ASTM D5024-07

(Test Method)Standard Test Method for Plastics: Dynamic Mechanical Properties: In Compression

Standard Test Method for Plastics: Dynamic Mechanical Properties: In Compression

SIGNIFICANCE AND USE

This test method provides a simple means of characterizing the thermomechanical behavior of plastic compositions using very small amounts of material. The data obtained can be used for quality control and/or research and development purposes. For some classes of materials, such as thermosets, it can also be used to establish optimum processing conditions.

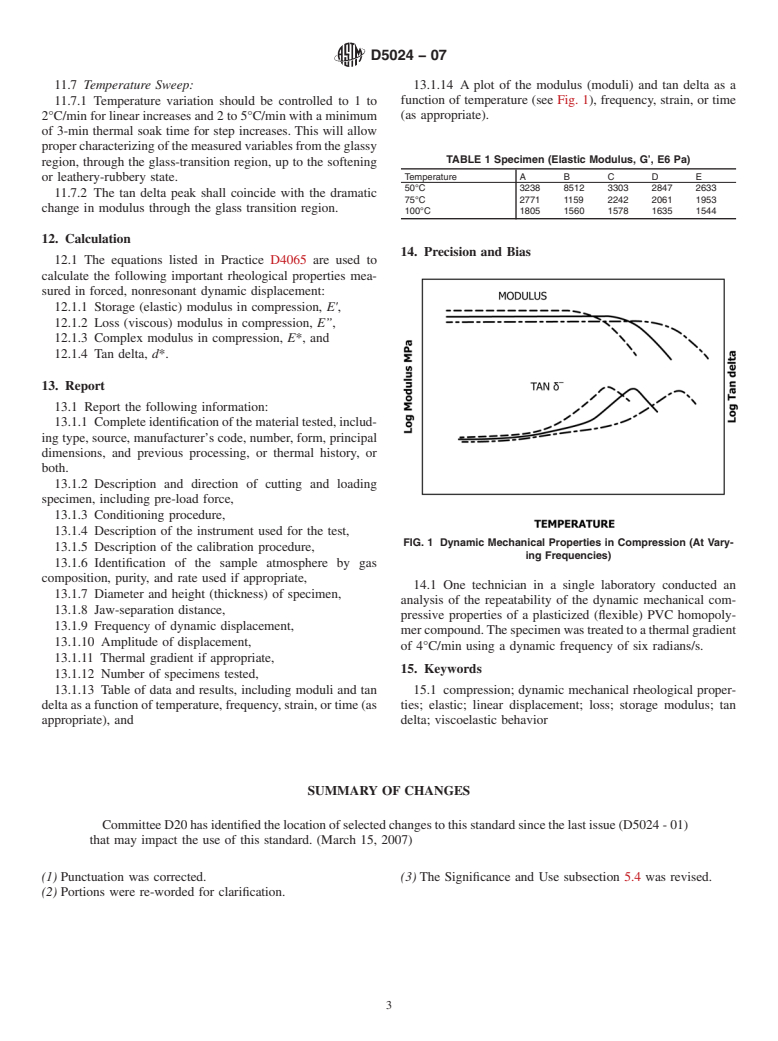

Dynamic mechanical testing provides a sensitive method for determining thermomechanical characteristics by measuring the elastic and loss moduli as a function of frequency, temperature, or time. Plots of moduli and tan delta of a material versus these variables provide graphical representation indicative of functional properties, effectiveness of cure (thermosetting resin system), and damping behavior under specified conditions.

This test method can be used to assess:

5.3.1 Modulus as a function of temperature,

5.3.2 Modulus as a function of frequency,

5.3.3 The effects of processing treatment, including orientation,

5.3.4 Relative resin behavioral properties, including cure and damping,

5.3.5 The effects of substrate types and orientation (fabrication) on elastic modulus, and,

5.3.6 The effects of formulation additives which might affect processability or performance.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the relevant ASTM materials specification shall take precedence over those mentioned in this test method. If there are no relevant ASTM material specifications, then the default conditions apply.

SCOPE

1.1 This test method outlines the use of dynamic mechanical instrumentation for determining and reporting the viscoelastic properties of thermoplastic and thermosetting resins as well as composite systems in the form of cylindrical specimens molded directly or cut from sheets, plates, or molded shapes. The compression data generated may be used to identify the thermomechanical properties of a plastics material or composition using a variety of dynamic mechanical instruments.

1.2 This test method is intended to provide a means for determining the thermomechanical properties (as a function of a number of viscoelastic variables) for a wide variety of plastic materials using nonresonant, forced-vibration techniques as outlined in Practice D 4065. Plots of the elastic (storage) modulus, loss (viscous) modulus, complex modulus, and tan delta as a function of frequency, time, or temperature are indicative of significant transitions in the thermomechanical performance of the polymeric material system.

1.3 This test method is valid for a wide range of frequencies, typically from 0.01 to 100 Hz.

1.4 Apparent discrepancies may arise in results obtained under differing experimental conditions. These apparent differences from results observed in another study can usually be reconciled, without changing the observed data, by reporting in full (as described in this test method) the conditions under which the data were obtained.

1.5 Due to possible instrumentation compliance, the data generated are intended to indicate relative and not necessarily absolute property values.

1.6 Test data obtained by this test method are relevant and appropriate for use in engineering design.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5024 − 07

StandardTest Method for

1

Plastics: Dynamic Mechanical Properties: In Compression

This standard is issued under the fixed designation D5024; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

1.1 Thistestmethodoutlinestheuseofdynamicmechanical

bility of regulatory limitations prior to use.

instrumentation for determining and reporting the viscoelastic

properties of thermoplastic and thermosetting resins as well as

NOTE 1—There is no similar or equivalent ISO standard.

composite systems in the form of cylindrical specimens

2. Referenced Documents

molded directly or cut from sheets, plates, or molded shapes.

2

The compression data generated may be used to identify the 2.1 ASTM Standards:

thermomechanical properties of a plastics material or compo-

D618 Practice for Conditioning Plastics for Testing

sition using a variety of dynamic mechanical instruments. D4000 Classification System for Specifying Plastic Materi-

als

1.2 This test method is intended to provide a means for

D4065 Practice for Plastics: Dynamic Mechanical Proper-

determining the thermomechanical properties (as a function of

ties: Determination and Report of Procedures

a number of viscoelastic variables) for a wide variety of plastic

D4092 Terminology for Plastics: Dynamic Mechanical

materials using nonresonant, forced-vibration techniques as

Properties

outlined in Practice D4065. Plots of the elastic (storage)

modulus, loss (viscous) modulus, complex modulus, and tan

3. Terminology

delta as a function of frequency, time, or temperature are

3.1 Definitions—For definitions applicable to this test

indicative of significant transitions in the thermomechanical

method refer to Terminology Standard D4092.

performance of the polymeric material system.

1.3 Thistestmethodisvalidforawiderangeoffrequencies,

4. Summary of Test Method

typically from 0.01 to 100 Hz.

4.1 This test method covers the determination of the com-

1.4 Apparent discrepancies may arise in results obtained

pressive modulus of both solid and cellular plastics using

under differing experimental conditions. These apparent differ-

dynamic mechanical techniques.Atest specimen of cylindrical

ences from results observed in another study can usually be

cross section is tested in dynamic compression. The specimen

reconciled, without changing the observed data, by reporting in

may be secured using appropriate grip fixtures or simply

full (as described in this test method) the conditions under

positioned between two parallel, flat plates or disks. The

which the data were obtained.

specimen of known geometry is placed in mechanical, linear

displacement at fixed frequencies and at either isothermal

1.5 Due to possible instrumentation compliance, the data

conditions or with a linear temperature variation. The elastic

generated are intended to indicate relative and not necessarily

moduli or loss moduli, or both, of the polymeric material

absolute property values.

system are measured in compression.

1.6 Test data obtained by this test method are relevant and

NOTE 2—The particular method for measurement of the elastic and loss

appropriate for use in engineering design.

moduli and tan delta depends upon the individual instrument’s operating

1.7 The values stated in SI units are to be regarded as the

principles.

standard. The values given in parentheses are for information

5. Significance and Use

only.

5.1 This test method provides a simple means of character-

1.8 This standard does not purport to address all of the

izing the thermomechanical behavior of plastic compositions

safety concerns, if any, associated with its use. It is the

using very small amounts of material.The data obtained can be

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

2

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2007. Published April 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2001 as D5024 - 01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D5024-07. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.