ASTM E517-00(2006)e1

(Test Method)Standard Test Method for Plastic Strain Ratio r for Sheet Metal

Standard Test Method for Plastic Strain Ratio r for Sheet Metal

SCOPE

1.1 This test method covers special tension testing for the measurement of the plastic strain ratio, r, of sheet metal intended for deep-drawing applications.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E517–00 (Reapproved 2006)

Standard Test Method for

Plastic Strain Ratio r for Sheet Metal

This standard is issued under the fixed designation E517; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Figure 1 was editorially corrected in August 2007.

1. Scope 3.1.1 delta r (D r)—measure of the tendency of sheet to

draw in nonuniformly and to form ears in the flange of

1.1 This test method covers special tension testing for the

deep-drawn cylindrical parts in the directions of higher r value

measurement of the plastic strain ratio, r, of sheet metal

(see 10.4).

intended for deep-drawing applications.

3.1.1.1 Discussion—In cold-reduced and annealed low-

1.2 The values stated in inch-pound units are to be regarded

carbonsteelsheet, r and r areusuallygreaterthan r ,while

as standard. The values given in parentheses are mathematical 0 90 45

in hot-rolled steels r may be greater. Other earing tendencies

conversions to SI units that are provided for information only

occur; thus, for some materials the earing tendency may be

and are not considered standard.

better represented by r − r .

max min

1.3 This standard does not purport to address all of the

3.1.2 plastic-strain ratio r (in sheet metal that has been

safety concerns, if any, associated with its use. It is the

strained by uniaxial tension sufficiently to induce plastic flow)

responsibility of the user of this standard to establish appro-

is the ratio of the true strain that has occurred in a width

priate safety and health practices and determine the applica-

direction w perpendicular to the direction of applied stress and

bility of regulatory limitations prior to use.

in the plane of the sheet, to the concomitant true strain in the

2. Referenced Documents

thickness direction t. Thus, r is numerically equal to

2.1 ASTM Standards: r 5´ /´ (1)

w t

E6 TerminologyRelatingtoMethodsofMechanicalTesting

where:

E8 Test Methods for Tension Testing of Metallic Materials

´ = width strain, and

w

E83 Practice for Verification and Classification of Exten-

´ = thickness strain.

t

someter Systems

3.1.2.1 Discussion—Due to difficulty in measuring thick-

E92 Test Method for Vickers Hardness of Metallic Materi-

nesschangeswithsufficientprecision,inpracticeanequivalent

als

relationship is commonly used, based on length and width

E177 Practice for Use of the Terms Precision and Bias in

strain measurements (see 9.1.2).

ASTM Test Methods

3.1.3 r —weighted average of r values obtained in three

m

E691 Practice for Conducting an Interlaboratory Study to

directions:0°(parallel),45°(diagonal),and90°(transverse)to

Determine the Precision of a Test Method

the rolling direction (see 10.3).

3.1.3.1 Discussion—Somematerialsmayshowsignificantly

3. Terminology

different values of r for other test directions, in which case an

3.1 Definitions of Terms Specific to This Standard:

averagevaluemayincludethesewhenspecialnoteismadeand

another subscript is used to avoid confusion with r as defined

m

This test method is under the jurisdiction of ASTM Committee E28 on

in3.1.3.Symbolswhichareoftenusedinterchangeablywithr

m

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

are r¯ and r-Bar.

Ductility and Flexure Testing.

3.1.4 yield point elongation (for a material that has a yield

Current edition approved Sept. 1, 2006. Published September 2006. Originally

approved in 1981. Last previous edition approved in 2000 as E517–00. DOI: point)isthetotalstrainassociatedwithdiscontinuousyielding.

10.1520/E0517-00R06E01.

3.2 The definitions relating to tension testing appearing in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Terminology E6 shall apply to this test method.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E517–00 (2006)

4. Significance and Use stress being applied to stretch the specimen, which causes

localized deformation. As a result, excessively high r values

4.1 Theplasticstrainratio risaparameterthatindicatesthe

may be calculated.

ability of a sheet metal to resist thinning or thickening when

subjectedtoeithertensileorcompressiveforcesintheplaneof

6. Apparatus

the sheet. It is a measure of plastic anisotropy and is related to

6.1 Measuring Devices:

the preferred crystallographic orientations within a polycrys-

6.1.1 Instruments for measuring length and width shall be

talline metal. This resistance to thinning or thicken-ing con-

tributes to the forming of shapes, such as cylindrical flat- checkedforaccuracyandbegraduatedtopermitmeasurements

to be made to 60.001 in. (6 0.02 mm) or better.

bottom cups, by the deep-drawing process. The r value,

therefore,isconsideredameasureofsheetmetaldrawability.It 6.1.2 If the longitudinal strain or the transverse strain, or

isparticularlyusefulforevaluatingmaterialsintendedforparts both, are to be obtained using an extensometer, the extensom-

where a substantial portion of the blank must be drawn from eter shall conform to Practice E83 as Class C or better. The

beneath the blank holder into the die opening. extensometersshallbeverifiedoverarangeappropriateforthe

strains used to determine r value.

4.2 For many materials this ratio remains essentially con-

6.2 Testing Machine—The testing machine used to strain

stant over a range of plastic strains up to maximum applied

the specimen shall be capable of uniaxially straining the

forceinatensiontest.Formaterialsthatgivedifferent rvalues

specimeninaccordancewiththerequirementsin9.2.5or9.3.4.

at various strain levels, a superscript is used to designate the

percentstrainatwhichthe rvaluewasmeasured.Forexample,

7. Test Specimen

if a 20% elongation is used, the report would show r .

4.3 Materials usually have different r values when tested in

7.1 Size—The length and width of the specimen are not

differentorientationsrelativetotherollingdirection.Theangle critical, provided care is used to stretch the gauge section in a

of sampling of the individual test coupon is noted by a

uniform manner, avoiding grip effects and anomalous changes

subscript. Thus, for a test specimen whose length is aligned along the gauge lengths.

parallel to the rolling direction, the r value would be reported

7.1.1 The specimen shall include the full sheet thickness

as r . If, in addition, the measurement was made at 20%

unless otherwise specified.

elongation and it was deemed necessary to note the percent

7.1.2 The thickness of the gauge section of the specimen

strain at which the value was measured, the value would be

shall be uniform within 0.0005 in. (0.013 mm) in the gauge

reported as r .

0 section. If the as-received surface is nonuniform, the surface

4.4 A material that has a yield point followed by discon- shallbepreparedbymachiningorbygrindingtothistolerance.

tinuous yielding stretches unevenly while this yielding is

7.1.3 Thedistancebetweenagaugemarkandagripshallbe

takingplace.Insteels,thisisassociatedwiththepropagationof

at least twice the width of the reduced section (or gauge width

Lüders’bandsonthesurface.Theaccuracyandreproducibility

for parallel strips) of the specimen.

of the determination of r will be reduced unless the test is

7.1.4 Duplicate specimens should be tested and the average

continued beyond this yield-point elongation. Similarly, the

r value of these reported for each test direction. If necessary, a

discontinuous yielding associated with large grain size in a

third determination may be made, rejecting the extreme.

material decreases the accuracy and reproducibility of deter-

7.2 Type—Any of three types of specimen may be used.

minations of r made at low strains.

Other types including subsize specimens are acceptable pro-

vided they give comparable values of equivalent accuracy.

5. Interferences

7.2.1 Specimen A, with reduced section, as shown in Fig.

1—While this is similar to Fig. 6 of Test Methods E8, the

5.1 Many factors may affect the measurements taken for

reduced section shall be parallel-sided rather than tapered.

determining rvalue.Inparticular,errorsinthemeasurementof

7.2.2 Specimen B, with a uniform width of 0.75 in. (20 mm),

the change in width can cause the reported r value to be

machined edges, and no reduced section, as shown in Fig. 2.

invalid. The following phenomena are known to cause severe

7.2.3 Specimen C, precision-sheared a uniform width of

errorsinthemeasurementofthechangeinwidththusaffecting

1.125 in. (28.58 mm), or with machined edges and no reduced

the r value reported.

section, as shown in Fig. 3.

5.1.1 Canoeing—Canoeing is a phenomenon which occurs

7.2.3.1 gauge lengths for Specimen C shall be marked on

in some materials when they are stretched. In these materials,

the sheet surface perpendicular to and parallel to the specimen

the test specimen bows about its longitudinal axis taking on a

edges. The gauge marks shall be made with Vickers diamond

shaperesemblingthebottomofacanoe.Inthiscase,unlessthe

indenters described in Test Method E92, or similar precise

measurements of the change in width are compensated for,

marks.

there will be significant errors in the r value calculated.

5.1.2 Sharp Knife Edges—Knife edges, used to measure the

8. Specimen Preparation

changeinwidthautomatically,whilethespecimenisstretched,

may cause localized deformation of the specimen under the 8.1 Specimen blanks shall be sheared or sawed individually

knife edges. This problem is intensified by the knife edges and with the exception of Specimen C, which may be used as

beingsharpandattachedtothespecimenwithhighforces.This sheared, shall be machined individually or in packs to remove

combination produces a compressive stress 90° to the tensile cold-worked edges.

´1

E517–00 (2006)

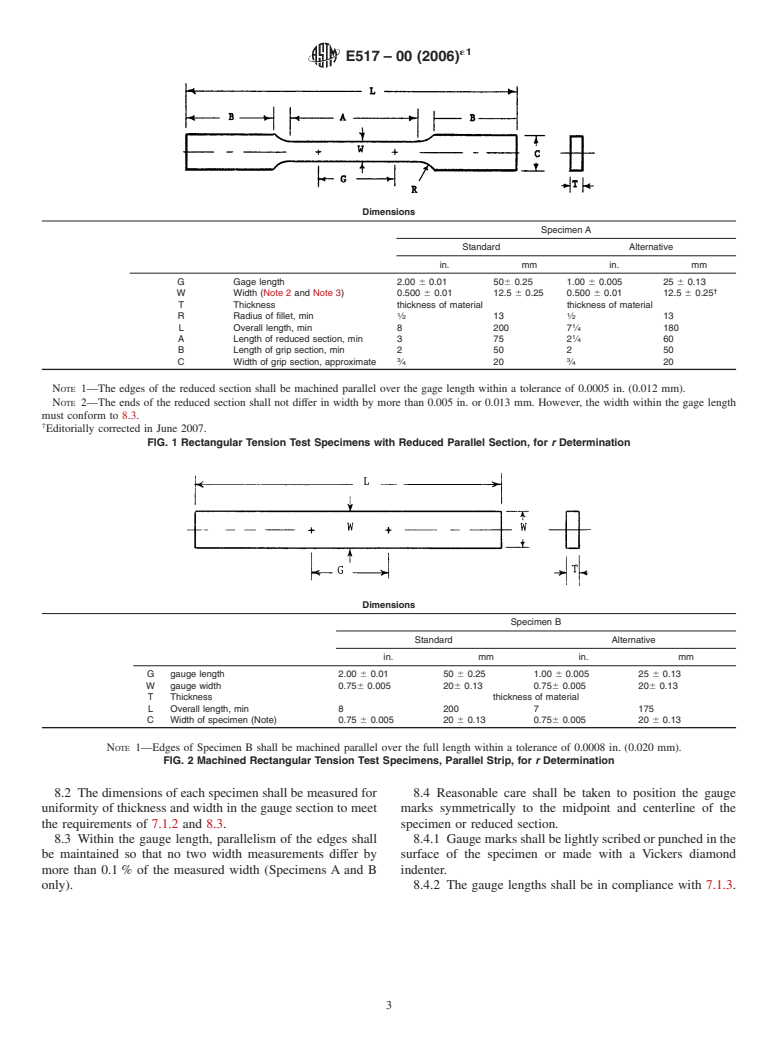

Dimensions

Specimen A

Standard Alternative

in. mm in. mm

G Gage length 2.00 6 0.01 506 0.25 1.00 6 0.005 25 6 0.13

†

W Width (Note 2 and Note 3) 0.500 6 0.01 12.5 6 0.25 0.500 6 0.01 12.5 6 0.25

T Thickness thickness of material thickness of material

1 1

R Radius of fillet, min ⁄2 13 ⁄2 13

L Overall length, min 8 200 7 ⁄4 180

A Length of reduced section, min 3 75 2 ⁄4 60

B Length of grip section, min 2 50 2 50

3 3

C Width of grip section, approximate ⁄4 20 ⁄4 20

NOTE 1—The edges of the reduced section shall be machined parallel over the gage length within a tolerance of 0.0005 in. (0.012 mm).

NOTE 2—The ends of the reduced section shall not differ in width by more than 0.005 in. or 0.013 mm. However, the width within the gage length

must conform to 8.3.

†

Editorially corrected in June 2007.

FIG. 1 Rectangular Tension Test Specimens with Reduced Parallel Section, for r Determination

Dimensions

Specimen B

Standard Alternative

in. mm in. mm

G gauge length 2.00 6 0.01 50 6 0.25 1.00 6 0.005 25 6 0.13

W gauge width 0.756 0.005 206 0.13 0.756 0.005 206 0.13

T Thickness thickness of material

L Overall length, min 8 200 7 175

C Width of specimen (Note) 0.75 6 0.005 20 6 0.13 0.756 0.005 20 6 0.13

NOTE 1—Edges of Specimen B shall be machined parallel over the full length within a tolerance of 0.0008 in. (0.020 mm).

FIG. 2 Machined Rectangular Tension Test Specimens, Parallel Strip, for r Determination

8.2 The dimensions of each specimen shall be measured for 8.4 Reasonable care shall be taken to position the gauge

uniformity of thickness and width in the gauge section to meet marks symmetrically to the midpoint and centerline of the

the requirements of 7.1.2 and 8.3. specimen or reduced section.

8.3 Within the gauge length, parallelism of the edges shall 8.4.1 Gaugemarksshallbelightlyscribedorpunchedinthe

be maintained so that no two width measurements differ by surface of the specimen or made with a Vickers diamond

more than 0.1% of the measured width (Specimens A and B indenter.

only). 8.4.2 The gauge lengths shall be in compliance with 7.1.3.

´1

E517–00 (2006)

Dimensions

Specimen C

in. mm

G Gage Length 0.75 6 0.005 20 6 0.13

W Gage Width 0.75 6 0.005 20 6 0.13

T Thickness thickness of material

L Overall Length, min 7 175

C Width of specimen 1.125 6 0.125 28.58 6 3.17

FIG. 3 Sheared Rectangular Tension Test Specimen, Parallel

Strip, for r Determination

NOTE 1—Strainsof15–20%arecommonlyutilizedfordeterminingthe

8.4.3 For SpecimenA, the gauge length shall be centered in

r-value of formable low carbon steel products.

the reduced section.

8.4.4 For Specimen C, a double set of gauge marks shall be

9.2.5 The rate of straining shall be 0.5/min or less, unless

used in compliance with 7.2.3.1.

otherwise specified.

9.2.6 Measure the final width, w , and gauge length, l,in

f f

9. Procedure

thesamemannerandtoleranceastheinitialvalues.Makethese

9.1 If the tensile properties of the material are unknown,

measurements with no tensile force applied to the specimen.

either make an autographic force/extension record or run a

9.3 Automatic Procedure:

separate tension test to determine the yielding characteristics

9.3.1 Attach extensometers conforming to 6.1.2 to the

and the elongation in accordance with Test Methods E8, using

specimen to measure the longitudinal and transverse strain.

the specimen shown in Fig. 6 of Test Methods E8. This will

Transverse extensometers must not cause and must not mea-

establish strain limits within which the r determination may be

sure additional transverse deformation due to the knife edges

made.

deforming the specimen during the test.

9.1.1 The plastic strain ratio r may be determined from

9.3.2 Record the gauge length of the extensometers. In the

widthandthicknesschangesresultingfromplasticdeformation

caseoftheextensometermeasuringtransversestrain,thegauge

provided these changes can be measured with sufficient accu-

length may be the width of the specimen.

racy in a tension test.

9.1.2 Formostthinsheetmetals,however,itispreferableto 9.3.3 Pull the specimen axially.

measure length and width changes and, assuming constant

9.3.4 The rate of straining shall be 0.5/min or less, unless

volume, calculate r by one of the following procedures:

otherwise specified.

9.2 Manual Procedure:

9.3.5 Determine the change in width corresponding to a

9.2.1 Determine the original width of the specimen, w ,

0 change in length from the data created by the extensometers,

within 60.0005 in. (60.013 mm). If a gauge length of 0.75 in.

when the specimen is stretched beyo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.