ASTM B827-05(2020)

(Practice)Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

Standard Practice for Conducting Mixed Flowing Gas (MFG) Environmental Tests

SIGNIFICANCE AND USE

4.1 Mixed flowing gas (MFG) tests are used to simulate or amplify exposure to environmental conditions which electrical contacts or connectors can be expected to experience in various application environments (1, 2).4

4.2 Test samples which have been exposed to MFG tests have ranged from bare metal surfaces, to electrical connectors, and to complete assemblies.

4.3 The specific test conditions are usually chosen so as to simulate, in the test laboratory, the effects of certain representative field environments or environmental severity levels on standard metallic surfaces, such as copper and silver coupons or porous gold platings (1, 2).

4.4 Because MFG tests are simulations, both the test conditions and the degradation reactions (chemical reaction rate, composition of reaction products, etc.) may not always resemble those found in the service environment of the product being tested in the MFG test. A guide to the selection of simulation conditions suitable for a variety of environments is found in Guide B845.

4.5 The MFG exposures are generally used in conjunction with procedures which evaluate contact or connector electrical performance such as measurement of electrical contact resistance before and after MFG exposure.

4.6 The MFG tests are useful for connector systems whose contact surfaces are plated or clad with gold or other precious metal finishes. For such surfaces, environmentally produced failures are often due to high resistance or intermittences caused by the formation of insulating contamination in the contact region. This contamination, in the form of films and hard particles, is generally the result of pore corrosion and corrosion product migration or tarnish creepage from pores in the precious metal coating and from unplated base metal boundaries, if present.

4.7 The MFG exposures can be used to evaluate novel electrical contact metallization for susceptibility to degradation due to environmental exposure to the test corrosive gases...

SCOPE

1.1 This practice provides procedures for conducting environmental tests involving exposures to controlled quantities of corrosive gas mixtures.

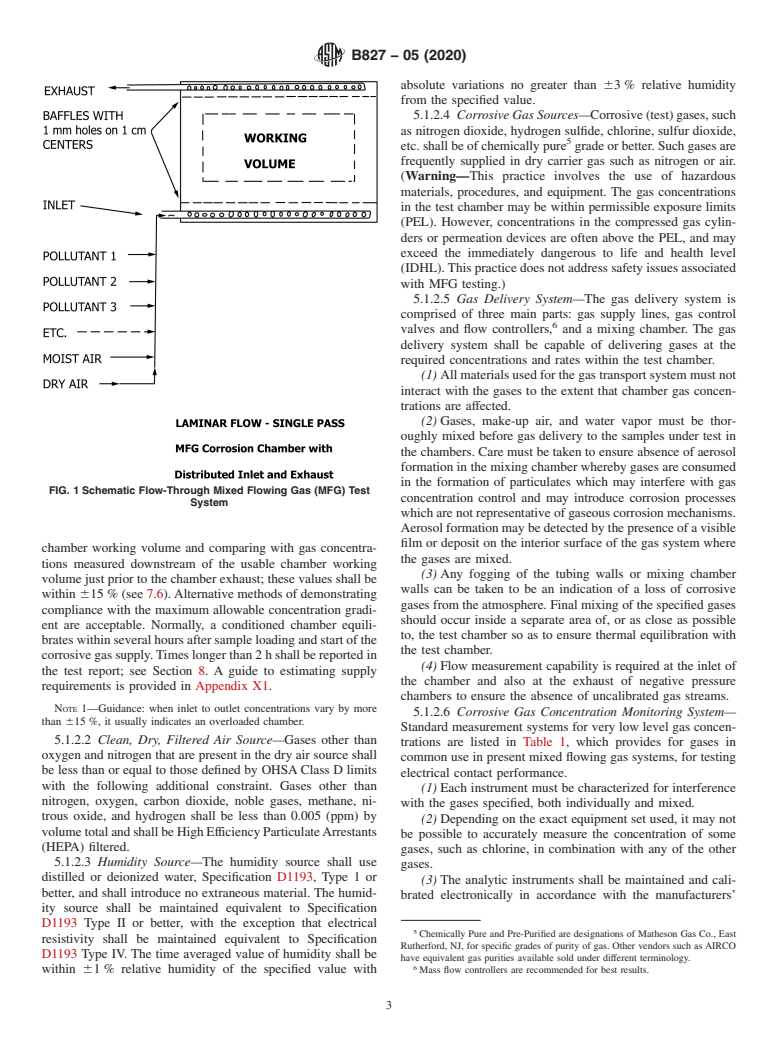

1.2 This practice provides for the required equipment and methods for gas, temperature, and humidity control which enable tests to be conducted in a reproducible manner. Reproducibility is measured through the use of control coupons whose corrosion films are evaluated by mass gain, coulometry, or by various electron and X-ray beam analysis techniques. Reproducibility can also be measured by in situ corrosion rate monitors using electrical resistance or mass/frequency change methods.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety, health, and environmental practices, and determine the applicability of regulatory limitations prior to use. See 5.1.2.4.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B827 − 05 (Reapproved 2020)

Standard Practice for

1

Conducting Mixed Flowing Gas (MFG) Environmental Tests

This standard is issued under the fixed designation B827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B542 Terminology Relating to Electrical Contacts and Their

Use

1.1 This practice provides procedures for conducting envi-

B765 Guide for Selection of Porosity and Gross Defect Tests

ronmental tests involving exposures to controlled quantities of

for Electrodeposits and Related Metallic Coatings

corrosive gas mixtures.

B808 Test Method for Monitoring of Atmospheric Corrosion

1.2 This practice provides for the required equipment and

Chambers by Quartz Crystal Microbalances

methods for gas, temperature, and humidity control which

B810 Test Method for Calibration of Atmospheric Corrosion

enable tests to be conducted in a reproducible manner. Repro-

Test Chambers by Change in Mass of Copper Coupons

ducibility is measured through the use of control coupons

B825 Test Method for Coulometric Reduction of Surface

whose corrosion films are evaluated by mass gain, coulometry,

Films on Metallic Test Samples

or by various electron and X-ray beam analysis techniques.

B826 Test Method for Monitoring Atmospheric Corrosion

Reproducibility can also be measured by in situ corrosion rate

Tests by Electrical Resistance Probes

monitors using electrical resistance or mass/frequency change

B845 Guide for Mixed Flowing Gas (MFG) Tests for Elec-

methods.

trical Contacts

1.3 The values stated in SI units are to be regarded as

D1193 Specification for Reagent Water

standard. No other units of measurement are included in this

D2912 Test Method for Oxidant Content of the Atmosphere

standard.

3

(Neutral Ki) (Withdrawn 1990)

1.4 This standard does not purport to address all of the

D2914 Test Methods for Sulfur Dioxide Content of the

safety concerns, if any, associated with its use. It is the

Atmosphere (West-Gaeke Method)

responsibility of the user of this standard to become familiar

D3449 Test Method for Sulfur Dioxide in Workplace Atmo-

with all hazards including those identified in the appropriate

3

spheres (Barium Perchlorate Method) (Withdrawn 1989)

Material Safety Data Sheet (MSDS) for this product/material

D3464 Test Method for Average Velocity in a Duct Using a

as provided by the manufacturer, to establish appropriate

Thermal Anemometer

safety, health, and environmental practices, and determine the

D3609 Practice for Calibration Techniques Using Perme-

applicability of regulatory limitations prior to use. See 5.1.2.4.

ation Tubes

1.5 This international standard was developed in accor-

D3824 Test Methods for Continuous Measurement of Ox-

dance with internationally recognized principles on standard-

ides of Nitrogen in the Ambient or Workplace Atmosphere

ization established in the Decision on Principles for the

by Chemiluminescence

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical D4230 Test Method for Measuring Humidity with Cooled-

Barriers to Trade (TBT) Committee. Surface Condensation (Dew-Point) Hygrometer

E902 Practice for Checking the Operating Characteristics of

3

2. Referenced Documents

X-Ray Photoelectron Spectrometers (Withdrawn 2011)

2

2.1 ASTM Standards: G91 Practice for Monitoring Atmospheric SO Deposition

2

Rate for Atmospheric Corrosivity Evaluation

1

This practice is under the jurisdiction of ASTM Committee B02 on Nonferrous

3. Terminology

Metals and Alloys and is the direct responsibility of Subcommittee B02.05 on

Precious Metals and Electrical Contact Materials and Test Methods.

3.1 Definitions relating to electrical contacts are in accor-

Current edition approved April 1, 2020. Published April 2020. Originally

dance with Terminology B542.

approved in 1992. Last previous edition approved in 2014 as B827 – 05 (2014).

DOI: 10.1520/B0827-05R20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B827 − 05 (2020)

4.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.