ASTM E925-09(2014)

(Practice)Standard Practice for Monitoring the Calibration of Ultraviolet-Visible Spectrophotometers whose Spectral Bandwidth does not Exceed 2 nm

Standard Practice for Monitoring the Calibration of Ultraviolet-Visible Spectrophotometers whose Spectral Bandwidth does not Exceed 2 nm

SIGNIFICANCE AND USE

4.1 This practice permits an analyst to compare the performance of an instrument to the manufacturer's supplied performance specifications and to verify its suitability for continued routine use. It also provides generation of calibration monitoring data on a periodic basis, forming a base from which any changes in the performance of the instrument will be evident.

SCOPE

1.1 This practice covers the parameters of spectrophotometric performance that are critical for testing the adequacy of instrumentation for most routine tests and methods2 within the wavelength range of 200 to 700 nm and the absorbance range of 0 to 2. The recommended tests provide a measurement of the important parameters controlling results in spectrophotometric methods, but it is specifically not to be inferred that all factors in instrument performance are measured.

1.2 This practice may be used as a significant test of the performance of instruments for which the spectral bandwidth does not exceed 2 nm and for which the manufacturer's specifications for wavelength and absorbance accuracy do not exceed the performance tolerances employed here. This practice employs an illustrative tolerance of ±1 % relative for the error of the absorbance scale over the range of 0.2 to 2.0, and of ±1.0 nm for the error of the wavelength scale. A suggested maximum stray radiant power ratio of 4 × 10-4 yields

1.3 This practice should be performed on a periodic basis, the frequency of which depends on the physical environment within which the instrumentation is used. Thus, units handled roughly or used under adverse conditions (exposed to dust, chemical vapors, vibrations, or combinations thereof) should be tested more frequently than those not exposed to such conditions. This practice should also be performed after any significant repairs are made on a unit, such as those involving the optics, detector, or radiant energy source.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E925 − 09 (Reapproved 2014)

Standard Practice for

Monitoring the Calibration of Ultraviolet-Visible

Spectrophotometers whose Spectral Bandwidth does not

Exceed 2 nm

This standard is issued under the fixed designation E925; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

In the application of spectrophotometric methods of analysis it is the responsibility of the analyst

to verify and validate that the instrument is functioning properly and is capable of providing

acceptable analytical results. It is preferable that the verification of instrument performance be

accomplished through the use of reference materials whose properties have been accurately

determined.Suchmaterialsarereadilyavailable,andtheiruseinthetestsandmeasurementsdescribed

in this practice is satisfactory for evaluating the performance of spectrophotometers whose spectral

bandwidth does not exceed the value for which the intrinsic or certified properties are valid. A

compromise maximum permissible spectral bandwidth of 2 nm is recommended for the reference

materials and error tolerances recommended here.

This practice covers some of the essential instrumental parameters that should be evaluated to

ensure the acceptability of the analytical data routinely obtained on the instrument. These parameters

include the accuracy of the wavelength and absorbance scales and stray radiant power levels.

Theaccuracyofthewavelengthscaleinboththeultraviolet(UV)andvisibleregionsisdetermined

using the sharp absorption bands of a holmium oxide glass or solution filter. The absorbance scale

accuracy in the UV region (235 to 350 nm) is determined using acidic solutions of potassium

dichromate. In the visible region (440 to 635 nm) the absorbance accuracy is determined using

individuallycertifiedneutraldensityglassfilters.Theuseofthesereferencematerialsprovidesavalid

andrelativelysimplemeanstotesttheerrorsinthewavelengthandabsorbancescalesofsmallspectral

bandwidth spectrophotometers in the spectral ranges indicated. A simplified version of the opaque

filter method is provided as a test for excessive stray radiant energy.

1. Scope 1.2 This practice may be used as a significant test of the

performance of instruments for which the spectral bandwidth

1.1 Thispracticecoverstheparametersofspectrophotomet-

does not exceed 2 nm and for which the manufacturer’s

ric performance that are critical for testing the adequacy of

specifications for wavelength and absorbance accuracy do not

instrumentation for most routine tests and methods within the

exceed the performance tolerances employed here. This prac-

wavelength range of 200 to 700 nm and the absorbance range

tice employs an illustrative tolerance of 61% relative for the

of0to2.Therecommendedtestsprovideameasurementofthe

error of the absorbance scale over the range of 0.2 to 2.0, and

important parameters controlling results in spectrophotometric

of 61.0 nm for the error of the wavelength scale.Asuggested

methods, but it is specifically not to be inferred that all factors

-4

maximum stray radiant power ratio of4×10 yields <1%

in instrument performance are measured.

absorbance bias at an absorbance of 2. These tolerances are

chosen to be compatible with many chemical applications

while comfortably exceeding the uncertainty of the certified

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

values for the reference materials and typical manufacturer’s

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

specifications for error in the wavelength and absorbance

mittee E13.01 on Ultra-Violet, Visible, and Luminescence Spectroscopy.

Current edition approved May 1, 2014. Published June 2014. Originally

scales of the instrument under test. The user is encouraged to

approved in 1983. Last previous edition approved in 2009 as E925–09. DOI:

develop and use tolerance values more appropriate to the

10.1520/E0925-09R14.

2 requirements of the end use application. This procedure is

Routine tests are defined as those in which absorbance data obtained on a

sample are compared to those of a standard sample preparation. designed to verify quantitative performance on an ongoing

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E925 − 09 (2014)

basis and to compare one instrument’s performance with that ISOGuide34General Requirements for the Competence of

of other similar units. Refer to Practice E275 to extensively Reference Material Producers

evaluate the performance of an instrument.

3. Terminology

1.3 This practice should be performed on a periodic basis,

3.1 Definitions:

the frequency of which depends on the physical environment

3.1.1 For the definitions of terms used in this practice, refer

within which the instrumentation is used. Thus, units handled

to Terminology E131.

roughly or used under adverse conditions (exposed to dust,

3.1.2 For a description of the instrumental parameters

chemical vapors, vibrations, or combinations thereof) should

evaluated in this practice, refer to Practice E275.

be tested more frequently than those not exposed to such

3.1.3 For a description of quantitative ultraviolet spectro-

conditions. This practice should also be performed after any

photometric techniques, refer to Practice E169.

significant repairs are made on a unit, such as those involving

the optics, detector, or radiant energy source.

4. Significance and Use

1.4 The values stated in SI units are to be regarded as

4.1 This practice permits an analyst to compare the perfor-

standard. No other units of measurement are included in this

mance of an instrument to the manufacturer’s supplied perfor-

standard.

mance specifications and to verify its suitability for continued

1.5 This standard does not purport to address all of the

routine use. It also provides generation of calibration monitor-

safety concerns, if any, associated with its use. It is the

ing data on a periodic basis, forming a base from which any

responsibility of the user of this standard to establish appro-

changes in the performance of the instrument will be evident.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Reference to this Calibration-Monitoring Procedure

5.1 Reference to this practice in any spectrophotometric

2. Referenced Documents

calibration-monitoring scheme shall constitute due notification

2.1 ASTM Standards:

that the adequacy of the spectrophotometer performance has

E131Terminology Relating to Molecular Spectroscopy

been evaluated by means of this practice. Performance is

E169PracticesforGeneralTechniquesofUltraviolet-Visible

considered to be adequate when the data obtained are within

Quantitative Analysis

the stated tolerances from the true values.

E275PracticeforDescribingandMeasuringPerformanceof

Ultraviolet and Visible Spectrophotometers 6. Instrument Operation

E387TestMethodforEstimatingStrayRadiantPowerRatio

6.1 In obtaining spectrophotometric calibration data the

of Dispersive Spectrophotometers by the Opaque Filter

analyst must select the proper instrumental operating condi-

Method

tions to realize satisfactory instrument performance. Operating

E1866Guide for Establishing Spectrophotometer Perfor-

conditions for individual instruments are best obtained from

mance Tests

the manufacturer’s literature because of variations in instru-

2.2 NIST Publications:

ment design.

NISTSpecialPublication260-54 Certification and Use of

6.2 When using reference materials, all the components of

AcidicPotassiumDichromateSolutionsAsAnUltraviolet

the spectrophotometer must be functioning properly. In

Absorbance Standard

addition, the temperature of the specimen compartment should

NISTSpecialPublication260-102 Holmium Oxide Solu-

be between 20 and 25°C. Matched solution cells should be

tion Wavelength Standard from 240 to 640 nm—SRM

used for calibration purposes.

6.3 Each of the above factors in instrument operation is

NISTSpecialPublication260-116Glass Filters as a Stan-

important in the determination of wavelength and absorbance

dard Reference Material for Spectrophotometry—

accuracy.

Selection,Preparation,Certification,andUseofSRM930

and SRM 1930

7. Determination of Wavelength Accuracy in the

NISTSpecialPublication260-140 Technical Specifications

Ultraviolet and Visible Spectral Regions

for Certification of Spectrophotometric NTRMs

7.1 Discussion—The holmium oxide glass filter (1, 2) or

2.3 ISO Publications:

solution standard (NISTSpecialPublication260-102) may be

ISO17025General Requirements for the Competence of

used for evaluating wavelength accuracy. The glass and solu-

Testing and Calibration Laboratories

tion standards are both available commercially from reference

material producers, in the sealed cuvette format (a cuvette-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

shaped metal holder is used for the glass) or as a bottled

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

solution, prepared from high purity Holmium Oxide (>

Standards volume information, refer to the standard’s Document Summary page on

99.99%),wherevalueassignmentisbyselfassertion(Note1).

the ASTM website.

Available from NationalTechnical Information Service (NTIS), 5301 Shawnee

Rd., Alexandria, VA 22312, http://www.ntis.gov.

5 6

Available from International Organization for Standardization (ISO), 1, ch. de The boldface numbers in parentheses refer to a list of references at the end of

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org. this standard.

E925 − 09 (2014)

Apurchasershouldrequirecertificationbythesupplierthatthe 7.2.1 Examine the holmium oxide reference material and

wavelengths of the absorption bands are within 0.2-nm of the remove any surface contamination using a soft brush or

values given in Ref. (2), and reported below. The appropriate lint-free cloth. Measure the temperature of the sample com-

solution standard is 4% (mass fraction) holmium oxide in partment by placing an appropriate sensor into the cell com-

10% (volume fraction) perchloric acid, contained in a 10-mm partment of a stabilized instrument and replacing the compart-

pathlengthcuvette.Forthismaterial,thetransmittanceminima mentcoversecurely.Placethesensorascloseaspossibletothe

of 18 absorption bands have been certified by a multi- actual position that will be occupied by the standard. After a

laboratory inter-comparison, at the highest level, allowing the suitable period of time record the temperature reading, remove

peakvalueassignmentsasanintrinsicwavelengthstandard (3). the sensor, and resume normal operations.

Absorbance maxima or transmittance minima must be located 7.2.2 Record the blank absorbance or transmittance (air

within 61 nm of the wavelengths given below: versus air) spectrum at the desired resolution and at the

A B

appropriate wavelength intervals and scan speeds, in order to

Glass Filter Dilute Acidic Solution

C

241.5 nm 241.1 nm

perform any necessary baseline adjustments. The wavelength

. . . 249.9 nm

intervalsshouldbenogreaterthanthespectralbandwidthused.

279.3 nm 278.1 nm

Acquire the appropriate spectrum of the holmium oxide

287.6 nm 287.2 nm

333.8 nm 333.5 nm

reference material with respect to air and baseline correct if

. . . 345.4 nm

necessaryusingtheblankspectrum.Recordthewavelengthsof

360.8 nm 361.3 nm

thepositionsoftherelevantbands,andcomparethesevaluesto

385.8 nm 385.6 nm

418.5 nm 416.3 nm

the expected values. If large discrepancies (>1 nm) exist

D

453.4 nm . . .

between the true and measured wavelengths, repeat the proce-

459.9 nm 467.8 nm

dure at a slower scan speed and smaller spectral bandwidth, if

. . . 485.3 nm

536.4 nm 536.6 nm

possible, to verify the nonconformity.

637.5 nm 640.5 nm

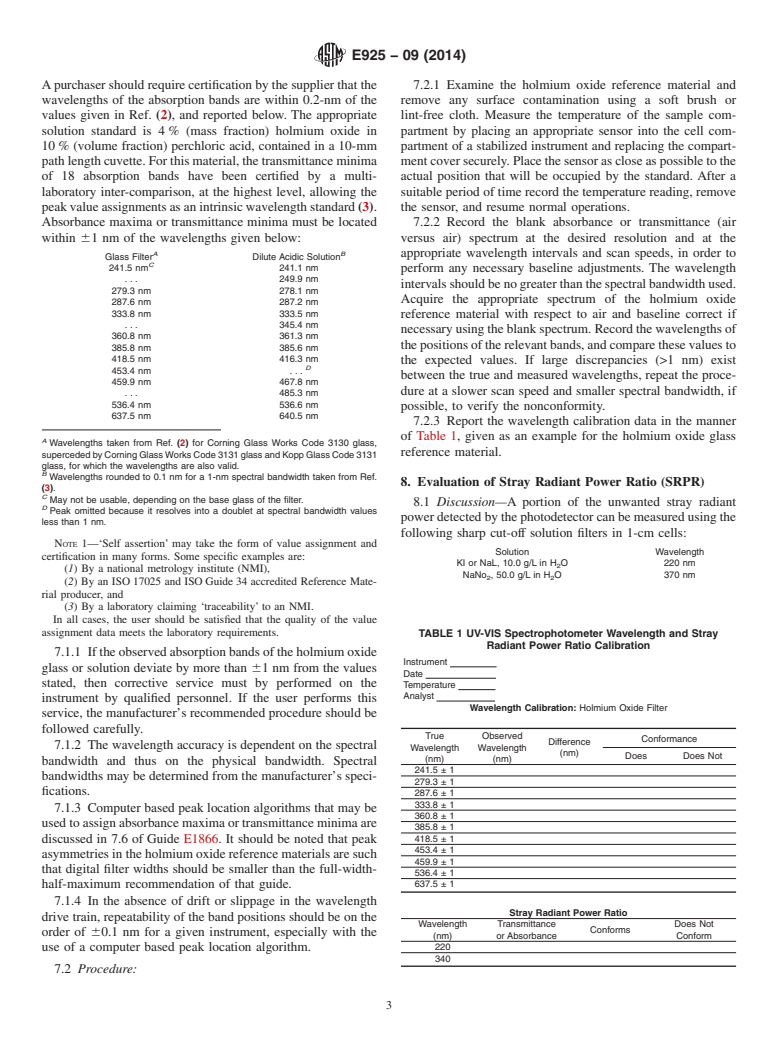

7.2.3 Report the wavelength calibration data in the manner

of Table 1, given as an example for the holmium oxide glass

A

Wavelengths taken from Ref. (2) for Corning Glass Works Code 3130 glass,

reference material.

supercededbyCorningGlassWorksCode3131glassandKoppGlassCode3131

glass, for which the wavelengths are also valid.

B

Wavelengths rounded to 0.1 nm for a 1-nm spectral bandwidth taken from Ref.

8. Evaluation of Stray Radiant Power Ratio (SRPR)

(3).

C

May not be usable, depending on the base glass of the filter.

8.1 Discussion—A portion of the unwanted stray radiant

D

Peak omitted because it resolves into a doublet at spectral bandwidth values

powerdetectedbythephotodetectorcanbemeasuredusingthe

less than 1 nm.

following sharp cut-off solution filters in 1-cm cells:

NOTE 1—‘Self assertion’ may take the form of value assignment and

Solution Wavelength

certification in many forms. Some specific examples are:

KI or NaL, 10.0 g/L in H O 220 nm

(1) By a national metrology institute (NMI),

NaNo , 50.0 g/L in H O 370 nm

2 2

(2) By an ISO17025 and ISOGuide34 accredited Reference Mate-

rial producer, and

(3) By a laboratory claiming ‘traceability’to an NMI.

In all cases, the user should be satisfied that the quality of the value

assignment data meets the laboratory requirements. TABLE 1 UV-VIS Spectrophotometer Wavelength and Stray

Radiant Power Ratio Calibration

7.1.1 Iftheobservedabsorptionbandsoftheholmiumoxide

Instrument

glass or solution deviate by more than 61 nm from the values

Date

stated, then corrective service must by performed on the

Temperature

Analyst

instrument by qualified personnel. If the user performs this

Wavelength Calibration: Holmium Oxide Filter

service, the manufacturer’s recommended procedure should be

followed carefully.

True Observed

Conformance

Difference

7.1.2 The wavelength accuracy is dependent on the spectral

Wavelength Wavelength

(nm)

Does Does Not

(nm) (nm)

bandwidth and thus on the physical bandwidth. Spectral

241.5 ± 1

bandwidthsmaybedeterminedfromthemanufacturer’sspeci-

279.3 ± 1

fications. 287.6 ± 1

333.8 ± 1

7.1.3 Computer based peak location algorithms that may be

360.8 ± 1

usedtoassignabsorbancemaximaortransmittanceminimaare

385.8 ± 1

discussed in 7.6 of Guide E1866. It should be noted that peak 418.5 ± 1

453.4 ± 1

asymmetriesintheholmiumoxidereferencematerialsaresuch

459.9 ± 1

that digital filter widths should be smaller than the full-width-

536.4 ± 1

637.5 ± 1

half-maximum recommendation of that guide.

7.1.4 In the absence of drift or slippage in the wavelength

Stray Radiant Power Ratio

drive train, repeatability of the band positions should be on the

Wavelength Transmittance Does Not

Conf

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.