ASTM E2218-23

(Test Method)Standard Test Method for Determining Forming Limit Curves

Standard Test Method for Determining Forming Limit Curves

SIGNIFICANCE AND USE

5.1 The forming limit curve (FLC) is specific to the material sampled. It can change if the material is subjected to cold work or any annealing process. Thus, two samples from a given lot of material can produce different curves if their processing is varied.

5.2 The processing history of the material must be known if the test is to be considered representative of a grade of a product.

5.3 A forming limit curve (FLC) defines the maximum (limiting) strain that a given sample of a sheet metal can undergo for a range of forming conditions, such as deep drawing, plane strain, biaxial stretching, and bending over a radius in a press and die drawing operation, without developing a localized zone of thinning (localized necking) that would indicate incipient failure.

5.3.1 FLCs may be obtained empirically by using a laboratory hemispherical punch biaxial stretch test and also a tension test to strain metal sheet test specimens, from a material sample, from beyond their elastic limit to just prior to localized necking and fracture.

5.3.1.1 Since the location of localized necking and fracture cannot be predetermined, one or both surfaces of test specimens are covered with a pattern of gauge length measurement units, usually as squares or small diameter circles, by a suitable method such as scribing, photo-grid, or electro-etching, and then each test specimen is formed to the point of localized necking, or fracture.

5.3.2 Strains in the major (e1) and minor (e2) directions are measured using individual gauge length measurement units on the pattern in the area of the localized necking or fracture.

5.3.2.1 Test specimens of varied widths are used to produce a wide range of strain states in the minor (e2) direction.

5.3.2.2 The major strain (e1) is determined by the capacity of the material to be stretched in one direction as simultaneous surface forces either stretch, do not change, or compress, the metal in the minor strain (e2) direction.

5.3.2.3 In the ten...

SCOPE

1.1 This test method gives the procedure for constructing a forming limit curve (FLC) for a metallic sheet material by using a hemispherical deformation punch test and a uniaxial tension test to quantitatively simulate biaxial stretching and deep drawing processes.

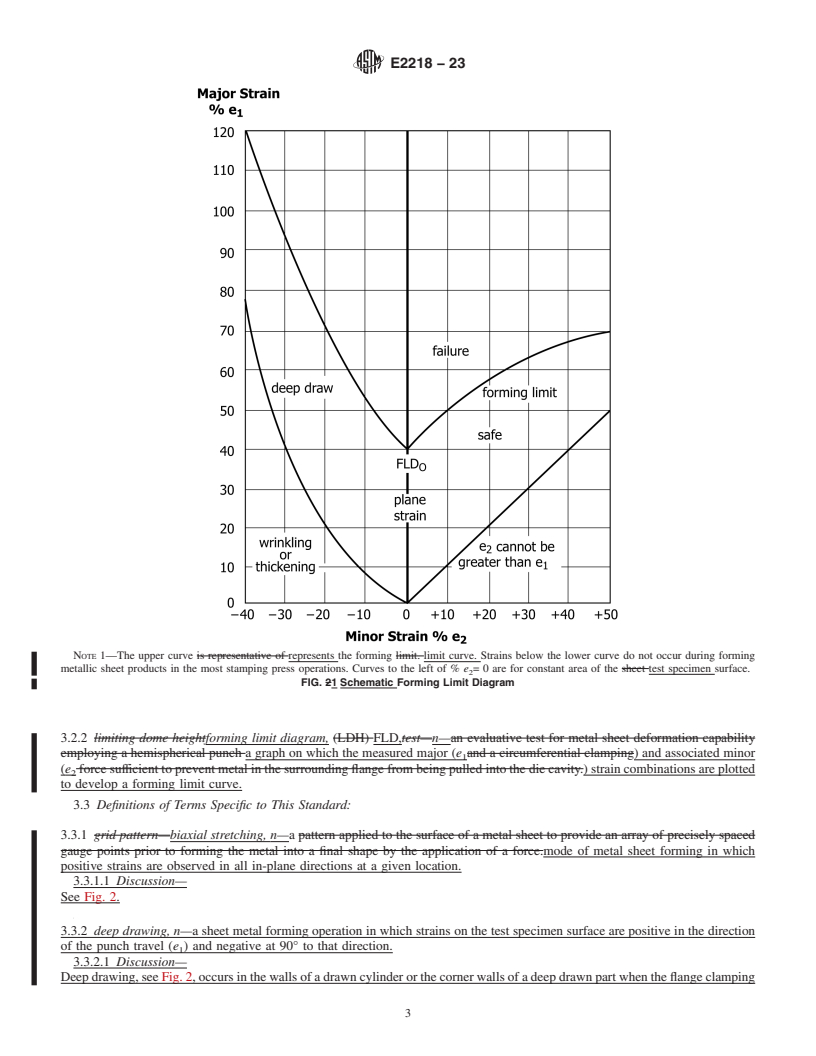

1.1.1 Fig. 1 shows an example of a forming limit curve on a schematic forming limit diagram (FLD).

FIG. 1 Schematic Forming Limit Diagram

Note 1: The upper curve represents the forming limit curve. Strains below the lower curve do not occur during forming metallic sheet products in the most stamping press operations. Curves to the left of % e2 = 0 are for constant area of the test specimen surface.

1.2 FLCs are useful in evaluating press performance by metal fabrication strain analysis.

1.3 The method applies to metallic sheet from 0.5 mm (0.020 in.) to 3.3 mm (0.130 in.).

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2218 − 23

Standard Test Method for

1

Determining Forming Limit Curves

This standard is issued under the fixed designation E2218; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.1 This test method gives the procedure for constructing a

E517 Test Method for Plastic Strain Ratio r for Sheet Metal

forming limit curve (FLC) for a metallic sheet material by

E646 Test Method for Tensile Strain-Hardening Exponents

using a hemispherical deformation punch test and a uniaxial

(n -Values) of Metallic Sheet Materials

tension test to quantitatively simulate biaxial stretching and

E2208 Guide for Evaluating Non-Contacting Optical Strain

deep drawing processes.

Measurement Systems

1.1.1 Fig. 1 shows an example of a forming limit curve on

a schematic forming limit diagram (FLD).

3. Terminology

1.2 FLCs are useful in evaluating press performance by

3.1 The terms accuracy, gauge length, necking, precision,

metal fabrication strain analysis.

strain hardening, engineering strain, and true strain are used as

defined in Terminology E6.

1.3 The method applies to metallic sheet from 0.5 mm

(0.020 in.) to 3.3 mm (0.130 in.).

3.2 Definitions of Terms Common to Mechanical Testing:

3.2.1 forming limit curve, FLC, n—an empirically derived

1.4 The values stated in SI units are to be regarded as the

curve showing the biaxial strain levels beyond which localized

standard. The values given in parentheses after SI units are

through-thickness thinning (necking) and subsequent failure

provided for information only and are not considered standard.

occur during the forming of a metallic sheet.

1.5 This standard does not purport to address all of the

3.2.1.1 Discussion—The forming limit curve is sometimes

safety concerns, if any, associated with its use. It is the

referred to as the “forming limit.”

responsibility of the user of this standard to establish appro-

3.2.2 forming limit diagram, FLD, n—a graph on which the

priate safety, health, and environmental practices and deter-

measured major (e ) and associated minor (e ) strain combi-

mine the applicability of regulatory limitations prior to use. 1 2

nations are plotted to develop a forming limit curve.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.3 Definitions of Terms Specific to This Standard:

ization established in the Decision on Principles for the

3.3.1 biaxial stretching, n—a mode of metal sheet forming

Development of International Standards, Guides and Recom-

in which positive strains are observed in all in-plane directions

mendations issued by the World Trade Organization Technical

at a given location.

Barriers to Trade (TBT) Committee.

3.3.1.1 Discussion—See Fig. 2.

3.3.2 deep drawing, n—a sheet metal forming operation in

2. Referenced Documents

which strains on the test specimen surface are positive in the

2

2.1 ASTM Standards:

direction of the punch travel (e ) and negative at 90° to that

1

A568/A568M Specification for Steel, Sheet, Carbon,

direction.

Structural, and High-Strength, Low-Alloy, Hot-Rolled and

3.3.2.1 Discussion—Deep drawing, see Fig. 2, occurs in the

Cold-Rolled, General Requirements for

walls of a drawn cylinder or the corner walls of a deep drawn

E6 Terminology Relating to Methods of Mechanical Testing

part when the flange clamping force is sufficient to restrain

metal movement and wrinkling, while permitting the punch to

1 push the center area of the test specimen into the cavity of the

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on

die. Strain conditions that can cause wrinkling or thickening

Ductility and Formability.

are shown in Fig. 1.

Current edition approved Feb. 1, 2023. Published April 2023. Originally

3.3.2.2 Discussion—In forming a square pan shape, metal

published in 2002. Last previous edition approved in 2015 as E2218–15. DOI:

from an area of the flange under a reduced clamping force is

10.1520/E2218-23

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

pulled into the die to form the side wall of the part.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.3.3 FLD , n—the location on the forming limit curve that

Standards volume information, refer to the standard’s Document Summary page

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2218 − 15 E2218 − 23

Standard Test Method for

1

Determining Forming Limit Curves

This standard is issued under the fixed designation E2218; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method gives the procedure for constructing a forming limit curve (FLC) for a metallic sheet material by using a

hemispherical deformation punch test and a uniaxial tension test to quantitatively simulate biaxial stretchstretching and deep

drawing processes.

1.1.1 Fig. 1 shows an example of a forming limit curve on a schematic forming limit diagram (FLD).

1.2 FLCs are useful in evaluating press performance by metal fabrication strain analysis.

1.3 The method applies to metallic sheet from 0.5 mm (0.020 in.) to 3.3 mm (0.130 in.).

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound equivalents are approximate.values given in

parentheses after SI units are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A568/A568M Specification for Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

E6 Terminology Relating to Methods of Mechanical Testing

E8/E8M Test Methods for Tension Testing of Metallic Materials

E517 Test Method for Plastic Strain Ratio r for Sheet Metal

E646 Test Method for Tensile Strain-Hardening Exponents (n -Values) of Metallic Sheet Materials

E2208 Guide for Evaluating Non-Contacting Optical Strain Measurement Systems

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.02 on Ductility and

Formability.

Current edition approved Oct. 1, 2015Feb. 1, 2023. Published December 2015April 2023. Originally published in 2002. Last previous edition approved in 20142015 as

ɛ1

E2218–14–15. . DOI: 10.1520/E2218-1510.1520/E2218-23

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2218 − 23

3. Terminology

3.1 TerminologyThe E6 shall apply including the special terms used in this method shown interms accuracy, gauge length,

necking, precision, strain hardening, engineering strain, and true strain 3.2are used as defined in Terminology E6.

3.2 Definitions:Definitions of Terms Common to Mechanical Testing:

3.2.1 biaxial stretching—a mode of metal sheet forming in which positive strains are observed in all directions at a given location.

3.2.1.1 Discussion—

See Fig. 1.

3.2.2 deep drawing—a metal sheet forming operation in which strains on the sheet surface are positive in the direction of the punch

travel (e ) and negative at 90° to that direction.

1

3.2.2.1 Discussion—

Deep drawing, see Fig. 1, occurs in the walls of a drawn cylinder or the corner walls of a deep drawn part when the flange clamping

force is sufficient to restrain metal movement and wrinkling, while permitting the punch to push the center area of the blank into

the cavity of the die. Strain conditions that can cause wrinkling or thickening are shown in Fig. 2.

3.2.2.2 Discussion—

In forming a square pan shape, metal from an area of the flange under a reduced clamping force is pulled into the die to form the

side wall of the part.

3.2.3 forming limit diagram (FLD)—a graph on which the measured major (e ) and associated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.