ASTM E740/E740M-03(2016)

(Practice)Standard Practice for Fracture Testing with Surface-Crack Tension Specimens

Standard Practice for Fracture Testing with Surface-Crack Tension Specimens

SIGNIFICANCE AND USE

4.1 The surface-crack tension (SCT) test is used to estimate the load-carrying capacity of simple sheet- or plate-like structural components having a type of flaw likely to occur in service. The test is also used for research purposes to investigate failure mechanisms of cracks under service conditions.

4.2 The residual strength of an SCT specimen is a function of the crack depth and length and the specimen thickness as well as the characteristics of the material. This relationship is extremely complex and cannot be completely described or characterized at present.

4.2.1 The results of the SCT test are suitable for direct application to design only when the service conditions exactly parallel the test conditions. Some methods for further analysis are suggested in Appendix X1.

4.3 In order that SCT test data can be comparable and reproducible and can be correlated among laboratories, it is essential that uniform SCT testing practices be established.

4.4 The specimen configuration, preparation, and instrumentation described in this practice are generally suitable for cyclic- or sustained-force testing as well. However, certain constraints are peculiar to each of these tests. These are beyond the scope of this practice but are discussed in Ref. (1).

SCOPE

1.1 This practice covers the design, preparation, and testing of surface-crack tension (SCT) specimens. It relates specifically to testing under continuously increasing force and excludes cyclic and sustained loadings. The quantity determined is the residual strength of a specimen having a semielliptical or circular-segment fatigue crack in one surface. This value depends on the crack dimensions and the specimen thickness as well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by strength, thickness, or toughness. However, tests of thick specimens of tough materials may require a tension test machine of extremely high capacity. The applicability of this practice to nonmetallic materials has not been determined.

1.3 This practice is limited to specimens having a uniform rectangular cross section in the test section. The test section width and length must be large with respect to the crack length. Crack depth and length should be chosen to suit the ultimate purpose of the test.

1.4 Residual strength may depend strongly upon temperature within a certain range depending upon the characteristics of the material. This practice is suitable for tests at any appropriate temperature.

1.5 Residual strength is believed to be relatively insensitive to loading rate within the range normally used in conventional tension tests. When very low or very high rates of loading are expected in service, the effect of loading rate should be investigated using special procedures that are beyond the scope of this practice.

Note 1: Further information on background and need for this type of test is given in the report of ASTM Task Group E24.01.05 on Part-Through-Crack Testing (1).2

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E740/E740M − 03 (Reapproved 2016)

Standard Practice for

Fracture Testing with Surface-Crack Tension Specimens

This standard is issued under the fixed designation E740/E740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

1.1 This practice covers the design, preparation, and testing

values from the two systems may result in non-conformance

of surface-crack tension (SCT) specimens. It relates specifi-

with the standard.

cally to testing under continuously increasing force and ex-

1.7 This standard does not purport to address all of the

cludes cyclic and sustained loadings. The quantity determined

safety concerns, if any, associated with its use. It is the

istheresidualstrengthofaspecimenhavingasemiellipticalor

responsibility of the user of this standard to establish appro-

circular-segment fatigue crack in one surface. This value

priate safety and health practices and determine the applica-

dependsonthecrackdimensionsandthespecimenthicknessas

bility of regulatory limitations prior to use.

well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by

2. Referenced Documents

strength, thickness, or toughness. However, tests of thick

2.1 ASTM Standards:

specimens of tough materials may require a tension test

E4Practices for Force Verification of Testing Machines

machine of extremely high capacity. The applicability of this

E8/E8MTest Methods for Tension Testing of Metallic Ma-

practice to nonmetallic materials has not been determined.

terials

1.3 This practice is limited to specimens having a uniform

E338Test Method of Sharp-Notch Tension Testing of High-

rectangular cross section in the test section. The test section

Strength Sheet Materials (Withdrawn 2010)

widthandlengthmustbelargewithrespecttothecracklength.

E399Test Method for Linear-Elastic Plane-Strain Fracture

Crack depth and length should be chosen to suit the ultimate

Toughness K of Metallic Materials

Ic

purpose of the test.

E466Practice for Conducting Force Controlled Constant

1.4 Residual strength may depend strongly upon tempera-

Amplitude Axial Fatigue Tests of Metallic Materials

ture within a certain range depending upon the characteristics

E561Test Method forK Curve Determination

R

of the material. This practice is suitable for tests at any

E1823TerminologyRelatingtoFatigueandFractureTesting

appropriate temperature.

3. Terminology

1.5 Residual strength is believed to be relatively insensitive

to loading rate within the range normally used in conventional

3.1 Definitions:

tension tests. When very low or very high rates of loading are

3.1.1 Definitions given in Terminology E1823 are appli-

expected in service, the effect of loading rate should be

cable to this practice.

investigatedusingspecialproceduresthatarebeyondthescope

3.1.2 crack mouth opening displacement (CMOD), 2v

m

of this practice.

(L)—crack—opening displacement resulting from the total

deformation (elastic plus plastic) measured under force at the

NOTE 1—Further information on background and need for this type of

test is given in the report of ASTM Task Group E24.01.05 on Part- location on the crack surface that has the largest displacement

Through-Crack Testing (1).

per unit force.

1.6 The values stated in either SI units or inch-pound units

NOTE 2—In surface-crack tension (SCT) specimens, CMOD is mea-

are to be regarded separately as standard. The values stated in

sured on the specimen surface along the normal bisector of the crack

length.

ThispracticeisunderthejurisdictionofASTMCommitteeE08onFatigueand

Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2016. Published October 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2010 as E740/ Standards volume information, refer to the standard’s Document Summary page on

ɛ2

E740M–03(2010) . DOI: 10.1520/E0740_E0740M-03R16. the ASTM website.

2 4

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof The last approved version of this historical standard is referenced on

this standard. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E740/E740M − 03 (2016)

3.1.3 fracture toughness—a generic term for measures of long as the crack growth is symmetrical and the plane of the

resistance to extension of a crack. E616 crack remains perpendicular to the specimen face and the

tensileforcevector.Theeffectofcyclicfrequencyisthoughtto

3.1.4 original crack size, a [L]—the physical crack size at

o

be negligible below 100 Hz in a nonaggressive environment.

the start of testing. (E616)

NOTE 4—Certain crack shapes are more readily produced in axial

3.2 Definitions of Terms Specific to This Standard:

tension, others in bending (see Annex A1).

3.2.1 crack depth, a [L]—in surface-crack tension (SCT)

5.2.1 Devices and fixtures for cantilever bending of sheet

specimens, the normal distance from the cracked plate surface

and plate specimens are described in Refs. (2) and (3),

tothepointofmaximumpenetrationofthecrackfrontintothe

respectively. Others may be equally suitable. The axial fatigue

material. Crack depth is a fraction of the specimen thickness.

machines described in Practice E466 are suitable for precrack-

3.2.1.1 Discussion—In this practice, crack depth is the

ing in tension; however, since the precracking operation is

original depth a and the subscript o is everywhere implied.

o

terminated prior to specimen failure, one should ensure that

3.2.2 crack length, 2c [L]—in surface-crack tension

load variations during slowdown or shutdown do not exceed

specimens, a distance measured on the specimen surface

those desired.

between the two points at which the crack front intersects the

5.2.2 A magnifier of about 20 power should be used to

specimensurface.Cracklengthisafractionofspecimenwidth.

monitor the fatigue precracking process. Ease of observation

3.2.2.1 Discussion—In this practice, crack length is the

willbeenhancedifthecyclicratecanbereducedtoabout1Hz

original length 2c and the subscript o is everywhere implied.

o

when desired.Alternatively, a stroboscopic light synchronized

−2

3.2.3 residual strength, σ (FL )—the maximum value of

r

with the maximum application of tensile force may serve as

the nominal stress, neglecting the area of the crack, that a

well.

cracked specimen is capable of sustaining.

5.3 Testing Machine—The test should be conducted with a

NOTE3—Insurface-cracktension(SCT)specimens,residualstrengthis

tension testing machine that conforms to the requirements of

the ratio of the maximum load (P ) to the product of test section width

max

Practices E4.

(W) times thickness (B), P /(BW). It represents the stress at fracture

max

5.3.1 The devices for transmitting force to the specimen

normal to and remote from the plane of the crack.

shallbesuchthatthemajoraxisofthespecimencoincideswith

4. Significance and Use theloadaxis.Thepin-and-clevisarrangementdescribedinTest

Method E338 should be suitable for specimens whose width is

4.1 The surface-crack tension (SCT) test is used to estimate

less than about 4 in. [100 mm]. An arrangement such as that

the load-carrying capacity of simple sheet- or plate-like struc-

shown in Fig. 2 of Practice E561 should be suitable for wider

tural components having a type of flaw likely to occur in

specimens.

service. The test is also used for research purposes to investi-

5.3.2 For tests at other than room temperature, the tempera-

gate failure mechanisms of cracks under service conditions.

turecontrolandtemperaturemeasurementrequirementsofTest

4.2 The residual strength of an SCT specimen is a function

Method E338 are appropriate.

of the crack depth and length and the specimen thickness as

5.4 Displacement Gage (Optional)—If used to measure

well as the characteristics of the material. This relationship is

CMOD, the displacement gage output should accurately indi-

extremely complex and cannot be completely described or

cate the relative displacement of two gage points on the

characterized at present.

cracked surface, spanning the crack at the midpoint of its

4.2.1 The results of the SCT test are suitable for direct

length. Further information on displacement gages appears in

application to design only when the service conditions exactly

Appendix X2.

parallel the test conditions. Some methods for further analysis

are suggested in Appendix X1. 5.5 For some combinations of material and crack geometry,

thecrackmaypropagateentirelythroughthethicknesspriorto

4.3 In order that SCT test data can be comparable and

totalfailure.Methodsofdetectingthisoccurrence,shoulditbe

reproducible and can be correlated among laboratories, it is

of interest, are discussed briefly in Ref. (1).

essential that uniform SCT testing practices be established.

4.4 The specimen configuration, preparation, and instru- 6. Test Specimen

mentation described in this practice are generally suitable for

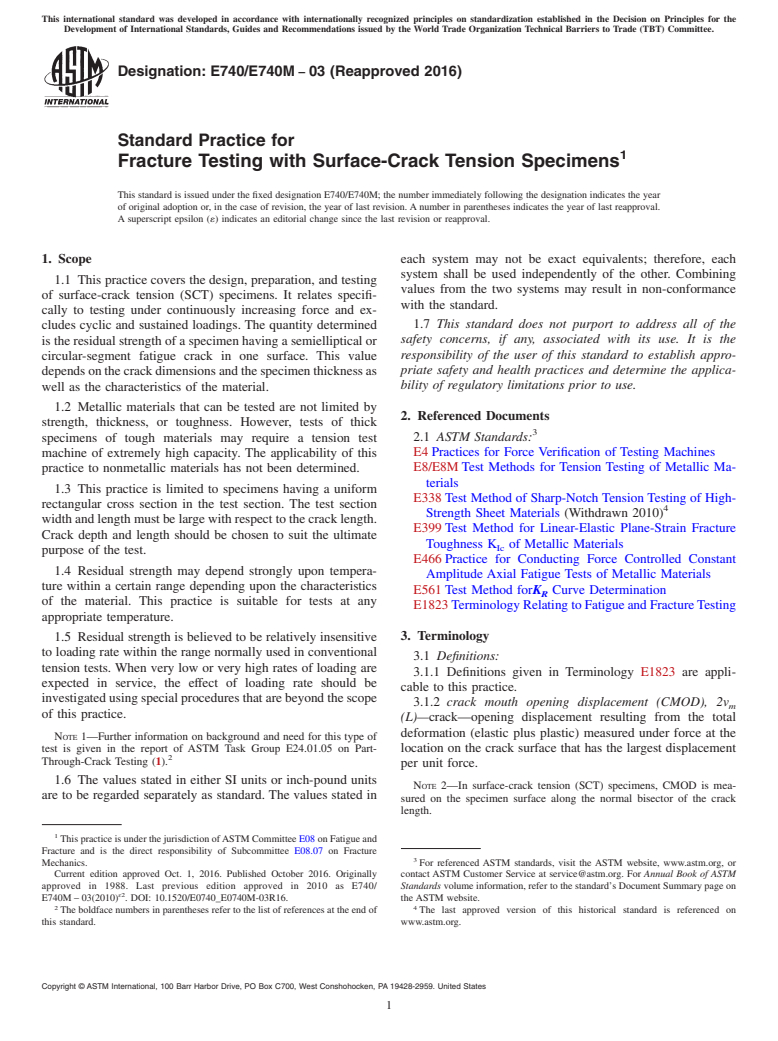

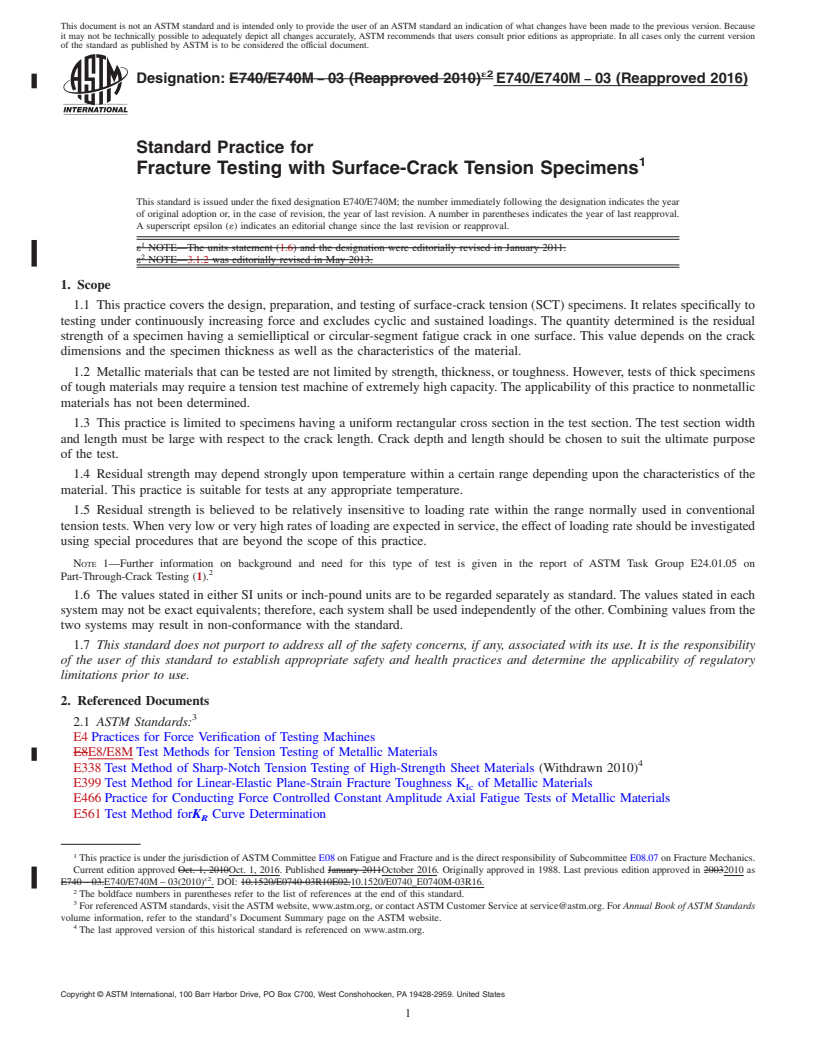

6.1 Configuration and Notation—The SCT test specimen

cyclic- or sustained-force testing as well. However, certain

and the notation used herein are shown in Fig. 1. Grip details

constraintsarepeculiartoeachofthesetests.Thesearebeyond

have been omitted, since grip design may depend on specimen

the scope of this practice but are discussed in Ref. (1).

size (5.3.1) and material toughness. In general, the only

gripping requirements are that the arrangement be strong

5. Apparatus

enough to carry the maximum expected force and that it allow

5.1 The procedure involves testing of specimens that have uniform distribution of force over the specimen cross section.

been precracked in fatigue. force versus CMOD, if CMOD is

6.2 Dimensions—The crack depth and length and specimen

measured, is recorded autographically or digitally.

thickness should be chosen according to the ultimate purpose

5.2 FatiguePrecrackingApparatus—Axialtensionorthree- of the test. Further discussion of this subject may be found in

point, four-point, or cantilever bending are all acceptable AppendixX3.ThespecimenwidthWshouldbeatleast5times

modes for fatigue precracking. Fixture design is not critical as the crack length 2c and the specimen test section length L

E740/E740M − 03 (2016)

starter is machined into the specimen surface at the center of

the test section (Fig. 2) to locate and help initiate the fatigue

crack.Regularityofcrackconfigurationisinfluencedprimarily

by fatigue force uniformity, which can be maximized by

careful alignment of force train and fixtures. Material

inhomogeneity, residual stresses, and starter notch root radius

variation can produce irregularities which may be beyond

control. Fatigue crack size and shape control are discussed in

Annex A1.

6.3.1 Crack starters have been produced by a variety of

methods. The following procedures are known to produce

acceptable results.

6.3.1.1 The crack starter should be machined, either by

slittingwithathinjeweler’scircularsaworsimilarcutterorby

electrical discharge machining (EDM) with a thin, shaped

electrode.

6.3.1.2 The crack starter plane should be perpendicular to

the specimen face and the tensile force vector within 10°.

6.3.1.3 The starter notch root radius should be less than

0.010 in. [0.25 mm].

6.3.1.4 The crack starter length and depth should be chosen

with the desired crack dimensions and the requirements of

6.3.2.2 in mind.

6.3.2 The following procedures should ensure the produc-

FIG. 1 Typical Surface-Crack Specimen (Grip Details Omitted)

tion of an effective sharp fatigue crack.

and Nomenclature

6.3.2.1 Fatigue crack with the specimen in the heat treat-

ment condition in which it is to be tested, if at all possible.

should be at least twice the width W. Should these width and

6.3.2.2 Whenever it is physically possible, the crack should

length dimensions exceed actual service dimensions, the ser-

be extended at least 0.05 in. [1.3 mm]; in any event the fatigue

vice dimensions should be used but one should not then

crack extension must not be less than 5% of the final crack

attempt to generalize data from such tests.

depth, and the crack and its starter must lie entirely within an

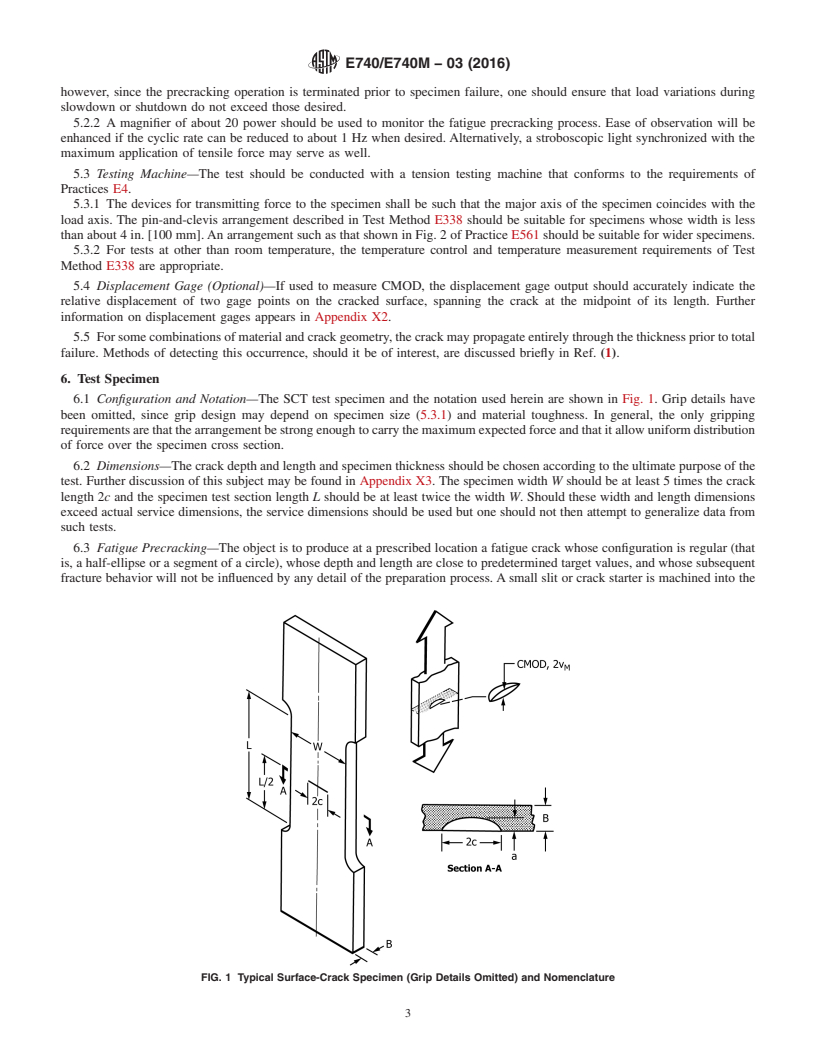

6.3 Fatigue Precracking—The object is to produce at a imaginary 30° wedge whose apex is at the crack tip. These

two-dimensional descriptions shall apply around the entire

prescribed location a fatigue crack whose configuration is

regular (that is, a half-ellipse or a segment of a circle), whose crackfront,thatis,inallplanesnormaltotangentstoallpoints

on the crack periphery (Fig. 2).

depth and length are close to predetermined target values, and

whose subsequent fracture behavior will not be influenced by 6.3.2.3 The ratio of minimum to maximum cyclic stress, R,

any detail of the preparation process. A small slit or crack should not be greater than 0.1.

NOTE 1—Section A-A refers to the plane normal to any tangent to the crack periphery and containing the point of tangency.

FIG. 2 Fatigue Crack and Starter Details

E740/E740M − 03 (2016)

6.3.2.4 For at least the final 2.5% of the total crack depth, of a circle. If the crack shape is irregular or unsymmetric the

1/2 1/2

theratioK /Eshouldnotexceed0.002in. [0.00032m ], test should be discarded. Using the actual crack dimensions,

max

where K is the maximum stress intensity factor during verify that the requirement 6.3.2.4 was indeed met.

max

fatigue cracking and E is the material’s elastic modulus. An

7.6 Residual Strength—Calculate the residual strength as σ

r

estimate of K can be computed based on the cyclic stress

max

=P /(BW).

max

and the target crack dimensions using the appropriate equation

8. Report

from AnnexA2. Compute K at the surface or at the deepest

max

point, whichever is greater.

8.1 The report should include the following for each speci-

men tested:

7. Procedure

8.1.1 Test section width, W, and thickness, B.

8.1.2 Maximum stress intensity factor during fatigue

7.1 Number of Tests—If only one crack geometry (that is,

precracking, K , based on actual crack dimensions.

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E740/E740M − 03 (Reapproved 2016)

Standard Practice for

Fracture Testing with Surface-Crack Tension Specimens

This standard is issued under the fixed designation E740/E740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

1.1 This practice covers the design, preparation, and testing

values from the two systems may result in non-conformance

of surface-crack tension (SCT) specimens. It relates specifi-

with the standard.

cally to testing under continuously increasing force and ex-

1.7 This standard does not purport to address all of the

cludes cyclic and sustained loadings. The quantity determined

safety concerns, if any, associated with its use. It is the

is the residual strength of a specimen having a semielliptical or

responsibility of the user of this standard to establish appro-

circular-segment fatigue crack in one surface. This value

priate safety and health practices and determine the applica-

depends on the crack dimensions and the specimen thickness as

bility of regulatory limitations prior to use.

well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by

2. Referenced Documents

strength, thickness, or toughness. However, tests of thick

2.1 ASTM Standards:

specimens of tough materials may require a tension test

E4 Practices for Force Verification of Testing Machines

machine of extremely high capacity. The applicability of this

E8/E8M Test Methods for Tension Testing of Metallic Ma-

practice to nonmetallic materials has not been determined.

terials

1.3 This practice is limited to specimens having a uniform

E338 Test Method of Sharp-Notch Tension Testing of High-

rectangular cross section in the test section. The test section

Strength Sheet Materials (Withdrawn 2010)

width and length must be large with respect to the crack length.

E399 Test Method for Linear-Elastic Plane-Strain Fracture

Crack depth and length should be chosen to suit the ultimate

Toughness K of Metallic Materials

Ic

purpose of the test.

E466 Practice for Conducting Force Controlled Constant

1.4 Residual strength may depend strongly upon tempera-

Amplitude Axial Fatigue Tests of Metallic Materials

ture within a certain range depending upon the characteristics

E561 Test Method forK Curve Determination

R

of the material. This practice is suitable for tests at any

E1823 Terminology Relating to Fatigue and Fracture Testing

appropriate temperature.

3. Terminology

1.5 Residual strength is believed to be relatively insensitive

to loading rate within the range normally used in conventional

3.1 Definitions:

tension tests. When very low or very high rates of loading are

3.1.1 Definitions given in Terminology E1823 are appli-

expected in service, the effect of loading rate should be

cable to this practice.

investigated using special procedures that are beyond the scope

3.1.2 crack mouth opening displacement (CMOD), 2v

m

of this practice.

(L)—crack—opening displacement resulting from the total

deformation (elastic plus plastic) measured under force at the

NOTE 1—Further information on background and need for this type of

test is given in the report of ASTM Task Group E24.01.05 on Part- location on the crack surface that has the largest displacement

Through-Crack Testing (1).

per unit force.

1.6 The values stated in either SI units or inch-pound units

NOTE 2—In surface-crack tension (SCT) specimens, CMOD is mea-

are to be regarded separately as standard. The values stated in

sured on the specimen surface along the normal bisector of the crack

length.

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and

Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2016. Published October 2016. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2010 as E740/ Standards volume information, refer to the standard’s Document Summary page on

ɛ2

E740M – 03(2010) . DOI: 10.1520/E0740_E0740M-03R16. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references at the end of The last approved version of this historical standard is referenced on

this standard. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E740/E740M − 03 (2016)

3.1.3 fracture toughness—a generic term for measures of long as the crack growth is symmetrical and the plane of the

resistance to extension of a crack. E616 crack remains perpendicular to the specimen face and the

tensile force vector. The effect of cyclic frequency is thought to

3.1.4 original crack size, a [L]—the physical crack size at

o

be negligible below 100 Hz in a nonaggressive environment.

the start of testing. (E616)

NOTE 4—Certain crack shapes are more readily produced in axial

3.2 Definitions of Terms Specific to This Standard:

tension, others in bending (see Annex A1).

3.2.1 crack depth, a [L]—in surface-crack tension (SCT)

5.2.1 Devices and fixtures for cantilever bending of sheet

specimens, the normal distance from the cracked plate surface

and plate specimens are described in Refs. (2) and (3),

to the point of maximum penetration of the crack front into the

respectively. Others may be equally suitable. The axial fatigue

material. Crack depth is a fraction of the specimen thickness.

machines described in Practice E466 are suitable for precrack-

3.2.1.1 Discussion—In this practice, crack depth is the

ing in tension; however, since the precracking operation is

original depth a and the subscript o is everywhere implied.

o

terminated prior to specimen failure, one should ensure that

3.2.2 crack length, 2c [L]—in surface-crack tension

load variations during slowdown or shutdown do not exceed

specimens, a distance measured on the specimen surface

those desired.

between the two points at which the crack front intersects the

5.2.2 A magnifier of about 20 power should be used to

specimen surface. Crack length is a fraction of specimen width.

monitor the fatigue precracking process. Ease of observation

3.2.2.1 Discussion—In this practice, crack length is the

will be enhanced if the cyclic rate can be reduced to about 1 Hz

original length 2c and the subscript o is everywhere implied.

o

when desired. Alternatively, a stroboscopic light synchronized

−2

3.2.3 residual strength, σ (FL )—the maximum value of

r

with the maximum application of tensile force may serve as

the nominal stress, neglecting the area of the crack, that a

well.

cracked specimen is capable of sustaining.

5.3 Testing Machine—The test should be conducted with a

NOTE 3—In surface-crack tension (SCT) specimens, residual strength is

tension testing machine that conforms to the requirements of

the ratio of the maximum load (P ) to the product of test section width

max

Practices E4.

(W) times thickness (B), P /(BW). It represents the stress at fracture

max

5.3.1 The devices for transmitting force to the specimen

normal to and remote from the plane of the crack.

shall be such that the major axis of the specimen coincides with

4. Significance and Use

the load axis. The pin-and-clevis arrangement described in Test

Method E338 should be suitable for specimens whose width is

4.1 The surface-crack tension (SCT) test is used to estimate

less than about 4 in. [100 mm]. An arrangement such as that

the load-carrying capacity of simple sheet- or plate-like struc-

shown in Fig. 2 of Practice E561 should be suitable for wider

tural components having a type of flaw likely to occur in

specimens.

service. The test is also used for research purposes to investi-

5.3.2 For tests at other than room temperature, the tempera-

gate failure mechanisms of cracks under service conditions.

ture control and temperature measurement requirements of Test

4.2 The residual strength of an SCT specimen is a function

Method E338 are appropriate.

of the crack depth and length and the specimen thickness as

5.4 Displacement Gage (Optional)—If used to measure

well as the characteristics of the material. This relationship is

CMOD, the displacement gage output should accurately indi-

extremely complex and cannot be completely described or

cate the relative displacement of two gage points on the

characterized at present.

cracked surface, spanning the crack at the midpoint of its

4.2.1 The results of the SCT test are suitable for direct

length. Further information on displacement gages appears in

application to design only when the service conditions exactly

Appendix X2.

parallel the test conditions. Some methods for further analysis

are suggested in Appendix X1. 5.5 For some combinations of material and crack geometry,

the crack may propagate entirely through the thickness prior to

4.3 In order that SCT test data can be comparable and

total failure. Methods of detecting this occurrence, should it be

reproducible and can be correlated among laboratories, it is

of interest, are discussed briefly in Ref. (1).

essential that uniform SCT testing practices be established.

6. Test Specimen

4.4 The specimen configuration, preparation, and instru-

mentation described in this practice are generally suitable for

6.1 Configuration and Notation—The SCT test specimen

cyclic- or sustained-force testing as well. However, certain

and the notation used herein are shown in Fig. 1. Grip details

constraints are peculiar to each of these tests. These are beyond

have been omitted, since grip design may depend on specimen

the scope of this practice but are discussed in Ref. (1).

size (5.3.1) and material toughness. In general, the only

gripping requirements are that the arrangement be strong

5. Apparatus

enough to carry the maximum expected force and that it allow

5.1 The procedure involves testing of specimens that have uniform distribution of force over the specimen cross section.

been precracked in fatigue. force versus CMOD, if CMOD is

6.2 Dimensions—The crack depth and length and specimen

measured, is recorded autographically or digitally.

thickness should be chosen according to the ultimate purpose

5.2 Fatigue Precracking Apparatus—Axial tension or three- of the test. Further discussion of this subject may be found in

point, four-point, or cantilever bending are all acceptable Appendix X3. The specimen width W should be at least 5 times

modes for fatigue precracking. Fixture design is not critical as the crack length 2c and the specimen test section length L

E740/E740M − 03 (2016)

starter is machined into the specimen surface at the center of

the test section (Fig. 2) to locate and help initiate the fatigue

crack. Regularity of crack configuration is influenced primarily

by fatigue force uniformity, which can be maximized by

careful alignment of force train and fixtures. Material

inhomogeneity, residual stresses, and starter notch root radius

variation can produce irregularities which may be beyond

control. Fatigue crack size and shape control are discussed in

Annex A1.

6.3.1 Crack starters have been produced by a variety of

methods. The following procedures are known to produce

acceptable results.

6.3.1.1 The crack starter should be machined, either by

slitting with a thin jeweler’s circular saw or similar cutter or by

electrical discharge machining (EDM) with a thin, shaped

electrode.

6.3.1.2 The crack starter plane should be perpendicular to

the specimen face and the tensile force vector within 10°.

6.3.1.3 The starter notch root radius should be less than

0.010 in. [0.25 mm].

6.3.1.4 The crack starter length and depth should be chosen

with the desired crack dimensions and the requirements of

6.3.2.2 in mind.

6.3.2 The following procedures should ensure the produc-

FIG. 1 Typical Surface-Crack Specimen (Grip Details Omitted)

tion of an effective sharp fatigue crack.

and Nomenclature

6.3.2.1 Fatigue crack with the specimen in the heat treat-

ment condition in which it is to be tested, if at all possible.

should be at least twice the width W. Should these width and

6.3.2.2 Whenever it is physically possible, the crack should

length dimensions exceed actual service dimensions, the ser-

be extended at least 0.05 in. [1.3 mm]; in any event the fatigue

vice dimensions should be used but one should not then

crack extension must not be less than 5 % of the final crack

attempt to generalize data from such tests.

depth, and the crack and its starter must lie entirely within an

imaginary 30° wedge whose apex is at the crack tip. These

6.3 Fatigue Precracking—The object is to produce at a

prescribed location a fatigue crack whose configuration is two-dimensional descriptions shall apply around the entire

crack front, that is, in all planes normal to tangents to all points

regular (that is, a half-ellipse or a segment of a circle), whose

depth and length are close to predetermined target values, and on the crack periphery (Fig. 2).

whose subsequent fracture behavior will not be influenced by 6.3.2.3 The ratio of minimum to maximum cyclic stress, R,

any detail of the preparation process. A small slit or crack should not be greater than 0.1.

NOTE 1—Section A-A refers to the plane normal to any tangent to the crack periphery and containing the point of tangency.

FIG. 2 Fatigue Crack and Starter Details

E740/E740M − 03 (2016)

6.3.2.4 For at least the final 2.5 % of the total crack depth, of a circle. If the crack shape is irregular or unsymmetric the

1/2 1/2

the ratio K /E should not exceed 0.002 in. [0.00032 m ], test should be discarded. Using the actual crack dimensions,

max

where K is the maximum stress intensity factor during verify that the requirement 6.3.2.4 was indeed met.

max

fatigue cracking and E is the material’s elastic modulus. An

7.6 Residual Strength—Calculate the residual strength as σ

r

estimate of K can be computed based on the cyclic stress

max

= P /(BW).

max

and the target crack dimensions using the appropriate equation

8. Report

from Annex A2. Compute K at the surface or at the deepest

max

point, whichever is greater.

8.1 The report should include the following for each speci-

men tested:

7. Procedure

8.1.1 Test section width, W, and thickness, B.

8.1.2 Maximum stress intensity factor during

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´2

Designation: E740/E740M − 03 (Reapproved 2010) E740/E740M − 03 (Reapproved 2016)

Standard Practice for

Fracture Testing with Surface-Crack Tension Specimens

This standard is issued under the fixed designation E740/E740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—The units statement (1.6) and the designation were editorially revised in January 2011.

ε NOTE—3.1.2 was editorially revised in May 2013.

1. Scope

1.1 This practice covers the design, preparation, and testing of surface-crack tension (SCT) specimens. It relates specifically to

testing under continuously increasing force and excludes cyclic and sustained loadings. The quantity determined is the residual

strength of a specimen having a semielliptical or circular-segment fatigue crack in one surface. This value depends on the crack

dimensions and the specimen thickness as well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by strength, thickness, or toughness. However, tests of thick specimens

of tough materials may require a tension test machine of extremely high capacity. The applicability of this practice to nonmetallic

materials has not been determined.

1.3 This practice is limited to specimens having a uniform rectangular cross section in the test section. The test section width

and length must be large with respect to the crack length. Crack depth and length should be chosen to suit the ultimate purpose

of the test.

1.4 Residual strength may depend strongly upon temperature within a certain range depending upon the characteristics of the

material. This practice is suitable for tests at any appropriate temperature.

1.5 Residual strength is believed to be relatively insensitive to loading rate within the range normally used in conventional

tension tests. When very low or very high rates of loading are expected in service, the effect of loading rate should be investigated

using special procedures that are beyond the scope of this practice.

NOTE 1—Further information on background and need for this type of test is given in the report of ASTM Task Group E24.01.05 on

Part-Through-Crack Testing (1).

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E338 Test Method of Sharp-Notch Tension Testing of High-Strength Sheet Materials (Withdrawn 2010)

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E561 Test Method forK Curve Determination

R

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture Mechanics.

Current edition approved Oct. 1, 2010Oct. 1, 2016. Published January 2011October 2016. Originally approved in 1988. Last previous edition approved in 20032010 as

ɛ2

E740 – 03.E740/E740M – 03(2010) . DOI: 10.1520/E0740-03R10E02.10.1520/E0740_E0740M-03R16.

The boldface numbers in parentheses refer to the list of references at the end of this standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E740/E740M − 03 (2016)

E1823 Terminology Relating to Fatigue and Fracture Testing

3. Terminology

3.1 Definitions:

3.1.1 Definitions given in Terminology E1823 are applicable to this practice.

3.1.2 crack mouth opening displacement (CMOD), 2v (L)—crack—opening displacement resulting from the total deformation

m

(elastic plus plastic) measured under force at the location on the crack surface that has the largest displacement per unit force.

NOTE 2—In surface-crack tension (SCT) specimens, CMOD is measured on the specimen surface along the normal bisector of the crack length.

3.1.3 fracture toughness—a generic term for measures of resistance to extension of a crack. E616

3.1.4 original crack size, a [L]—the physical crack size at the start of testing. (E616)

o

3.2 Definitions of Terms Specific to This Standard:

3.2.1 crack depth, a [L]—in surface-crack tension (SCT) specimens, the normal distance from the cracked plate surface to the

point of maximum penetration of the crack front into the material. Crack depth is a fraction of the specimen thickness.

3.2.1.1 Discussion—

In this practice, crack depth is the original depth a and the subscript o is everywhere implied.

o

3.2.2 crack length, 2c [L]—in surface-crack tension specimens, a distance measured on the specimen surface between the two

points at which the crack front intersects the specimen surface. Crack length is a fraction of specimen width.

3.2.2.1 Discussion—

In this practice, crack length is the original length 2c and the subscript o is everywhere implied.

o

−2

3.2.3 residual strength, σ (FL )—the maximum value of the nominal stress, neglecting the area of the crack, that a cracked

r

specimen is capable of sustaining.

NOTE 3—In surface-crack tension (SCT) specimens, residual strength is the ratio of the maximum load (P ) to the product of test section width (W)

max

times thickness (B), P /(BW). It represents the stress at fracture normal to and remote from the plane of the crack.

max

4. Significance and Use

4.1 The surface-crack tension (SCT) test is used to estimate the load-carrying capacity of simple sheet- or plate-like structural

components having a type of flaw likely to occur in service. The test is also used for research purposes to investigate failure

mechanisms of cracks under service conditions.

4.2 The residual strength of an SCT specimen is a function of the crack depth and length and the specimen thickness as well

as the characteristics of the material. This relationship is extremely complex and cannot be completely described or characterized

at present.

4.2.1 The results of the SCT test are suitable for direct application to design only when the service conditions exactly parallel

the test conditions. Some methods for further analysis are suggested in Appendix X1.

4.3 In order that SCT test data can be comparable and reproducible and can be correlated among laboratories, it is essential that

uniform SCT testing practices be established.

4.4 The specimen configuration, preparation, and instrumentation described in this practice are generally suitable for cyclic- or

sustained-force testing as well. However, certain constraints are peculiar to each of these tests. These are beyond the scope of this

practice but are discussed in Ref. (1).

5. Apparatus

5.1 The procedure involves testing of specimens that have been precracked in fatigue. force versus CMOD, if CMOD is

measured, is recorded autographically or digitally.

5.2 Fatigue Precracking Apparatus—Axial tension or three-point, four-point, or cantilever bending are all acceptable modes for

fatigue precracking. Fixture design is not critical as long as the crack growth is symmetrical and the plane of the crack remains

perpendicular to the specimen face and the tensile force vector. The effect of cyclic frequency is thought to be negligible below

100 Hz in a nonaggressive environment.

NOTE 4—Certain crack shapes are more readily produced in axial tension, others in bending (see Annex A1).

5.2.1 Devices and fixtures for cantilever bending of sheet and plate specimens are described in Refs. (2) and (3), respectively.

Others may be equally suitable. The axial fatigue machines described in Practice E466 are suitable for precracking in tension;

E740/E740M − 03 (2016)

however, since the precracking operation is terminated prior to specimen failure, one should ensure that load variations during

slowdown or shutdown do not exceed those desired.

5.2.2 A magnifier of about 20 power should be used to monitor the fatigue precracking process. Ease of observation will be

enhanced if the cyclic rate can be reduced to about 1 Hz when desired. Alternatively, a stroboscopic light synchronized with the

maximum application of tensile force may serve as well.

5.3 Testing Machine—The test should be conducted with a tension testing machine that conforms to the requirements of

Practices E4.

5.3.1 The devices for transmitting force to the specimen shall be such that the major axis of the specimen coincides with the

load axis. The pin-and-clevis arrangement described in Test Method E338 should be suitable for specimens whose width is less

than about 4 in. [100 mm]. An arrangement such as that shown in Fig. 2 of Practice E561 should be suitable for wider specimens.

5.3.2 For tests at other than room temperature, the temperature control and temperature measurement requirements of Test

Method E338 are appropriate.

5.4 Displacement Gage (Optional)—If used to measure CMOD, the displacement gage output should accurately indicate the

relative displacement of two gage points on the cracked surface, spanning the crack at the midpoint of its length. Further

information on displacement gages appears in Appendix X2.

5.5 For some combinations of material and crack geometry, the crack may propagate entirely through the thickness prior to total

failure. Methods of detecting this occurrence, should it be of interest, are discussed briefly in Ref. (1).

6. Test Specimen

6.1 Configuration and Notation—The SCT test specimen and the notation used herein are shown in Fig. 1. Grip details have

been omitted, since grip design may depend on specimen size (5.3.1) and material toughness. In general, the only gripping

requirements are that the arrangement be strong enough to carry the maximum expected force and that it allow uniform distribution

of force over the specimen cross section.

6.2 Dimensions—The crack depth and length and specimen thickness should be chosen according to the ultimate purpose of the

test. Further discussion of this subject may be found in Appendix X3. The specimen width W should be at least 5 times the crack

length 2c and the specimen test section length L should be at least twice the width W. Should these width and length dimensions

exceed actual service dimensions, the service dimensions should be used but one should not then attempt to generalize data from

such tests.

6.3 Fatigue Precracking—The object is to produce at a prescribed location a fatigue crack whose configuration is regular (that

is, a half-ellipse or a segment of a circle), whose depth and length are close to predetermined target values, and whose subsequent

fracture behavior will not be influenced by any detail of the preparation process. A small slit or crack starter is machined into the

FIG. 1 Typical Surface-Crack Specimen (Grip Details Omitted) and Nomenclature

E740/E740M − 03 (2016)

specimen surface at the center of the test section (Fig. 2) to locate and help initiate the fatigue crack. Regularity of crack

configuration is influenced primarily by fatigue force uniformity, which can be maximized by careful alignment of force train and

fixtures. Material inhomogeneity, residual stresses, and starter notch root radius variation can produce irregularities which may be

beyond control. Fatigue crack size and shape control are discussed in Annex A1.

6.3.1 Crack starters have been produced by a variety of methods. The following procedures are known to produce acceptable

results.

6.3.1.1 The crack starter should be machined, either by slitting with a thin jeweler’s circular saw or similar cutter or by electrical

discharge machining (EDM) with a thin, shaped electrode.

6.3.1.2 The crack starter plane should be perpendicular to the specimen face and the tensile force vector within 10°.

6.3.1.3 The starter notch root radius should be less than 0.010 in. [0.25 mm].

6.3.1.4 The crack starter length and depth should be chosen with the desired crack dimensions and the requirements of 6.3.2.2

in mind.

6.3.2 The following procedures should ensure the production of an effective sharp fatigue crack.

6.3.2.1 Fatigue crack with the specimen in the heat treatment condition in which it is to be tested, if at all possible.

6.3.2.2 Whenever it is physically possible, the crack should be extended at least 0.05 in. [1.3 mm]; in any event the fatigue crack

extension must not be less than 5 % of the final crack depth, and the crack and its starter must lie entirely within an imaginary

30° wedge whose apex is at the crack tip. These two-dimensional descriptions shall apply around the entire crack front, that is,

in all planes normal to tangents to all points on the crack periphery (Fig. 2).

6.3.2.3 The ratio of minimum to maximum cyclic stress, R, should not be greater than 0.1.

1/2 1/2

6.3.2.4 For at least the final 2.5 % of the total crack depth, the ratio K /E should not exceed 0.002 in. [0.00032 m ], where

max

K is the maximum stress intensity factor during fatigue cracking and E is the material’s elastic modulus. An estimate of K

max max

can be computed based on the cyclic stress and the target crack dimensions using the appropriate equation from Annex A2.

Compute K at the surface or at the deepest point, whichever is greater.

max

7. Procedure

7.1 Number of Tests—If only one crack geometry (that is, fixed crack depth and length) is to be studied, at least three specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.