ASTM D2218-67(1996)e1

(Specification)Standard Specification for Molybdate Orange Pigments

Standard Specification for Molybdate Orange Pigments

SCOPE

1.1 This specification covers the pigment known as molybdate orange.

1.2 The following hazard caveat applies to the test method portion of this specification only. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

0) Designation: D 2218 - 67 (Reapproved 1996)'' AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr. West Conshohocken. PA 19428

"

from the Annual Book of ASTM Standards. ASTM

Copyright

Reprinted

in the current combined will appear in the next editm.

If not listed index,

Standard Specification for

Molybdate Orange Pigments'

This standard is issued under the fixed designation D 2218; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicam the year of last reapproval. A

superscript epsilon (e) indicates an editorial change sincc the last revision or reapproval.

This standard has been approved for use by agencies of the Depanment of Ddense to replace Method 7133 Federal Test Method

Standard No. 141. Consult the DoD Index of Spec$cations and Standardsfor the specfic year of issue which has been adapted by the

Department of Defense.

NOTE-Keywords were added editorially in August 1996.

1. Scope

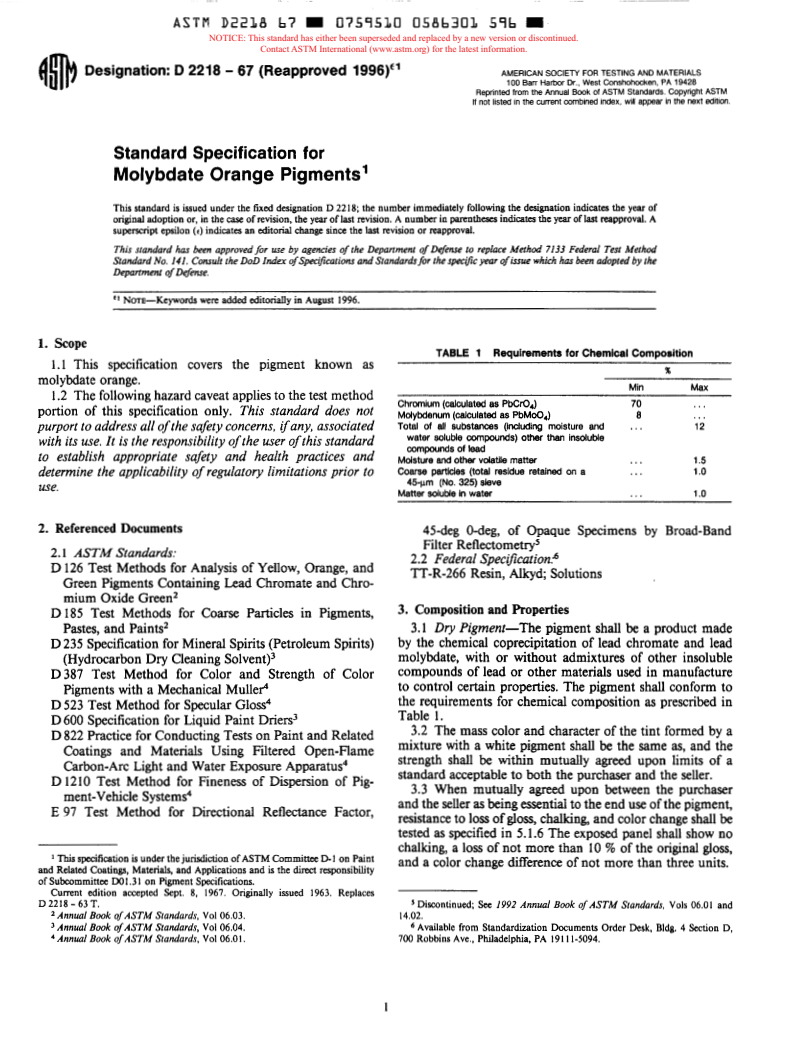

TABLE 1 Requirements for Chemical Composition

1.1 This specification covers the pigment known as

%

molybdate orange.

Min MW

1.2 The following hazard caveat applies to the test method

Chromium (calculated as PbCrO,) 70 .

portion of this specification only. This standard does not

Molybdenum (calculated as PbMo0,)

0 .

Total of all substanœs (including moisture and . . . 12

purport to address all of the safety concerns, fany, associated

water soluble compounds) other than insoluble

with its use. It is the responsibility of the user of this standard

compounds of lead

to establish appropriate safety and health practices and

Mdsture and other volatile matter .

1 .S

Coarse partldes (total residue retained on a . 1 .o

determine the applicability of regulatory limitations prior to

45-pm (No. 325) sieve

use.

Matter soluble in water . 1 .o

2. Referenced Documents

45-deg O-deg, of Opaque Specimens by Broad-Band

Filter Reflectometry5

2. I ASTM Standards:

2.2 Federaì Specification!

D 126 Test Methods for Analysis of Yellow, Orange, and

TT-R-266 Resin, Alkyd; Solutions

Green Pigments Containing Lead Chromate and Chro-

mium Oxide Green2

3. Composition and Properties

D 185 Test Methods for Coarse Particles in Pigments,

3.1 Dry Pigment-The pigment shall be a product made

Pastes, and Paints2

by the chemical coprecipitation of lead chromate and lead

D 235 Specification for Mineral Spirits (Petroleum Spirits)

molybdate, with or without admixtures of other insoluble

(Hydrocarbon Dry Cleaning S01vent)~

compounds of lead or other materials used in manufacture

D 387 Test Method for Color and Strength of Color

to control certain properties. The pigment shall conform to

Pigments with a Mechanical Muller"

the requirements for chemical composition as prescribed in

D 523 Test Method for Specular Gloss4

Table 1.

D 600 Specification for Liquid Paint Driers3

3.2 The mass color and character of the tint formed by a

D 822 Practice for Conducting Tests on Paint and Related

mixture with a white pigment shall be the same as, and the

Coatings and Materials Using Filtered Open-Flame

strength shall be within mutually agreed upon limits of a

Carbon-Arc Light and Water Exposure Apparatus4

standard acceptable to both the purchaser and the seller.

D 1210 Test Method for Fineness of Dispersion of Pig-

3.3 When mutually agreed upon between the purchaser

ment-Vehicle Systems4

and the seller as being essential to the end use of the pigment,

E 97 Test Method for Directional Reflectance Factor,

resistance to loss of gloss, chalking, and color change shall be

tested as specified in 5.1.6 The exposed panel shall show no

chalking, a loss of not more than 10 ?G of the original gloss,

This specification is under the jurisdiction of ASTM Committee D- 1 on Paint

and a color change difference of not more than three units.

and Related Coatings, Materials, and Applications and is the direct responsibility

of Subcommittee W1.31 on Pigment Specifications.

Current edition accepted Sept. 8, 1967. Originally issued 1963. Replaces

D 2218 - 63 T.

Discontinued; See 1992 Annual Book of ASTM Standards, Vols 06.01 and

14.02.

Annual Book of ASTM Standards, Vol 06.03.

6 Available from Standardization Documents Order Desk, Bldg. 4 Section D,

Annual Book of ASTM Standards, Vol 06.04.

Annual Book of ASTM Slandards, Vol 06.0 I, 700 Robbins Ave., Philadelphia, PA 191 11-5094.

~~ ~

ASTM D22L8 67 m 0759530 0586302 422 m

D 2218

5.1.6.1 Prepare a test enamel consisting of ingredients

4. Sampling

conforming to the applicable specifications in the following

4.1 Two samples shall be taken at random from different

proportions:

packages from each lot, batch, day's pack, or other unit of

production in a shipment. When no markings distinguishing

between units of production appear, samples shall be taken Molybdate orange

Alkyd min 1.72

from different packages in the ratio of two samples for each

8.37

10 O00 lb (4540 kg), except that for shipments of less

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.