ASTM D7267-13

(Test Method)Standard Test Method for Edge Ravel Resistance of Finished Loop Pile, Pile Yarn Floor Covering

Standard Test Method for Edge Ravel Resistance of Finished Loop Pile, Pile Yarn Floor Covering

SIGNIFICANCE AND USE

5.1 The satisfactory performance of a loop pile floor covering depends, to a considerable extent, on the installation and maintenance of the product. A loop pile floor covering with inadequate edge ravel strength may result in loops pulling out from the backing, resulting in an aesthetically displeasing appearance. Tuft rows located at the seam of a loop pile floor covering are the most susceptible to raveling.

SCOPE

1.1 This test method covers the determination of the force required to ravel a straight sewn yarn from the edge of a loop pile, textile floor covering.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7267 − 13

Standard Test Method for

Edge Ravel Resistance of Finished Loop Pile, Pile Yarn

1

Floor Covering

This standard is issued under the fixed designation D7267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of the force 4.1 A yarn end is raveled from a straight sewn, loop pile

required to ravel a straight sewn yarn from the edge of a loop textile floor covering using a tensile testing machine.The force

pile, textile floor covering. required to pull the tufted yarn from the edge of a tufted loop

pilefloorcoveringismeasuredandrecorded.Therequiredload

1.2 The values stated in inch-pound units are to be regarded

orforcetoremovetheyarnfromthespecimeniscalculatedand

as standard. The values given in parentheses are mathematical

defined as “edge ravel strength.” Floor covering installation

conversions to SI units that are provided for information only

experts recommend using a seam sealer to secure the cut edges

and are not considered standard.

of a textile floor covering.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The satisfactory performance of a loop pile floor cover-

priate safety and health practices and determine the applica-

ing depends, to a considerable extent, on the installation and

bility of regulatory limitations prior to use.

maintenance of the product. A loop pile floor covering with

inadequate edge ravel strength may result in loops pulling out

2. Referenced Documents

from the backing, resulting in an aesthetically displeasing

2

2.1 ASTM Standards:

appearance. Tuft rows located at the seam of a loop pile floor

D76 Specification for Tensile Testing Machines for Textiles

covering are the most susceptible to raveling.

D123 Terminology Relating to Textiles

6. Apparatus

D1776 Practice for Conditioning and Testing Textiles

D5684 Terminology Relating to Pile Floor Coverings

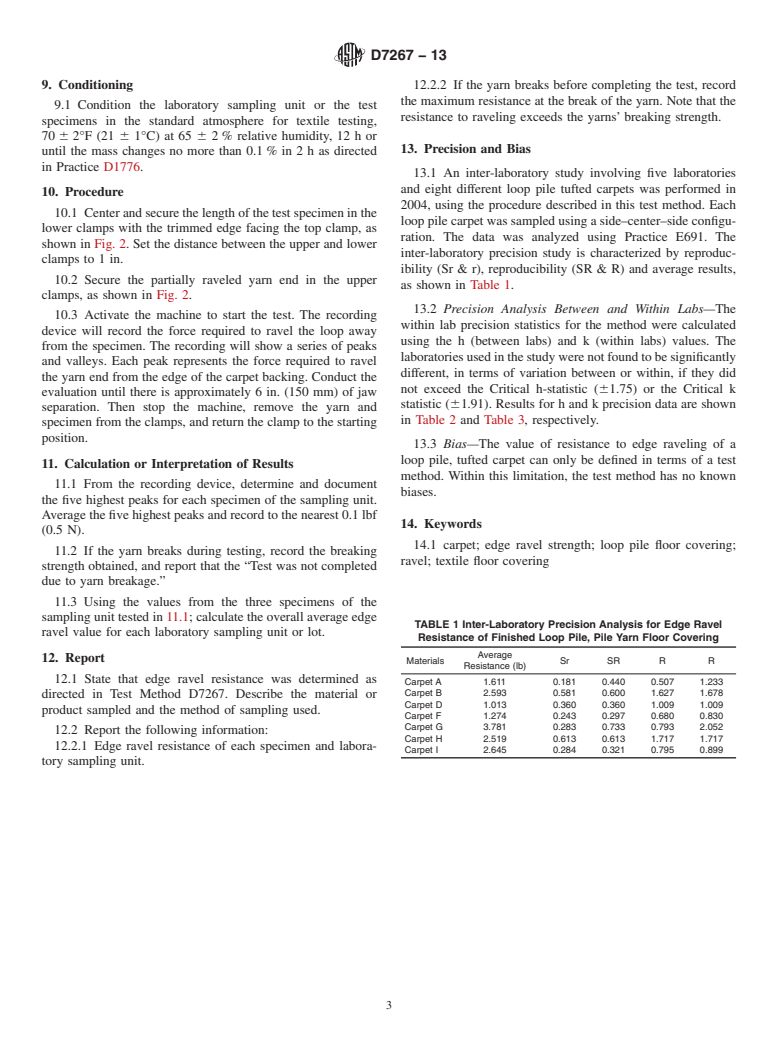

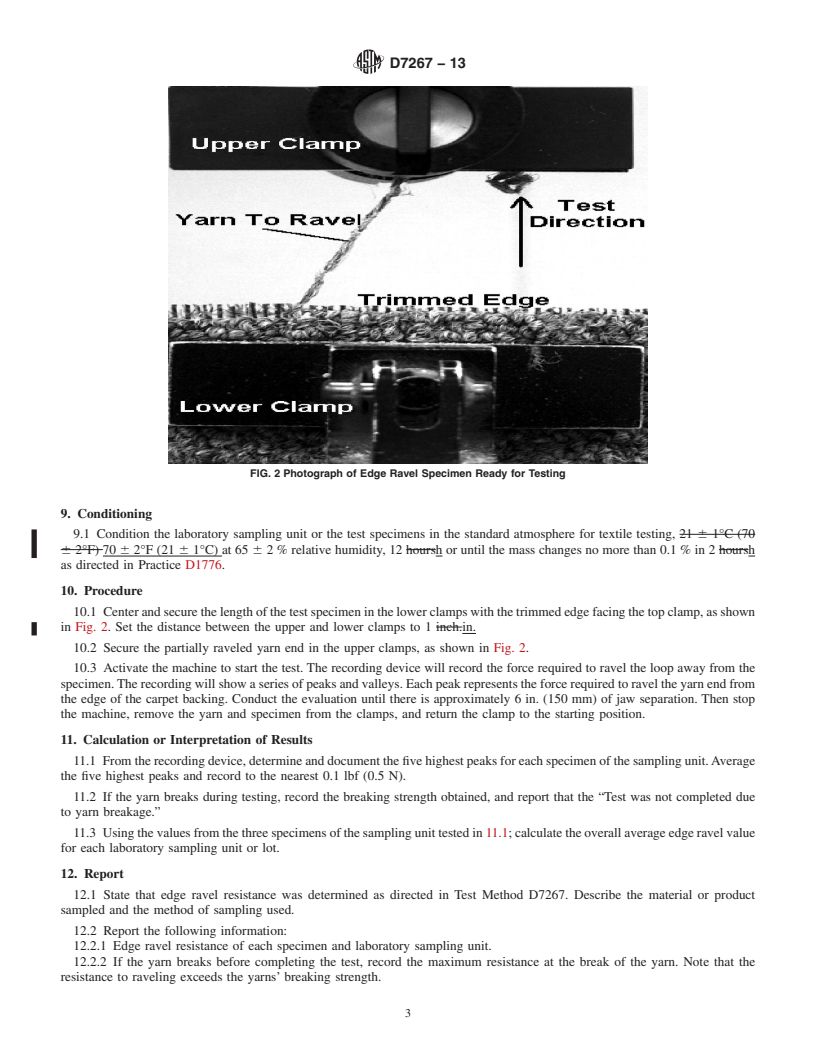

6.1 Tensile Testing Machine—A constant-rate-of extension

(CRE) type conforming to Specification D76, a constant rate of

3. Terminology

speed of 12 6 0.5 in./min (300 6 10 mm/min) is required.

Full-scale loads range from 1 to 10 lb (0.545 to 4.53 kg) are

3.1 For definitions of terms relating to pile floor coverings,

generally adequate. A constant rate of traverse (CRT) type

refer to Terminology D5684.

tensile testing machine conforming to the Specification D76

3.2 Thefollowingtermsarerelevanttothisstandard:carpet,

and operated at the same speed is permitted. There may be no

constant-rate-of-extension, finished, finished pile yarn floor

overall correlation with CRE-type and CRT-type testing ma-

covering, floor covering, loop pile yarn floor covering, pile,

chines. Consequently, the two machines cannot be used inter-

pile yarn floor covering, textile floor covering, tuft, tuft leg,

changeably. In the case of controversy, the CRE-type testing

tufted fabric, edge ravel.

machine shall prevail.

3.3 For definition of other terms related to textiles, refer to

6.2 Clamps and Jaw Faces—The use of hydraulic or

Terminology D123.

pneumatic, serrated or padded face, clamping systems with a

minimum of 1 by 3 in. (25 by 75 mm) are recommended to

reduce specimen slippage. The faces shall be parallel and have

1

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

matching centers with respect to one another (in the same

and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

clamp) and to the corresponding jaw face of the other clamp.

Current edition approved July 1, 2013. Published August 2013. Originally

approved in 2006. Last previous edition approved in 2012 as D7267–12. DOI:

7. Sampling, Test Specimens, and Test Units

10.1520/D7267-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Lot Sample—When performing acceptance testing for a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sample lot, take at random the number of rolls or pieces of pile

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. yarn floor covering as directed on an applicable material

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7267 − 13

FIG. 1 Photograph of Trimming the Edge of a Pulled Tufted Row of Yarn

FIG. 2 Photograph of Edge Ravel Specimen Ready for

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7267 − 12 D7267 − 13

Standard Test Method for

Edge Ravel Resistance of Finished Loop Pile, Pile Yarn

1

Floor Covering

This standard is issued under the fixed designation D7267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the force required to ravel a straight sewn yarn from the edge of a loop pile,

textile floor covering.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D76 Specification for Tensile Testing Machines for Textiles

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D5684 Terminology Relating to Pile Floor Coverings

3. Terminology

3.1 For definitions of terms relating to pile floor coverings, refer to Terminology D5684.

3.2 The following terms are relevant to this standard: carpet, constant-rate-of-extension, finished, finished pile yarn floor

covering, floor covering, loop pile yarn floor covering, pile, pile yarn floor covering, textile floor covering, tuft, tuft leg, tufted

fabric, edge ravel.

3.3 For definition of other terms related to textiles, refer to Terminology D123.

4. Summary of Test Method

4.1 A yarn end is raveled from a straight sewn, loop pile textile floor covering using a tensile testing machine. The force required

to pull the tufted yarn from the edge of a tufted loop pile floor covering is measured and recorded. The required load or force to

remove the yarn from the specimen is calculated and defined as “edge ravel strength.” Floor covering installation experts

recommend using a seam sealer to secure the cut edges of a textile floor covering.

5. Significance and Use

5.1 The satisfactory performance of a loop pile floor covering depends, to a considerable extent, on the installation and

maintenance of the product. A loop pile floor covering with inadequate edge ravel strength may result in loops pulling out from

the backing, resulting in an aesthetically displeasing appearance. Tuft rows located at the seam of a loop pile floor covering are

the most susceptible to raveling.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

Current edition approved Dec. 1, 2012July 1, 2013. Published December 2012August 2013. Originally approved in 2006. Last previous edition approved in 20062012 as

D7267–06.–12. DOI: 10.1520/D7267-12.10.1520/D7267-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7267 − 13

6. Apparatus

6.1 Tensile Testing Machine—A constant-rate-of extension (CRE) type conforming to Specification D76, a constant rate of

speed of 12 6 0.5 in./min (300 6 10 mm/min) is required. Full-scale loads range from 1 to 10 lb (0.545 to 4.53 kg) are generally

adequate. A constant rate of traverse (CRT) type tensile testing machine conforming to the Specification D76 and operated at the

same speed is permitted. There may be no overall correlation with CRE-type and CRT-type testing machines. Consequently, the

two machines cannot be used interchangeably. In the case of controversy, the CRE-type testing machine shall prevail.

6.2 Clamps and Jaw Faces—The use of hydraulic or pneumatic, serrated or padded face, clamping systems with a minimum

of 1 by 3 in. (25 by 75 mm) are recommended to reduce specimen slippage. The faces shall be parallel and have matching centers

with respect to one another (in the same clamp) and to the corresponding jaw face of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.