ASTM C1211-13

(Test Method)Standard Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures

Standard Test Method for Flexural Strength of Advanced Ceramics at Elevated Temperatures

SIGNIFICANCE AND USE

4.1 This test method may be used for material development, quality control, characterization, and design data generation purposes. This test method is intended to be used with ceramics whose flexural strength is ∼ 50 MPa (∼ 7 ksi) or greater.

4.2 The flexure stress is computed based on simple beam theory, with assumptions that the material is isotropic and homogeneous, the moduli of elasticity in tension and compression are identical, and the material is linearly elastic. The average grain size should be no greater than 1/50 of the beam thickness. The homogeneity and isotropy assumptions in the test method rule out the use of it for continuous fiber-reinforced composites for which Test Method C1341 is more appropriate.

4.3 The flexural strength of a group of test specimens is influenced by several parameters associated with the test procedure. Such factors include the testing rate, test environment, specimen size, specimen preparation, and test fixtures. Specimen and fixture sizes were chosen to provide a balance between the practical configurations and resulting errors as discussed in Test Method C1161, and Refs (1-3).4 Specific fixture and specimen configurations were designated in order to permit the ready comparison of data without the need for Weibull size scaling.

4.4 The flexural strength of a ceramic material is dependent on both its inherent resistance to fracture and the size and severity of flaws. Variations in these cause a natural scatter in test results for a sample of test specimens. Fractographic analysis of fracture surfaces, although beyond the scope of this test method, is highly recommended for all purposes, especially if the data will be used for design as discussed in Ref (4) and Practices C1322 and C1239.

4.5 This method determines the flexural strength at elevated temperature and ambient environmental conditions at a nominal, moderately fast testing rate. The flexural strength under these conditions may or may not necessarily be ...

SCOPE

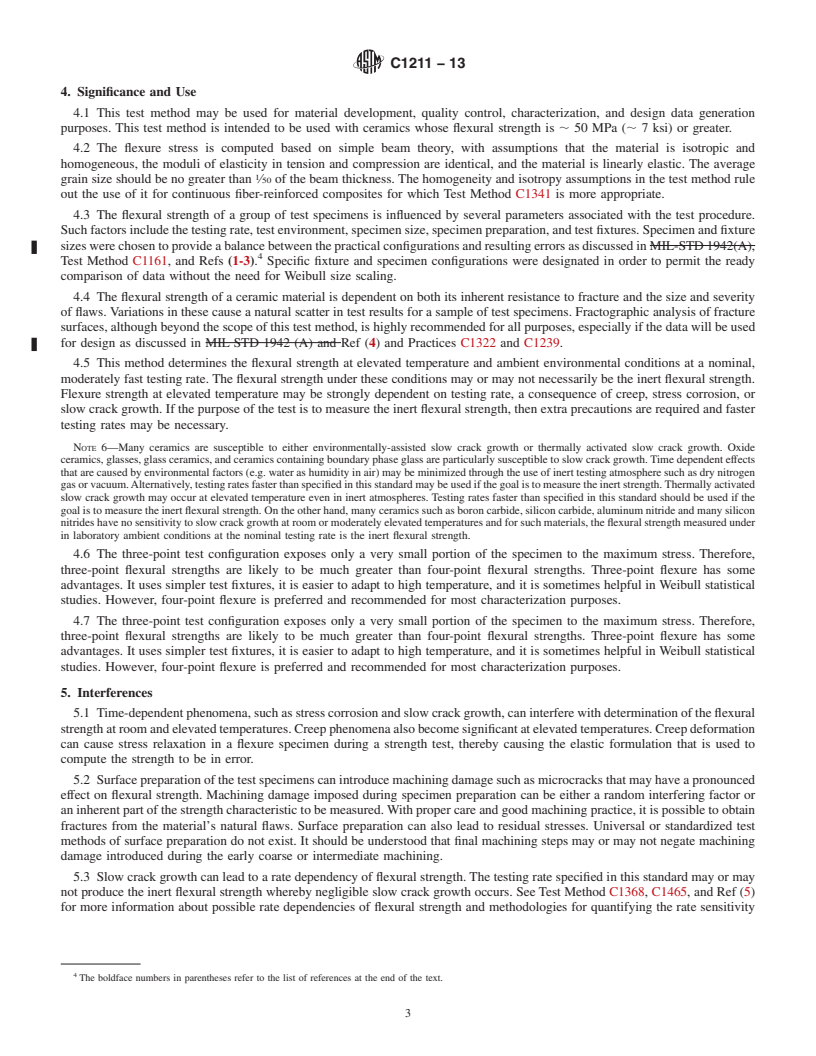

1.1 This test method covers determination of the flexural strength of advanced ceramics at elevated temperatures.2 Four-point-1/4 point and three-point loadings with prescribed spans are the standard as shown in Fig. 1. Rectangular specimens of prescribed cross-section are used with specified features in prescribed specimen-fixture combinations. Test specimens may be 3 by 4 by 45 to 50 mm in size that are tested on 40 mm outer span four-point or three-point fixtures. Alternatively, test specimens and fixture spans half or twice these sizes may be used. The test method permits testing of machined or as-fired test specimens. Several options for machining preparation are included: application matched machining, customary procedures, or a specified standard procedure. This test method describes the apparatus, specimen requirements, test procedure, calculations, and reporting requirements. The test method is applicable to monolithic or particulate- or whisker-reinforced ceramics. It may also be used for glasses. It is not applicable to continuous fiber-reinforced ceramic composites.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1211 −13

Standard Test Method for

Flexural Strength of Advanced Ceramics at Elevated

1

Temperatures

This standard is issued under the fixed designation C1211; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1161Test Method for Flexural Strength of Advanced

Ceramics at Ambient Temperature

1.1 This test method covers determination of the flexural

2 C1239Practice for Reporting Uniaxial Strength Data and

strength of advanced ceramics at elevated temperatures.

Estimating Weibull Distribution Parameters forAdvanced

1

Four-point- ⁄4 point and three-point loadings with prescribed

Ceramics

spans are the standard as shown in Fig. 1. Rectangular

C1322Practice for Fractography and Characterization of

specimens of prescribed cross-section are used with specified

Fracture Origins in Advanced Ceramics

features in prescribed specimen-fixture combinations. Test

C1341Test Method for Flexural Properties of Continuous

specimensmaybe3by4by45to50mminsizethataretested

Fiber-Reinforced Advanced Ceramic Composites

on 40 mm outer span four-point or three-point fixtures.

C1368 Test Method for Determination of Slow Crack

Alternatively, test specimens and fixture spans half or twice

Growth Parameters of Advanced Ceramics by Constant

these sizes may be used. The test method permits testing of

Stress-Rate Strength Testing at Ambient Temperature

machined or as-fired test specimens. Several options for

C1465 Test Method for Determination of Slow Crack

machining preparation are included: application matched

Growth Parameters of Advanced Ceramics by Constant

machining, customary procedures, or a specified standard

Stress-Rate Flexural Testing at Elevated Temperatures

procedure. This test method describes the apparatus, specimen

E4Practices for Force Verification of Testing Machines

requirements, test procedure, calculations, and reporting re-

E220Test Method for Calibration of Thermocouples By

quirements. The test method is applicable to monolithic or

Comparison Techniques

particulate- or whisker-reinforced ceramics. It may also be

E230Specification and Temperature-Electromotive Force

used for glasses. It is not applicable to continuous fiber-

(EMF) Tables for Standardized Thermocouples

reinforced ceramic composites.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

3.1 Definitions:

only.

3.1.1 complete gage section, n—theportionofthespecimen

1.3 This standard does not purport to address all of the

between the two outer bearings in four-point flexure and

safety concerns, if any, associated with its use. It is the

three-point flexure fixtures.

responsibility of the user of this standard to establish appro-

NOTE 1—In this standard, the complete four-point flexure gage section

priate safety and health practices and determine the applica-

is twice the size of the inner gage section. Weibull statistical analyses, in

bility of regulatory limitations prior to use.

this instance, only include portions of the specimen volume or surface

which experience tensile stresses.

2. Referenced Documents

3.1.2 flexural strength—a measure of the ultimate strength

3

2.1 ASTM Standards:

of a specified beam in bending.

3.1.3 four-point-1/4 point flexure—a configuration of flex-

ural strength testing in which a specimen is symmetrically

1

This test method is under the jurisdiction of ASTM Committee C28 on

loaded at two locations that are situated at one-quarter of the

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on

Mechanical Properties and Performance. overall span, away from the outer two support bearings (see

Current edition approved Aug. 1, 2013. Published September 2013. Originally

Fig. 1).

approved in 1992. Last previous edition approved in 2008 as C1211 – 02 (2008).

3.1.4 fully-articulating fixture, n—a flexure fixture designed

DOI: 10.1520/C1211-13.

2

Elevatedtemperaturestypicallydenote,butarenotrestrictedto200to1600°C.

to be used either with flat and parallel specimens or with

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

uneven or nonparallel specimens. The fixture allows full

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

independent articulation, or pivoting, of all rollers about the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specimenlongaxistomatchthespecimensurface.Inaddition,

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1211 − 02 (Reapproved 2008) C1211 − 13

Standard Test Method for

Flexural Strength of Advanced Ceramics at Elevated

1

Temperatures

This standard is issued under the fixed designation C1211; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1

1.1 This test method covers determination of the flexural strength of advanced ceramics at elevated temperatures. Four-point- ⁄4

point and three-point loadings with prescribed spans are the standard. standard as shown in Fig. 1. Rectangular specimens of

prescribed cross-section are used with specified features in prescribed specimen-fixture combinations. Test specimens may be 3 by

4 by 45 to 50 mm in size that are tested on 40 mm outer span four-point or three-point fixtures. Alternatively, test specimens and

fixture spans half or twice these sizes may be used. The test method permits testing of machined or as-fired test specimens. Several

options for machining preparation are included: application matched machining, customary procedures, or a specified standard

procedure. This test method describes the apparatus, specimen requirements, test procedure, calculations, and reporting

requirements. The test method is applicable to monolithic or particulate- or whisker-reinforced ceramics. It may also be used for

glasses. It is not applicable to continuous fiber-reinforced ceramic composites.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1

This test method is under the jurisdiction of ASTM Committee C28 on Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on Mechanical

Properties and Performance.

Current edition approved Jan. 1, 2008Aug. 1, 2013. Published January 2008September 2013. Originally approved in 1992. Last previous edition approved in 19982008

as C1211-98a. -02 (2008). DOI: 10.1520/C1211-02R08.10.1520/C1211-13.

2

Elevated temperatures typically denote, but are not restricted to 200 to 1600°C.

NOTE 1—Configuration:

A: L = 20 mm

B: L = 40 mm

C: L = 80 mm

1

FIG. 1 Four-Point- ⁄4 Point and Three-Point Fixture Configurations

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1211 − 13

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

C1161 Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature

C1239 Practice for Reporting Uniaxial Strength Data and Estimating Weibull Distribution Parameters for Advanced Ceramics

C1322 Practice for Fractography and Characterization of Fracture Origins in Advanced Ceramics

C1341 Test Method for Flexural Properties of Continuous Fiber-Reinforced Advanced Ceramic Composites

C1368 Test Method for Determination of Slow Crack Growth Parameters of Advanced Ceramics by Constant Stress-Rate

Strength Testing at Ambient Temperature

C1465 Test Method for Determination of Slow Crack Growth Parameters of Advanced Ceramics by Constant Stress-Rate

Flexural Testing at Elevated Temperatures

E4 Practices for Force Verification of Testing Machines

E220 Test Method for Calibration of Thermocouples By Comparison Techniques

E230 Specification and Temperature-Electromotive Force (EMF) Tables for Standardized Thermocouples

2.2 Military Standard:

4

MIL-STD 1942(A) Flexural Strength of High Performance Ceramics at Ambient Temperature

3. Terminology

3.1 Definitions:

3.1.1 complete gage section, n—the portion of the specimen between the two outer bearings in four-point flexure and three-point

flexure fixtures.

NOTE 1—In this standard, the complete four-point flexure gage section is twice the size of the inner gage section. Weibull statistical analyses, in this

instance, only include portions of the specimen volume or surface which experience tensile stresses.

3.1.2 flexural strength—a measure of the ultimate strength of a specified beam in bending.

3.1.3 four-point-1/4 point flexure—a config

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.