ASTM F2773-09

(Practice)Standard Practice for Transfilling Compressed Air or Nitrogen and Safe Handling of Small Paintball Cylinders

Standard Practice for Transfilling Compressed Air or Nitrogen and Safe Handling of Small Paintball Cylinders

ABSTRACT

This practice details the basic procedures for the safe handling and transfilling of small (not bulk) paintball compressed air cylinders commonly used with a paintball marker for propulsion of a paintball. It does not address issues related to the transfilling, storage, and handling of supply cylinders that may be used in transfilling smaller cylinders. Included herein are general safety considerations, requirements for fill stations, and compressed air/nitrogen fill procedures for the pressure cylinder transfilling method most commonly used by paintball fields or store operators, or both.

SCOPE

DESIG

1.1 This practice is intended to satisfy the demand for information on the basic procedures for the safe handling and transfilling of small (not bulk) paintball compressed air cylinders commonly used with a paintball marker for propulsion of a paintball. This standard does not address issues dealing with the transfilling, storage, and handling of supply cylinders that may be used in transfilling smaller cylinders.

1.2 The compressed air fill procedures are written for the pressure cylinder transfilling method most commonly used by paintball field or store operators, or both.

1.3 This document should not be confused with federal, state, provincial, or municipal specifications or regulations; insurance requirements; or national safety codes.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations, such as and not limited to DOT, CGA, and OSHA, prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2773 – 09

Standard Practice for

Transfilling Compressed Air or Nitrogen and Safe Handling

of Small Paintball Cylinders

This standard is issued under the fixed designation F2773; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This standard is intended to provide basic procedures for the safe handling and transfilling of small

(not bulk) paintball compressed air cylinders commonly used with a paintball marker for propulsion

of a paintball.

This practice is written within the current state-of-the-art of transfilling compressed gas technology.

The intent is to revise this specification whenever substantive information becomes available which

justifies revising existing requirements or adding new requirements.

1. Scope 2. Referenced Documents

1.1 This practice is intended to satisfy the demand for 2.1 ASTM Standards:

information on the basic procedures for the safe handling and F1979 Specification for Paintballs Used in the Sport of

transfilling of small (not bulk) paintball compressed air cylin- Paintball

ders commonly used with a paintball marker for propulsion of 2.2 CGA Standards:

a paintball. This standard does not address issues dealing with CGAC-6.1 Standards for visual inspection of high pressure

the transfilling, storage, and handling of supply cylinders that aluminum compressed gas cylinders

may be used in transfilling smaller cylinders. CGA C-6.2 Guidelines for visual inspection and requalifi-

1.2 The compressed air fill procedures are written for the cation of fiber reinforced high pressure cylinders

pressure cylinder transfilling method most commonly used by 2.3 Federal Standards:

paintball field or store operators, or both. CFR 49 Parts 100 to 185

1.3 This document should not be confused with federal,

3. Terminology

state, provincial, or municipal specifications or regulations;

3.1 Definitions:

insurance requirements; or national safety codes.

1.4 The values stated in inch-pound units are to be regarded 3.1.1 blow-down valve, n—valve which is part of a fill

station assembly, and which is intended to vent gas from the

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only paintball cylinder being filled.

3.1.2 fill station, n—device designed to attach to a supply

and are not considered standard.

1.5 This standard does not purport to address all of the cylinderandtoapaintballcylinderwhichfacilitatestransfilling

the paintball cylinder.

safety concerns, if any, associated with its use. It is the

3.1.3 paintball, n—spherical ball, commonly with a diam-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- eter of 0.68 in. (17.3 mm), comprised of a shell and a fill,

designed to be expelled from a paintball marker and conform-

bility of regulatory limitations, such as and not limited to DOT,

CGA, and OSHA, prior to use. ing to Specification F1979.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This practice is under the jurisdiction of ASTM Committee F08 on Sports Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

Equipment and Facilities and is the direct responsibility of Subcommittee F08.24 on Floor, Chantilly, VA 20151-2923, http://www.cganet.com.Available from

Paintball and Equipment. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

Current edition approved June 1, 2009. Published July 2009. DOI: 10.1520/ 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

F2773-09. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2773 – 09

4. General Considerations

3AL The specification standard the cylinder conforms

to

4.1 Persons, who are transfilling compressed air, should be

3000 The working pressure rating of the cylinder

trained in the hazards associated with compressed air or

M4625 The manufacturer’s name or number of the cyl-

inder

nitrogen, or both.

04^03 The hydrostatic test date of the cylinder.

4.2 Always wear eye protection while filling cylinders.

The first two digits are the month.

4.3 Always have any required MSDS at the location that the The ^ is the testing agency mark.

The last two digits are the year.

filling takes place.

The above date would be valid to use until April

4.4 Always read and understand all fill station instructions.

1, 2008.

4.5 Ensure that there is proper ventilation in the filling area. A051391 The serial number of the tank.

4.6 The receiving cylinder (paintball cylinder) must be of a

NOTE 1—Re-qualification period for cylinders is typically five (5) years

refillable type (that is, not disposable) and pressure rating that

for 3 AL aluminum cylinders.

it can safely hold stamped or marked on the cylinder.

(1) An example of a composite wrapped tank label:

4.7 Supply cylinders must be secured and supported, such

asfastenedtoawallorsimilarimmovablestructure(thatis,not

free standing).

5. Fill Stations

5.1 Fill stations and related equipment should be rated the

same as the supply tank.

5.2 Fill stations should be used for the purpose of transfill-

ing compressed air or nitrogen, or both, for the paintball

industry only.

5.3 Fill stations shall be supplied with instructions by the

manufacturer or distributor of the product.

5.4 Fill stations should be marked or tagged with safety

warnings.

5.4.1 Read owners manual before using.

The label translates as follows:

5.4.2 Use only with compressed air or nitrogen. 68cu Cylinder size in cubic inches

TC-3FCM-207 Transport Canada approval

5.4.3 Do not use for oxygen.

DOT Department of Transportation

5.4.4 Close bulk tank valve when not in use.

E9634 Exemption number

5.4.5 Vent down system.

3000 Cylinder working pressure

DK 117512 The serial number of the tank

5.4.6 Never add or introduce oil to the fill station, cylinder,

LUXFER Cylinder manufacturer

or regulator/valve.

5 ^ 07 The hydrostatic test date of the cylinder

The first two digits are the month

The ^ is the testing agency mark

6. Cylinder Inspection

The last two digits are the year

The above date would be valid to use until May 1, 2010

6.1 Ensure that the regulator is properly attached to the

cylinder.

(2) After hydrostatic testing, the retest date will look like

6.2 Ensure that the regulator is in good, serviceable condi-

this:

tion.

6.2.1 Ensure that the proper cylinder safety burst disk is

installed correctly.

6.3 Visually inspect the cylinder condition before each fill.

6.3.1 Cylinders must be stamped or labeled with a DOT

(Department of Transportation) or potentially TC (Transport

Canada) mark working pressure, manufacturer’s code or name,

serial number, and hydrostatic test date.

6.3.1.1 An example of an aluminum cylinder shoulder

stamping:

Label attached to bottle with epoxy

G7

12 7 7 07

The first two digits are the month

The G7 is the re-testing agency RIN (Re-testers identification number)

6.3.1.2 DOT – 3AL 3000 M4625 04^03 A051391

The cylinder neck layline translates as follows:

The RIN number is read in a clock wise direction, G777

DOT Department of Transportation (a Federal Agency) Contact D.O.T. for RIN information

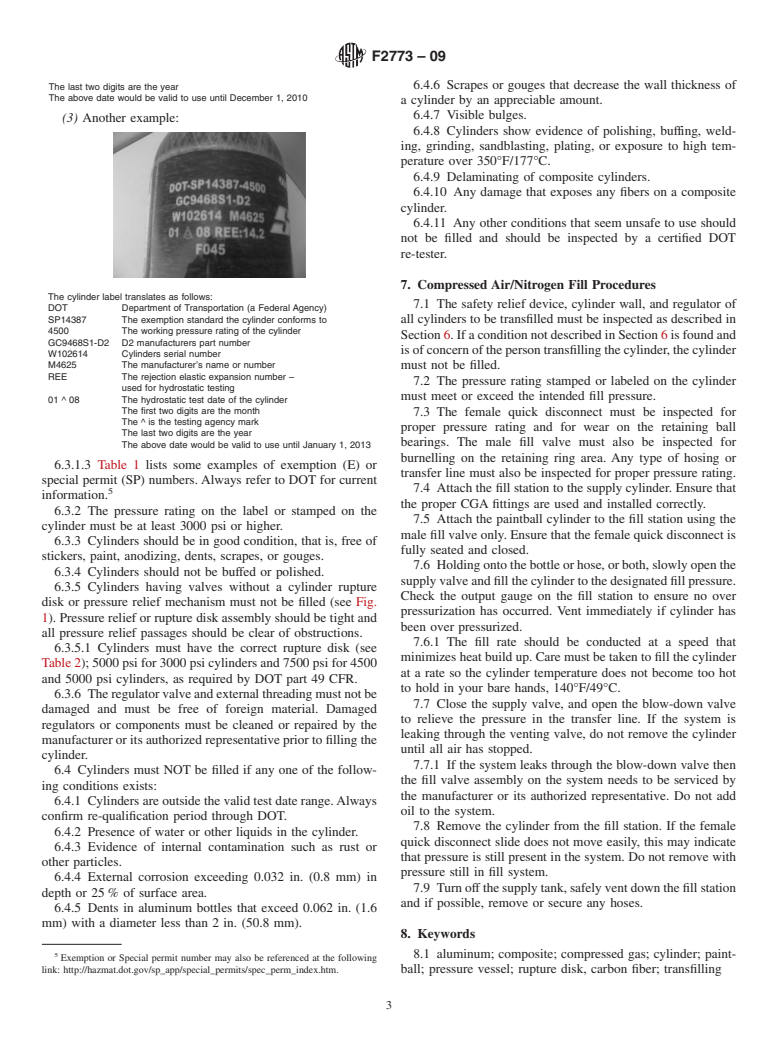

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.