ASTM D7195-06

(Guide)Standard Guide for Protocol for Setting Color Specifications for a Material

Standard Guide for Protocol for Setting Color Specifications for a Material

SIGNIFICANCE AND USE

The rejection of materials due to color is a common and expensive occurrence, and it is useful for a customer and producer to set a color specification with an associated tolerance before the transaction. This guide discusses the concept and details the ASTM standards to be used in the process.

SCOPE

1.1 This guide leads the user through the process for setting a color tolerance for a product or material. It points to the appropriate ASTM standards that affect each step of the process. It includes the discussion points on which the two parties must agree and provides caveats for various options selected.

1.2 This guide does not suggest numerical values for tolerances. These values must be agreed upon by the two parties involved.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation:D7195 −06

Standard Guide for

Protocol for Setting Color Specifications for a Material

This standard is issued under the fixed designation D7195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Measurement of Reflection and Transmission Properties

of Materials (Withdrawn 2012)

1.1 This guide leads the user through the process for setting

E253 Terminology Relating to Sensory Evaluation of Mate-

a color tolerance for a product or material. It points to the

rials and Products

appropriate ASTM standards that affect each step of the

E284 Terminology of Appearance

process. It includes the discussion points on which the two

E308 PracticeforComputingtheColorsofObjectsbyUsing

parties must agree and provides caveats for various options

the CIE System

selected.

E805 Practice for Identification of Instrumental Methods of

1.2 This guide does not suggest numerical values for toler-

Color or Color-Difference Measurement of Materials

ances. These values must be agreed upon by the two parties

E1164 PracticeforObtainingSpectrometricDataforObject-

involved.

Color Evaluation

1.3 This standard does not purport to address all of the E1345 Practice for Reducing the Effect of Variability of

safety concerns, if any, associated with its use. It is the

Color Measurement by Use of Multiple Measurements

responsibility of the user of this standard to establish appro- E1347 Test Method for Color and Color-Difference Mea-

priate safety and health practices and determine the applica-

surement by Tristimulus Colorimetry

bility of regulatory limitations prior to use. E1499 Guide for Selection, Evaluation, and Training of

Observers

2. Referenced Documents

E1708 Practice for Electronic Interchange of Color and

Appearance Data

2.1 ASTM Standards:

E1808 Guide for Designing and Conducting Visual Experi-

D523 Test Method for Specular Gloss

ments

D1729 Practice for Visual Appraisal of Colors and Color

E2214 Practice for Specifying and Verifying the Perfor-

Differences of Diffusely-Illuminated Opaque Materials

mance of Color-Measuring Instruments

D2244 Practice for Calculation of Color Tolerances and

Color Differences from Instrumentally Measured Color

2.2 CIE Publications

rd 4

Coordinates

CIE 15:2004 Colorimetry, 3 edition

D3134 Practice for Establishing Color and Gloss Tolerances

D3964 Practice for Selection of Coating Specimens for 3. Terminology

Appearance Measurements

3.1 Definitions—For definitions of terms related to this

D4086 Practice for Visual Evaluation of Metamerism

guide see Terminology E253 and Terminology E284.

D4449 Test Method for Visual Evaluation of Gloss Differ-

ences Between Surfaces of Similar Appearance

4. Summary of Guide

D5531 GuideforPreparation,Maintenance,andDistribution

4.1 This guide describes the process for establishing a color

of Physical Product Standards for Color and Geometric

specification for a material, including the decision as to

Appearance of Coatings

whether this specification will be based on visual or instrumen-

E179 Guide for Selection of Geometric Conditions for

tal methods.

4.2 General considerations of appearance, evaluation of

This guide is under the jurisdiction of ASTM Committee D01 on Paint and

observers, and measurement techniques are included.

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.26 on Optical Properties.

Current edition approved April 1, 2006. Published April 2006. DOI: 10.1520/

D7195-06. The last approved version of this historical standard is referenced on

For referenced ASTM standards, visit the ASTM website, www.astm.org, or www.astm.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

Standards volume information, refer to the standard’s Document Summary page on on Illumination), C/o Thomas M. Lemons, TLA-Lighting Consultants, Inc., 7 Pond

the ASTM website. St., Salem, MA 01970.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7195−06

4.3 It begins the process of setting a tolerance by first the two parties involved. For years, color tolerances were set

selecting a standard or target color for the material, including up as boxes. However, it is now possible and desirable to use

the production, measurement, and storage of that target. elliptical tolerancing.

4.4 It next identifies methods to establish acceptable color

7.4 In most cases, the limits of acceptability will be greater

tolerances.

than a just perceptible difference, but in some cases, the

tolerance may be less than a perceptible difference. If it is less

4.5 Finally, it discusses reporting techniques.

than a perceptible difference, then instrumental methods will

have to be used. Both the producer and the customer should

5. Significance and Use

refer to Practice E2214.

5.1 The rejection of materials due to color is a common and

expensive occurrence, and it is useful for a customer and 7.5 While the goal is to have an agreed color specification

with an acceptable tolerance for both the producer and the

producer to set a color specification with an associated toler-

ance before the transaction. This guide discusses the concept customer, each party must carefully consider their position.

The producer must know that they are able to control the color

and details the ASTM standards to be used in the process.

inproductiontothelevelspecifiedwithoutexcessivewasteand

6. Introduction undue loss. The customer must be assured that the tolerance is

suchthatthecolorofthegoodswillbefunctionallyacceptable.

6.1 A common reason stated for rejection of goods or

materials is that the product color does not meet expectations.

7.6 Color is one aspect of the appearance of a material.

The best way to avoid the problem of returned goods or

Other appearance parameters include, but are not limited to,

materials because of color is to establish a color specification

gloss, haze, and texture. In order to compare the color of a test

with an associated tolerance. Then the producer can be

material to a target material, either visually or instrumentally,

confident that if they supply material that falls within the color

the other aspects of appearance should be the same, or as

specification, the customer will accept the color of the product.

similar as possible. Test Method D4449 covers the visual

evaluation of gloss, while Test Method D523 covers instru-

6.2 To supply color within specification consistently re-

mental gloss measurement.

quires production that is in statistical control, and a program of

color measurement and evaluation

7.7 Since it is not always possible to have all appearance

parameters the same or even if they are the same, it is

6.3 This guide will lead the user through the decision-

important to use established viewing conditions. These include

making process and point to the appropriate ASTM standards

the illumination, the positioning of the standard and specimen,

that are pertinent to each step. It will include the discussion

andthereceptorsystem,whetherhumanorinstrumental.Ifone

points on which the two parties must agree and will provide

is trying to have instrumental readings that correlate with the

caveats for various options selected.

visual appearance of a material, one needs to establish consis-

tency between the visual situation and the instrumental set up.

7. General Discussions

Guide E179 discusses the terminology and instrumentation for

7.1 In setting up the specification, one must first decide

evaluating appearance characteristics. Some of the consider-

whether there will be a visual or instrumental evaluation of the

ations when choosing the geometry of evaluation are:

color.Observershavedifferentcolorperceptionskills.Ahighly

7.7.1 What are your internal needs such as formulation,

trained colorist can see very minute color differences whereas

quality control, auditing, trouble shooting?

the more casual observer or color-anomalous observer would

7.7.2 What are your customer’s specifications and needs?

not normally detect very small differences. Additionally, the

7.7.3 Do you want the numbers to match visual evaluation?

visual abilities or perception levels of observers, may vary

betweenpersonsandovertimewithinanindividual.Thusifthe 7.7.4 If the gloss or surface texture of the standard and

color of the material will be evaluated visually, we must ensure specimen are different, do you want specimen’s gloss or grain

consistent conditions for the evaluation. Guide E1499 provides levels to produce the same colorimetric values when mea-

more detailed information. sured?

7.7.5 Do you want to deal with a small or large process

7.2 Numerous advances have occurred in both the accuracy

window?

and repeatability of color measurement instruments. However,

theremaystillbeconsiderabledifferencesbetweeninstruments

7.8 It is important to have the producer and the customer

of different make, type, and geometry. Advances have also

agree on the target color and the criterion for acceptance. For

occurredintheequationsandsoftwareprogramsforevaluating

many users the final criterion is visual acceptance, that is,

color and color quality control. It is not uncommon for the

visual appearance is the final deciding factor. However, some

specification to be set numerically and evaluated by instrumen-

usershavedemonstratedthatmoreconsistentproductqualityis

tal measurement, but then the question “what should my

obtainedinstrumentally,avoidingthe“finalvisualinspection.”

tolerance be?” must be resolved.

Once the color is agreed upon, then one should decide whether

to use visual or objective standards and tolerances.

7.3 A number of color difference calculations are widely

7.8.1 Someoftheadvantagesofusingadigitalstandardare:

used throughout industry. See Practice D2244 for more details

on the color difference and color tolerance equations. Which 7.8.1.1 Both supplier and customer have the same absolute

color-difference metric will be used should be agreed upon by numbers to judge against, the same starting point,

D7195−06

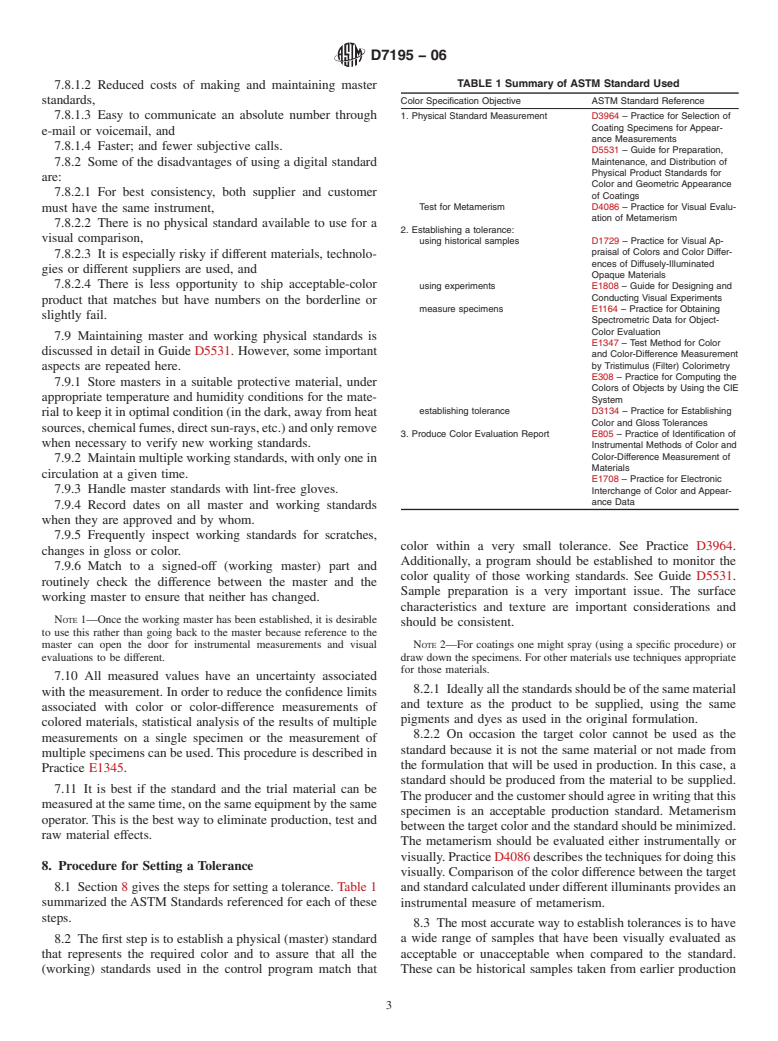

TABLE 1 Summary of ASTM Standard Used

7.8.1.2 Reduced costs of making and maintaining master

standards, Color Specification Objective ASTM Standard Reference

7.8.1.3 Easy to co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.