ASTM F1835-97(2012)e1

(Guide)Standard Guide for Cable Splicing Installations

Standard Guide for Cable Splicing Installations

SIGNIFICANCE AND USE

4.1 Splicing of cables in the shipbuilding industry, both in Navy and commercial undertakings, has been concentrated in repair, conversion, or overhaul programs. However, many commercial industries, including aerospace and nuclear power, have standards defining cable splicing methods and materials that establish the quality of the splice to prevent loss of power or signal, ensure circuit continuity, and avoid potential catastrophic failures. This guide presents cable splicing techniques and hardware for application to commercial and Navy shipbuilding to support the concept of modular ship construction.

4.2 This guide resulted from a study that evaluated the various methods of cable splicing, current technologies, prior studies and recommendations, performance testing, and the expertise of manufacturers and shipbuilders in actual cabling splicing techniques and procedures.

4.3 The use of this guide by a shipbuilder will establish cabling splicing systems that are: simple and safe to install; waterproof; corrosion- and impact-resistant; industry accepted with multiple suppliers available; low-cost methods; and suitable for marine, Navy, and IEC cables.

SCOPE

1.1 This guide provides direction and recommends cable splicing materials and methods that would satisfy the requirements of extensive cable splicing in modular ship construction and offers sufficient information and data to assist the shipbuilder in evaluating this option of cable splicing for future ship construction.

1.2 This guide deals with cable splicing at a generic level and details a method that will satisfy the vast majority of cable splicing applications.

1.3 This guide covers acceptable methods of cable splicing used in shipboard cable systems and provides information on current applicable technologies and additional information that the shipbuilder may use in decision making for the cost effectiveness of splicing in electrical cable installations.

1.4 This guide is limited to applications of 2000 V or less, but most of the materials and methods discussed are adaptable to higher voltages, such as 5-kV systems. The cables of this guide relate to all marine cables, domestic and foreign, commercial or U.S. Navy.

1.5 The values stated in SI units shall be regarded as standard. The values given in parentheses are inch-pound units and are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the application of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F1835 − 97 (Reapproved 2012) An American National Standard

Standard Guide for

Cable Splicing Installations

This standard is issued under the fixed designation F1835; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reapproved with editorial changes throughout the guide in October 2012.

1. Scope B8 Specification for Concentric-Lay-Stranded Copper

Conductors, Hard, Medium-Hard, or Soft

1.1 This guide provides direction and recommends cable

D2671 Test Methods for Heat-Shrinkable Tubing for Elec-

splicing materials and methods that would satisfy the require-

trical Use

ments of extensive cable splicing in modular ship construction

2.2 IEEE Standards:

and offers sufficient information and data to assist the ship-

IEEE 45 Recommended Practice for Electrical Installations

builder in evaluating this option of cable splicing for future

on Shipboard

ship construction.

2.3 UL Standards:

1.2 This guide deals with cable splicing at a generic level

UL STD 224 Extruded Insulating Tubing

and details a method that will satisfy the vast majority of cable

ULSTD 486A Wire Connectors and Soldering Lugs for Use

splicing applications.

with Copper Conductors

1.3 This guide covers acceptable methods of cable splicing

2.4 IEC Standards:

used in shipboard cable systems and provides information on

IEC 228 Conductors of Insulated Cables

current applicable technologies and additional information that

2.5 Federal Regulations:

the shipbuilder may use in decision making for the cost

Title 46 Code of Federal Regulations (CFR), Shipping

effectiveness of splicing in electrical cable installations.

2.6 Military Specifications:

MIL-T-16366 Terminals, Electric Lug and Conductor

1.4 This guide is limited to applications of 2000 V or less,

Splices, Crimp-Style

but most of the materials and methods discussed are adaptable

MIL-T-7928 Terminals, Lug, Splices, Conductors, Crimp-

to higher voltages, such as 5-kV systems. The cables of this

Style, Copper

guide relate to all marine cables, domestic and foreign,

commercial or U.S. Navy.

3. Terminology

1.5 The values stated in SI units shall be regarded as

3.1 Definitions of Terms Specific to This Standard:

standard. The values given in parentheses are inch-pound units

3.1.1 adhesive, n—a wide range of materials used exten-

and are for information only.

sively for bonding and sealing; coating added to the inner wall

1.6 This standard does not purport to address all of the

of heat-shrinkable tubing to seal the enclosed area against

safety concerns, if any, associated with its use. It is the

moisture. Adhesive is for pressure retention and load-bearing

responsibility of the user of this standard to establish appro-

applications (see also sealant).

priate safety and health practices and determine the applica-

3.1.2 barrel, n—the portion of a terminal that is crimped;

tion of regulatory limitations prior to use.

designed to receive the conductor, it is called the wire barrel.

2. Referenced Documents

3.1.3 butt connector, n—a connector in which two conduc-

tors come together end to end with their axes in line, but do not

2.1 ASTM Standards:

overlap.

This guide is under the jurisdiction of ASTM Committee F25 on Ships and

Marine Technology and is the direct responsibility of Subcommittee F25.10 on Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

Electrical. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Current edition approved Oct. 1, 2012. Published October 2012. Originally Available from Underwriters Laboratories (UL), 333 Pfingsten Rd.,

approved in 1997. Last previous edition approved in 2007 as F1835 – 97 (2007). Northbrook, IL 60062-2096, http://www.ul.com.

DOI: 10.1520/F1835-97R12E01. Available from International Electrotechnical Commission (IEC), 3, rue de

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Varembé, P.O. Box 131, CH-1211 Geneva 20, Switzerland, http://www.iec.ch.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standards volume information, refer to the standard’s Document Summary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. dodssp.daps.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F1835 − 97 (2012)

3.1.4 butt splice, n—device for joining conductors by butt- waterproof; corrosion- and impact-resistant; industry accepted

ing them end to end. with multiple suppliers available; low-cost methods; and suit-

able for marine, Navy, and IEC cables.

3.1.5 circumferential crimp, n—final configuration of a

barrelmadewhencrimpingdiescompletelysurroundthebarrel

5. General Requirements for Cable Splicing

and form symmetrical indentations.

5.1 Cable splicing requires that cable joints be insulated and

3.1.6 compression connector, n—connector crimped by an

sealed with an insulation equal in electrical and mechanical

externally applied force; the conductor is also crimped by such

properties to the original cable. Cable splicing shall consist of

force inside the tube-like connector body.

a conductor connector, replacement of conductor insulation,

3.1.7 cold-shrink tubing, n—tubular rubber sleeves that are

replacement of the overall cable jacket, and where applicable,

factory expanded and assembled onto a removable core. No

reestablishment of shielding in shielded cables and electric

heat is used in installation. Also known as prestretched tubing

continuity in the armor of armored cables.

(PST).

5.2 Nonsplice Applications—Unacceptable areas for cable

3.1.8 crimp connectors, n—tubular copper connectors made

splices are established by regulations and concern the restric-

to match various wire sizes and fastened to the conductor ends

tionofbeingunabletosplicecablesindefinedhazardousareas.

by means of a crimping tool.

Hazardous areas are locations in which fire or explosion

3.1.9 crimping die, n—portion of the crimping tool that

hazards may exist as a result of flammable gases or vapors,

shapes the crimp.

flammable liquids, combustible dust, or ignitable fibers or

3.1.10 crimping tool, n—amechanicaldevice,whichisused

flyings.

tofastenelectricalconnectorstocableconductorsbyforcefully

compressing the connector onto the conductor. This tool may

6. Cable Splicing

have interchangeable dies or “jaws” to fit various size connec-

6.1 Cable splicing as presented in this guide uses a system

tors.

of compression-crimp, tubular-metal connectors for butt con-

3.1.11 heat-shrink tubing, n—electrical insulation tubing of

nection of cable conductors and insulating systems of shrink-

a polyolefin material, which shrink in diameter from an

able tubing to reinsulate the individual conductors and replace

expanded size to a predetermined size by the application of

the overall cable jacket.

heat. It is available in various diameter sizes.

6.2 Crimp Connectors—For splice connection of

3.1.12 primary insulation, n—the layer of material that is

conductors, compression-crimped connectors shall be used for

designedtodotheelectricalinsulating,usuallythefirstlayerof

joininganelectricalconductor(wire)toanotherconductor.The

material applied over the conductor.

joint requires proper compression to achieve good electrical

3.1.13 sealant, n—inner-wall coating optional to shrinkable

performance while not overcompressing and mechanically

tubing to prevent ingress of moisture to the enclosed area (see damaging the conductor. Compression connections are accom-

also adhesive).

plished by applying a controlled force on a barrel sleeve to the

conductor with special tools and precision dies.

3.1.14 splice, n—a joint connecting conductors with good

mechanical strength and good conductivity.

6.3 Conductor Reinsulation—Thin-wall shrinkable tubing

shall be used to reinsulate the conductor and the installed

3.1.15 tensile, n—amount of axial load required to break or

connector. The insulation tubing, when shrunk or recovered,

pull wire from the crimped barrel of a terminal or splice.

shall be equal in electrical and mechanical properties to the

4. Significance and Use original conductor insulation. Tubing used for conductor rein-

sulation does not require an interior adhesive sealant coating.

4.1 Splicing of cables in the shipbuilding industry, both in

Navy and commercial undertakings, has been concentrated in 6.4 Cable Jacket Reinsulation—Shrinkable tubing shall be

repair, conversion, or overhaul programs. However, many used to envelop the overall splice. To satisfy more abusive

commercial industries, including aerospace and nuclear power, conditions that cable jackets are exposed to, a flame-retardant,

have standards defining cable splicing methods and materials thick-wall tubing construction with factory applied sealant

that establish the quality of the splice to prevent loss of power shall be used.

or signal, ensure circuit continuity, and avoid potential cata-

strophic failures. This guide presents cable splicing techniques 7. Cable Preparation

and hardware for application to commercial and Navy ship-

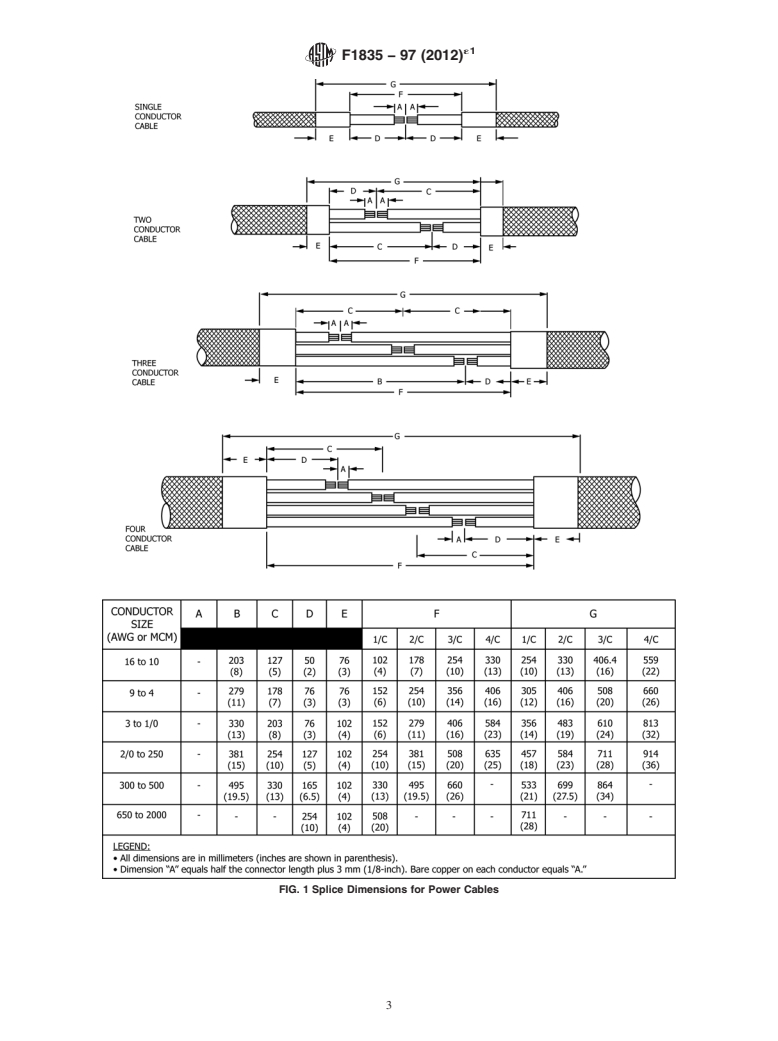

7.1 Cables to be spliced shall be prepared to the dimensions

building to support the concept of modular ship construction.

specified in Fig. 1 and Fig. 2. Fig. 1 provides cable preparation

4.2 This guide resulted from a study that evaluated the for power cables from single to four conductor sizes. Dimen-

various methods of cable splicing, current technologies, prior sions for multiple conductor cables (conductor size of No. 14

studies and recommendations, performance testing, and the or less) are shown in Fig. 2.

expertise of manufacturers and shipbuilders in actual cabling

7.2 Care must be exercised when preparing the cable ends

splicing techniques and procedures.

so that conductor insulation is not cut when removing the

4.3 The use of this guide by a shipbuilder will establish overall cable jacket, shield, or cable armor, where applicable.

cabling splicing systems that are: simple and safe to install; Similarcareisrequiredwhenremovingtheindividualshieldor

´1

F1835 − 97 (2012)

FIG. 1 Splice Dimensions for Power Cables

´1

F1835 − 97 (2012)

FIG. 2 Splice Dimensions for Control-Multiple Conductor Cables

insulation protecting the conductor to prevent cuts or nicks on 7.3 Match the geometrical arrangement between cables to

the individual conductor strands. be spliced using conductor color code identification to elimi-

7.2.1 Insulation cutting tools that limit depth of cut should nate crossovers or mismatch when splicing.

be used to prepare cable ends so that underlying insulation is

7.4 Cable ends shall be in or near their final position before

not cut. Similar care is required when removing the individual

being spliced.

conductor insulation to protect the conductor copper strands

from nicks and cuts.

8. Materials and Tools

7.2.2 Cable preparation shall result in stripping the indi-

vidual conductors so that the bare copper is long enough to 8.1 Cable Splicing Materials—The following sections pro-

reach the full depth of the butt connector plus 3.2 mm ( ⁄8 in.). vide an overview of the various splice materials. In addition,

´1

F1835 − 97 (2012)

specific recommendations and suggested guidelines are offered in accordance with UL STD 224 requirements. Performance

that would enhance the cable splicing process. requirements shall include:

8.1.1 Crimp-Type Connectors—Splice connectors shall be

Shrink ratio 2:1

Operating temperature range –55 to +135°C

compression-type, butt connectors conforming to the require-

Minimum shrinkage temperature +121°C

ments of UL STD 486A and shall be satisfactory to Section

Longitudinal shrinkage ±5 %

20.11 of IEEE 45.

Electrical rating 600-V continuous operation

Dielectric strength in accordance with 19.7 kV/mm (500 V/mil) min

8.1.1.1 Connector shall be seamless, tin-plated copper.

Test Methods D2671

8.1.1.2 Butt connector shall have positive center wire stops

for proper depth of conductor insertion. 8.1.2.3 Shrink tubing to cover the connection of individual

8.1.1.3 Connectors shall be marked with wire size for easy conductors does not require an interior coating of adhesive

identification. (mastic) sealant.

8.1.1.4 Connector shall have inspection holes to allow

8.1.3 Cable Jacket Replacement Materials—Several meth-

visual inspection for proper wire insertion.

odsandavarietyofmaterialsareavailablethatwillprovidethe

8.1.1.5 Butt connector for wire sizes No. 10 (AWG) or

mechanical protection, moisture-sealing properties, and elec-

larger shall be the “long barrel” type to permit multiple crimps

trical performance characteristics needed in a cable splice. For

on each side of the connector for greater tensile strength. The

a splice reliability and ease of installation replacement of cable

conductorendsshallbefullyinsertedtothe“stop”atthecenter

jacket and to envelop the splice area, however, either the

of the connector. For smaller conductor sizes (No. 10AWG or

heat-shrink or the cold-shrink (prestretched) type shall be used.

less), a single crimp should be spaced half way between the

8.1.3.1 The tubing used, when recovered or shrunk, shall be

end of the connector and the center wire stop.

equal to or greater than the thickness of the original conductor

8.1.1.6 Connector shall be color-coded in accordance with

insulation (see Table 3).

Table 1 or Table 2.

8.1.3.2 The tubing used for cable jacket replacement shall

8.1.2 Conductor Reinsulating Material—To reinsulate the

be thick wall, also referred to as heavy-duty shrink tubing,

conductor and the installed connector, heat-shrink tubing shall

cross-linked polyolefin tubing.

be used (see Table 3).

8.1.3.3 Shrink tubing shall be flame retardant (FR-1) in

8.1.2.1 When recovered or shrink, the tubing used shall be

accordance with UL STD 224 requirements.

equal to or greater than the thickness of the original conductor

8.1.3.4 Tubing used for rejacketing of a splice bundle shall

insulation.

have an interior coating of adhesive (mastic) sealant.

8.1.2.2 Shrink tubing used for conductor reinsulation shall

be heat-shrink tubing. The tubing shall be thin-wall cross- 8.1.3.5 Table 3 provides dimensions for thick-wall tubing

linked polyolefin tubing, flame-retardant (FR-1) construction used for rejacketing of cables.

TABLE 1 Connector Data

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.