ASTM D7142-05(2011)

(Test Method)Standard Test Method for Holding Strength of Prong-Ring Attached Snap Fasteners

Standard Test Method for Holding Strength of Prong-Ring Attached Snap Fasteners

SIGNIFICANCE AND USE

Both test methods are considered satisfactory for acceptance testing of commercial shipments of garments with prong-ring type snap fasteners.

In case of dispute arising from differences in reported test results when using this test method for acceptance of commercial shipment, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and that are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using appropriate statistical analysis and an acceptable probability level chosen by the parties before testing is begun. If a bias is found, either the cause must be determined and corrected, or the purchaser and supplier must agree to interpret future test results with consideration to the known bias.

Comparison of results from test equipment operating on different principles is not recommended. In cases of conflict between the test results achieved with manual test equipment (Option 2) and motorized CRE (constant rate of extension) tensile testing machine (Option 1), the results from the motorized equipment shall take precedence.

This test method may be used to determine the compatibility of prong-ring type snap fasteners and fabrics for use in apparel. In which case, the fasteners are attached to the fabric in the manner in which they will be used and the combined units tested. See Annex A1.

SCOPE

1.1 This test method covers the determination of the holding strength of a prong-ring to the socket or stud of a snap fastener using a tensile testing machine (Option 1) or a manual test stand and force-measuring gage (Option 2).

1.2 This test method is applicable to prong-ring type snap fasteners in garments or to be attached to fabrics intended for use in apparel (see Annex A1).

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7142 − 05(Reapproved 2011)

Standard Test Method for

Holding Strength of Prong-Ring Attached Snap Fasteners

This standard is issued under the fixed designation D7142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 force, n—a physical influence exerted by one body on

another which produces acceleration of bodies that are free to

1.1 Thistestmethodcoversthedeterminationoftheholding

move and deformation of bodies that are not free to move.

strength of a prong-ring to the socket or stud of a snap fastener

using a tensile testing machine (Option 1) or a manual test

3.1.2 holding strength, n—in snap fasteners, the force re-

stand and force-measuring gage (Option 2).

quired to separate the prong-ring from its attached mating part

(socket or stud).

1.2 This test method is applicable to prong-ring type snap

fasteners in garments or to be attached to fabrics intended for

3.1.2.1 Discussion—In this test method, a diametric force is

use in apparel (see Annex A1).

applied which simulates the diametric biting or pinching of a

child; however, in practice, the disengaging force used to

1.3 The values stated in either SI units or inch-pound units

unsnap a snap fastener is usually applied at the edge of the

are to be regarded separately as standard. Within the text, the

fastener.

inch-pound units are shown in parentheses. The values stated

in each system are not exact equivalents; therefore, each

3.1.3 prong-ring type fastener, n—generic name for snap

system shall be used independently of the other. Combining

fasteners which use a multi-pronged ring to penetrate through

values from the two systems may result in non-conformance

fabric to mechanically set a matching socket on one side of a

with the specification.

closure and to set a matching stud on the facing closure

1.4 This standard does not purport to address all of the

allowing the outer and inner closure facings to be snapped

safety concerns, if any, associated with its use. It is the

together. (See Fig. 1.)

responsibility of the user of this standard to establish appro-

3.1.4 socket, n—insnapfasteners,thefemalefunctionalpart

priate safety and health practices and determine the applica-

of the fastener which engages with the stud part of the fastener

bility of regulatory limitations prior to use.

to form the closure of two parts of the item on which the

fastener is used. (See Fig. 1.)

2. Referenced Documents

3.1.4.1 Discussion—Prong-ringattachedsocketorstudsnap

2.1 ASTM Standards:

fasteners are designed to be mechanically attached to garments

D76 Specification for Tensile Testing Machines for Textiles

or other items through the deformation interaction of the

D123 Terminology Relating to Textiles

prong-ring with the socket or stud. Other forms of snap

D1776 Practice for Conditioning and Testing Textiles

fasteners exist which may be attached to the foundation of the

2.2 Federal Document:

garment or other item by means of sewn threads or adhesive

16 CFR Parts 1500.48-1500.53 and 1501.4 Engineering Test

bonding.

Manual for Children’s Toys

3.1.5 strength, n—the property of a material that resists

3. Terminology

deformation induced by external forces.

3.1 Definitions:

3.1.5.1 Discussion—In this standard, the deformation is the

separation of the prong-ring from the socket or stud of a snap

fastener.

This test method is under the jurisdiction ofASTM Committee D13 on Textiles

and is the direct responsibility of Subcommittee D13.54 on Subassemblies.

3.1.6 stud, n—in snap fasteners, the male functional part of

Current edition approved Jan. 1, 2011. Published March 2011. Originally

asnapfastenerwhichengageswith,orsnapsinto,themouthof

approved in 2005. Last previous edition approved in 2005 as D7142 - 05. DOI:

10.1520/D7142-05R11. thesockettoformaclosureoftwopartsoftheitem,orgarment

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

on which the fastener is used. (See Fig. 1.)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.6.1 Discussion—See discussion for socket.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3.1.7 For definitions of other textile terms used in this

Available from Federal Register, Vol 44, No. 117, June 1979, Consumer

Product Commission, 16 CFR Parts 1500 and 1501. standard, refer to Terminology D123.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7142 − 05 (2011)

FIG. 1 Prong-ring Attached Fastener Parts

4. Summary of Test Method supplier must agree to interpret future test results with consid-

eration to the known bias.

4.1 Option 1—A specimen, consisting of a fastener socket

or stud attached to fabric by a prong-ring, is mounted in a

5.2 Comparison of results from test equipment operating on

special test fixture on a tensile testing machine. A force is

different principles is not recommended. In cases of conflict

applied diametrically until the prong-ring separates from the

between the test results achieved with manual test equipment

socket or stud, or the fabric is torn. The force at separation is

(Option 2) and motorized CRE (constant rate of extension)

reported as the holding strength. If the fabric tears, the force at

tensile testing machine (Option 1), the results from the motor-

fabric failure is recorded and the data is reported and it is

ized equipment shall take precedence.

consideredasadifferentcategoryandisreportedseparatefrom

5.3 This test method may be used to determine the compat-

the holding strength of the fasteners.

ibility of prong-ring type snap fasteners and fabrics for use in

4.2 Option 2—A specimen, consisting of a fastener socket

apparel. In which case, the fasteners are attached to the fabric

or stud attached to fabric by a prong-ring, is mounted in a

in the manner in which they will be used and the combined

special test fixture on a manual pull test stand which is fitted

units tested. See Annex A1.

with a portable force gage. A force is applied until the

prong-ring separates from the socket or stud, or the fabric is

6. Apparatus

torn.Theforceatseparationisreportedastheholdingstrength.

6.1 For Option 1:

If the fabric tears, the force at fabric failure is recorded and the

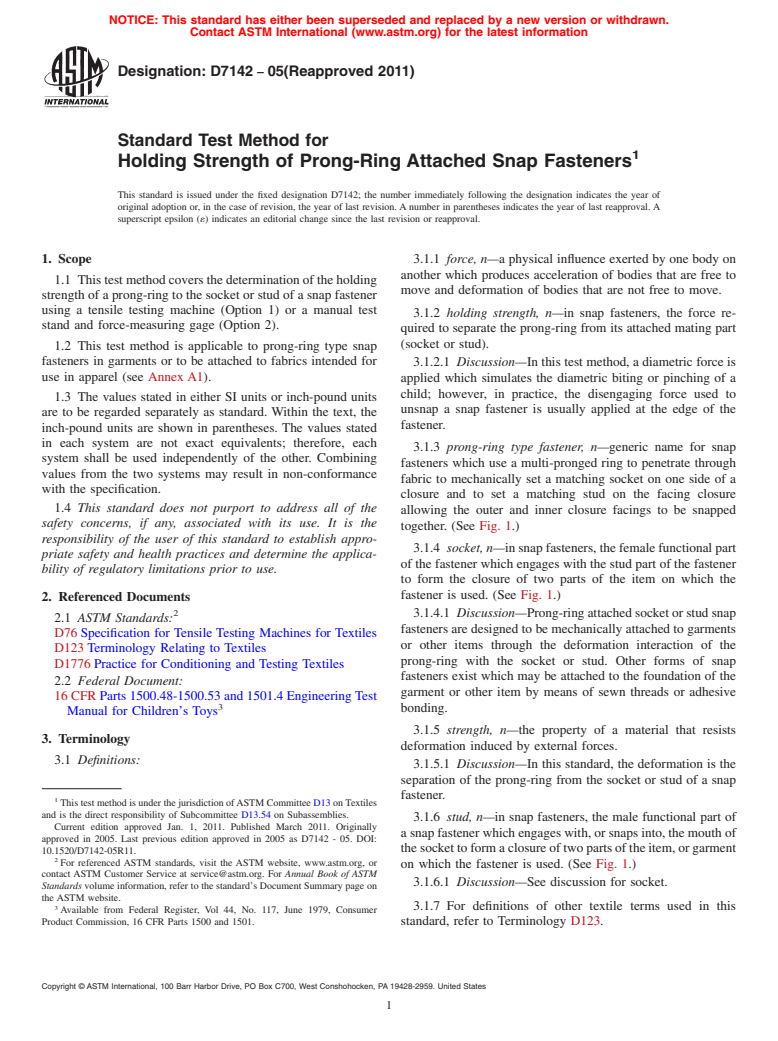

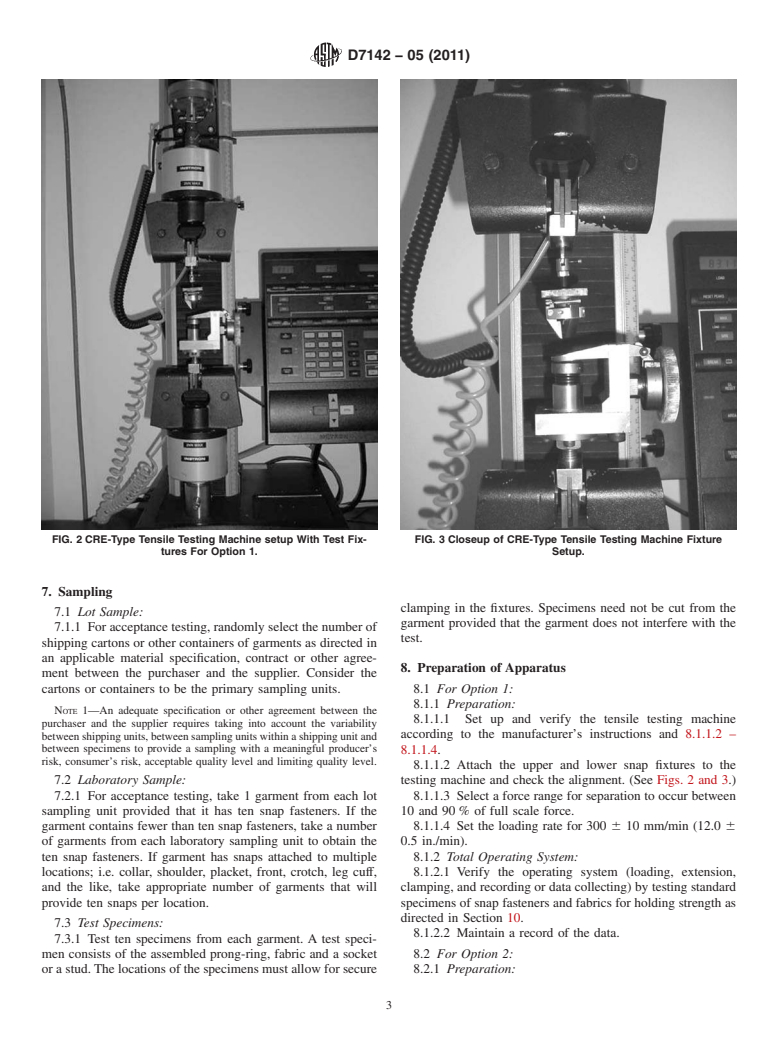

6.1.1 Tensile Testing Machine, CRE type, meeting Specifi-

data is reported and it is considered as a different category and

cation D76. (See Figs. 2 and 3.)

is reported separate from the holding strength of the fasteners.

6.1.2 Upper Snap FixtureAttachment 4, Fig. 4, designed to

5. Significance and Use

diametrically attach to the socket or stud of the snap fastener

which is attached to the fabric specimen or garment being

5.1 Both test methods are considered satisfactory for accep-

tested.

tance testing of commercial shipments of garments with

prong-ring type snap fasteners. 6.1.3 Lower Snap FixtureAttachment 4, Fig. 4, designed to

5.1.1 In case of dispute arising from differences in reported

secure the fabric and thereby the socket or stud attached to it in

test results when using this test method for acceptance of a horizontal plane.

commercial shipment, the purchaser and the supplier should

6.2 For Option 2:

conduct comparative tests to determine if there is a statistical

6.2.1 Force Measuring Gage 5, modified with an attachment

bias between their laboratories. Competent statistical assis-

tobefastenedontotheupperarmofateststandwiththeupper

tance is recommended for the investigation of bias. As a

test fixture suspended from it. (See Fig. 3.)

minimum, the two parties should take a group of test speci-

6.2.2 Upper Snap FixtureAttachment 4, Fig. 4, designed to

mens that are as homogeneous as possible and that are from a

diametrically attach to the socket or stud of the snap fastener

lot of material of the type in question. The test specimens

which is attached to the fabric specimen or garment being

should then be randomly assigned in equal numbers to each

tested.

laboratory for testing. The average results from the two

6.2.3 Lower Snap FixtureAttachment 4, Fig. 4, designed to

laboratories should be compared using appropriate statistical

secure the fabric and thereby the socket or stud attached to it in

analysis and an acceptable probability level chosen by the

a horizontal plane.

parties before testing is begun. If a bias is found, either the

cause must be determined and corrected, or the purchaser and 6.2.4 Test Stand, see Fig. 5.

D7142 − 05 (2011)

FIG. 2 CRE-Type Tensile Testing Machine setup With Test Fix- FIG. 3 Closeup of CRE-Type Tensile Testing Machine Fixture

tures For Option 1. Setup.

7. Sampling

clamping in the fixtures. Specimens need not be cut from the

7.1 Lot Sample:

garment provided that the garment does not interfere with the

7.1.1 For acceptance testing, randomly select the number of

test.

shipping cartons or other containers of garm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.