ASTM G50-76(2003)

(Practice)Standard Practice for Conducting Atmospheric Corrosion Tests on Metals

Standard Practice for Conducting Atmospheric Corrosion Tests on Metals

SIGNIFICANCE AND USE

The procedures described herein can be used to evaluate the corrosion resistance of metals when exposed to the weather, as well as to evaluate the relative corrosivity of the atmosphere at specific locations. Because of the variability and complexity of weather effects and the industrial and natural factors influencing the atmospheric corrosivity of a test site, a multi-year exposure period should be considered to minimize their influence. Also, as corrosivity may vary at a site from season to season, exposures should be made either at the same time of the year to minimize variability or these differences should be established by multiple exposures.

Control specimens should always be employed in weathering tests. The control specimens should be from a material having established weathering characteristics. A substantial amount of corrosion data shall have been accumulated for the control specimens. It is also good practice to retain samples of all materials exposed so that possible effects of long-term aging can be measured.

SCOPE

1.1 This practice defines conditions for exposure of metals and alloys to the weather. It sets forth the general procedures that should be followed in any atmospheric test. It is presented as an aid in conducting atmospheric corrosion tests so that some of the pitfalls of such testing may be avoided. As such, it is concerned mainly with panel exposures to obtain data for comparison purposes.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G50–76 (Reapproved 2003)

Standard Practice for

Conducting Atmospheric Corrosion Tests on Metals

This standard is issued under the fixed designation G50; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope year exposure period should be considered to minimize their

influence.Also, as corrosivity may vary at a site from season to

1.1 This practice defines conditions for exposure of metals

season, exposures should be made either at the same time of

and alloys to the weather. It sets forth the general procedures

the year to minimize variability or these differences should be

that should be followed in any atmospheric test. It is presented

established by multiple exposures.

as an aid in conducting atmospheric corrosion tests so that

3.2 Control specimens should always be employed in

some of the pitfalls of such testing may be avoided.As such, it

weathering tests. The control specimens should be from a

is concerned mainly with panel exposures to obtain data for

material having established weathering characteristics. A sub-

comparison purposes.

stantial amount of corrosion data shall have been accumulated

1.2 This standard does not purport to address all of the

for the control specimens. It is also good practice to retain

safety concerns, if any, associated with its use. It is the

samples of all materials exposed so that possible effects of

responsibility of whoever uses this standard to consult and

long-term aging can be measured.

establish appropriate safety and health practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Test Sites

2. Referenced Documents 4.1 Test sites should be chosen at a number of locations

representative of the atmospheric environments where the

2.1 ASTM Standards:

metals or alloys are likely to be used. If such information is not

A380 Practice for Cleaning, Descaling, and Passivation of

available, the selection should include sites typical of indus-

Stainless Steel Parts, Equipment, and Systems

trial, rural, and marine atmospheres.

D2010/D2010M Test Methods for Evaluation of Total Sul-

4.2 Exposure racks should be located in cleared, well-

fation Activity in the Atmosphere by the Lead Dioxide

drained areas such that the exposed specimens will be sub-

Technique

jected to the full effects of the atmosphere at the location of the

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

test site. Shadows of trees, buildings, or structures should not

sion Test Specimens

fall on the specimens, and local contamination of the atmo-

G33 Practice for Recording Data from Atmospheric Corro-

sphereshouldbeavoided,unlessthespecificinfluencesofsuch

sion Tests of Metallic-Coated Steel Specimens

conditions are intended to be assessed.

G46 Guide for Examination and Evaluation of Pitting

4.3 In special cases, the exposure racks may be partially

Corrosion

shelteredtoallowaccumulationofcorrosivematerialsfromthe

3. Significance and Use

air but at the same time prevent washing by rain. If sheltering

is used, its purpose and configuration should be described in

3.1 The procedures described herein can be used to evaluate

detail.

thecorrosionresistanceofmetalswhenexposedtotheweather,

4.4 If local pollution effects are to be investigated, the

as well as to evaluate the relative corrosivity of the atmosphere

samples should be exposed at different distances from the

at specific locations. Because of the variability and complexity

source and at different elevations. Where it is particularly

of weather effects and the industrial and natural factors

important to obtain corrosion rates involving a micro-

influencing the atmospheric corrosivity of a test site, a multi-

environment, samples should be mounted directly on the

structure involved. Suitable attachment must be devised for

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

each case.

of Metals, and is the direct responsibility of Subcommittee G01.04 onAtmospheric

Corrosion.

5. Exposure Racks and Frames

Current edition approved Aug. 27, 1976. Published March 1977. DOI: 10.1520/

G0050-76R03.

5.1 Test racks and frames should be constructed of a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

material that will remain intact for the entire proposed period

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of exposure. Galvanized pipe has been found adequate for rack

Standards volume information, refer to the standard’s Document Summary page on

construction in most environments (Note 1).Type 304 stainless

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G50–76 (2003)

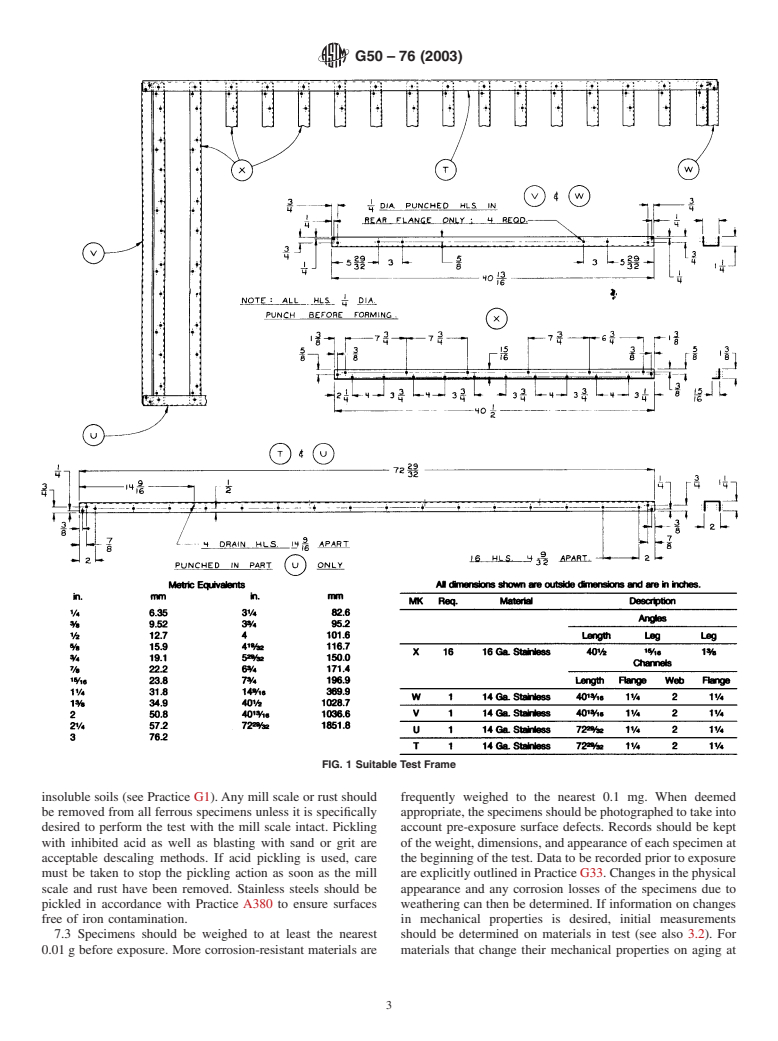

steel is adequate as a frame material for all environments. For 5.7 ArackofthedesignanddimensionsshowninFig.2will

marine exposures, alloy 400 UNS No. N04400 or Type 316 give the correct exposure angle and can support the specimen

stainless steel has also been successfully used. Aluminum frame described in 5.4.

(5052 and 6061-T6) and copper frames also have given 5.8 The ground under the racks should be kept free of

satisfactory service in a wide range of environments. Care weeds, bushes, and debris. Organic herbicides, defoliants, or

should be observed in the use of copper frames, as corrosion pesticides should not be used for this purpose.

products splashed during rainfall might affect the corrosion of

6. Test Specimens

other metals such as aluminum or magnesium.

6.1 When the material to be tested is in sheet form, a

NOTE 1—If galvanized pipe is field-threaded, thread areas must be

specimen size of 4 by 6 in. (100 by 150 mm) is appropriate.

protected to ensure joint integrity for long exposure periods. In severe

Specimens may be larger, for example, 4 by 8 in. (100 by 200

environments, additional coatings may be required to provide corrosion-

mm), to suit a particular test; however, the specimens prefer-

free service.

ably should not be smaller than 4 by 6 in.

5.2 Racks and frames also may be constructed of wood.

6.2 Toassureadequaterigidityofthespecimensontherack,

Insulators may be attached to wooden frames with aluminum

a minimum thickness of 0.030 in. (0.75 mm) is suggested. It

bronze, alloy 400, or stainless steel screws. In such a case, no

maybedifficulttoaccommodatethicknessesgreaterthan0.250

wood sections should be used with dimensions less than 2 by

in. (6.25 mm) in the insulator grooves. (Special deep-throated

4 in. (50 by 100 mm), and at least two coats of an exterior

insulators can be obtained to accommodate thicker specimens,

grade paint or enamel over a suitable primer must be applied.

or the edges of thicker specimens can be machined to fit

Periodic maintenance will be required on all wood construc-

standard insulators.)

tion.

6.3 When it is desired to test samples of odd shapes, such as

5.3 Solid, glazed, electrical insulator knobs should be used

bolts, nuts, pipes, angles, assemblies, and structures, etc., a

to hold the specimens on the frames, using stainless steel, alloy

means of supporting them in the test racks must be devised. It

400, aluminum, nylon, or bronze bolts and nuts. Specimens

is important that the specimens be electrically insulated from

shallbemountedinthegroovesoftheseinsulators.Inselecting

their respective supports and from each other to prevent

fasteners for use on specific frame materials, care should be

unintentional galvanic corrosion. However, if desired, galvanic

taken to avoid unfavorable galvanic relationships.

couples of dissimilar metals can be exposed on these frames.

5.4 Asuitable frame for mounting the insulators is shown in

Efforts should be made to minimize crevices between speci-

Fig. 1. This frame will accommodate 70 standard 4 by 6-in.

mens and support materials.

(100 by 150-mm) specimens; other sizes can be mounted by

6.4 The total number of test specimens required should be

rearrangingtheinsulatorsintheholesprovided.Itisacceptable

determinedfromaknowledgeofthedurationofthetestandthe

to slot the holes in the frames in such a manner that the

planned removals of the specimens for intermediate evalua-

mounting frames are adjustable for specimens of other sizes.

tions. Usually it should not be necessary to remove specimens

This is a convenience when it is not possible to prepare

prior to completing one year’s exposure, unless specific data

specimens of a preplanned size, and it is often helpful in fitting

are required for corrosion occurring during earlier stages of

the specimens snugly into the frames.

exposure. For reliable results, sufficient specimens should be

5.5 The racks should be designed to give exposure to as

used for multiple removals at each exposure period. Triplicate

large an area of the underside of the specimens as possible.

specimens for each examination period will usually satisfy this

Structural members of the rack should not be located directly

requirement. A suggested suitable removal schedule is 1, 2, 4,

under the specimens where they would shelter the underside of

8, and 16 years. Removal schedules for tests of different

the specimens.

periods of total exposure should be adjusted accordingly.

5.6 As most published data on atmospheric corrosion of

6.5 Included with each series of test specimens should be an

metals are based on an exposure angle of 30 deg from the

appropriate number of control specimens, as defined in 3.2.

horizontal, facing south, it is recommended that this angle be

used. Racks should be designed so that the lowest specimens

7. Preparation of Test Specimens

are at least 30 in. (760 mm) above the ground.

7.1 Specimens should be identified in a manner that will

NOTE 2—Maximum exposure to the sun may be obtained by exposing

endure for the life of the test. A good method is the use of a

specimens facing south (for the northern hemisphere) at an angle equal to

series of edge notches or drilled holes in the body of the

the latitude of the test site. Exposure at this angle will yield the lowest

specimen arranged according to some desired code. Another

corrosion rates for most materials. Although these corrosion rates will

method is to attach a stainless steel tag by means of an

change at other angles of exposure, the order of merit established for each

insulated cord and a suitably located hole. Numbers stamped

material will be the same.

NOTE 3—In special instances, it may be desirable to orient racks and on the back of the specim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.