ASTM D8222-21a

(Guide)Standard Guide for Establishing a Quality Management System (QMS) for Consumer Use of Cannabis/Hemp Products

Standard Guide for Establishing a Quality Management System (QMS) for Consumer Use of Cannabis/Hemp Products

SIGNIFICANCE AND USE

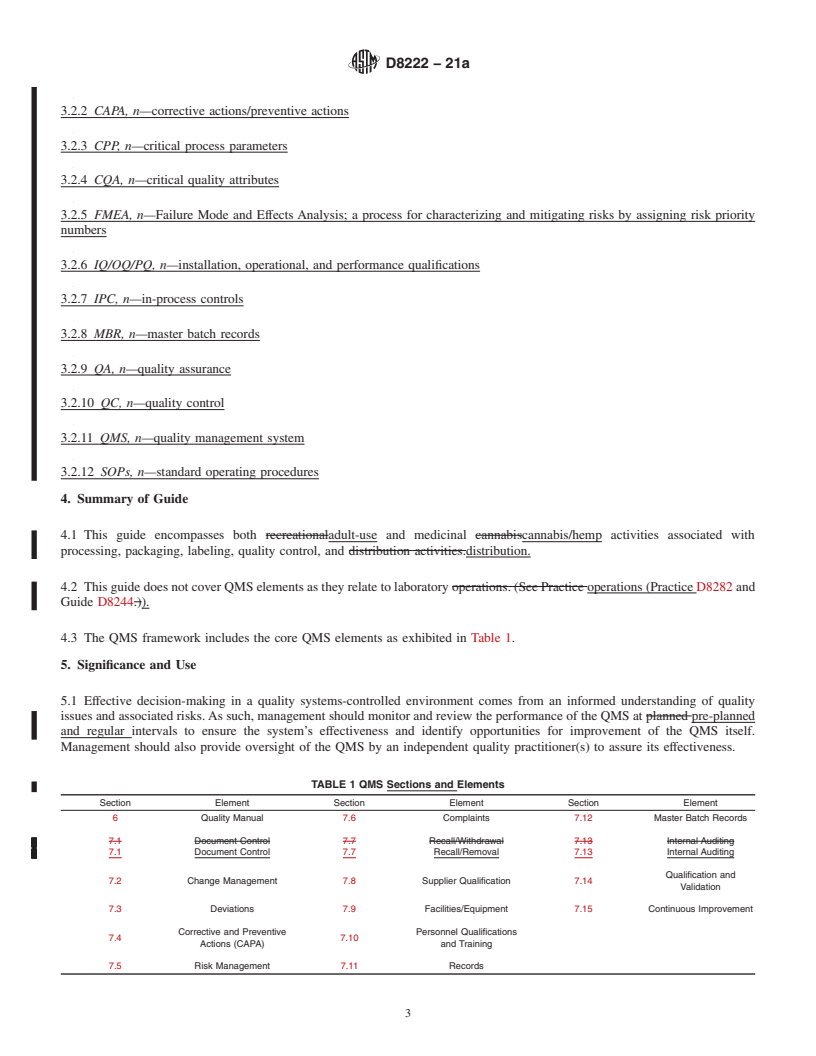

5.1 Effective decision-making in a quality systems-controlled environment comes from an informed understanding of quality issues and associated risks. As such, management should monitor and review the performance of the QMS at pre-planned and regular intervals to ensure the system’s effectiveness and identify opportunities for improvement of the QMS itself. Management should also provide oversight of the QMS by an independent quality practitioner(s) to assure its effectiveness.

5.2 Moreover, risk-based decision-making encompasses all elements of the QMS and should be at the forefront of each decision. Consumer safety is the top priority, regardless of other considerations.

5.3 Aspects of risk should be considered relative to intended (or unintended) uses of a product to ensure consumer safety. Management should assign priorities and adequate resources to activities or actions based on assessing the risk, including the probability of harm and the potential severity of that harm. It is essential to engage appropriate parties in evaluating the risk. Such parties may include:

5.3.1 Consumers;

5.3.2 Manufacturing personnel;

5.3.3 Marketing personnel; and

5.3.4 Other stakeholders, as needed.

5.4 Implementation of risk management includes assessing the risks, implementing risk management controls commensurate with the level of risk, and evaluating the risk management efforts’ results. Risk management assessment is an iterative process and continues when additional information emerges that changes the potential risk’s nature.

5.5 Risk management works in conjunction with process understanding to manage and control change and helps drive continuous improvement.

SCOPE

1.1 This guide focuses on the core elements of an effective quality management system (QMS) necessary to optimize consumer and product safety, product quality, and conformance with requirements from industry, governmental agencies, and other authorities having jurisdiction. This guide incorporates basic quality principles, guidelines, and industry best practices necessary to establish a QMS adaptable to all organizations.

1.2 Laws and regulations from authorities having jurisdiction supersede recommendations within this guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8222 − 21a

Standard Guide for

Establishing a Quality Management System (QMS) for

1

Consumer Use of Cannabis/Hemp Products

This standard is issued under the fixed designation D8222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D8282 Practice for Laboratory Test Method Validation and

Method Development

1.1 This guide focuses on the core elements of an effective

D8286 Guide for Processing Cannabis Product Complaints

quality management system (QMS) necessary to optimize

3

2.2 ASQ Document:

consumerandproductsafety,productquality,andconformance

Failure Mode and Effects Analysis (FMEA) Brief Summary

with requirements from industry, governmental agencies, and

other authorities having jurisdiction. This guide incorporates

3. Terminology

basic quality principles, guidelines, and industry best practices

necessary to establish a QMS adaptable to all organizations. 3.1 Definitions of Terms Specific to This Standard:

3.1.1 controlled document, n—a document with an alpha-

1.2 Laws and regulations from authorities having jurisdic-

numeric assignment that is integrated into a QMS and subject

tion supersede recommendations within this guide.

to revision and revision tracking.

1.3 This standard does not purport to address all of the

3.1.2 equipment, n—non-expendable, tangible moveable

safety concerns, if any, associated with its use. It is the

property needed for the performance of a task or useful in

responsibility of the user of this standard to establish appro-

effecting an obligation.

priate safety, health, and environmental practices and deter-

3.1.3 instrumentation, n—equipment capable of performing

mine the applicability of regulatory limitations prior to use.

measurements used to generate analytical data (for example,

1.4 This international standard was developed in accor-

GC-MS, IR, NMR, balances, etc.).

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.1.4 qualified individual, n—an individual who meets ap-

Development of International Standards, Guides and Recom-

plicable skill, experience, education, or other requirements of

mendations issued by the World Trade Organization Technical

an employment position that they hold or seek, and who can

Barriers to Trade (TBT) Committee.

perform the essential functions of the job with or without

reasonable accommodation.

2. Referenced Documents

3.1.5 planned deviation, n—pre-approved deviations from

2

2.1 ASTM Standards:

the current operational document or system, covering a speci-

D8220 Guide for Conducting Recall/Removal Procedures

fied period or number of batches.

for Products in the Cannabis Industry

D8229 Guide for Corrective Action and Preventive Action 3.1.5.1 Discussion—Planned deviations must be approved

(CAPA) for the Cannabis Industry before execution. Planned deviations should be handled

D8244 Guide forAnalytical Laboratory Operations Support- through approved change control procedures.

ing the Cannabis/Hemp Industry 3.1.6 recall, n—a product recall is the process of retrieving

D8250 Practice for Applying a Hazard Analysis Critical defective or potentially unsafe goods from consumers and

Control Points (HACCP) System for Cannabis Consum- providing those consumers with compensation.

able Products

3.1.7 removal, n—a product is removed from the supply

chain, but not for health and safety reasons.

1

This guide is under the jurisdiction ofASTM Committee D37 on Cannabis and

3.1.8 unplanned deviation, n—a state of nonconformance

is the direct responsibility of Subcommittee D37.02 on Quality Management

Systems. from the designed systems or procedures at any stage of

Current edition approved July 15, 2021. Published August 2021. Originally

manufacturing, packaging, testing, holding, or storage of the

approved in 2021. Last previous edition approved in 2021 as D8222 – 21. DOI:

product.

10.1520/D8222-21A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

the ASTM website. Milwaukee, WI 53203, http://www.asq.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D8222 − 21 D8222 − 21a

Standard Guide for

Establishing a Quality Management System (QMS) for

1

Consumer Use of Cannabis/Hemp Products

This standard is issued under the fixed designation D8222; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide focuses on the core elements of an effective quality management system (QMS) necessary to assureoptimize

consumer and product safety, product quality, and conformance with requirements from industry, governmental agencies, and other

authorities having jurisdiction. This guide incorporates basic quality principles, guidelines, and industry best practices necessary

to establish a QMS adaptable to all organizations.

1.2 Laws and regulations from authorities having jurisdiction supersede recommendations within this guide.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D8220 Guide for Conducting Recall/Removal Procedures for Products in the Cannabis Industry

D8229 Guide for Corrective Action and Preventive Action (CAPA) for the Cannabis Industry

D8220D8244 Guide for Conducting Recall/Removal Procedures for Products in the CannabisAnalytical Laboratory Operations

Supporting the Cannabis/Hemp Industry

D8250 Practice for Applying a Hazard Analysis Critical Control Points (HACCP) System for Cannabis Consumable Products

D8286 Guide for Processing Cannabis Product Complaints

D8308 Practice for Cannabis/Hemp Operation Compliance Audits

D8270 Terminology Relating to Cannabis

D8282 Practice for Laboratory Test Method Validation and Method Development

D8244D8286 Guide for Analytical Laboratory Operations Supporting the Cannabis/Hemp IndustryProcessing Cannabis Product

Complaints

3

2.2 ASQ Document:

Failure Mode and Effects AnalysesAnalysis (FMEA) Brief Summary

1

This guide is under the jurisdiction of ASTM Committee D37 on Cannabis and is the direct responsibility of Subcommittee D37.02 on Quality Management Systems.

Current edition approved Feb. 1, 2021July 15, 2021. Published February 2021August 2021. Originally approved in 2021. Last previous edition approved in 2021 as D8222

– 21. DOI: 10.1520/D8222-21.10.1520/D8222-21A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave., Milwaukee, WI 53203, http://www.asq.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D8222 − 21a

3. Terminology

3.1 Definitions:Definitions of Terms Specific to This Standard:

3.1.1 controlled document, n—a document with an alpha-numeric assignment that is integrated into a QMS and subject to revision

and revision tracking.

3.1.2 equipment, n—non-expendable, tangible moveable property needed for the performance of a task or useful in effecting an

obligation.

3.1.3 instrumentation, n—equipment capable of performing measurements used to generate analytical data (for example, GC-MS,

IR, NMR, balances, etc.).

3.1.4 qualified individual, n—an individual who meets legitimateapplicable skill, experience, education, or other requirements of

an employment position that they hold or seek, and who can perform the essential functions of the job with or without reasonable

accommodation.

3.1.5 planned deviation, n—pre-approved deviations from the current operational document or system, covering a specified period

or number of batches.

3.1.5.1 Discussion—

Planned deviations must be approved before execution.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.