

8.3.4 Test all gypsum mixtures containing aggregates with

8.2.5 Graduated Cylinder, shall be made to deliver the

different amounts of water until a penetration of 20 6 2mmis

indicated volume at 20°C (68°F) and shall be subdivided to not

obtained. Add weight to the rod and plunger to bring the total

less than 1 mL.

weight to 50 g for these determinations.

8.3 Procedure:

8.3.5 Mix gypsum neat plaster with standard sand (see 5.2)

8.3.1 Clean the plunger, mold, and base plate of the modi-

in the ratio of 200 g of sand to 100 g of plaster before testing

fied Vicat apparatus. Apply a thin coat of petroleum jelly or

for normal consistency.

other suitable lubricant to the upper surface of the base plate in

8.4 Report:

order to prevent leaks during the test.

Report the normal consistency as the average number of

8.3.2 Sift a weighed quantity of the sample (200 to 300 g as

milliliters of water required to be added to 100 g of the dry

required to fill the mold) into a known volume of water (See

mixture to the nearest whole milliliter.

5.1). If the plaster is unretarded, add to the mixing water 0.2 g

8.5 Precision and Bias—The precision and bias of the test

of sodium citrate per 100 g of sample. After allowing the

method for normal consistency of gypsum plaster have not

sample to soak for 2 min, stir the mixture for 1 min to an even

been determined.

fluidity. Pour this sample into the ring mold, work slightly to

remove air bubbles, and then strike off flush with the top of the

9. Normal Consistency of Gypsum Concrete

mold. Wet the plunger of the modified Vicat apparatus and

lower it to the surface of the sample at approximately the center 9.1 Significance and Use—This test method is used to

of the mold. Read the scale and release the plunger immedi- determine the volume of water required for mixing gypsum

ately. After the rod has settled, read the scale again. Make three concrete when performing the setting time and compressive

determinations on each mix, care being taken to have the mold strength tests.

completely filled and the plunger clean and wet. 9.2 Apparatus:

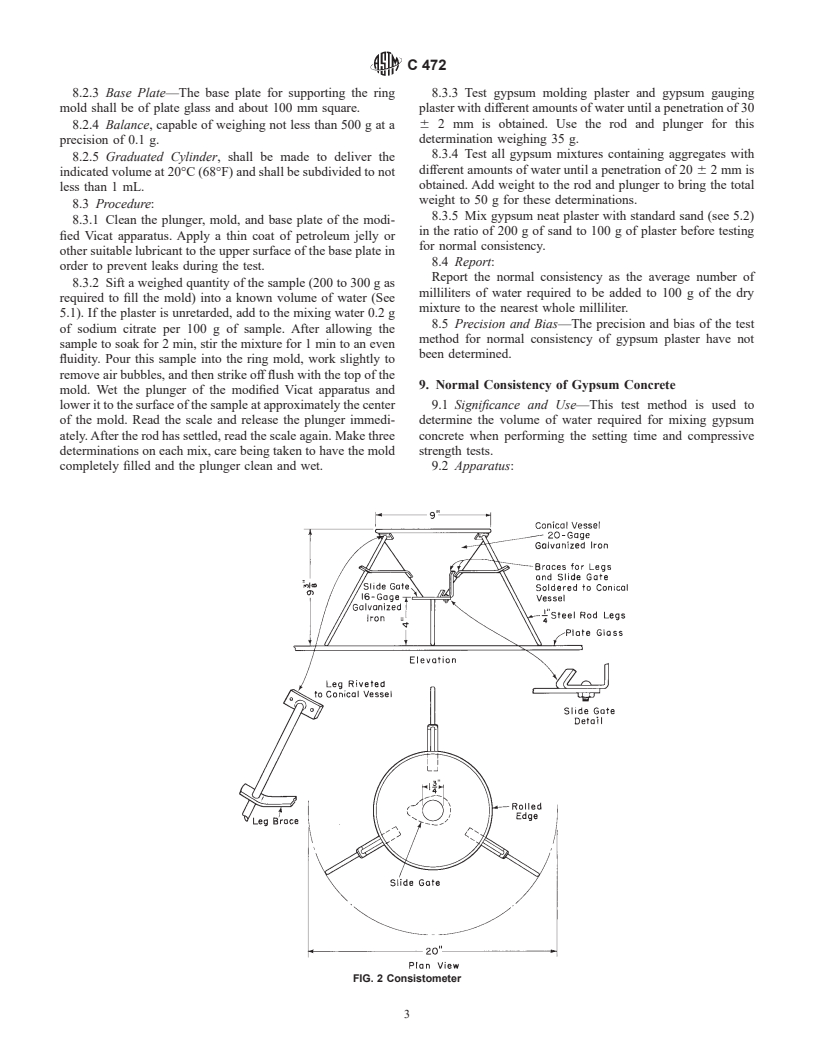

FIG. 2 Consistometer

C 472

9.2.1 Consistometer (Fig. 2)—The consistometer consists of 10. Setting Time

a conical vessel made of noncorroding, nonabsorbent material,

10.1 Significance and Use—This test method is used to

and having an inside diameter of 9 in. (229 mm) at the top and

determine the setting time of gypsum plaster and gypsum

3 1

1 ⁄4in. (44.5 mm) at the bottom, and a height of 5 ⁄2 in. (139.7

concrete, and is used to determine compliance with gypsum

mm). It shall be provided with a sliding gate at the bottom and

plaster and gypsum concrete specifications. Since variable job

supported so that the bottom is 4 in. (102 mm) above the base

conditions influence the setting time, the degree of correlation

plate. The base plate shall be of plate glass, free of scratches

between this test method and service performance has not been

and about 18 in. (457 mm) square.

determined.

9.2.2 Balance, capable of weighing not less than 2000 g at

10.1.1 This test method does not determine the time of

a precision of 1 g.

complete hydration of gypsum plaster or gypsum concrete. To

9.3 Procedure:

determine the time of complete hydration see Setting Time,

9.3.1 Clean and dry the consistometer and the base plate and

(Temperature Rise Method,) Section 11.

close the sliding gate.

10.2 Apparatus:

9.3.2 Sift 2000 g of the sample into a known volume of

10.2.1 Vicat Apparatus—The Vicat apparatus (Fig. 3) shall

water (see 5.1) to which 1.0 g of sodium citrate has previously

consist of a frame, A, bearing a movable rod, B, weighing 300

been added. After allowing the sample to soak for 1 min, stir

g, one end, C, the plunger end, being 10 mm in diameter for a

the mixture for 3 min to an even fluidity. Pour the mixture into

distance of not less than 50 mm, the other end having a

the consistometer until level with the top. Then rapidly and

removable needle, D, 1 mm in diameter and 50 mm in length.

completely open the sliding gate, allowing the mixture to run

The rod, B, shall be reversible, shall be able to be held in any

out onto the base plate. When the sliding gate is opened, take

position by a screw, E, and shall have an adjustable indicator,

care to avoid jarring the consistometer.

F, that moves over a scale (graduated in millimeters) attached

9.3.3 Measure the resulting patty along its major and minor

to the frame, A. The paste shall be held in a rigid conical ring,

axes and determine the average diameter.

G, resting on a glass plate, H, about 100 mm square. The ring

9.3.4 Test gypsum concrete with different amounts of water

1 shall be made of a noncorroding, nonabsorbent material and

until a patty dimaeter of 380 6 13 mm (15 6 ⁄2in.) is obtained.

shall have an inside diameter of 70 mm at the base and 60 mm

9.4 Report—Report the normal consistency as the number

at the top, and a height of 40 mm.

of milliliters of water to the nearest whole milliliter required to

10.2.2 In addition, the Vicat apparatus shall conform to the

be added to 100 g of the gypsum concrete.

following requirements:

9.5 Precision and Bias—The precision and bias of the test

method for normal consistency of gypsum concrete have not Weight of plunger 300 6 0.5 g

Diameter of larger end of plunger 10 6 0.05 mm

been determined.

FIG. 3 Vicat Apparatus

C 472

10.4 Report—Report the setting time as the elapsed time in

Diameter of needle 1 6 0.05 mm

Inside diameter of ring at bottom 70 6 3mm

minutes from the time when the sample was first added to the

Inside diameter of ring at top 60 6 3mm

water to the time when set is complete.

Height of ring 40 6 1mm

10.5 Precision and Bia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.