ASTM F1733-96

(Specification)Standard Specification for Butt heat Fusion Polyamide(PA) Plastic Fitting for Polyamide(PA) Plastic Pipe and Tubing

Standard Specification for Butt heat Fusion Polyamide(PA) Plastic Fitting for Polyamide(PA) Plastic Pipe and Tubing

SCOPE

1.1 this specification covers polyamide (PA) butt fusion fittings for use with polyamide pipe (IPS and ISO) and tubing (CTS). Included are requirements for materials, workmanship, dimensions, marking, sustained pressure, and burst pressure.

1.2 The values given in parentheses are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1733 – 96

Standard Specification for

Butt Heat Fusion Polyamide(PA) Plastic Fitting for

Polyamide(PA) Plastic Pipe and Tubing

This standard is issued under the fixed designation F 1733; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope unless otherwise specified.

3.2 dimension ratio (DR) for thermoplastic pipe—the ratio

1.1 This specification covers polyamide (PA) butt fusion

of diameter to wall thickness. For this specification it is

fittings for use with polyamide pipe (IPS and ISO) and tubing

calculated by dividing the specified outside diameter by the

(CTS). Included are requirements for materials, workmanship,

specified wall thickness of the fitting at its area of fusion. DRs

dimensions, marking, sustained pressure, and burst pressure.

are rounded and do not calculate exactly.

1.2 The values given in parentheses are provided for infor-

mation only.

4. Classification

2. Referenced Documents 4.1 General—This specification covers butt fusion fittings

intended for use with polyamide pipe and tubing.

2.1 ASTM Standards:

4.1.1 Fittings covered by this specification are normally

D 1598 Test Method for Time-to-Failure of Plastic Pipe

2 molded. Fittings may be machined from extruded or molded

Under Constant Internal Pressure

stock.

D 1599 Test Method for Short-Time Hydraulic Failure Pres-

2 4.1.2 Fittings fabricated by thermal welding are not in-

sure of Plastic Pipe, Tubing, and Fittings

cluded in this specification.

D 1600 Terminology for Abbreviated Terms Relating to

3 4.1.3 Fittings intended for use in the distribution of natural

Plastics

gas or petroleum fuels shall also meet the requirements of

D 2122 Test Method for Determining Dimensions of Ther-

Specification D 2513.

moplastic Pipe and Fittings

D 2513 Specification for Thermoplastic Gas Pressure Pipe,

5. Ordering Information

Tubing, and Fittings

5.1 When ordering fittings under this specification, the

D 4066 Specification for Nylon Injection and Extrusion

following should be specified:

Materials

2 5.1.1 Polyamide compound (material designation or trade

F 412 Terminology Relating to Plastic Piping Systems

name)

2.2 Federal Standard:

5 5.1.2 Style of fitting (tee, 90° ell, and the like)

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

5.1.3 Size:

2.3 Military Standard:

5 5.1.3.1 Nominal diameter.

MIL-STD-129 Marking for Shipment and Storage

5.1.3.2 CTS, IPS, or schedule.

2.4 National Sanitation Foundation Standard:

5.1.3.3 Dimension ratio number or schedule number.

Standard No. 14 for Plastic Piping Components and Related

Materials

6. Materials

3. Terminology 6.1 Basic Materials—This specification covers fittings

made from polyamide plastics as defined in Specification

3.1 Definitions are in accordance with Terminology F 412

D 4066.

and abbreviations are in accordance with Terminology D 1600,

NOTE 1—The PA plastic fittings intended for use in the transport of

1 potable water should be evaluated and certified as safe for this purpose by

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

a testing agency acceptable to the local health authority. The evaluation

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

should be in accordance with requirements for chemical extraction, taste,

Current edition approved Sept. 10, 1996. Published November 1996.

Annual Book of ASTM Standards, Vol 08.04. and odor, that are no less restrictive than those included in National

Annual Book of ASTM Standards, Vol 08.01.

Sanitation Foundation (NSF) Standard 14. The seal or mark of the

Annual Book of ASTM Standards, Vol 08.02.

laboratory making the evaluation should be included on the pipe and

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

tubing.

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from the National Sanitation Foundation, P.O. Box 1468, Ann Arbor, 6.2 Compounds—The polyamide fittings compounds shall

MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1733

TABLE 2 ISO Sizing System (ISO 161/1) Outside Diameters and

meet the requirements for Group 3, Class 2, and Grade 3, as

Tolerances for Fit for Use with Polyamide Pipe, mm

prescribed in Specification D 4066.

Average Outside Diameter at Area of Fusion

6.3 Rework Material—Clean rework material generated Nominal Pipe

A

Size

from the manufacturer’s own production may be used by the Min Max

same manufacturer as long as the fittings produced conform to 90 90.0 90.8

110 110.0 111.0

the requirements of this specification.

160 160.0 161.4

200 200.0 201.8

7. Requirements

250 250.0 252.3

280 280.0 282.5

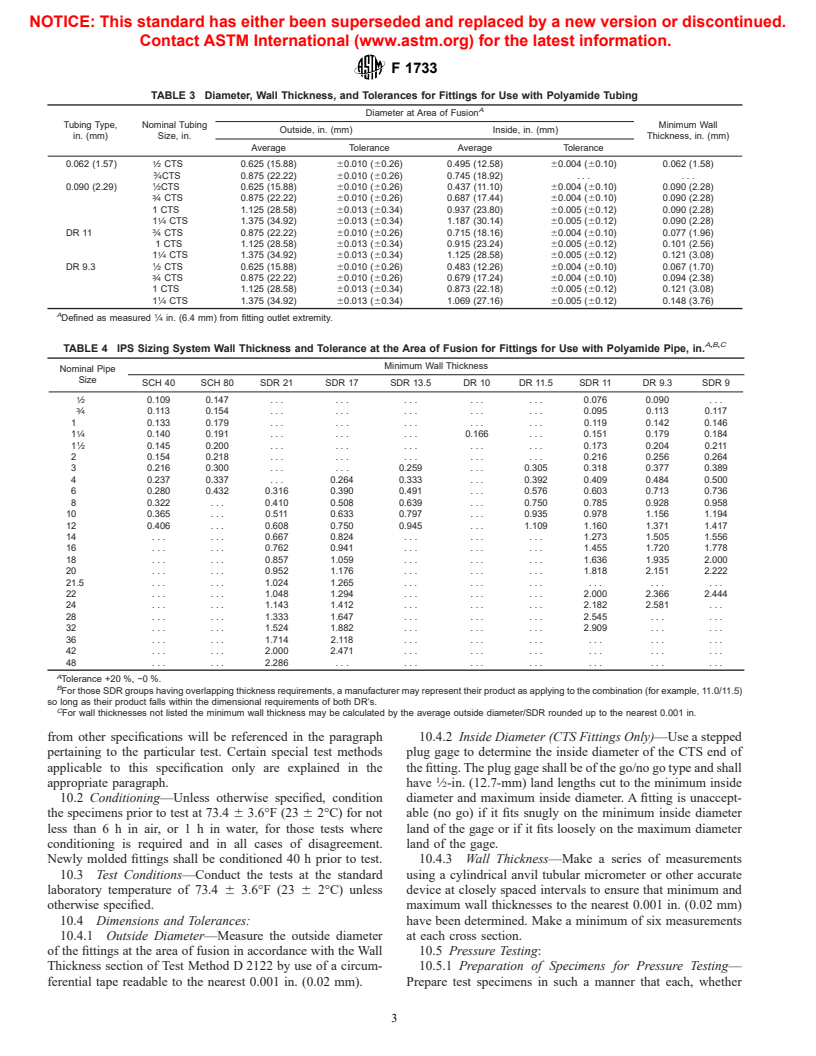

7.1 Dimensions and Tolerances:

315 315.0 317.8

7.1.1 Outside Diameter—Nominal outside diameters of butt

355 355.0 358.2

fusion fittings shall conform to the nominal iron pipe size (IPS)

400 400.0 403.6

450 450.0 454.1

or copper tubing size (CTS) dimensions at area of fusion.

500 500.0 504.5

These dimensions and tolerances shall be as shown in Table 1,

560 560.0 565.0

Table 2, and Table 3of this specification.

630 630.0 635.7

710 710.0 716.4

7.1.2 Inside Diameter (CTS Fittings Only)—Inside diam-

800 800.0 807.2

eters of butt fusion fittings for tubing at area of fusion shall

900 900.0 908.1

conform to the dimensions of the tubing being joined. The 1000 1000.0 1009.0

1200 1200.0 1210.8

dimensions and tolerances for the fittings are shown in Table 3.

1400 1400.0 1412.6

7.1.3 Wall Thickness—The wall thicknesses of butt fusion

1600 1600.0 1614.4

fittings shall not be less than the minimum specified for the

A

Specified in ISO 3607.

pipe or tubing. The wall thicknesses and tolerances at the area

of fusion shall be as shown in Table 3, Table 4, and Table 5 of

Table 6 of this specification. Test specimens shall be prepared

this specification.

for testing in the manner described in 10.5.1 of this specifica-

7.1.4 Measurements—These shall be made in accordance

tion. The test equipment, procedures, and failures definitions

with Test Method D 2122 for roundable pipe.

shall be as specified in Test Method D 1599.

7.1.5 Design Dimensions—Overall fitting dimensions may

7.2.2 Short-Term Strength for Fittings 14 to 48 in. and 355

be as preferred from a design standpoint by the manufacturer

to 1600 mm, Nominal Diameter—Fittings shall not fail when

and accepted by the purchaser consistent with 7.1.3.

tested in accordance with 10.5.3. The minimum pressure shall

7.2 Pressure Test Requirements:

be as shown in Table 6 of this specification. Test specimens

7.2.1 Short-Term Rupture Strength for Fittings ⁄2 to 12 in.

shall be prepared for testing in the manner described in 10.2 of

and 90 to 315 mm, Nominal Diameter—The minimum short-

this specification. The test equipment and procedures shall be

term rupture strength of the fitting and fused pipe or tubing

as specified in Test Method D 1599.

shall not be less than the minimum short-term rupture strength

7.2.3 Sustained Pressure—The fitting and fused pipe or

of the pipe or tubing in the system when tested in accordance

tubing shall not fail, as defined in Test Method D 1598, when

with 10.5.3. These minimum pressures shall be as shown in

tested at the time, pressures, and test temperatures selected

from test options offered in Table 7. The test specimens shall be

TABLE 1 IPS Sizing System Outside Diameters and Tolerances

for Fittings for Use with Polyamide Pipe, in.

prepared for testing in the manner prescribed in 10.5.1.

Nominal Pipe Average Outside Diameter

Tolerance

A

Size at Area of Fusion 8. Workmanship, Finish, and Appearance

⁄2 0.840 60.008

8.1 The manufacture of these fittings shall be in accordance

⁄4 1.050 60.008

with good commercial practice so as to produce fittings

1 1.315 60.010

meeting the requirements of this specification. Fittings shall be

1 ⁄4 1.660 60.010

1 ⁄2 1.900 60.010

homogeneous throughout and free of cracks, holes, foreign

2 2.375 60.010

inclusions, or other injurious defects. The fittings shall be as

3 3.500 60.012

4 4.500 60.015 uniform as commercially practicable in color, opacity, density,

6 6.625 60.018

and other physical properties.

8 8.625 60.025

10 10.750 60.027

9. Sampling

12 12.750 60.036

14 14.000 60.063

9.1 Parts made for sale under this specification should be

16 16.000 60.072

sampled at a frequency appropriate for the end use intended.

18 18.000 60.081

20 20.000 60.090 When the fittings are to be installed under a system specifica-

21.5 21.500 60.097

tion (such as Specification D 2513 for gas), the minimum

22 22.000 60.099

requirements of that specification must be satisfied.

24 24.000 60.108

28 28.000 60.126

32 32.000 60.144

10. Test Methods

36 36.000 60.162

10.1 General—The test methods in this specification cover

42 42.000 60.189

48 48.000 60.216

fittings to be used with pipe and tubing for gas, water, and other

A

Defined as measured ⁄4 in. (6.4 mm) from fitting outlet extremity. engineered piping systems. Test methods that are applicable

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1733

TABLE 3 Diameter, Wall Thickness, and Tolerances for Fittings for Use with Polyamide Tubing

A

Diameter at Area of Fusion

Tubing Type, Nominal Tubing Minimum Wall

Outside, in. (mm) Inside, in. (mm)

in. (mm) Size, in. Thickness, in. (mm)

Average Tolerance Average Tolerance

0.062 (1.57) ⁄2 CTS 0.625 (15.88) 60.010 (60.26) 0.495 (12.58) 60.004 (60.10) 0.062 (1.58)

⁄4CTS 0.875 (22.22) 60.010 (60.26) 0.745 (18.92) . .

0.090 (2.29) ⁄2CTS 0.625 (15.88) 60.010 (60.26) 0.437 (11.10) 60.004 (60.10) 0.090 (2.28)

⁄4 CTS 0.875 (22.22) 60.010 (60.26) 0.687 (17.44) 60.004 (60.10) 0.090 (2.28)

1 CTS 1.125 (28.58) 60.013 (60.34) 0.937 (23.80) 60.005 (60.12) 0.090 (2.28)

1 ⁄4 CTS 1.375 (34.92) 60.013 (60.34) 1.187 (30.14) 60.005 (60.12) 0.090 (2.28)

DR 11 ⁄4 CTS 0.875 (22.22) 60.010 (60.26) 0.715 (18.16) 60.004 (60.10) 0.077 (1.96)

1 CTS 1.125 (28.58) 60.013 (60.34) 0.915 (23.24) 60.005 (60.12) 0.101 (2.56)

1 ⁄4 CTS 1.375 (34.92) 60.013 (60.34) 1.125 (28.58) 60.005 (60.12) 0.121 (3.08)

DR 9.3 ⁄2 CTS 0.625 (15.88) 60.010 (60.26) 0.483 (12.26) 60.004 (60.10) 0.067 (1.70)

⁄4 CTS 0.875 (22.22) 60.010 (60.26) 0.679 (17.24) 60.004 (60.10) 0.094 (2.38)

1 CTS 1.125 (28.58) 60.013 (60.34) 0.873 (22.18) 60.005 (60.12) 0.121 (3.08)

1 ⁄4 CTS 1.375 (34.92) 60.013 (60.34) 1.069 (27.16) 60.005 (60.12) 0.148 (3.76)

A

Defined as measured ⁄4 in. (6.4 mm) from fitting outlet extremity.

A,B,C

TABLE 4 IPS Sizing System Wall Thickness and Tolerance at the Area of Fusion for Fittings for Use with Polyamide Pipe, in.

Minimum Wall Thickness

Nominal Pipe

Size

SCH 40 SCH 80 SDR 21 SDR 17 SDR 13.5 DR 10 DR 11.5 SDR 11 DR 9.3 SDR 9

⁄2 0.109 0.147 . . . . . . . . . . . . . . . 0.076 0.090 . . .

⁄4 0.113 0.154 . . . . . . . . . . . . . . . 0.095 0.113 0.117

1 0.133 0.179 . . . . . . . . . . . . . . . 0.119 0.142 0.146

1 ⁄4 0.140 0.191 . . . . . . . . . 0.166 . . . 0.151 0.179 0.184

1 ⁄2 0.145 0.200 . . . . . . . . . . . . . . . 0.173 0.204 0.211

2 0.154 0.218 . . . . . . . . . . . . . . . 0.216 0.256 0.264

3 0.216 0.300 . . . . . . 0.259 . . . 0.305 0.318 0.377 0.389

4 0.237 0.337 . . . 0.264 0.333 . . . 0.392 0.409 0.484 0.500

6 0.280 0.432 0.316 0.390 0.491 . . . 0.576 0.603 0.713 0.736

8 0.322 . . . 0.410 0.508 0.639 . . . 0.750 0.785 0.928 0.958

10 0.365 . . . 0.511 0.633 0.797 . . . 0.935 0.978 1.156 1.194

12 0.406 . . . 0.608 0.750 0.945 . . . 1.109 1.160 1.371 1.417

14 . . . . . . 0.667 0.824 . . . . . . . . . 1.273 1.505 1.556

16 . . . . . . 0.762 0.941 . . . . . . . . . 1.455 1.720 1.778

18 . . . . . . 0.857 1.059 . . . . . . . . . 1.636 1.935 2.000

20 . . . . . . 0.952 1.176 . . . . . . . . . 1.818 2.151 2.222

21.5 . . . . . . 1.024 1.265 . . . . . . . . . . . . . . . . . .

22 . . . . . . 1.048 1.294 . . . . . . . . . 2.000 2.366 2.444

24 . . . . . . 1.143 1.412 . . . . . . . . . 2.182 2.581 . . .

28 . . . . . . 1.333 1.647 . . . . . . . . . 2.545 . . . . . .

32 . . . . . . 1.524 1.882 . . . . . . . . . 2.909 . . . . . .

36 . . . . . . 1.714 2.118 . . . . . . . . . . . . . . . . . .

42 . . . . . . 2.000 2.471 . . . . . . . . . . . . . . . . . .

48 . . . . . . 2.286 . . . . . . . . . . . . . . . . . . . . .

A

Tolerance +20 %, −0 %.

B

For those SDR groups having overlapping thickness requirements, a manufacturer may represent their product as applying to the combination (for example, 11.0/11.5)

so long as their product falls within the dimensional requirements of both DR’s.

C

For wall thicknesses not listed the minimum wall thickness may be calculated by the average outside diameter/SDR rounded up to the nearest 0.001 in.

from other specifications will be referenced in the paragraph 10.4.2 Inside Diameter (CTS Fittings Only)—Use a stepped

pertaining to the particular test. Certain special test methods plug gage to determine the inside diameter of the CTS end of

applicable to this specification only are explained in the the fitting. The plug gage shall be of the go/no go type and shall

appropriate paragraph. have ⁄2-in. (12.7-mm) land lengths cut to the minimum inside

10.2 Conditioning—Unless otherwise specified, condition diameter and maximum inside diameter. A fitting is unaccept-

the specimens prior to test at 73.4 6 3.6°F (23 6 2°C) for not able (no go) if it fits snugly on the minimum inside diameter

less than6hinair,or1hin water, for those tests where land of the gage or if it fits loosely on the maximum diameter

conditioning is required and in all cases of disagreement. land of the gage.

Newly molded fittings shall be conditioned 40 h prior to test. 10.4.3 Wall Thickness—Make a series of measurements

10.3 Test Conditions—Conduct the tests at the standard using a cylindrical anvil tubular micrometer or other accurate

laboratory temperature of 73.4 6 3.6°F (23 6 2°C) unless device at closely spaced intervals to ensure that minimum and

otherwise specified. maximum wall thicknesses to the nearest 0.001 in. (0.02 mm)

10.4 Dimensions and Tolerances: have been determined. Make a minimum of six measurements

10.4.1 Outside Diameter—Measure the outside diameter at each cross section.

of the fittings at the area of fusion in accordance with the Wall 10.5 Pressure Testing:

Thickness section of Test Method D 2122 b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.