ASTM E594-96(2019)

(Practice)Standard Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

Standard Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

SIGNIFICANCE AND USE

4.1 Although it is possible to observe and measure each of the several characteristics of a detector under different and unique conditions, it is the intent of this recommended practice that a complete set of detector specifications should be obtained at the same operating conditions, including geometry, flow rates, and temperatures. It should be noted that to specify a detector’s capability completely, its performance should be measured at several sets of conditions within the useful range of the detector. The terms and tests described in this recommended practice are sufficiently general so that they may be used at whatever conditions may be chosen for other reasons.

4.2 The FID is generally only used with non-ionizable supercritical fluids as the mobile phase. Therefore, this standard does not include the use of modifiers in the supercritical fluid.

4.3 Linearity and speed of response of the recording system or other data acquisition device used should be such that it does not distort or otherwise interfere with the performance of the detector. Effective recorder response, Bonsall (5) and McWilliam (6), in particular, should be sufficiently fast so that it can be neglected in sensitivity of measurements. If additional amplifiers are used between the detector and the final readout device, their characteristics should also first be established.

SCOPE

1.1 This practice covers the testing of the performance of a flame ionization detector (FID) used as the detection component of a gas or supercritical fluid (SF) chromatographic system.

1.2 This recommended practice is directly applicable to an FID that employs a hydrogen-air or hydrogen-oxygen flame burner and a dc biased electrode system.

1.3 This recommended practice covers the performance of the detector itself, independently of the chromatographic column, the column-to-detector interface (if any), and other system components, in terms that the analyst can use to predict overall system performance when the detector is made part of a complete chromatographic system.

1.4 For general gas chromatographic procedures, Practice E260 should be followed except where specific changes are recommended herein for the use of an FID. For definitions of gas chromatography and its various terms see recommended Practice E355.

1.5 For general information concerning the principles, construction, and operation of an FID, see Refs (1, 2, 3, 4).2

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific safety information, see Section 5.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E594 − 96 (Reapproved 2019)

Standard Practice for

Testing Flame Ionization Detectors Used in Gas or

Supercritical Fluid Chromatography

This standard is issued under the fixed designation E594; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This practice covers the testing of the performance of a

mendations issued by the World Trade Organization Technical

flame ionization detector (FID) used as the detection compo-

Barriers to Trade (TBT) Committee.

nent of a gas or supercritical fluid (SF) chromatographic

system.

2. Referenced Documents

1.2 This recommended practice is directly applicable to an

2.1 ASTM Standards:

FID that employs a hydrogen-air or hydrogen-oxygen flame

E260Practice for Packed Column Gas Chromatography

burner and a dc biased electrode system.

E355PracticeforGasChromatographyTermsandRelation-

1.3 This recommended practice covers the performance of ships

the detector itself, independently of the chromatographic

2.2 CGA Standards:

column, the column-to-detector interface (if any), and other

CGAP-1 Standard for Safe Handling of Compressed Gases

systemcomponents,intermsthattheanalystcanusetopredict

in Containers

overall system performance when the detector is made part of

CGAG-5.4Standard for Hydrogen Piping Systems at Con-

a complete chromatographic system.

sumer Locations

CGAP-9The Inert Gases: Argon, Nitrogen, and Helium

1.4 For general gas chromatographic procedures, Practice

CGAV-7Standard Method of Determining Cylinder Valve

E260 should be followed except where specific changes are

Outlet Connections for Industrial Gas Mixtures

recommended herein for the use of an FID. For definitions of

CGAP-12Safe Handling of Cryogenic Liquids

gas chromatography and its various terms see recommended

HB-3Handbook of Compressed Gases

Practice E355.

1.5 For general information concerning the principles,

3. Terminology

construction, and operation of an FID, see Refs (1, 2, 3, 4).

3.1 Definitions:

1.6 The values stated in SI units are to be regarded as

3.1.1 drift—the average slope of the baseline envelope

standard. No other units of measurement are included in this 1

expressed in amperes per hour as measured over ⁄2 h.

standard.

3.1.2 noise (short-term)—the amplitude expressed in am-

1.7 This standard does not purport to address all of the

peres of the baseline envelope that includes all random

safety concerns, if any, associated with its use. It is the

variations of the detector signal of a frequency on the order of

responsibility of the user of this standard to establish appro-

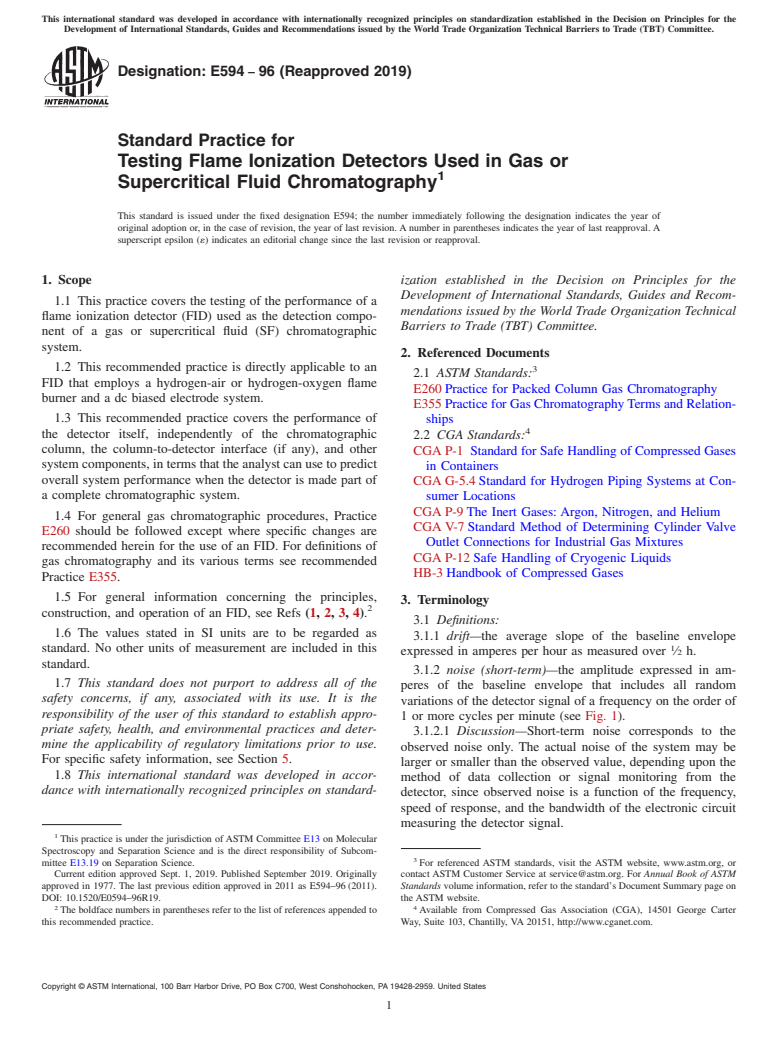

1 or more cycles per minute (see Fig. 1).

priate safety, health, and environmental practices and deter-

3.1.2.1 Discussion—Short-term noise corresponds to the

mine the applicability of regulatory limitations prior to use.

observed noise only. The actual noise of the system may be

For specific safety information, see Section 5.

larger or smaller than the observed value, depending upon the

1.8 This international standard was developed in accor-

method of data collection or signal monitoring from the

dance with internationally recognized principles on standard-

detector, since observed noise is a function of the frequency,

speed of response, and the bandwidth of the electronic circuit

measuring the detector signal.

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

mittee E13.19 on Separation Science. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2019. Published September 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1977. The last previous edition approved in 2011 as E594–96(2011). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/E0594–96R19. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references appended to Available from Compressed Gas Association (CGA), 14501 George Carter

this recommended practice. Way, Suite 103, Chantilly, VA 20151, http://www.cganet.com.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E594 − 96 (2019)

FIG. 1 Example of the FID Noise Level and Drift Measurement

3.1.3 other noise—Fluctuations of the baseline envelope of amplifiers are used between the detector and the final readout

a frequency less than 1 cycle per minute can occur in device, their characteristics should also first be established.

chromatographic systems.

5. Hazards

3.1.4 Discussion—The amplitude of these fluctuations may

5.1 Gas Handling Safety—The safe handling of compressed

actually exceed the short-term noise. Such fluctuations are

gases and cryogenic liquids for use in chromtography is the

difficult to characterize and are not typically to be expected.

responsibility of every laboratory. The CGA, a member group

Theyareusuallycausedbyotherchromatographiccomponents

of specialty and bulk gas suppliers, publishes the following

such as the column, system contaminants, and flow variations.

guidelines to assist the laboratory chemist to establish a safe

These other noise contributions are not derived from the

work environment. Applicable CGA publications include

detector itself and are difficult to quantitate in a general

CGAP-1, CGAG-5.4, CGAP-9, CGAV-7, CGAP-12, and

manner.Itis,however,importantforthepracticingchromatog-

HB-3.

rapher to be aware of the occurrence of this type of noise

contribution.

6. Noise and Drift

6.1 Methods of Measurement:

4. Significance and Use

6.1.1 With the attenuator set at maximum sensitivity (mini-

4.1 Although it is possible to observe and measure each of

mum attenuation), adjust the detector output with the “zero”

the several characteristics of a detector under different and

controltonearmid-scaleontherecorder.Allowatleast ⁄2hof

uniqueconditions,itistheintentofthisrecommendedpractice

baseline to be recorded. Draw two parallel lines to form an

that a complete set of detector specifications should be ob-

envelopethatenclosestherandomexcursionsofafrequencyof

tained at the same operating conditions, including geometry,

approximately 1 cycle per minute or more. Measure the

flow rates, and temperatures. It should be noted that to specify

distance between the parallel lines at any particular time.

a detector’s capability completely, its performance should be

Express the value as amperes of noise.

measured at several sets of conditions within the useful range

6.1.2 Measurethenetchangeinamperesofthelowerlineof

of the detector. The terms and tests described in this recom-

the envelope over ⁄2 h and multiply by two. Express as

mended practice are sufficiently general so that they may be

amperes per hour drift.

used at whatever conditions may be chosen for other reasons.

NOTE1—Thismethodcoversmostcasesofbaselinedrift.Occasionally,

4.2 The FID is generally only used with non-ionizable

with sinusoidal baseline oscillations of lower frequency, a longer mea-

supercritical fluids as the mobile phase. Therefore, this stan-

surement time should be used. This time must then be stated and the drift

dard does not include the use of modifiers in the supercritical

value normalized to 1 h.

fluid.

6.1.3 In specifications giving the measured noise and drift

4.3 Linearity and speed of response of the recording system oftheFID,specifythetestconditionsinaccordancewith7.2.4.

orotherdataacquisitiondeviceusedshouldbesuchthatitdoes

7. Sensitivity (Response)

not distort or otherwise interfere with the performance of the

detector. Effective recorder response, Bonsall (5) and McWil- 7.1 Sensitivity(response)oftheFIDisthesignaloutputper

liam (6), in particular, should be sufficiently fast so that it can unit mass of a test substance in the carrier gas, in accordance

be neglected in sensitivity of measurements. If additional with the following relationship:

E594 − 96 (2019)

A

i C = initial concentration of the test compound introduced

o

S 5 (1)

m

into the flask, g/mL,

F = carriergasflowrate,correctedtoflasktemperature(see

f

where:

Annex A1), mL/min,

S = sensitivity (response), A·s/g,

t = time, min, and

A = integrated peak area, A·s, and

i

V = volume of flask, mL.

f

m = mass of the test substance in the carrier gas, g.

7.4.3 Calculatethesensitivityofthedetectoratanyconcen-

7.2 Test Conditions:

tration as follows:

7.2.1 Normalbutaneisthepreferredstandardtestsubstance.

60E

7.2.2 The measurement must be made within the linear

S 5 (3)

C F

f f

range of the detector.

7.2.3 The measurement must be made at a signal level at

where:

least 200 times greater than the noise level.

S = sensitivity, A·s/g,

7.2.4 The test substance and the conditions under which the

E = detector signal, A,

detector sensitivity is measured must be stated. This will

C = concentration of the test substance at time, t, after

f

include, but not necessarily be limited to, the following:

introducton into the flask, g/mL, and

7.2.4.1 Type of detector,

F = carriergasflowrate,correctedtoflasktemperature(see

f

7.2.4.2 Detector geometry (for example, electrode to which

Annex A1), mL/min.

bias is applied),

NOTE 2—This method is subject to errors due to inaccuracies in

measuring the flow rate and flask volume. An error of 1% in the

7.2.4.3 Carrier gas,

measurement of either variable will propagate to 2% over two decades in

7.2.4.4 Carrier gas flow rate (corrected to detector tempera-

concentration and to 6% over six decades.Therefore, this method should

ture and fluid presssure),

not be used for concentration ranges of more than two decades over a

7.2.4.5 Make-up gas,

single run.

7.2.4.6 Make-up gas flow rate, NOTE 3—A temperature difference of 1°C between flask and flow-

measuring apparatus will, if uncompensated, introduce an error of ⁄3 %

7.2.4.7 Detector temperature,

into the flow rate.

7.2.4.8 Detector polarizing voltage,

NOTE 4—Extreme care should be taken to avoid unswept volumes

7.2.4.9 Hydrogen flow rate,

betweentheflaskandthedetector,asthesewillintroduceadditionalerrors

7.2.4.10 Air or oxygen flow rate, into the calculations.

NOTE 5—Flask volumes between 100 and 500 mLhave been found the

7.2.4.11 Method of measurement, and

most convenient. Larger volumes should be avoided due to difficulties in

7.2.4.12 Electrometer range setting.

obtaining efficient mixing and likelihood of temperature gradients.

NOTE 6—This method may not be used with supercritical-fluid mobile

7.3 Methods of Measurement:

phases unless the flask is specifically designed and rated for the pressure

7.3.1 Sensitivitymaybemeasuredbyanyofthreemethods:

in use.

7.3.1.1 Experimental decay with exponential dilution flask

7.5 Method Utilizing Permeation Devices:

(7) (see 7.4).

7.5.1 Permeation devices consist of a volatile liquid en-

7.3.1.2 Utilizing the permeation device (8) under steady-

closed in a container with a permeable wall.They provide low

state conditions (see 7.5).

concentrations of vapor by diffusion of the vapor through the

7.3.1.3 UtilizingYoung’s apparatus (9) under dynamic con-

permeablesurface.Therateofdiffusionforagivenpermeation

ditions (see 7.6).

device is dependent only on the temperature. The weight loss

7.3.2 Calculation of FID sensitivity by utilizing actual

over a period of time is carefully and accurately determined;

chromatograms is not preferred because in such a case the

thus, these devices have been proposed as primary standards.

amountoftestsubstanceatthedetectormaynotbethesameas

7.5.2 Accurately known permeation rates can be prepared

that introduced.

by passing a gas over the previously calibrated permeation

7.4 Exponential Dilution Method:

device at constant temperature. Knowing this permeation rate,

7.4.1 Purge a mixing vessel of known volume fitted with a

R, the sensitivity of the detector can be obtained from the

t

magneticallydrivenstirrerwiththecarriergasataknownrate.

following equation:

The effluent from the flask is delivered directly to the detector.

60E

Introduce a measured quantity of the test substance into the

S 5 (4)

R

t

flask to give an initial concentration, C , of the test substance

o

in the carrier gas, and simultaneously start a timer.

where:

7.4.2 Calculatetheconcentrationofthetestsubstanceinthe

S = sensitivity, A·s/g,

carrier gas at the outlet of the flask at any time as follows (see

E = detector signal, A, and

Annex A1):

R = permeationrateofatestsubstancefromthepermeation

t

device, g/min.

C 5 C exp@2F t/V # (2)

f o f f

NOTE 7—Permeation devices are suitable only for preparing relatively

where:

low concentrations in the part-per-million range. In addition, only a

limited range of linearity can be explored because it is experimentally

C = concentration of the test substance at time t after

f

difficult to vary the permeation rate over an extended range. Thus, for

introduction into the flask, g/mL,

detectorsofrelativelylowsensitivityorofhighernoiselevels,thismethod

E594 − 96 (2019)

may not satisfy the criteria given in 7.2.3, which requires that the signal

preferably at the same time. When giving minimum

beatleast200timesgreaterthanthenoiselevel.Afurtherlimitationinthe

detectability, state the noise level on which the calculation was

use of permeation devices is the relatively slow equilibration of the

based.

permeation rate, coupled with the life expectancy of a typical device

which is on the order of a few months.

9. Linear Range

NOTE 8—This method may not be used with supercritical-fluid mobile

phase. SC-CO would adversly affect the permeation tube by either

9.1 The linear range of an FID is the range of mass flow

extracting the polymer or swelling the tube, resulting in a potential safety

rates of the test substance in the carrier gas, over which the

hazard.

sensitivity of the detector is constant to within 5% as deter-

7.6 Dynamic Method:

mined from the linearity plot specified in 9.2.2.

7.6.1 In this method, inject a known quantity of test sub-

9.1.1 The linear range may be expressed in three different

stance into the flowing carrier gas stream. A length of empty

ways:

tubing or an empty high-pressure cell between the sample

9.1.1.1 As the ratio of the upper limit of linear

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.