ASTM A1075-12(2017)e1

(Specification)Standard Specification for Flanged Steel U-Channel Posts

Standard Specification for Flanged Steel U-Channel Posts

ABSTRACT

This specification covers flanged U-channel carbon steel posts having a nominal weight ranging from 0.75 to 6.0 lb/ft and a nominal width ranging from 1.25 to 4.0 in. These posts are furnished in the as-wrought condition intended for applications requiring high tensile strength or crashworthiness and with a lower carbon (LC) designation for use where higher ductility or improved weldability are required. This specification indicates that tension tests and tensile tests are conducted on the flanged steel U-channel posts, and notes that retesting for failed mechanical properties may be permitted.

SCOPE

1.1 This specification covers flanged U-channel carbon steel posts having a nominal weight ranging from 0.75 to 6.0 lb/ft and a nominal width ranging from 1.25 to 4.0 in. These posts are furnished in the as-wrought condition intended for applications requiring high tensile strength or crashworthiness and with a lower carbon (LC) designation for use where higher ductility or improved weldability are required. These materials are available in multiple yield strength levels of 50, 60, 70, and 80 ksi (345, 420, 485, and 550 MPa). The 50- and 60-ksi (345- and 420-MPa) yield strength grades are available as lower carbon posts, designated as Grades 50LC or 60LC.

Note 1: This specification does not cover high-strength low-alloy (HSLA) post. Refer to Specification A572/A572M for HSLA. For structural Grade 36, refer to Specification A36/A36M.

1.2 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A1075 −12 (Reapproved 2017)

Standard Specification for

Flanged Steel U-Channel Posts

This standard is issued under the fixed designation A1075; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Table references in 8.2 and 8.3 were corrected editorially in September 2017.

1. Scope 2. Referenced Documents

1.1 ThisspecificationcoversflangedU-channelcarbonsteel 2.1 ASTM Standards:

posts having a nominal weight ranging from 0.75 to 6.0 lb/ft A1Specification for Carbon Steel Tee Rails

and a nominal width ranging from 1.25 to 4.0 in. These posts A6/A6MSpecification for General Requirements for Rolled

Structural Steel Bars, Plates, Shapes, and Sheet Piling

are furnished in the as-wrought condition intended for appli-

cations requiring high tensile strength or crashworthiness and A29/A29MSpecificationforGeneralRequirementsforSteel

Bars, Carbon and Alloy, Hot-Wrought

with a lower carbon (LC) designation for use where higher

ductility or improved weldability are required.These materials A36/A36MSpecification for Carbon Structural Steel

A123/A123MSpecification for Zinc (Hot-Dip Galvanized)

areavailableinmultipleyieldstrengthlevelsof50,60,70,and

80ksi(345,420,485,and550MPa).The50-and60-ksi(345- Coatings on Iron and Steel Products

A370Test Methods and Definitions for Mechanical Testing

and 420-MPa) yield strength grades are available as lower

carbon posts, designated as Grades 50LC or 60LC. of Steel Products

NOTE 1—This specification does not cover high-strength low-alloy A499Specification for Steel Bars and Shapes, Carbon

(HSLA) post. Refer to Specification A572/A572M for HSLA. For

Rolled from “T” Rails

structural Grade 36, refer to Specification A36/A36M.

A572/A572MSpecification for High-Strength Low-Alloy

1.2 Units—The values stated in inch-pound units are to be

Columbium-Vanadium Structural Steel

regarded as the standard. The values given in parentheses are

2.2 AASHTO Standard:

mathematical conversions to SI units that are provided for

AASHTOManual for Assessing Safety Hardware

information only and are not considered standard.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.1.1 crashworthiness, n—abilityofsigns,signals,andother

responsibility of the user of this standard to establish appro-

safety hardware to fail in such a manner so as not to shatter or

priate safety, health, and environmental practices and deter-

cause injury to passengers in vehicles involved in an impact or

mine the applicability of regulatory limitations prior to use.

collision.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.1.2 lot, n—for product produced from rolled “T” rails, a

ization established in the Decision on Principles for the lot shall consist of material of the same size product produced

in one shift in accordance with Specification A499.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3.1.3 U-channel post, n—bars with a “flanged U shape” to

Barriers to Trade (TBT) Committee.

provide increased stiffness when loaded in the transverse

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction ofASTM Committee A01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.15 on Bars. the ASTM website.

Current edition approved Sept. 1, 2017. Published September 2017. Originally Available from American Association of State Highway and Transportation

approved in 2012. Last previous edition approved in 2012 as A1075–12. DOI: Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

10.1520/A1075-12R17E01. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A1075−12 (2017)

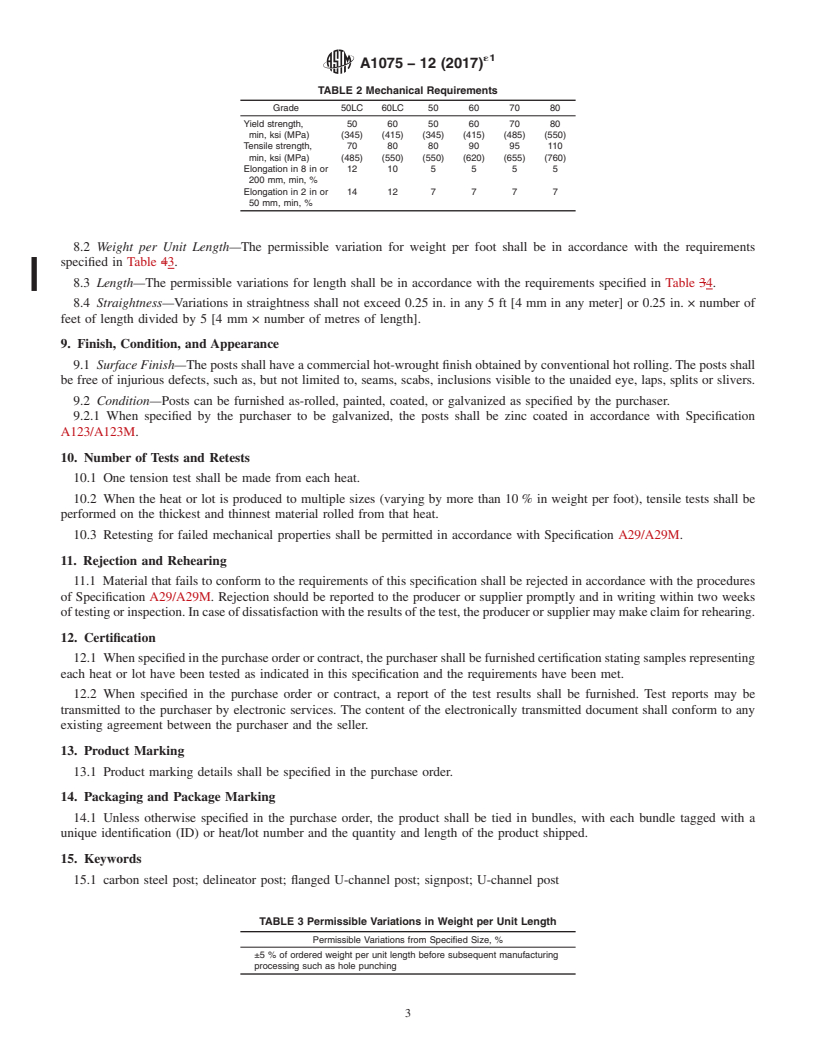

TABLE 2 Mechanical Requirements

direction, typically having punched holes and primarily used

for the attachment of highway signs. Grade 50LC 60LC 50 60 70 80

Yield strength, 50 60 50 60 70 80

4. Ordering Information

min, ksi (MPa) (345) (415) (345) (415) (485) (550)

Tensile strength, 70 80 80 90 95 110

4.1 Orders for material under this specification should

min, ksi (MPa) (485) (550) (550) (620) (655) (760)

include the following information: Elongation in 8 in or 12 10 5 5 5 5

200 mm, min, %

4.1.1 Quantity (weight or number of pieces);

Elongation in 2 in or 14 12 7 7 7 7

4.1.2 Name of material (steel posts);

50 mm, min, %

4.1.3 Gradeofsteel(Grades50,50LC,60,60LC,70,or80);

4.1.4 Weight per foot;

4.1.5 Condition (as-rolled, painted, powder coated, or gal-

7.2 Test Specimens—Test specimens may be taken from a

vanized);

full section or a machined section.

4.1.6 Hole punching, if required;

7.2.1 Sub-sized tensile specimens shall be taken from the

4.1.7 ASTM designation and date of issue;

flat part of the U-shaped section.

4.1.8 Certification, if required (Section 11);

7.3 Test Method—Tensile tests shall be made in accordance

4.1.9 Product marking; and

with Test Methods and Definitions A370.

4.1.10 Product packaging and package marking.

NOTE 2—A typical ordering description is as follows: 1000 pieces,

8. Dimensions, Mass, and Permissible Variations

flanged u-channel post, Grade 60, 8 ft (2.4 m) long, 2 lb (0.9 kg) per foot,

8.1 Dimensions—Because of differences in mill facilities,

as-rolled, ASTM AXXXX dated _______.

tolerances of post sections vary among the manufacturers and

5. Materials and Manufacture

suchtolerancesaresubjecttoagreementbetweenmanufacturer

5.1 Feedstock—Material may be manufactured from re-

and purchaser.

rolled rail steel or rolled from billet steel.

8.2 Weight per Unit Length—The permissible variation for

5.2 Material produced from rerolled rails shall be made to

weight per foot shall be in accordance with the requirements

conform to Specification A499.

specified in Table 3.

5.3 Materialproducedfrombilletsteelshallbemadebythe

8.3 Length—The permissible variations for length shall be

commercially available steel-making processes.

in accordance with the requirements specified in Table 4.

5.4 Postsshallbesuppliedinthehotrolledcon

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1075 − 12 A1075 − 12 (Reapproved 2017)

Standard Specification for

Flanged Steel U-Channel Posts

This standard is issued under the fixed designation A1075; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Table references in 8.2 and 8.3 were corrected editorially in September 2017.

1. Scope

1.1 This specification covers flanged U-channel carbon steel posts having a nominal weight ranging from 0.75 to 6.0 lb/ft and

a nominal width ranging from 1.25 to 4.0 in. These posts are furnished in the as-wrought condition intended for applications

requiring high tensile strength or crashworthiness and with a lower carbon (LC) designation for use where higher ductility or

improved weldability are required. These materials are available in multiple yield strength levels of 50, 60, 70, and 80 ksi (345,

420, 485, and 550 MPa). The 50- and 60-ksi (345- and 420-MPa) yield strength grades are available as lower carbon posts,

designated as Grades 50LC or 60LC.

NOTE 1—This specification does not cover high-strength low-alloy (HSLA) post. Refer to Specification A572/A572M for HSLA. For structural Grade

36, refer to Specification A36/A36M.

1.2 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A1 Specification for Carbon Steel Tee Rails

A6/A6M Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling

A29/A29M Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought

A36/A36M Specification for Carbon Structural Steel

A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A499 Specification for Steel Bars and Shapes, Carbon Rolled from “T” Rails

A572/A572M Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel

2.2 AASHTO Standard:

AASHTO Manual for Assessing Safety Hardware

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 crashworthiness, n—ability of signs, signals, and other safety hardware to fail in such a manner so as not to shatter or

cause injury to passengers in vehicles involved in an impact or collision.

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.15

on Bars.

Current edition approved March 1, 2012Sept. 1, 2017. Published April 2012September 2017. Originally approved in 2012. Last previous edition approved in 2012 as

A1075–12. DOI: 10.1520/A1075-12.10.1520/A1075-12R17E01.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from American Association of State Highway and Transportation Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A1075 − 12 (2017)

3.1.2 lot, n—for product produced from rolled “T” rails, a lot shall consist of material of the same size product produced in one

shift in accordance with Specification A499.

3.1.3 U-channel post, n—bars with a “flanged U shape” to provide increased stiffness when loaded in the transverse direction,

typically having punched holes and primarily used for the attachment of highway signs.

4. Ordering Information

4.1 Orders for material under this specification should include the following information:

4.1.1 Quantity (weight or number of pieces);

4.1.2 Name of material (steel posts);

4.1.3 Grade of steel (Grades 50, 50LC , 50LC, 60, 60LC, 70, or 80);

4.1.4 Weight per foot;

4.1.5 Condition (as-rolled, painted, powder coated, or galvanized);

4.1.6 Hole punching, if required;

4.1.7 ASTM designation and date of issue;

4.1.8 Certification, if required (Section 11);

4.1.9 Product marking; and

4.1.10 Product packaging and package marking.

NOTE 2—A typical ordering description is as follows: 1000 pieces, flanged u-channel post, Grade 60, 8 ft (2.4 m) long, 2 lb (0.9 kg) per foot, as-rolled,

ASTM AXXXX dated _______.

5. Materials and Manufacture

5.1 Feedstock—Material may be manufactured from rerolled rail steel or rolled from billet steel.

5.2 Material produced from rerolled rails shall be made to conform to Specification A499.

5.3 Material produced from billet steel shall be made by the commercially available steel-making processes.

5.4 Posts shall be supplied in the hot rolled condition, unless otherwise specified in the purchase order.

6. Chemical Composition

6.1 Material rerolled from rails shall conform to the chemistry requirements of Specification A1, as the chemistry is not

significantly changed by the hot rolling process.

6.2 Material rolled from billets shall conform to the requirements prescribed in Table 1.

6.2.1 The heat analysis report shall be furnished to the purchaser.

6.2.2 By agreement between the purchaser and supplier, limits can be established for elements or compounds not specified in

Table 1.

6.2.3 The product analysis shall be permitted to vary from the heat analysis according to the limits established in Table A of

Specification A6/A6M.

7. Mechanical Properties

7.1 Requirements—The material as represented by the test specimens shall conform to the tensile requirements specified in

Table 2.

7.2 Test Specimens—Test specimens may be taken from a full section or a machined section.

7.2.1 Sub-sized tensile specimens shall be taken from the flat part of the U-shaped secti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.