ASTM C549-81(1995)e1

(Specification)Standard Specification for Perlite Loose Fill Insulation

Standard Specification for Perlite Loose Fill Insulation

SCOPE

1.1 This specification covers the composition and physical properties of expanded perlite loose fill insulation. The specification also includes the testing procedures by which the acceptability of the material may be determined. These testing procedures deal primarily with material performance in the temperature range associated with the thermal envelope of buildings; however, the commercially usable temperature range for this insulation is from -459 to 1400°F (1 to 1033 K). For specialized applications, refer to the manufacturer's instructions.

1.2 The specification also covers the composition and properties of perlite that has been surface-treated to produce water repellency and dust suppression for installations where liquid moisture and dust may be a factor.

1.3 When the installation or use of thermal insulation materials, accessories and systems, may pose safety or health problems, the manufacturer shall provide the user appropriate current information regarding any known problems associated with the recommended use of the company's products, and shall also recommend protective measures to be employed in their safe utilization. The user shall establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use. For additional precautionary statements, see Section 11.

1.4 The following precautionary caveat pertains to the test methods portion, Section 8, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

Designation: C 549 – 81 (Reapproved 1995)

Standard Specification for

Perlite Loose Fill Insulation

This standard is issued under the fixed designation C549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

ϵ NOTE—Keywords were added editorially in May 1995.

1. Scope 2. Referenced Documents

1.1 This specification covers the composition and physical 2.1 ASTM Standards:

properties of expanded perlite loose fill insulation. The speci- C136 Test Method for Sieve Analysis of Fine and Coarse

fication also includes the testing procedures by which the Aggregates

acceptability of the material may be determined. These testing C168 Terminology Relating to Thermal Insulating Materi-

procedures deal primarily with material performance in the als

temperature range associated with the thermal envelope of C177 Test Method for Steady-State Heat Flux Measure-

buildings; however, the commercially usable temperature ments and Thermal Transmission Properties by Means of

rangeforthisinsulationisfrom−459to1400°F(1to1033K). the Guarded Hot Plate Apparatus

For specialized applications, refer to the manufacturer’s in- C390 Criteria for Sampling and Acceptance of Preformed

structions. Thermal Insulation Lots

1.2 The specification also covers the composition and prop- C518 Test Method for Steady-State Heat Flux Measure-

erties of perlite that has been surface-treated to produce water ments and Thermal Transmission Properties by Means of

repellency and dust suppression for installations where liquid the Heat Flow Meter Apparatus

moisture and dust may be a factor. C520 Test Methods for Density of Granular Loose Fill

1.3 When the installation or use of thermal insulation Insulations

materials, accessories and systems, may pose safety or health E84 Test Method for Surface Burning Characteristics of

problems, the manufacturer shall provide the user appropriate Building Materials

current information regarding any known problems associated E136 Test Method for Behavior of Materials in a Vertical

with the recommended use of the company’s products, and Tube Furnace at 750°C

shall also recommend protective measures to be employed in E177 Practice for Use of the Terms Precision and Bias in

their safe utilization. The user shall establish appropriate ASTM Test Methods

safety and health practices and determine the applicability of 2.2 Federal Specification:

regulatory requirements prior to use. For additional precau- HH-I-515D InsulationThermal(LooseFillforPneumaticor

tionary statements, see Section 11. Poured Application) Cellulosic or Wood Fiber

1.4 The following precautionary caveat pertains to the test

3. Classification

methods portion, Section 8, of this specification. This standard

3.1 Perlite loose fill insulation shall be specified by four

does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this type designations as follows:

3.1.1 Type I—The product that results from the expanding

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior of natural perlite ore by grading and heating to meet the

requirements of this specification.

to use.

Annual Book of ASTM Standards, Vol 04.02.

1 3

This specification is under the jurisdiction of ASTM Committee C-16 on Annual Book of ASTM Standards, Vol 04.06.

Thermal Insulation and is the direct responsibility of Subcommittee C16.23 on Annual Book of ASTM Standards, Vol 04.07.

Blanket and Loose Fill Insulation. Annual Book of ASTM Standards, Vol 14.02.

Current edition approved Oct. 30, 1981. Published February 1982. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as C549–64T. Last previous edition C549–73 (1979). Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

C 549 – 81 (1995)

a flux of 1.07 W/cm . When tested for Smoldering Combustion, Types III and IV

3.1.2 Type II—Expanded perlite that has been surface-

perlite insulation showed no flaming combustion and 0 % weight loss.

treated to produce water repellency and limited absorption of

moisture from both liquid and vapor phase.

7. Sampling

3.1.3 Type III—Expanded perlite that has been surface-

7.1 For purposes of standard tests, sampling shall be in

treated to limit the amount of dust generated during applica-

accordance with Criteria C390C390.

tion.

3.1.4 Type IV—Expanded perlite that has been surface-

8. Test Methods

treated to produce water repellency and to limit the dust

generated during application.

8.1 Bulk Density—Test Methods C520C520, Method A.

8.2 Grading—TestMethodC136C136,exceptthatwhena

4. Ordering Information

mechanical sieving device is used, the sieving time shall be 5

4.1 All purchase orders should designate the type of insu-

min and the test sample shall be 50 g of material.

lation desired. The type and grade classification in this speci-

8.3 Water Repellency (Types II and IV only):

fication differ from the classification in earlier issues. Purchas-

8.3.1 Apparatus:

ers referencing this specification should include the date of

8.3.1.1 Rigid Plastic Tube, 50 mm inside diameter by 300

issue.

mm long with a 150-µm (100-mesh) screen covering firmly

fastened or adhered to the bottom.The tube shall be marked at

5. Materials and Manufacture

400 mL from the screen-covered end.

5.1 Perlite is a generic term for a naturally occurring

8.3.1.2 Rubber Stopper, No. 15.

siliceous mineral which is mined, crushed, sieved and dried to

8.3.1.3 Graduated Cylinder, 250-mL.

produce a crude perlite ore. The crude ore, in the form of

8.3.1.4 Beaker, 500-mL.

particles of varying size, weighing 60 to 75 lb/ft (960 to 1200

kg/m ), is expanded in high-temperature furnaces to densities

8.3.2 Sample Preparation:

3 3

in the range from 2.0 to 11.0 lb/ft (32 to 176 kg/m ). As a

8.3.2.1 Spoon a representative sample into the test cylinder

naturally occurring mineral, it is classified as an elementary

to a level slightly above the 400-mL mark.

building material. It is noncombustible as determined by Test

8.3.2.2 Compact it by dropping the tube from a height of

Method C136C136.

approximately 75 mm on a large rubber stopper (No. 15

recommended)foratotaloftendrops.Asthesamplecompacts

6. Physical Requirements Physical Requirements

to a level below the 400-mL mark, add additional material so

6.1 The physical requirements listed in this section are

that after the tenth drop the level of the sample is within 3 mL

defined as Inspection Requirements (see Criteria C390C390).

of the 400-mL mark.

The insulation shall conform to the following requirements:

8.3.3 Procedure:

All Types

8.3.3.1 With the tube supported in a vertical position and a

3 3

Bulk density, lb/ft (kg/m ) 2–11 (32–176)

beaker positioned under the tube, pour 250 mL of cold tap

Grading (particle size):

Cumulative percentage retained, maximum (by 5

waterrapidlyontotheperlite.Takecarewhilepouring,thatthe

weight), Sieve No. 4 (4.75 mm), %

stream hits the middle of the surface of the bed of perlite and

Types I Types II and

does not merely slide down the side of the test cylinder.

and III IV only

Water repellency, min mL of water repelled N.A. 175

8.3.3.2 Allow the water to drain through the bed of perlite

Small-scale fire test no sparking or ignition

for exactly 3 min. Tilt the tube at approximately 45° to drain

6.2 The physical requirements listed in this section are

water collected on the screen. Tilt it only momentarily for this

defined as Qualification Requirements (see Criteria purpose.

C390C390). The insulation shall conform to the following

8.3.3.3 Measurethecollectedwaterinthe250-mLgraduate.

requirements:

8.3.4 Calculations:

All Types

8.3.4.1 Reporttheamountofcollectedwaterinmillilitresas

2 2

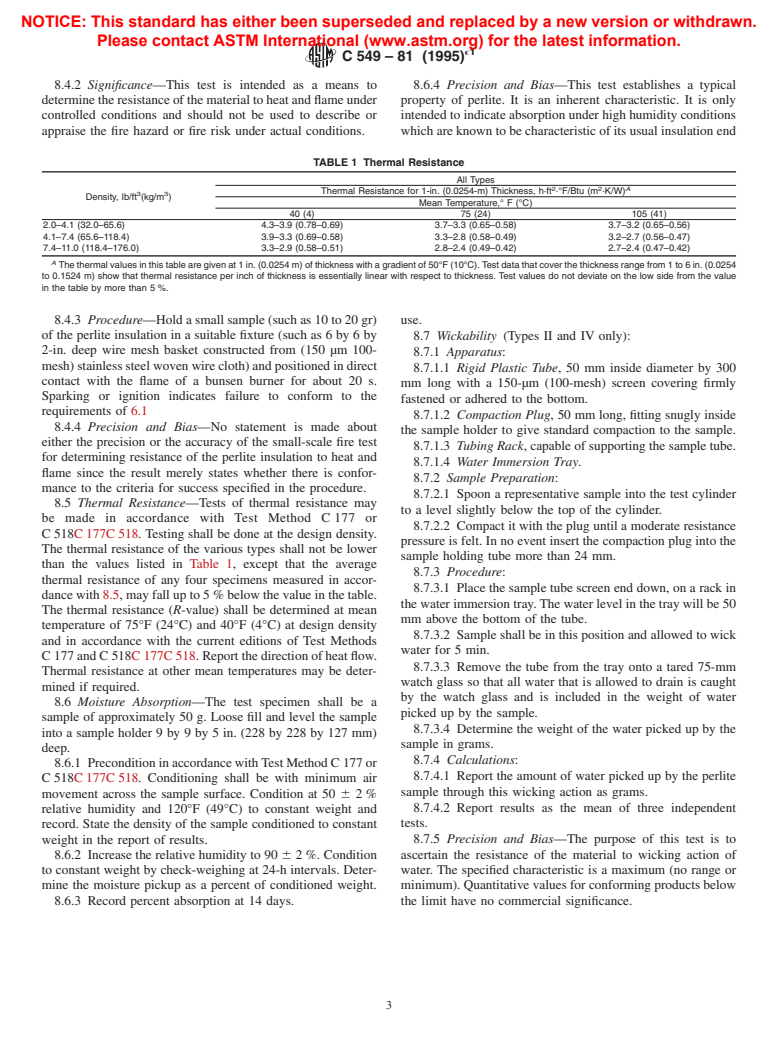

Thermal resistance, h·ft ·°F/Btu (m ·K/W) See Table 1

“millilitres repelled.”

Moisture absorption, weight %/14 days, max, % 1.0

8.3.4.2 Report results as the mean of three independent

tests.

Types I and III Types II and

IV 8.3.5 Precision and Bias—The purpose of this test is to

Wickability, max g wicked in 5 min N.A. 1.0

confirm that the intended degree of surface treatment has been

A

Combustibility (by Test Method noncombustible N.A.

accomplished to achieve water repellency. The specified char-

E 136E 136)

Surface burning characteristics: acteristic is a minimum (no range or maximum). Quantitative

Flame spread, max 0 25

values for conforming products exceeding the limit have no

Smoke developed, max 0 50

commercial significance.

Dust suppression:

Weight of collected material, max, mg N.A. 85

8.4 Small-Scale Fire Test:

A

Federal Standards for attic floor insulation require conformance to two

8.4.1 Scope—The purpose of this quality control test is to

non-ASTM tests for combustibility: Critical Radiant Flux (HH-I-515D, 4.8.7) and

confirmthatexcessivecoatingororganicmaterialhasnotbeen

Smoldering Combustion (HH-I-515D, 4.8.8). Types III and IV perlite insulation,

when tested for Critical Radiant Flux, showed no ignition or flame front advance at added during processing.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

C 549 – 81 (1995)

8.4.2 Significance—This test is intended as a means to 8.6.4 Precision and Bias—This test establishes a typical

determinetheresistanceofthematerialtoheatandflameunder property of perlite. It is an inherent characteristic. It is only

controlled conditions and should not be used to describe or intendedtoindicateabsorptionunderhighhumidityconditions

appraise the fire hazard or fire risk under actual conditions. whichareknowntobecharacteristicofitsusualinsulationend

TABLE 1 Thermal Resistance

All Types

2 2 A

Thermal Resistance for 1-in. (0.0254-m) Thickness, h·ft ·°F/Btu (m ·K/W)

3 3

Density, lb/ft (kg/m )

Mean Temperature,° F (°C)

40 (4) 75 (24) 105 (41)

2.0–4.1 (32.0–65.6) 4.3–3.9 (0.78–0.69) 3.7–3.3 (0.65–0.58) 3.7–3.2 (0.65–0.56)

4.1–7.4 (65.6–118.4) 3.9–3.3 (0.69–0.58) 3.3–2.8 (0.58–0.49) 3.2–2.7 (0.56–0.47)

7.4–11.0 (118.4–176.0) 3.3–2.9 (0.58–0.51) 2.8–2.4 (0.49–0.42) 2.7–2.4 (0.47–0.42)

A

The thermal values in this table

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.