ASTM F2574-06(2014)

(Specification)Standard Specification for Low Velocity Projectile Marker

Standard Specification for Low Velocity Projectile Marker

ABSTRACT

This specification covers low velocity projectile (LVP) markers that eject a low velocity resilient material (LVRM) projectile using compressed air, compressed gas, or a combination of both. Included in this specification are performance requirements and test methods for LVP markers as well as the minimum warnings and instructions that need to be provided in literature, on labels, on packaging, and on the marker itself. The LVP markers shall be manufactured to operate only in semi-automatic or pump mode and with exposed edges that shall be smooth and free of sharp edges and burrs. LVP markers shall be provided with a disabling device which shall keep it from firing and with a provision against accidental discharge. The markers shall undergo tests for disabling device, accidental discharge, barrel blocking device, and impact, and shall conform to the requirements specified.

SCOPE

1.1 This specification covers low velocity projectile markers (herein referred to as LVP marker) that propel a low velocity resilient material projectile (herein referred to as LVRM projectile as defined in Specification F2573) by means of energy released by compressed air, compressed gas, or a combination thereof, with velocity not to exceed 53.34 m/s (175 ft/s).

1.2 LVRM projectiles are made of a resilient material and have a diameter no smaller than 20 mm (0.7874 in) and no greater than 30 mm (1.18 in.). The hardness of the LVRM projectile is to be no greater than 75 Shore 00. The weight of the LVRM projectile is not to exceed 4.0 g.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2574 −06 (Reapproved 2014) An American National Standard

Standard Specification for

Low Velocity Projectile Marker

This standard is issued under the fixed designation F2574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standard:

Z535.1 Safety Color Code

1.1 Thisspecificationcoverslowvelocityprojectilemarkers

(herein referred to as LVP marker) that propel a low velocity

3. Terminology

resilient material projectile (herein referred to as LVRM

3.1 Definitions of Terms Specific to This Standard:

projectile as defined in Specification F2573) by means of

3.1.1 auto-trigger—trigger that, when held in the discharge

energy released by compressed air, compressed gas, or a

position, will automatically cause the LVPmarker to discharge

combination thereof, with velocity not to exceed 53.34 m/s

when the pump or bolt action is manipulated.

(175 ft/s).

3.1.2 backstop—object intended to stop a LVRM projectile.

1.2 LVRM projectiles are made of a resilient material and

3.1.3 barrel—that portion of a LVP marker through which

have a diameter no smaller than 20 mm (0.7874 in) and no

the LVRM projectile is discharged.

greater than 30 mm (1.18 in.). The hardness of the LVRM

3.1.4 barrel blocking device—muzzle blocking safety de-

projectile is to be no greater than 75 Shore 00. The weight of

vice that when properly installed, reduces the likelihood of an

the LVRM projectile is not to exceed 4.0 g.

intact LVRM projectile discharging from the marker or leaving

1.3 The values stated in SI units are to be regarded as

the confines of the barrel blocking device. The device is often

standard. The values given in parentheses are for information

referred to as a barrel plug or sleeve.

only.

3.1.5 cautionary statement—warning outlined in Section 9

1.4 The following precautionary caveat pertains only to the

that is to be placed on LVP markers, packaging, and literature.

test method portion, Section 8, of this specification. This

3.1.6 disabling device—device that, when activated, dis-

standard does not purport to address all of the safety concerns,

ables a part of the LVP marker, usually the trigger, to prevent

if any, associated with its use. It is the responsibility of the user

unintentional discharges and must be released to allow the

of this standard to establish appropriate safety and health

marker to be discharged by the movement of the trigger. The

practices and determine the applicability of regulatory limita-

device is sometimes referred to as the “safety,” “safety button,”

tions prior to use.

or “safety lever.” An electronic on/off switch is considered a

disabling device if when placed in the “off” position, it renders

2. Referenced Documents

the marker inoperable.

2.1 ASTM Standards:

3.1.7 discharge mode—mode that controls the number of

F1750 Specification for Paintball Marker Threaded-

LVRM projectiles discharged per trigger cycle.

Propellant Source Interface

3.1.8 feed mechanism—mechanism that stores, transports,

F1776 Specification for Eye Protective Devices for Paintball

and facilitates the loading of LVRM projectiles. It may be

Sports

gravity,mechanicallyorairassisted,orautomaticinitsactions.

F2573 Specification for Low Velocity Resilient Material

Projectile

3.1.9 hopper—device used with a LVP marker to store

LVRM projectiles.

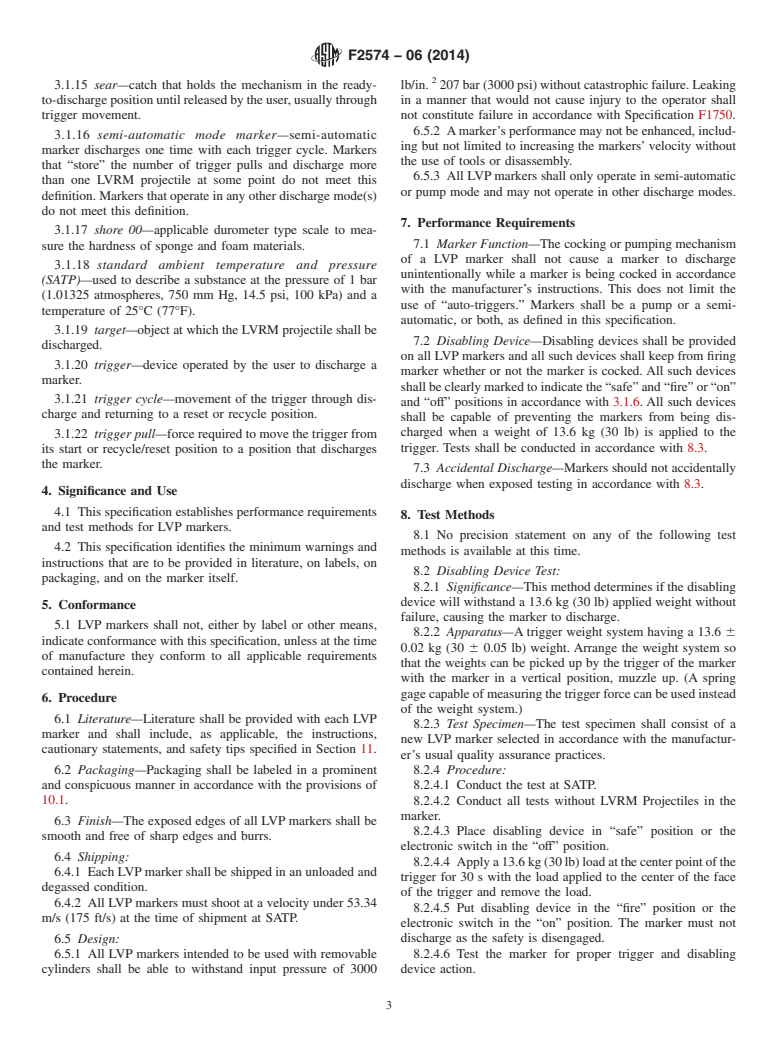

3.1.10 impact tester—device used to test for accidental

discharges of LVP marker. See Fig. 1.

This specification is under the jurisdiction ofASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

3.1.11 low velocity resilient material projectile—object pro-

Subcommittee F08.24 on Paintball and Equipment.

pelled by means of a discharge mechanism, capable of storing

Current edition approved May 1, 2014. Published September 2014. Originally

approved in 2006. Last previous edition approved in 2010 as F2574 – 06 (2010).

and releasing energy under the control of the operator, com-

DOI: 10.1520/F2574-06R14.

prised of a resilient material, and has a diameter no smaller

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2574−06 (2014)

A. Release Latch

B. Compression Spring (spring rate 1.145 kg/cm or 16.28 lb/in.)

C. Impact Ball (new pressurized tennis ball with regular felt, total mass of moving parts is 1.13 kg or 2.5 lb)

D. Plastic tube with 7.62 cm (3 in.) internal diameter

E. Face placed against marker

F. Cocking arm

G. Stroke of 15.21 cm (6 in.)

H. Secured support base

FIG. 1Impact Tester

than 20 mm (0.7874 in) and no greater than 30 mm (1.18 in.). 3.1.13 pump mode marker—marker that requires the opera-

The hardness of the low velocity resilient material projectile is tor to manually cock or engage the sear of the marker before

to be no greater than 75 Shore 00. The weight is not to exceed

each shot by a means of a pump, bolt, lever, cocking handle, or

4.0 g.

similar device.

3.1.12 low velocity projectile marker—device specifically

3.1.14 range—maximum distance to which an object may

designed to discharge low velocity resilient material projec-

be propelled, whether limited by energy or an obstacle.

tiles.

F2574−06 (2014)

3.1.15 sear—catch that holds the mechanism in the ready- lb/in. 207 bar (3000 psi) without catastrophic failure. Leaking

to-dischargepositionuntilreleasedbytheuser,usuallythrough in a manner that would not cause injury to the operator shall

trigger movement. not constitute failure in accordance with Specification F1750.

6.5.2 Amarker’s performance may not be enhanced, includ-

3.1.16 semi-automatic mode marker—semi-automatic

ing but not limited to increasing the markers’velocity without

marker discharges one time with each trigger cycle. Markers

the use of tools or disassembly.

that “store” the number of trigger pulls and discharge more

6.5.3 All LVP markers shall only operate in semi-automatic

than one LVRM projectile at some point do not meet this

or pump mode and may not operate in other discharge modes.

definition. Markers that operate in any other discharge mode(s)

do not meet this definition.

7. Performance Requirements

3.1.17 shore 00—applicable durometer type scale to mea-

7.1 Marker Function—The cocking or pumping mechanism

sure the hardness of sponge and foam materials.

of a LVP marker shall not cause a marker to discharge

3.1.18 standard ambient temperature and pressure

unintentionally while a marker is being cocked in accordance

(SATP)—used to describe a substance at the pressure of 1 bar

with the manufacturer’s instructions. This does not limit the

(1.01325 atmospheres, 750 mm Hg, 14.5 psi, 100 kPa) and a

use of “auto-triggers.” Markers shall be a pump or a semi-

temperature of 25°C (77°F).

automatic, or both, as defined in this specification.

3.1.19 target—object at which the LVRM projectile shall be

7.2 Disabling Device—Disabling devices shall be provided

discharged.

on all LVP markers and all such devices shall keep from firing

3.1.20 trigger—device operated by the user to discharge a

marker whether or not the marker is cocked. All such devices

marker.

shall be clearly marked to indicate the “safe” and “fire” or “on”

3.1.21 trigger cycle—movement of the trigger through dis-

and “off” positions in accordance with 3.1.6. All such devices

charge and returning to a reset or recycle position.

shall be capable of preventing the markers from being dis-

charged when a weight of 13.6 kg (30 lb) is applied to the

3.1.22 trigger pull—force required to move the trigger from

trigger. Tests shall be conducted in accordance with 8.3.

its start or recycle/reset position to a position that discharges

the marker.

7.3 Accidental Discharge—Markers should not accidentally

discharge when exposed testing in accordance with 8.3.

4. Significance and Use

4.1 This specification establishes performance requirements

8. Test Methods

and test methods for LVP markers.

8.1 No precision statement on any of the following test

4.2 This specification identifies the minimum warnings and

methods is available at this time.

instructions that are to be provided in literature, on labels, on

8.2 Disabling Device Test:

packaging, and on the marker itself.

8.2.1 Significance—This method determines if the disabling

device will withstand a 13.6 kg (30 lb) applied weight without

5. Conformance

failure, causing the marker to discharge.

5.1 LVP markers shall not, either by label or other means,

8.2.2 Apparatus—A trigger weight system having a 13.6 6

indicate conformance with this specification, unless at the time

0.02 kg (30 6 0.05 lb) weight. Arrange the weight system so

of manufacture they conform to all applicable requirements

that the weights can be picked up by the trigger of the marker

contained herein.

with the marker in a vertical position, muzzle up. (A spring

gagecapableofmeasuringthetriggerforcecanbeusedinstead

6. Procedure

of the weight system.)

6.1 Literature—Literature shall be provided with each LVP

8.2.3 Test Specimen—The test specimen shall consist of a

marker and shall include, as applicable, the instructions,

new LVP marker selected in accordance with the manufactur-

cautionary statements, and safety tips specified in Section 11.

er’s usual quality assurance practices.

6.2 Packaging—Packaging shall be labeled in a prominent

8.2.4 Procedure:

and conspicuous manner in accordance with the provisions of 8.2.4.1 Conduct the test at SATP.

10.1.

8.2.4.2 Conduct all tests without LVRM Projectiles in the

marker.

6.3 Finish—The exposed edges of all LVP markers shall be

8.2.4.3 Place disabling device in “safe” position or the

smooth and free of sharp edges and burrs.

electronic switch in the “off” position.

6.4 Shipping:

8.2.4.4 Applya13.6kg(30lb)loadatthecenterpointofthe

6.4.1 Each LVPmarker shall be shipped in an unloaded and

trigger for 30 s with the load applied to the center of the face

degassed condition.

of the trigger and remove the load.

6.4.2 All LVP markers must shoot at a velocity under 53.34

8.2.4.5 Put disabling device in the “fire” position or the

m/s (175 ft/s) at the time of shipment at SATP.

electronic switch in the “on” position. The marker must not

6.5 Design: discharge as the safety is disengaged.

6.5.1 All LVP markers intended to be used with removable 8.2.4.6 Test the marker for proper trigger and disabling

cylinders shall be able to withstand input pressure of 3000 device action.

F2574−06 (2014)

8.2.4.7 The marker passes the test if it withstands the load (3) The rearmost point of the marker aligned with the

applied without causing the marker to discharge during the barrel’s axis.

application of the load and does not discharge upon the

8.3.3.8 The marker fails if it discharges on any impact.

disengagement of the disabling device, and the disabling

8.4 Barrel Blocking Device Requirement:

device and trigger function properly after testing.

8.4.1 Significance—All LVP markers that include a barrel

8.3 Accidental Discharge Test:

must be packaged with a barrel blocking device.

8.3.1 Significance—LVP markers should not discharge

8.4.2 Test Specimen—The test specimen shall consist of a

while their disabling device is disengaged.

new LVP marker packaged in the manufacturer’s original

8.3.2 Test Specimen—The test specimen shall consist of a

packaging.

new LVP marker, selected in accordance with the manufactur-

8.4.3 Procedure—Open packaging and inspect for the pres-

er’s usual quality assurance practices.

ence of a barrel blocking device. Any package not containing

8.3.3 Procedure:

a barrel blocking device fails this requirement.

8.3.3.1 Conduct the test at SATP.

8.5 Impact Testing:

8.3.3.2 Attach a properly charged propellant source if re-

8.5.1 Significance—The test is intended to simulate situa-

quired in accordance with the manufacturer’s instructions. Test

tions in which possible damage can occur by reason of its

discharge the marker.

falling or other impact situations that may occur as a result of

8.3.3.3 Leave the marker in the ready to discharge condi-

reasonably foreseeable abuse.After undergoing the appropriate

tion.

test, the marker shall be examined for damaged or fractured

8.3.3.4 Suspend marker using a sling (see Fig. 2).

components or parts. The marker is not fit for use if damage or

8.3.3.5 Place the cocked impact tester (see Fig. 1) against

fracture is observed.

the side of the marker centered on the grip frame directly

8.5.2 Apparatus:

behind the center point of the trigger with the impact tester

8.5.2.1 Tile Floor Area—The impact medium shall consist

firmly affixed to an immobile surface.

ofa3mm( ⁄8 in.) nominal thickness of Type IV vinyl

8.3.3.6 Release the impact tester and observe if the marker

composition tile, composition 1-asbestos free, as specified in

discharges.

FederalSpecificationSS-T-312Boveratleasta64mm(2.5in.)

8.3.3.7 Repeat by impacting the marker on the following

thickness of concrete. The impact area shall be at least 0.3

axis:

2 2

m (3 ft ).

(1) 180 degrees to the first impact.

(2) The front of the barrel aligned with the barrel’s axis. 8.5.2.2 Concrete Floor, on which to place the tiles.

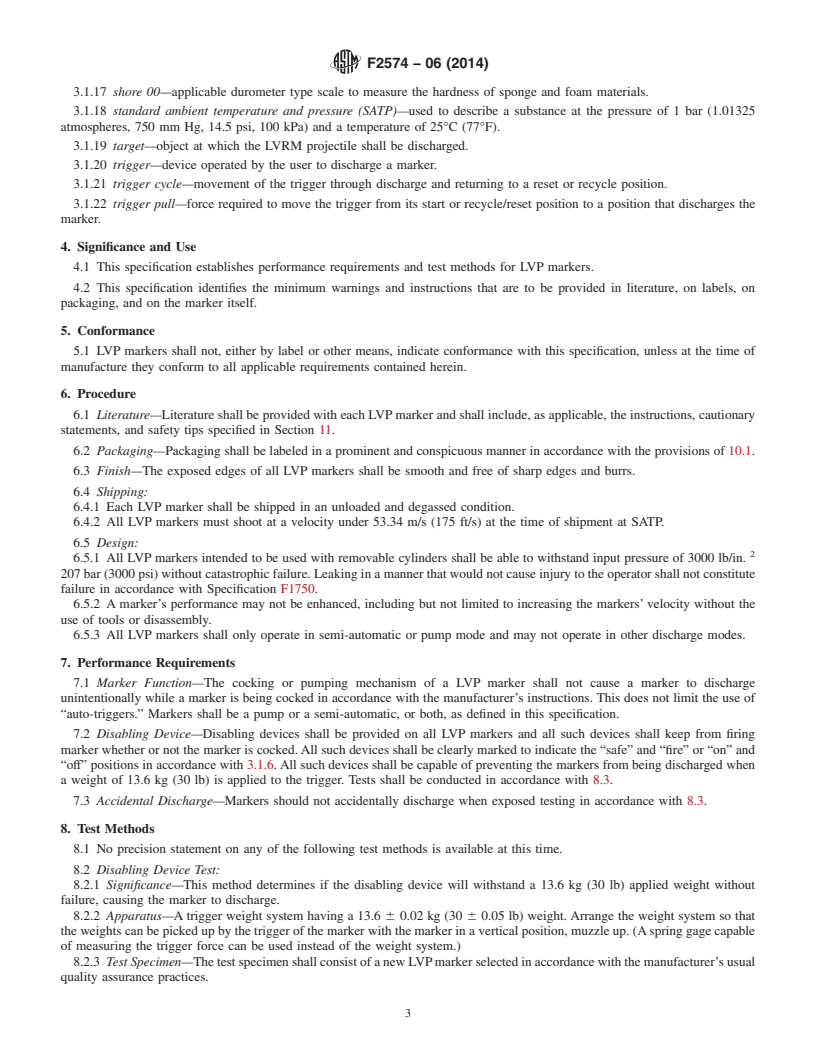

A. Yoke

B. Pivot Bolt

C. Swivel

D. 91.29 cm (36 in.) Strap or Rope

E. 60.86 cm (24 in.) aluminum bar with 1.27 cm (0.5 in.) diameter or 1.9 cm (0.75 in.) copper tube

F. Hook and loop strap able to suspend marker parallel to and 15.21 cm (6 in.) below E

FIG. 2 Sling Example

F2574−06 (2014)

8.5.2.3 Measure,0.93m(3ft,0.5in.),toestablishtheheight 9.1.15 Each LVP marker shall be marked to show the

of the drop. “safe/off” and “fire/on” position of the disabling device.

8.5.2.4 Projectiles, to fill the magazine or an equivalent. 9.1.16 The muzzle end of the barrel shall be a blaze orange

or brighter orange color covering the circumference.

8.5.3 Test Specimen—The test specimen shall consist of a

9.1.17 The colored end shall not be recessed more than 6

new LVP marker selected in accordance with the manufactur-

mm (0.25 in.) from the muzzle end of the barrel.

er’s usual quality assurance practices.

8.5.4 Procedure:

10. Packaging and Package Marking

8.5.4.1 Conduct the test at

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2574 − 06 (Reapproved 2010) F2574 − 06 (Reapproved 2014)An American National Standard

Standard Specification for

Low Velocity Projectile Marker

This standard is issued under the fixed designation F2574; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers low velocity projectile markers (herein referred to as LVP marker) that propel a low velocity

resilient material projectile (herein referred to as LVRM projectile as defined in Specification F2573) by means of energy released

by compressed air, compressed gas, or a combination thereof, with velocity not to exceed 53.34 m/s (175 ft/s).

1.2 LVRM projectiles are made of a resilient material and have a diameter no smaller than 20 mm (0.7874 in) and no greater

than 30 mm (1.18 in.). The hardness of the LVRM projectile is to be no greater than 75 Shore 00. The weight of the LVRM

projectile is not to exceed 4.0 g.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 8, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

F1750 Specification for Paintball Marker Threaded-Propellant Source Interface

F1776 Specification for Eye Protective Devices for Paintball Sports

F2573 Specification for Low Velocity Resilient Material Projectile

2.2 ANSI Standard:

Z535.1 Safety Color Code

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 auto-trigger—trigger that, when held in the discharge position, will automatically cause the LVP marker to discharge when

the pump or bolt action is manipulated.

3.1.2 backstop—object intended to stop a LVRM projectile.

3.1.3 barrel—that portion of a LVP marker through which the LVRM projectile is discharged.

3.1.4 barrel blocking device—muzzle blocking safety device that when properly installed, reduces the likelihood of an intact

LVRM projectile discharging from the marker or leaving the confines of the barrel blocking device. The device is often referred

to as a barrel plug or sleeve.

3.1.5 cautionary statement—warning outlined in Section 9 that is to be placed on LVP markers, packaging, and literature.

3.1.6 disabling device—device that, when activated, disables a part of the LVP marker, usually the trigger, to prevent

unintentional discharges and must be released to allow the marker to be discharged by the movement of the trigger. The device

is sometimes referred to as the “safety,” “safety button,” or “safety lever.” An electronic on/off switch is considered a disabling

device if when placed in the “off” position, it renders the marker inoperable.

3.1.7 discharge mode—mode that controls the number of LVRM projectiles discharged per trigger cycle.

This specification is under the jurisdiction of ASTM Committee F08 on Sports Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.24 on Paintball and Equipment.

Current edition approved Dec. 1, 2010May 1, 2014. Published March 2011September 2014. Originally approved in 2006. Last previous edition approved in 20062010 as

F2574 – 06.F2574 – 06 (2010). DOI: 10.1520/F2574-06R10.10.1520/F2574-06R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2574 − 06 (2014)

3.1.8 feed mechanism—mechanism that stores, transports, and facilitates the loading of LVRM projectiles. It may be gravity,

mechanically or air assisted, or automatic in its actions.

3.1.9 hopper—device used with a LVP marker to store LVRM projectiles.

3.1.10 impact tester—device used to test for accidental discharges of LVP marker. See Fig. 1.

3.1.11 low velocity resilient material projectile—object propelled by means of a discharge mechanism, capable of storing and

releasing energy under the control of the operator, comprised of a resilient material, and has a diameter no smaller than 20 mm

(0.7874 in) and no greater than 30 mm (1.18 in.). The hardness of the low velocity resilient material projectile is to be no greater

than 75 Shore 00. The weight is not to exceed 4.0 g.

3.1.12 low velocity projectile marker—device specifically designed to discharge low velocity resilient material projectiles.

3.1.13 pump mode marker—marker that requires the operator to manually cock or engage the sear of the marker before each

shot by a means of a pump, bolt, lever, cocking handle, or similar device.

3.1.14 range—maximum distance to which an object may be propelled, whether limited by energy or an obstacle.

3.1.15 sear—catch that holds the mechanism in the ready-to-discharge position until released by the user, usually through trigger

movement.

3.1.16 semi-automatic mode marker—semi-automatic marker discharges one time with each trigger cycle. Markers that “store”

the number of trigger pulls and discharge more than one LVRM projectile at some point do not meet this definition. Markers that

operate in any other discharge mode(s) do not meet this definition.

A. Release Latch

B. Compression Spring (spring rate 1.145 kg/cm or 16.28 lb/in.)

C. Impact Ball (new pressurized tennis ball with regular felt, total mass of moving parts is 1.13 kg or 2.5 lb)

D. Plastic tube with 7.62 cm (3 in.) internal diameter

E. Face placed against marker

F. Cocking arm

G. Stroke of 15.21 cm (6 in.)

H. Secured support base

FIG. 1 Impact Tester

F2574 − 06 (2014)

3.1.17 shore 00—applicable durometer type scale to measure the hardness of sponge and foam materials.

3.1.18 standard ambient temperature and pressure (SATP)—used to describe a substance at the pressure of 1 bar (1.01325

atmospheres, 750 mm Hg, 14.5 psi, 100 kPa) and a temperature of 25°C (77°F).

3.1.19 target—object at which the LVRM projectile shall be discharged.

3.1.20 trigger—device operated by the user to discharge a marker.

3.1.21 trigger cycle—movement of the trigger through discharge and returning to a reset or recycle position.

3.1.22 trigger pull—force required to move the trigger from its start or recycle/reset position to a position that discharges the

marker.

4. Significance and Use

4.1 This specification establishes performance requirements and test methods for LVP markers.

4.2 This specification identifies the minimum warnings and instructions that are to be provided in literature, on labels, on

packaging, and on the marker itself.

5. Conformance

5.1 LVP markers shall not, either by label or other means, indicate conformance with this specification, unless at the time of

manufacture they conform to all applicable requirements contained herein.

6. Procedure

6.1 Literature—Literature shall be provided with each LVP marker and shall include, as applicable, the instructions, cautionary

statements, and safety tips specified in Section 11.

6.2 Packaging—Packaging shall be labeled in a prominent and conspicuous manner in accordance with the provisions of 10.1.

6.3 Finish—The exposed edges of all LVP markers shall be smooth and free of sharp edges and burrs.

6.4 Shipping:

6.4.1 Each LVP marker shall be shipped in an unloaded and degassed condition.

6.4.2 All LVP markers must shoot at a velocity under 53.34 m/s (175 ft/s) at the time of shipment at SATP.

6.5 Design:

6.5.1 All LVP markers intended to be used with removable cylinders shall be able to withstand input pressure of 3000 lb/in.

207 bar (3000 psi) without catastrophic failure. Leaking in a manner that would not cause injury to the operator shall not constitute

failure in accordance with Specification F1750.

6.5.2 A marker’s performance may not be enhanced, including but not limited to increasing the markers’ velocity without the

use of tools or disassembly.

6.5.3 All LVP markers shall only operate in semi-automatic or pump mode and may not operate in other discharge modes.

7. Performance Requirements

7.1 Marker Function—The cocking or pumping mechanism of a LVP marker shall not cause a marker to discharge

unintentionally while a marker is being cocked in accordance with the manufacturer’s instructions. This does not limit the use of

“auto-triggers.” Markers shall be a pump or a semi-automatic, or both, as defined in this specification.

7.2 Disabling Device—Disabling devices shall be provided on all LVP markers and all such devices shall keep from firing

marker whether or not the marker is cocked. All such devices shall be clearly marked to indicate the “safe” and “fire” or “on” and

“off” positions in accordance with 3.1.6. All such devices shall be capable of preventing the markers from being discharged when

a weight of 13.6 kg (30 lb) is applied to the trigger. Tests shall be conducted in accordance with 8.3.

7.3 Accidental Discharge—Markers should not accidentally discharge when exposed testing in accordance with 8.3.

8. Test Methods

8.1 No precision statement on any of the following test methods is available at this time.

8.2 Disabling Device Test:

8.2.1 Significance—This method determines if the disabling device will withstand a 13.6 kg (30 lb) applied weight without

failure, causing the marker to discharge.

8.2.2 Apparatus—A trigger weight system having a 13.6 6 0.02 kg (30 6 0.05 lb) weight. Arrange the weight system so that

the weights can be picked up by the trigger of the marker with the marker in a vertical position, muzzle up. (A spring gage capable

of measuring the trigger force can be used instead of the weight system.)

8.2.3 Test Specimen—The test specimen shall consist of a new LVP marker selected in accordance with the manufacturer’s usual

quality assurance practices.

F2574 − 06 (2014)

8.2.4 Procedure:

8.2.4.1 Conduct the test at SATP.

8.2.4.2 Conduct all tests without LVRM Projectiles in the marker.

8.2.4.3 Place disabling device in “safe” position or the electronic switch in the “off” position.

8.2.4.4 Apply a 13.6 kg (30 lb) load at the center point of the trigger for 30 s with the load applied to the center of the face

of the trigger and remove the load.

8.2.4.5 Put disabling device in the “fire” position or the electronic switch in the “on” position. The marker must not discharge

as the safety is disengaged.

8.2.4.6 Test the marker for proper trigger and disabling device action.

8.2.4.7 The marker passes the test if it withstands the load applied without causing the marker to discharge during the

application of the load and does not discharge upon the disengagement of the disabling device, and the disabling device and trigger

function properly after testing.

8.3 Accidental Discharge Test:

8.3.1 Significance—LVP markers should not discharge while their disabling device is disengaged.

8.3.2 Test Specimen—The test specimen shall consist of a new LVP marker, selected in accordance with the manufacturer’s

usual quality assurance practices.

8.3.3 Procedure:

8.3.3.1 Conduct the test at SATP.

8.3.3.2 Attach a properly charged propellant source if required in accordance with the manufacturer’s instructions. Test

discharge the marker.

8.3.3.3 Leave the marker in the ready to discharge condition.

8.3.3.4 Suspend marker using a sling (see Fig. 2).

8.3.3.5 Place the cocked impact tester (see Fig. 1) against the side of the marker centered on the grip frame directly behind the

center point of the trigger with the impact tester firmly affixed to an immobile surface.

8.3.3.6 Release the impact tester and observe if the marker discharges.

8.3.3.7 Repeat by impacting the marker on the following axis:

(1) 180 degrees to the first impact.

(2) The front of the barrel aligned with the barrel’s axis.

(3) The rearmost point of the marker aligned with the barrel’s axis.

A. Yoke

B. Pivot Bolt

C. Swivel

D. 91.29 cm (36 in.) Strap or Rope

E. 60.86 cm (24 in.) aluminum bar with 1.27 cm (0.5 in.) diameter or 1.9 cm (0.75 in.) copper tube

F. Hook and loop strap able to suspend marker parallel to and 15.21 cm (6 in.) below E

FIG. 2 Sling Example

F2574 − 06 (2014)

8.3.3.8 The marker fails if it discharges on any impact.

8.4 Barrel Blocking Device Requirement:

8.4.1 Significance—All LVP markers that include a barrel must be packaged with a barrel blocking device.

8.4.2 Test Specimen—The test specimen shall consist of a new LVP marker packaged in the manufacturer’s original packaging.

8.4.3 Procedure—Open packaging and inspect for the presence of a barrel blocking device. Any package not containing a barrel

blocking device fails this requirement.

8.5 Impact Testing:

8.5.1 Significance—The test is intended to simulate situations in which possible damage can occur by reason of its falling or

other impact situations that may occur as a result of reasonably foreseeable abuse. After undergoing the appropriate test, the marker

shall be examined for damaged or fractured components or parts. The marker is not fit for use if damage or fracture is observed.

8.5.2 Apparatus:

8.5.2.1 Tile Floor Area—The impact medium shall consist of a 3 mm ( ⁄8 in.) nominal thickness of Type IV vinyl composition

tile, composition 1-asbestos free, as specified in Federal Specification SS-T-312B over at least a 64 mm (2.5 in.) thickness of

2 2

concrete. The impact area shall be at least 0.3 m (3 ft ).

8.5.2.2 Concrete Floor, on which to place the tiles.

8.5.2.3 Measure, 0.93 m (3 ft, 0.5 in.), to establish the height of the drop.

8.5.2.4 Projectiles, to fill the magazine or an equivalent.

8.5.3 Test Specimen—The test specimen shall consist of a new LVP marker selected in accordance with the manufacturer’s usual

quality assurance practic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.